|

Production

and Operations Management

MGT613

VU

Lesson

09

Time

Series Forecasts

∑Trend

-

long-term upward or downward

movement in data often relates to

population shifts,

changing

incomes, and cultural changes.

∑Seasonality

-

short-term fairly regular

variations in data related to

factors like weather,

festive

holidays

and vacations. Mostly experienced by

supermarkets, restaurants, theatres,

theme

parks.

∑Cycle

wavelike variations of more

than one year's duration

these occurs because of

political,

economic

and even agricultural

conditions

∑Irregular

variations -

caused by unusual circumstances

such as severe weathers,

earthquakes,

worker

strikes, or major change in product or

service. They do not capture

or reflect the true

behavior

of a variable and can distort the

overall picture. These should be

identified and

removed

from the data.

∑Random

variations -

caused by chance and are in reality

are the residual variations

that remain

after

the other behaviors have

been identified and accounted

for.

Forecast

Variations

Techniques

for Averaging

∑Moving

average

∑Weighted

moving average

∑Exponential

smoothing

∑Moving

average A

technique that averages a

number of recent actual

values, updated as new

values

become available.

∑Weighted

moving average

More recent values in a

series are given more

weight in

computing

the forecast.

Simple

Moving Average Formula

∑The

simple moving average model

assumes an average is a good estimator of

future behavior

∑The

formula for the simple

moving average is:

A

t-1 + A t-2

+ A t-3 +

... + A t-n

Ft =

n

Ft =

Forecast for the coming

period

N

= Number of periods to be

averaged

At-1 =

Actual occurrence in the past

period for up to "n"

periods

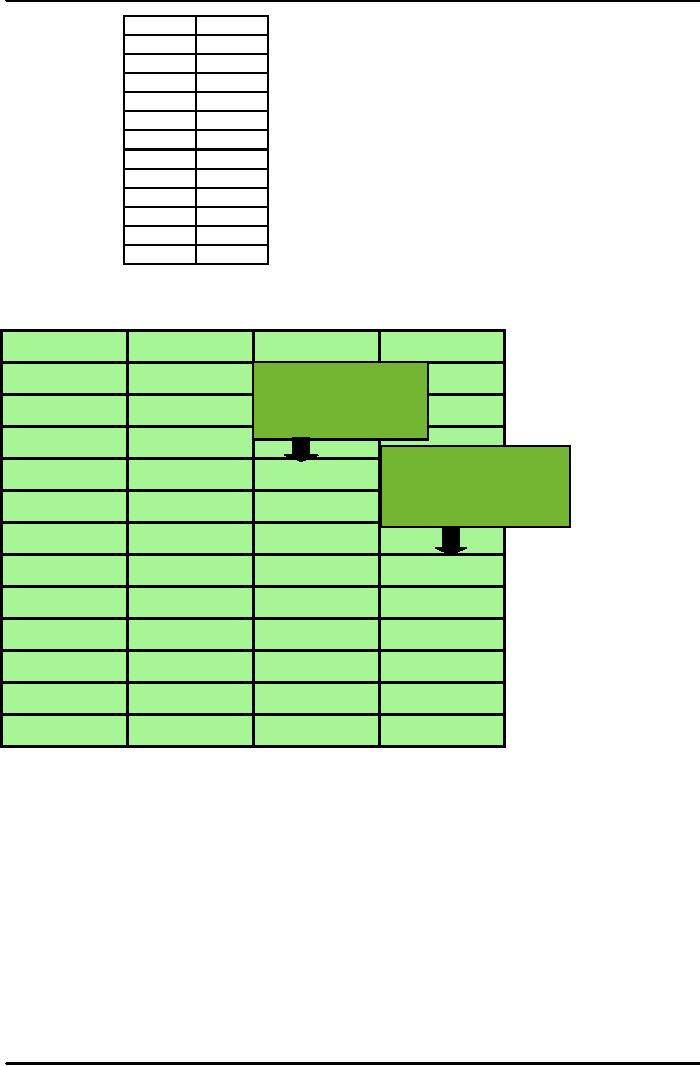

Simple

Moving Average Problem

(1)

Question:

What are the 3-week and

6-week moving average forecasts for

demand?

Assume

you only have 3 weeks and 6 weeks of

actual demand data for the

respective forecasts.

37

Production

and Operations Management

MGT613

VU

Week

Demand

1

650

2

678

3

720

4

785

5

859

6

920

7

850

8

758

9

892

10

920

11

789

12

844

Simple

Moving Average Solution

(1)

W

eek

Demand

3-W eek

6-W

eek

1

650

F4=(650+678+720)/

678

3

=682.67

2

3

720

F

=(650+678+720

4

785

682.67

7

+785+859+920)/6

5

859

727.67

=768.67

6

920

788.00

7

850

854.67

768.67

8

758

876.33

802.00

9

892

842.67

815.33

10

920

833.33

844.00

11

789

856.67

866.50

12

844

867.00

854.83

38

Production

and Operations Management

MGT613

VU

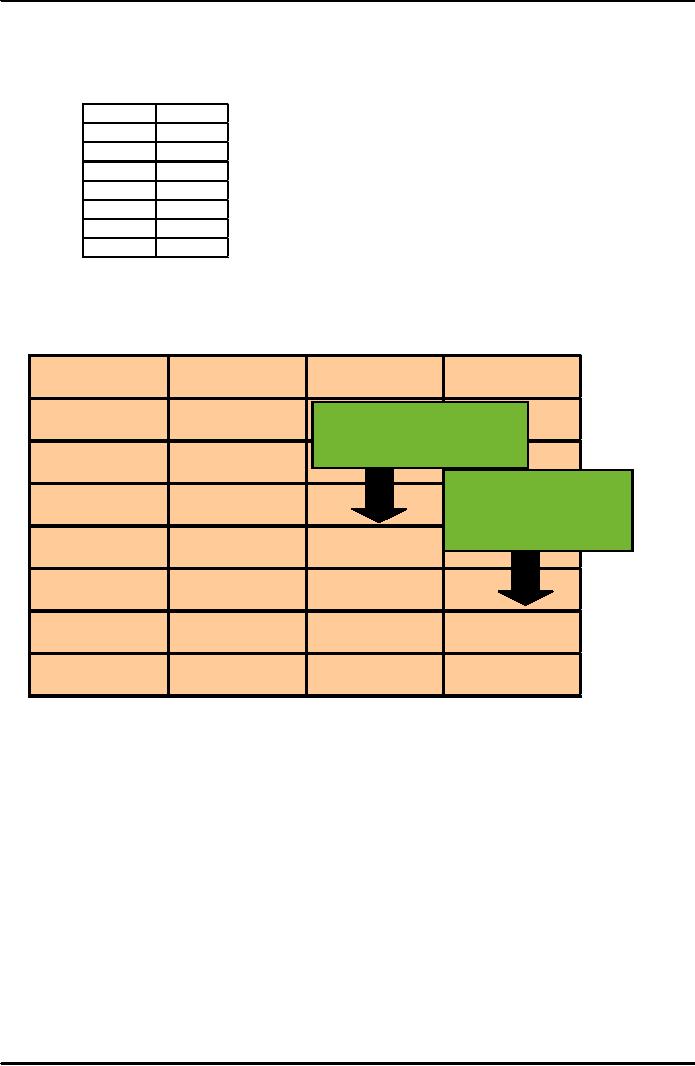

Simple

Moving Average Problem (2)

Data

Question:

What is the 3 week moving

average forecast for this

data?

Assume

you only have 3 weeks and 5 weeks of

actual demand data for the

respective forecasts.

Week

Demand

1

820

2

775

3

680

4

655

5

620

6

600

7

575

Simple

Moving Average Problem (2)

Solution

W

eek

Demand

3-W

eek

5-W

eek

1

820

F4=(820+775+680)/3

=758.33

2

775

F6=(820+775+680

3

680

+655+620)/5

=710.00

4

655

758.33

5

620

703.33

6

600

651.67

710.00

7

575

625.00

666.00

39

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model