|

PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY |

| << QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management |

| CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes >> |

Project

Management MGMT627

VU

LESSON

36

PRINCIPLES

OF TOTAL QUALITY

BROAD

CONTENTS

Definitions

of Total Quality

Total

Quality Practices

Principles

of Total Quality

Scope

of Total Quality Management

(TQM)

Empowerment

Cost

of Quality

36.1

DEFINITIONS

OF TOTAL QUALITY:

1.

According to Crosby:

·

Quality

is not only free, it is

profit maker

·

Increase

of 5% -10% in profitability by

concentrating on quality

·

Quality

provides a lot of money for

free

2.

PandG Total Quality Management

(TQM) Definition:

Total

Quality is the unyielding and continually

improving effort by everyone is

an

organization

to understand, meet, and exceed the expectations of

customers.

3.

A V. Feigenbaum:

As

already discussed in lecture

34, A V. Feigenbaum introduced

comprehensive approach

to

quality in 50s by virtue of

which, quality of products

and services were influenced

by the

following

9Ms:

·

Market

·

Money

·

Material

·

Management

·

Machines

·

Men/Women

·

Motivation

·

Mechanizations

·

Modern

Information Methods

·

Mounting

Products Requirements

As

already discussed in the previous

lecture, total quality is a

people-focused management system

that

aims at continual increase in

customer satisfaction at continually

lower real cost. Not

a

separate

area or program.

·

Integral

part of high-level strategy

·

Works

horizontally across functions

and departments

·

Involves

all employees, top to

bottom

·

Extends

backward and forward to include

"supply chain and customer

chain"

36.2

TOTAL

QUALITY PRACTICES:

It

includes the following:

·

Encouraging

openness

262

Project

Management MGMT627

VU

·

Creating

climates of trust and eliminate

fear

·

Listening

and providing feedback

·

Leading

and participating in group

meetings

·

Solving

problems with data

·

Clarifying

goals and resolving conflicts

·

Delegating

and coaching

·

Implementing

change

·

Making

continuous improvement a way of

life

36.3

PRINCIPLES

OF TOTAL QUALITY:

There

are three basic principles of

total quality. These are as

follows:

·

Customer

Focus

·

Participation

and Team work

·

Continuous

improvement (CI) and

learning

36.4

SCOPE

OF TOTAL QUALITY MANAGEMENT:

The

figure 36.1 below depicts the

scope of Total Quality

Management (TQM). It is explained

in

the

ensuing paragraphs.

Figure

36.1: Scope

of Total Quality Management

(TQM)

Infrastructure:

Basic

management system necessary to

function as a high

performing

organization.

Practices:

Activities

that occurs within a management

system to achieve high

performance

objectives.

Tools:

A

wide variety of graphical and

statistical methods to plan

work activities, collect

data

analyze

results, monitor progress, and solve

problems.

36.5

EMPOWERMENT:

Empowerment

means that managers must

relinquish some of power

that they previously

held.

Power

shift creates management

fears that workers will

abuse this privilege.

Employees

have authority and responsibility to make

things happen. No one can be best

at

everything.

But when all of us combine

our talents, we can be best at

virtually anything.

Everyone

in organization is "captain of his

game". He thinks of his work

unit as his "own

business",

and perceives that his "work

unit" is key part of

"corporate enterprise". It

builds

"confidence

in workers" by showing them that company

has confidence in them "to

make

decision"

on their own. Empowerment can be

viewed as vertical teamwork between

managerial

263

Project

Management MGMT627

VU

and

non-managerial personnel. People can be trusted to

make important decisions

about

management

of their work activities.

When people make decisions about

management of their

work,

its result is greater organizational

effectiveness.

As

a whole participation and empowerment

assumes that employees are

willing to improve

their

"daily

work process" and "relationships".

Employee participation is essential

active,

enthusiastic

participation by employees essential to

success of performance improvement

initiative.

Workers

know what goes wrong and

where hurdle in their processes. If

given targets and

support

they are best to develop

creative and effective ideas

for "positive

change".

Problem

for many project based

organization reduction of "bureaucratic

red tape" "that prevents

employees

from seizing the

initiative.

36.5.1

Participative Management:

Participative

organizations are those that

give:

·

Information

·

Knowledge

·

Power

·

Rewards

to all employees so that everyone

can be involved in

organization's

performance

Participative management. It is essential

basis for empowered

workforce.

Put "everybody's intellect" to work

good thinking is not solely

province

of

managers. Different points of

view can help shape

better decision.

Participative

management require that

"responsibility and accountability" takes

to

lowest

possible level empowerment- for three

eyes only creation of

"corporate" spirit of

participation

required that workforce have

information, involvement and

influence.

Participative

management does not imply

abrogation by management of

its

responsibility

it does imply workforce

involvement in decision making

process, but

final

decision on corporate matters remains

responsibility of manager.

When

empowered employees become convinced that

their duty is to their

"process" not

to

their "boss", wonderful

things begin to happen. Teams shoulder

responsibility for

their

"process", and new, more "cooperative

style" of work

evolves.

Empowerment

encourages "innovation" because employees

have authority to "try

out"

new

ideas and make decisions that

result in new ways of doing

things. Access to

information

when employees are given

access to information their

willingness to

cooperation

and to use empowerment is

enhanced.

Due

to this "Accessibility", Teams

"Manage and Control

Opportunity" More

Effectively

Than under old "Hierarchical

Rules and Structure" where access to

info

provided

on A Need to Know

Basis".

264

Project

Management MGMT627

VU

36.5.2

Accountability:

Employees

empowered to make decision, yet

also held accountable for

results.

Accountability

is not to punish person or to

generate immediate, short term

results.

Intent

is to ensure that empowered employees

are:

Giving

their best efforts

a)

Working toward "agreed-upon

goals"

b)

Behaving responsibly toward

each other

36.5.3

Empowerment Some Key

Principles:

·

People

are valuable resource

because they have "knowledge

and ideas".

·

People

want to participate.

·

When

people participate, they

feel empowered; they think

like owners.

·

When

people participate, they

look for ways to improved

opportunities.

·

When

people have importance into

"corporate and department decisions",

better

solutions

are developed.

·

People

should be treated fairly and

with respect.

Organizations

should make long term

commitment for development of

people because

it

makes them valuable to organization.

People can develop knowledge to

make

important

decision about management of

their work

activities.

36.5.4

Six Ways of Empowering Employees

for Quality Improvement in

Projects:

1.

Involve

employees in developing strategies for

continuous improvement.

2.

Provide

employees with skills required

solving problems and making

decisions.

3.

Define

involvement and empowerment based on mission of

organization.

4.

Establish

organizational and individual

goals.

5.

Establish

customer-driven performance measurement at

individual level.

6.

Involve

and empower everyone to focus on continuous

improvement.

Successful

empowerment of employees requires:

·

Employees

should be provided

with:

o

Education

o

Resources

o

Encouragement

·

Policies

and procedures should be examined

for needless

restrictions.

·

Atmosphere

of trust should be fostered rather than

resentment and punishment for

failure.

·

Information

should be shared "freely" rather

than "closely guarded" as "source

of

control

and power".

36.6

COST

OF QUALITY:

To

verify that a product or service

meets the customer's requirements requires the

measurement

of

the cost of quality. For

simplicity's sake, the costs

can be classified as "the

cost of

conformance"

and "the cost of nonconformance."

Conformance costs include items such

as

training,

indoctrination, verification, validation,

testing, maintenance, calibration, and

audits.

Nonconforming

costs include items such as

scrap, rework, warranty repairs,

product recalls, and

complaint

handling.

265

Project

Management MGMT627

VU

Trying

to save a few project

dollars by reducing conformance costs

could prove disastrous.

For

example,

an American company won a contract as a

supplier of Japanese parts.

The initial

contract

called for the delivery of

10,000 parts. During

inspection and testing at the

customer's

(that

is, Japanese) facility, two

rejects were discovered. The Japanese

returned all 10,000

components

to the American supplier stating

that this batch was not

acceptable. In this

example,

the

nonconformance cost could easily be an

order of magnitude greater than the

conformance

cost.

The moral is clear:

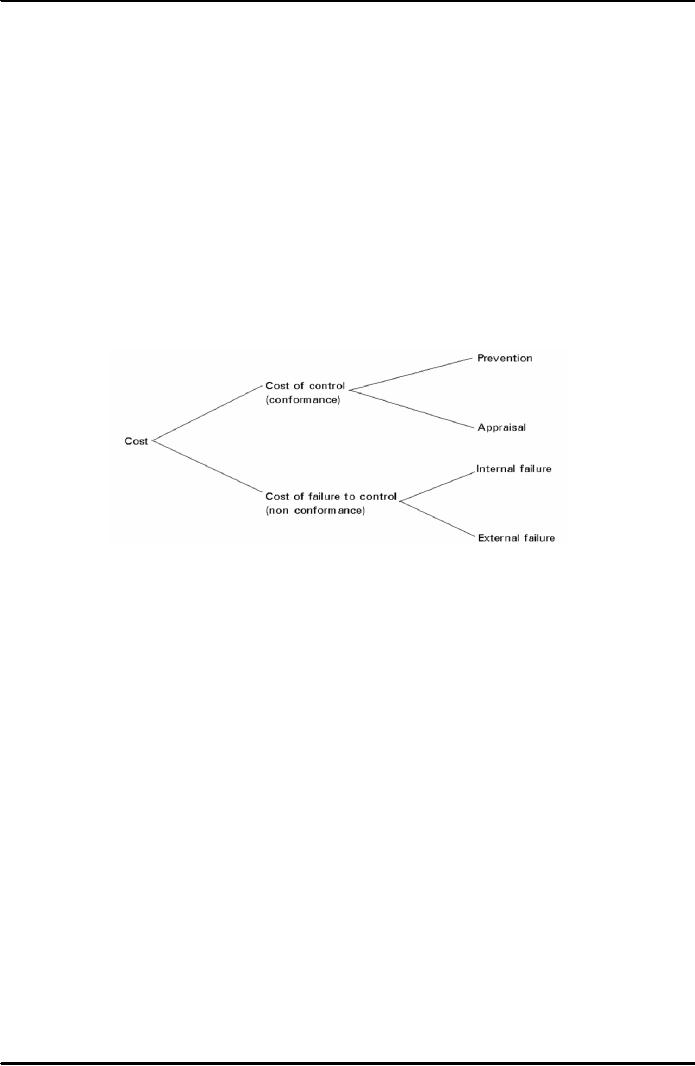

Feigenbaum

divided cost of quality into

two categories and four sub

categories:

·

Costs

of Control

o

Prevention

costs

o

Appraisal

costs

·

Costs

of Failure of Control

o

Internal

defect costs

o

External

defect costs

Figure

36.2: Cost

of Quality

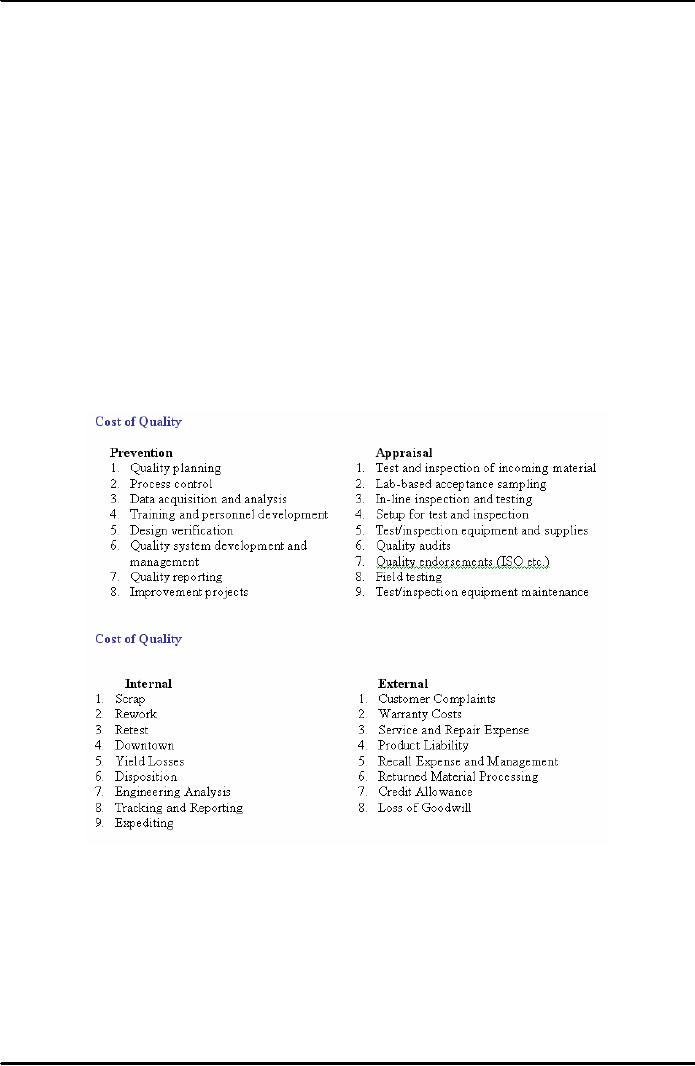

·

Prevention

costs are

the up-front costs oriented

toward the satisfaction of

customer's

requirements

with the first and all

succeeding units of product produced

without defects.

Included

in this are typically such

costs as design review, training,

quality planning, surveys

of

vendors, suppliers, and subcontractors, process

studies, and related

preventive activities.

·

Appraisal

costs are

costs associated with

evaluation of product or process to

ascertain how

well

all of the requirements of the customer have

been met. Included in this

are typically

such

costs as inspection of product,

lab test, vendor control,

in-process testing, and

internal

external

design reviews.

·

Internal

failure costs are

those costs associated with

the failure of the processes to

make

products

acceptable to the customer, before

leaving the control of the organization.

Included

in

this area are scrap,

rework, repair, downtime, defect

evaluation, evaluation of scrap,

and

corrective

actions for these internal

failures.

·

External

failure costs are

those costs associated with

the determination by the

customer

that

his requirements have not been

satisfied. Included are

customer returns and allowances,

evaluation

of customer complaints, inspection at

the customer, and customer visits

to

resolve

quality complaints and necessary

corrective action.

Prevention

costs are expected to actually rise as

more time is spent in prevention

activities

throughout

the organization. As processes improve

over the long run, appraisal

costs will go

down

as the need to inspect in quality

decreases. The biggest savings

will come from the

266

Project

Management MGMT627

VU

internal

failure areas of rework,

scrap, reengineering, redo,

etc. The additional time

spent in up-

front

design and development will really

pay off here. And,

finally, the external costs

will also

come

down as processes yield

first-time quality on a regular

basis. The improvements

will

continue

to affect the company on a long-term

basis in both improved

quality and lower

costs.

Also,

as project management begins to mature, there

should be further decreases in the

cost of

both

maintaining quality and

developing products.

Prevention

costs actually decrease

without sacrificing the purpose of

prevention if we can

identify

and eliminate the costs

associated with waste, such

as waste due to:

·

Rejects

of completed work

·

Design

flaws

·

Work

in progress

·

Improperly

instructed manpower

·

Excess

or noncontributing management (who

still charge time to the

project)

·

Improperly

assigned manpower

·

Improper

utilization of facilities

·

Excessive

expenses that do not necessarily

contribute to the project (that is,

unnecessary

meetings,

travel, lodgings, etc.)

Table

36.1: Cost

of Quality

267

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles