|

Operations

Research (MTH601)

80

LINEAR

PROGRAMMING

Linear

programming is a mathematical technique

designed to aid managers in allocating

scarce resources

(such

as labor, capital, or energy) among

competing activities. It reflects, in the

form of a model, the

organization's

attempt

to achieve some objective (frequently,

maximizing profit contribution,

maximizing rate of

return,

minimizing

cots) in view of limited or

constrained resources (available

capital or labor, service levels,

available

machine

time, budgets).

The

linear programming technique

can be said to have a linear

objective function that is to be

optimized

(either

maximized or minimized) subject to

linear equality or inequality constraints

and sign restrictions on

the

variables.

The term linear describes

the proportionate relationship of

two or more variables. Thus,

a given change in

one

variable will always cause a

resulting proportional change in

another variable.

Some

areas in which linear

programming has been applied

will be helpful in setting the climate

for learning

about

this important technique.

(i)

A

company produces agricultural

fertilizers. It is interested in

minimizing costs while

meeting certain

specified

levels of nitrogen, phosphate,

and potash by blending

together a number of raw

materials.

(ii)

An

investor wants to maximize

his or her rate of return by

investing in stocks and

bonds. The investor

can

set

specific conditions that have to be

met including availability of

capital.

(iii)

A

company wants the best

possible advertising exposure

among a number of national

magazines, and radio

and

television commercials within its

available capital

requirements.

(iv)

An

oil refinery blends several

raw gasoline and additives

to meet a car manufacturer's

specifications while

still

maximizing its profits.

(v)

A

city wants to maximize the

daytime use of recreational

properties being proposed

for purchase with a

limited

capital available.

This

technique, called linear

programming (L.P), is solved in a

step-by-step manner called

iterations. Each

step

of the procedure is an attempt to improve

on the solution until the

"best answer" is obtained or

until it is shown

that

no feasible answer

exists.

Formulation

of the Linear Programming

Problem

To

formulate a real-life problem as a linear

program is an art in itself. To

aid you in this task, it is

helpful to

isolate

the essential elements of

the problem as a means of

asking what the clients

wants and what information

can

be

gained from the data

that has been

provided.

The

first step in formulating a problem is to

set forth the objective

called the objective

function.

80

Operations

Research (MTH601)

81

A

second element of a problem is

that there are certain

constraints on the company's

ability to maximize

the

total

contribution. These constraints

are:

(1)

quantity of raw materials

available,

(2)

the level of demand for the

products, and

(3)

the equipment productive

capacity.

A

further element that must be

considered in the problem is

the time period being

used. The duration

may

be

either long term or short

term. Although time is an important

element, it is one that has

flexibility so that the

time

horizon

may be changed as long as the

restrictions are compatible

with the periods under

consideration.

The

last element is that every

product has a likelihood of

being made. These products

are the dependent or

decision

variables. Of course, the

likelihood of a variable's being in

the answer may change

with the price or

contribution

values (usually profit and

the nature of the

restraints. Yet, at this point there is

nothing to indicate

that

differing

chances of occurrence exists

for the possibility of making

each of the products.

The

first stage of solving linear

programming problems is to set forth

the problem in a mathematical

form

by

defining the variables and

the resulting constraints.

Generally, the relationship is

fairly simple using

only

elementary

algebraic notation. The

relationships can be seen by

first identifying the

decision variables. To aid

in

using

algebraic notation, the

decision variables can be

represented by symbols such as X, Y,

Z.

Next,

we must build the objective

function. If the goal is to maximize

profit, we identify our

objective

function

as

Maximize

total profit or Minimize total loss

(cost).

Then

we write problem

constraints.

These

steps are now illustrated by taking

some examples.

Example

1:

Product

Mix

The

Regal China Company produces

two products daily plates

and mugs. The company

has limited

amounts

of two resources used in the

production of these products clay

and labor. Given these limited

resources, the

company

desires to know how many

plates to produce each day,

in order to Maximize profit.

The two products

have

the

following resource requirements

for production and profit

per item produced (i.e.,

the model

parameters).

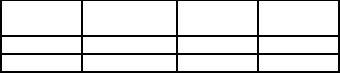

Product

Labor

Clay

Profit

(hours/unit)

(lbs./unit)

(Rs./unit)

Plate

1

4

4

Mug

2

3

5

There

are 40 hours of labour and

120 pounds of clay available

each day for

production.

81

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION