|

BUSINESS EXCELLENCE MODELS:Excellence in all functions |

| << OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management |

| DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership >> |

Total

Quality Management

MGT510

VU

Lesson

# 20

BUSINESS

EXCELLENCE MODELS

Excellence

starts with

`Marketing'

The

`marketing' function of an organization

must take the lead in

establishing the true requirements

for

the

product or service. Having determined the

need, marketing should

define the market sector

and

demand.

This will determine product

or service features such as the grade, price,

quality, timings,

etc.

For

example, a major hotel

chain, before opening a new

hotel or refurbishing an old one,

will need to

consider

its location and accessibility,

before deciding whether it

will be predominantly a budget,

first

class,

business or family

hotel.

Marketing

will also need to establish

customer requirements by reviewing the

market needs,

particularly

in

terms of unclear or unstated expectations or

preconceived ideas held by customers.

Marketing is

responsible

for determining the key

characteristics which determine the

suitability of the product or

service

in the eyes of the customer. This may, of

course, involve the use of

market research techniques,

data

gathering, and analysis of customer

complaints.

Excellent

communication between customers and suppliers is the

key to total organizational

excellence.

This

will eradicate the `demanding

nuisance/idiot' view of customers,

which pervades some

organizations.

Poor communications often occur in the supply

chain between organizations,

when

neither

party realizes how poor they

are. Feedback from both

customers and suppliers needs to

be

improved,

where dissatisfied customers and

suppliers do not communicate their problems. In

such cases

non-conformance

of purchased products or services is

often due to the customer's inability

to

communicate

their requirements clearly. If these

ideas are also used

within an organization, then

the

internal

supplier/customer interfaces will operate much more

smoothly.

Marketing

must also establish systems

for feedback of customer information and

reaction, which

should

be

designed on a continuous monitoring

basis. Any information pertinent to the

product or service

should

be collected and collated, interpreted,

analyzed, and communicated to improve the

response to

customer

experience and expectations. These same

principles must also be

applied inside the

organization

for continuous improvement at

every transformation process

interface to be achieved. If

one

department has problems recruiting the correct sort of

staff, and `HR' have not

established

mechanisms

for gathering, analyzing, and

responding to information on new

employees, then frustration

and

conflict will replace communication and

co-operation.

Excellence

in all functions

For

an organization to be truly excellent,

each part of it must work

properly together. Each

part, each

activity,

each person in the organization affects

and is in turn affected by others. Errors have a

way of

multiplying

and failure to meet the requirements in

one part or area creates problems

elsewhere, leading

to

yet more errors, yet more problems and so

on. The benefits of getting

it right first time

everywhere

are

enormous.

Everyone

experience almost accepts problems in

working life. This causes

people to spend a

large

part

of their time on useless

activities, correcting errors, looking

for things, finding out

why things are

late,

and checking suspect information,

rectifying and reworking,

apologizing to customers for

mistakes,

poor

quality and lateness. The

list is endless and it is estimated that

about one-third of our

efforts are

wasted

in this way. In the service sector it

can be much higher.

Quality,

the way we have defined it as meeting the

customer requirements, gives people

indifferent

functions

of an organization a common language for

improvement. It enables all the

people, with

different

abilities and priorities, to communicate

readily with one another, in

pursuit of a common goal.

When

business and industry was

local, the craftsman could

manage more or less on his

own. Business is

67

Total

Quality Management

MGT510

VU

now

so complex and employs so many

different specialist skills that

everyone has to rely on

the

activities

of others in doing their

jobs.

Frameworks

for Quality and Performance

Excellence

The

philosophies of Deming, Juran, and

Crosby provide fundamental

principles on which total

quality is

based.

Business firms tend to be

highly individualized. As a result, it is

difficult to apply one

specific

philosophy.

Company leaders must understand the

differences and commonalties in the

three

philosophies

and tailor an approach that fits

their unique culture. Some

of the most successful

firms,

such

as Texas Instruments and Dana Corporation, have done

this. Aspects of implementation

are

addressed

further in chapter 11.

None

of thee philosophies, however,

provide a framework for how

to implement total quality

within an

organization

or a means of assessing total

quality efforts relative to

one's peers or

world-class

companies.

Award criteria and certification

procedures fill this

important role. The two

most prominent

frameworks

for quality that have had

world-wide influence are ISO

9000 and the Malcolm

Baldrige

National

Quality Award

Criteria.

The

Malcolm Baldrige National Quality

Award

In

this section we present an overview of

the Award, the Criteria, and the

Award Process. The

Baladrige

Award

recognizes U.S. companies

that excel in quality

management practice and performance.

The

Baldrige

Award does not exist

simply to practice and performance. The

Baldrige Award does not

exist

simply

to recognize product excellence, nor does

it exist for the purposes of

"winning." Its

principal

focus

is on promoting high-performance

management practices that

lead to customer satisfaction

and

business

results. Up to three companies can

receive an award in each of the categories of

manufacturing,

small

business, service, nonprofit health

care, and nonprofit education.

Health care and education

award

categories

were established in 1999.

The

purposes of the award are to

·

Help

stimulate American companies to

improve quality and productivity

for the pride of

recognition

while

obtaining a competitive edge

through increased

profits;

·

Recognize

the achievements of those companies

that improve the quality of

their goods and

services

and

provide an example to others;

·

Establish

guidelines and criteria that

can be used by business,

industrial, governmental, and

other

enterprises

in evaluating their own

quality improvement efforts;

and

·

Provide

specific guidance for other

American enterprises that

wish to learn how to manage

for high

quality

by making available detailed

information on how winning

enterprises were able to

change

their

cultures and achieve eminence.

The

Criteria for Performance

Excellence

The

award examination is based upon a

rigorous set of criteria,

called the Criteria for

Performance

Excellence,

designed to encourage companies to

enhance their competitiveness through an

aligned

approach

to organizational performance management

that result in:

1.

Deliver

of ever-improving value to customers,

contributing to marketplace

success.

2.

Improvement

of overall company performance and

capabilities

3.

Organizational

and personal learning

The

criteria consist of a hierarchical

set of categories, items, and areas to

address. The seven

categories

are

68

Total

Quality Management

MGT510

VU

1.

Leadership:

This category examines how

an organization's senior leaders address

values,

direction,

and performance expectations, as well as

their focus on customer s and

other

stakeholders,

empowerment, innovation, and learning.

Also examined is how an

organization

addresses

its responsibilities to the public and

supports its key

communities.

2.

Strategic

Planning: this category examines

how an organization develops strategic

objectives

and

action plans. Also examined

are how chosen strategic

objectives and action plans

are

deployed

and how progress is

measured.

3.

Customer

and Market Focus: This category

examines how an organization

determines

requirements,

expectations, and preferences of customer

s and markets. Also examined is

how

the

organization builds relationships

with customers and determines the

key factors that lead

to

customer

acquisition, satisfaction, and

retention and to business

expansion.

4.

Information

and Analysis: This category

examines an organization's information

management

and

performance measurement systems and how

the organization analyzes performance

data

and

ensures hardware and software

quality.

5.

Human

Resource Focus: This

category examines how an

organization motivates and

enables

employees

to develop and utilize their

full potential in alignment

with the organization's

overall

objectives

and action plans. Also examined

are the organization's efforts to

build and maintain a

work

environment and an employee support

climate conducive to performance excellence

and

to

personal and organizational

growth.

6.

Process

Management: This category

examines the key aspects of an

organization's process

management,

including customer-focused design,

product and service delivery, key

business,

and

support processes. This category

encompasses all key

processes and all work

units.

7.

Business

Results: This category

examines an organization's performance and

improvement in

key

business areas customer

satisfaction, product and service

performance, financial and

marketplace

performance, human resource results, and

operational performance. Also

examined

are

performance levels, relative to those of

competitors.

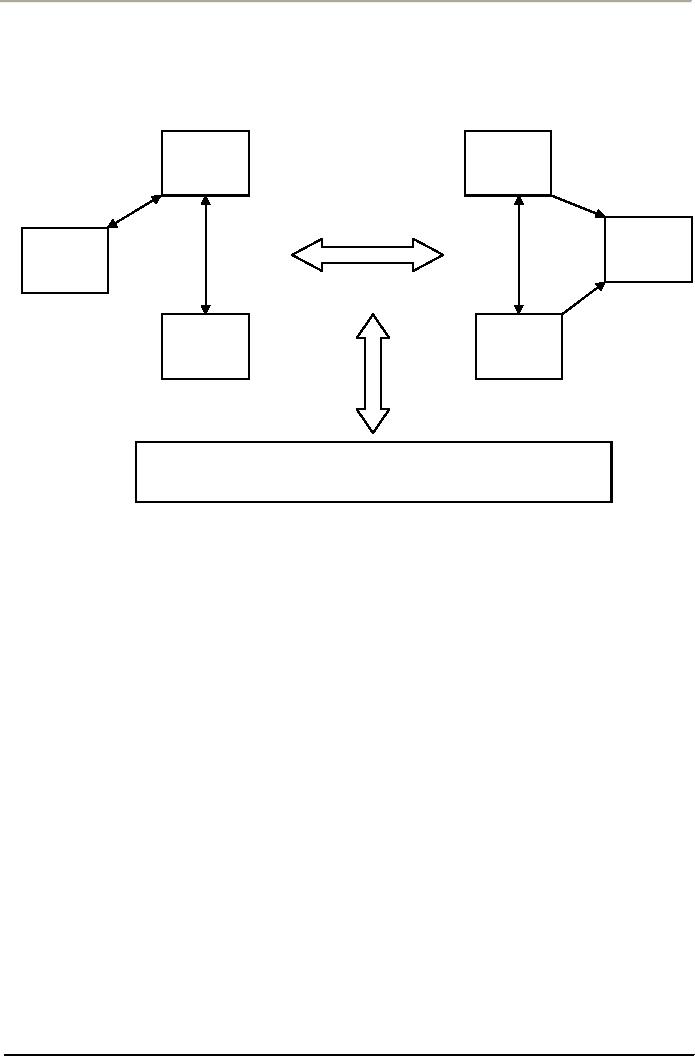

The

seven categories form an

integrated management system.

The umbrella over the seven

categories

reflects

the focus that organizations must have on

customers through their strategy

and action plans for

all

key decisions. Leadership, Strategic

Planning, and Customer and Market

Focus represent the

"leadership

triad," and suggest the

importance of integrating these three

functions. Human

Resource

focus

and Process Management represent

how the work in an organization is

accomplished and leads to

Business

Results. These functions are

linked to the leadership triad.

Malcolm

Baldrige National Quality

Award Criteria

Framework

69

Total

Quality Management

MGT510

VU

Baldrige

Award Criteria

Framework

A

systems Perspective

Organizational

Profile:

Environment,

Relationships, and

Challenges

2

5

Strategic

Human

Resources

Planning

Focus

7

1

Business

Leadership

Results

3

6

Customer

Process

and

Market

Management

Focus

4

Information

and Analysis

Each

category consists of several items (numbered

1.1, 1.2, 2.1, etc.) or

major requirements on which

businesses

should focus. For example, the

Leadership Category consists of the

following items and

areas

to address:

1.1

Organizational

Leadership

a.

Senior

Leadership Direction

b.

Organizational

Performance Review

1.2

Public

Responsibility and Citizenship

a.

Responsibilities

to the Public

b.

Support

of Key Communities

The

Senior Leadership Direction

area asks organizations to

answer the following questions:

·

How

do senior leaders set and deploy

organizational values, short-and longer-term

directions, and

performance

expectations, including a focus on creating and

balancing value for

customers and

other

stakeholders? Include how senior

leaders communicate values, directions, and

expectations

through

your leadership system and to all

employees.

·

How

do senior leaders create an environment

for empowerment, innovation,

organizational agility,

and

organizational and employee

learning?

One

thing the criteria do not do is prescribe

specific quality tolls, techniques,

technologies, systems, or

starting

points. Companies are

encouraged to develop and

demonstrate creative, adaptive,

and flexible

approaches

to meeting basic requirements. Many

innovative approaches have been

developed by

Baldrige

winners and are now commonly

used by many other

companies.

70

Total

Quality Management

MGT510

VU

Baldrige

Award Item Point

Values

2002

Categories/Items

Point

Values

1.

Leadership

120

1.1

Organizational

Leadership. ...

..........................................................

80

1.2

Public

Responsibility and Citizenship

.............................................

....40

2.

Strategic

Planning

85

2.1

Strategy

Development.

...................................................................

40

2.2

Strategy

Development.

...................................................................

45

3.

Customer

and Market Focus

3.1

Customer

and Market Knowledge. .

....................................................40

3.2

Customer

Satisfaction and Relationships.

.............................................45

4.

Information

and Analysis

90

4.1

Measurement

and Analysis of Organizational

Performance ........................50

4.2

Information

Management.

...............................................................40

5.

Human

Resources Focus

85

5.1

Work

systems.

............................................................................

35

5.2

Employee

Education, Training, and

Development.

..................................25

5.3

Employee

Well-Being and Satisfaction. .

.............................................25

6.

Process

Management

85

6.1

Product

and Service

Processes...........................................................55

6.2

Business

Process.

.........................................................................15

6.3

Support

Processes.........................................................................15

7.

Business

Results

450

7.1

Customer-Focused

Results

............................................................

125

7.2

Financial

and Market Results

........................................................

125

7.3

Human

Resource Results

..............................................................

80

7.4

Organizational

Effectiveness Results

...............................................

120

Total

Points

.......................................................................................1,

000

ISO

9000 (2000) International

Quality Management

System

As

quality became a major focus of

businesses throughout the world,

various organizations

developed

standards

and guidelines. Terms such as

quality

management, quality control,

quality system,

and

quality

assurance acquired

different, and sometimes

conflicting meanings from

country to country,

within

a country, and even within an industry.10

As the European Community moved toward

the

European

free trade agreement, which

went into effect at the end of

1992, quality management

became a

key

strategic objective. To standardize quality

requirements for European countries within the

common

market

and those wishing to do

business with those countries, a

specialized agency for

standardization,

the

International Organization for

Standardization, founded in 1946 and

composed of representatives

from

the national standards bodies of 91

nations, adopted a series of written

quality standards in

1987,

which

were revised in 1994, and again

(significantly) in 2000. The

most recent version is

called the ISO

9000:2000

family of standards.

71

Total

Quality Management

MGT510

VU

ISO

9000 is an international quality

standard for goods and

services. The term quality

standard tends

to

be

misleading. For example, ISO

9000 does not set

any specifications for

quality. Rather, it sets

broad

requirements

for the assurance of quality and

for management's involvement. The

emphasis is on

prevention

rather than inspection and rework. In

fact, this emphasis is placed

not only on the

production

process

but also on the product design

process. The ISO 9000

approach is completely compatible

with

the

total quality philosophy,

though it is not as all

encompassing. ISO 9000 is

composed of three

standards:

ISO

9000:2000 Quality Management

Systems Fundamentals and

Vocabulary

ISO

9001:2000 Quality Management

Systems Requirements

ISO

9004:2000 Quality Management

Systems Guidelines for Performance

Improvements

ISO

9000 Can Improve Operations in a

Traditional Environment

By

"traditional environment," we mean an

organizational environment that

has persisted in

companies

for

decades, until the Total

Quality Management movement began to

change things. A

traditional

organizational

environment is one which still

operates according to the "old

way of doing things"

rather

than

according to the principles of Total

Quality Management.

When

ISO 9000 is implemented by a

traditional organization, the company

should be the better for

it.

We

will not go so far as to say

it will be the better for it,

because much depends on the

organization's

reasons

for adopting ISO 9000 and

the degree of executive-level commitment

to it. Put another way, if

ISO

9000 is approached inappropriately and

for the wrong reasons, it

can become nothing more than

a

marketing

ploy, and the organization's functional

departments might develop even more

problems than

they

had before ISO 9000.

ISO

9000 May be Redundant in a

Mature TQM Environment

Just

as ISO 9000 should help

traditional organizations, it should

also benefit TQM

organizations.

However,

in an organization that has achieved a

high level of maturity in

its total quality journey,

say in

the

400-600 range on the Baldrige

scale of 1,000 points, all

ISO 9000 criteria may

already be in place.

In

such a case, the only

compelling reason for

registration under ISO 9000

would be for

marketing

purposes.

What would a company such as

Toyota gain from ISO

9000 registration? Probably

nothing. It

already

does everything required by

ISO 9000. Its products and

processes are recognized as world

class.

Consequently,

It wouldn't gain even a marketing

advantage. However, there are many

fine TQM

organizations

that are not as well

known as Toyota. Such

organizations, even though they

may already

meet

or exceed the requirements of ISO 9000,

may find it necessary to register in

order to let

potential

customers

know that their products or

services satisfy the international

standard.

For

Software and IT companies, the standard

which is more acceptable and regarded

worldwide is

called

CMMI levels 1-5.

ISO

9000 and TQM are not in

Competition

This

is not case of one or the other.

Organizations can adopt TQM or

ISO 9000, or both. While

there

may

be those who advocate one to the

exclusion of the other, in the larger

scheme of things, the

two

concepts

fit well with each

other. Both have worthwhile and

similar aims. Our view is

those not only

are

TQM

and ISO 9000 compatible;

they actually support each

other and are complementary.

There are

good

reasons for using both in a

single management

system.

Management

Motivation for Registration to ISO

9000

Management

motivation for adopting

either ISO 9000 or TQM can

vary widely. There are

both

appropriate

and inappropriate motives. For

example, if a company seeks ISO

9000 registration to

obtain

72

Total

Quality Management

MGT510

VU

a

marketing advantage, its motive is

inappropriate. As a result, the

organization will likely

give mere lip

service

to adopting the standard. Appropriate

motives for adopting ISO

9000 include the

following:

·

To

improve operations by implementing a

quality management system

that satisfies the

ISO

9000

requirements for management

responsibility; resource management;

product realization;

and

measurement, analysis, and

improvement

·

To

create or improve a quality

management system that will

be recognized by customers

worldwide.

·

To

improve product or service quality r the

consistency of quality

·

To

improve customer

satisfaction.

·

To

improve competitive posture

·

To

conform to the requirements of one or more major

customers (although adoption

would be

better

motivated by internal consideration,

such as the preceding

five)

What

we are saying here is that,

ideally, management will

adopt ISO 9000 as a way to

make real

improvements

in the company's operations, serve its

customers in a more responsible way, and, as

a

result,

be more successful. This approach is more

likely to assure commitment

and participation by

top

management.

Approaching ISO 9000 from a

strictly marketing perspective may

result in a negative

reaction

t the amount of work required by the

functional departments, ad only

enough management

commitment

to do the bare minimum for

registration. In other words, if ISO

9000 is viewed as a

necessary

evil that one must

adopt to compete in certain

markets, every dollar and

every hour spent on

ISO

9000 will be seen as a

burden to be endured rather than an

investment in the organization's

future.

By

definition, a burden is a load

that is difficult to bear; the

connotation is negative. When

negative

feelings

abound among employees, commitment to ISO

9000 will suffer. It may be

possible to fool the

ISO

9000 registrar's auditor,

but we guarantee that

customers will not be fooled

at least not for

long.

Newfound

markets will soon wither and

disappear. If ISO 9000 is to have a real

and permanent effect, it

must

be approached with a positive

attitude and the unwavering commitment of

top management.

73

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION