|

Inventory Control:SOME DEFINITIONS, Computation of Safety Stock |

| << Inventory Control:ORDER QUANTITY WITH PRICE-BREAK |

| Linear Programming:Formulation of the Linear Programming Problem >> |

Operations

Research (MTH601)

72

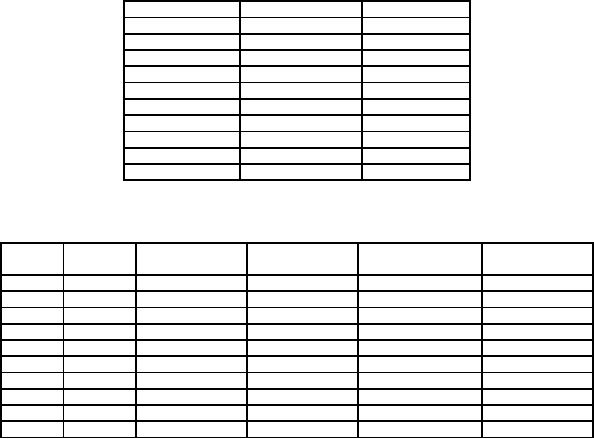

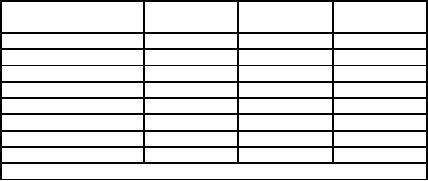

STEP 1:

Calculate

usage value by multiplying

annual usage of each item

with its unit cost

and tabulate them

and

assign

rank by giving rank to the

largest usage value as in

table below.

Items

No.

Annual

Usage

Ranking

1

3000

6

2

40500

1

3

300

9

4

5000

4

5

200

10

6

22000

2

7

800

7

8

4000

5

9

9000

3

10

700

8

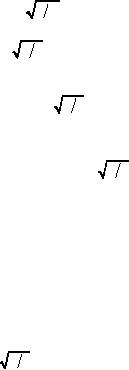

STEP

2: Arrange

items as per ranking and

calculate cumulative usage

and % cumulative value as in

the table below.

%

of cumulative

Cumulative

%

Rank

Item

No.

Annual

usage

Cumulative

Annual

usage

Annual

usage

of

item

1

2

40500

40500

47

10

2

6

22000

62500

73

20

3

9

9000

71500

84

30

4

4

5000

76500

91

40

5

8

4000

80500

94.2

50

6

1

3000

83500

98

60

7

7

800

84300

98.6

70

8

10

700

85000

99.4

80

9

3

300

85300

99.8

90

10

5

200

85500

100

100

If

you draw the figure,

you will see that

the curve changes at points

(say) X and Y. The items

upto X is classified as

class

A items and between X and Y

as class B and the rest as

class C items.

SOME

DEFINITIONS

Lead-time:

This is

defined as the time interval

between the placing of the

orders and the actual

receipt of goods.

Lead-time

Demand: This

is the lead-time multiplied by

demand rate. For example, if

the lead-time is 3 weeks

and

the

demand is at the rate of 50

items per week, then

the lead-time demand is 3

x

50 = 150

items.

The

lead-time may not be

constant. For one batch, a

vendor may take 45 days

and for the next

batch 50 days and so

on.

Lead-time itself is therefore a

stochastic variable. This

complicates the problem of

accumulating stock over

the

period

encompassed by the lead-time.

Lead-time may also be

forecast exponentially as is done

with the demand.

Safety

stock or Buffer stock:

Lead-time

demand is the stock level,

which, on the average is

sufficient to satisfy

the

customer's

orders as the stocks are

being replenished. "On the

average" would mean that

during this period of

replenishment

50% of the customer's order

can be filled and the

remaining 50% may either be

refused or back

ordered

to be filled later. The

reason for this is obvious.

Forecast is after all a

point estimate only. If the

demand is

72

Operations

Research (MTH601)

73

greater

than the forecasts, the

customers would not be

serviced. If the demand is less

then the forecasts,

overstocking

would occur. When these

two variables, stock level

and service to the customer,

are summed up over

thousands

of stock level and service

to the customer, are becomes

a major problem for an

organisation to find an

acceptable

compromise between the two.

Sometimes the management in an

organisation would like to

limit the

disservice

to the customer down to 5% or

10% at the cost of extra

stocking. This extra stock

in excess of the

lead-

time

demand is called the safety

stock. Saftely stock may be

expressed as percentages of the

lead-time demand. It

may

be computed in different

ways.

Reorder

level: This

is defined as the level of

the inventory at which the

order is placed. It has

generally two

components

(i) Lead time Demand

and (ii) Safety

Stock.

Reorder

level (ROL) = Lead time

demand (LTD) + Safety stock

(SS).

Computation

of Safety Stock:

As

discussed earlier, if the

demand exceeds the forecast,

the result is bad service to

the customer and if the

demand

is

less than the forecast

figure, this results in

overstocking. Thus there is a

forecast error. This error

is assumed to be

normally

distributed, with zero mean.

If the standard deviation of

the forecast error is

calculated, then safety

stock

may

be set with the desired

confidence level to result in

not more the 5 or 10%

shortages etc.

There

is another measure of variation,

popularly known as mean

absolute deviation (MAD),

which can be computed

far

more easily. It can be

routinely smoothed every

period for obtaining better

estimates of the safety

stock.

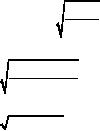

MAD

is related to the standard

deviation for a normal

distribution as given

by.

MAD

=

2

�

SD.

SD

=

� 2MAD

Therefore,

Now

safety stock = Z

(S.D)

=

Z

� 2MAD

=

K

MAD

where

K is called service factor

K

=

Z

� 2

The

safety stock is for just

one period and has to be

extended over the lead

time. The necessary formula

has been

derived

by extensive simulation by statisticians

and is given below.

MADLT

= (0.659+ 0.341 LT)

MAD

Safety

stock over the

lead-time

=

K

(0.659

+

0.341

LT

) MAD

=

Z

� 2

(0.659 + 0.34

LT

)MAD

Example:

A company

uses annually 50000 units of

raw materials at a cost Rs.

1.2 per item. Ordering

cost of items is

Rs.

45 per order and item

carrying cost is 15% per

year of the average

inventory.

73

Operations

Research (MTH601)

74

1.

Find

the economic

quantity.

2.

Suppose

that the company follows

the EOQ policy and it

operates for 300 days a

year, that the

procurement

time is 12 days and mum,

minimum and average

inventories.

Solution:

D

= Demand = 50000/year

No.

of days = 300/year

C1

= Rs.

1.2 per item

Lead

time = 12 days

C2

= Rs. 45

per order

Safety

stock = 500

C3

= 15% of

Rs. 1.2/item/year.

=

Rs. 0.18 per item

per year.

2C2D

EOQ

=

(1)

C3

2�45�50000

=

0.18

=

25000000

=

5000

(2)

Requirement

per day = 50000/300

Lead

time demand = 12 x 500/3 =

2000

Safety

stock

=

500

Reorder

level

=

Lead time demand + safety

stock

=

2000 + 500 = 2500

Maximum

inventory = E.O.Q + Safety

stock

=

5000 + 500 = 5500

Minimum

inventory = Safety stock =

500

Average

inventory

=

(Max. Inv. + Min.

Inv.)/2

=

(5500 + 500)/2 = 3000

Example

A scrutiny of

past records gives the

following distributions for

lead time and daily

demand during lead

time.

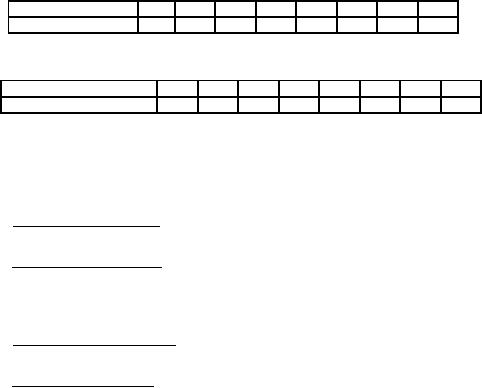

Lead

time distribution

74

Operations

Research (MTH601)

75

Lead

time (days)

3

4

5

6

7

8

9

10

Frequency

2

3

4

4

2

2

2

1

Demand

distribution

Demand/day

(units)

0

1

2

3

4

5

6

7

Frequency

2

4

5

5

4

2

1

2

What

should be the buffer

stock?

Solution:

Computation

of average or mean lead

time.

∑

(Frequency

�

lead

time)

=

∑

Frequency

6+12+20+24+14+6+18+10

=

20

=

6

days

Average

demand

∑

(Frequency

�

demand/day)

=

∑

frequency

0+4+10+15+16+10+6+14

=

25

=3

Average

lead-time demand

=

Average lead time x Average

demand/day

=

6 x 3 = 18.

Maximum

lead-time demand.

=

Max. lead time x Max.

demand/day

=

10 x 7 = 70

∴

Buffer

stock = Max. lead time

demand - Average lead time

demand

*Example

7.7.3

For

a fixed order quantity

system find the EOQ,

SS, ROL and average

inventory for an item with

the

following

data.

Demand

= 10000 units

Cost

of item = Re. 1

Order

cost = Rs. 12

75

Operations

Research (MTH601)

76

Holding

cost = 24%

Post

lead times = 13 days

Solution:

2C2D

EOQ

=

(1)

C3

2�12�10000

=

=

1000

items

0.24�1

(2)

The

Average lead time = (13 + 14

+ 15 + 16 + 17)/5

=

15 days ( 30 days time is

omitted)

Maximum

lead time = 30 days

Safety

stock = ( 30 - 15) x 10000/(30 x

12) = 420

(3)

Reorder

level = Lead time demand +

Safety stock

=

417 + 420 = 837

(4)

Average

inventory = (1420 +

420)/2

=

1840/2 = 920.

Example:

An airline

has determined that 10 spare

brake cylinders will give

them stock out risk of

30%, whereas 14

will

reduce the risk to 15%

and 16 to 10%. It takes 3

months to receive items from

supplier and the airline

has an

average

of 4 cylinders per month. At

what stock level should

they reorder assuming that

they wish to maintain

an

85%

service level.

Solution:

Lead

time demand = 3 x 4 = 12

items

Safety

stock at 85% service

=

15% disservice

or

15% stock out

risk

=

14 items

Reorder

level = 12 + 14 = 26 items.

Example:

Data on

the distribution of lead

time for a motor component

were collected as shown.

Management would

like

to set safety stock levels

that will limit the

stock out to 10%.

Lead

time (weeks)

1

2

3

4

5

6

7

8

Frequency

of occurrence

10

20

70

40

30

10

10

10

76

Operations

Research (MTH601)

77

How

many weeks of safety stock

are required to provide the

desired service

level?

Solution:

Lead

time (weeks)

Frequency

Probability

Cumulative

Probability

1

10

0.05

0.05

2

20

0.10

0.15

3

70

0.35

0.50

4

40

0.20

0.70

5

30

0.15

0.85

6

10

0.05

0.90

7

10

0.05

0.95

8

10

0.05

1.00

200

Average

lead time = ∑

(lead

time x frequency)/ ∑

frequency

=

(10 + 40 + 210 + 160 + 150 +

60 + 70 + 80)/200

=

770/200 = 3.85 weeks

Upto

90% service level max.

lead time is 6 weeks.

Hence

6 - 3.85 = 2.15 weeks of

stock would provide the

service level of 90%

(Note:

If the lead time is given as

a continuous time distribution

take the mid

point.)

Example:

Demand for

a product during an order

period is assumed to be normally

distributed with mean of

1000

units

and standard deviation of 40

units. What % service can a

company expect to provide

(i) if it satisfies

the

average

demand only (ii) if it

carries a safety stock of 60

units.

Solution:

1.

If

the company provides only

average demand, we can

expect only 50% service

level.

2.

The

standard normal variate Z is

computed with the following

formula.

Z

= (Safety stock - 0)/

Standard deviation

=

(60 - 0)/40 = 1.5

The

area under normal curve

for Z = 1.5 is

0.4332.

∴

Service

level = 0.50 + 0.4332 =

0.9332

04

93.32%

Example:

A manufacturer of

water filters purchases

components in EOQ's of 850

units/order. Total

demand

averages

12000 components per year

and MAD = 32 units per

month. If the manufacturer

carries a safety stock of

80

units,

what service level does

the this give the

firm?

Solution:

77

Operations

Research (MTH601)

78

2

�

MAD

=

MAD

/

0.8 =

32 /

0.8 =

40

Standard

deviation =

�

Z

= (S S - 0)/S.D = (80 - 0)/40 =

2

The

area under normal curve

for Z = 2 = 0.4772.

Service

level = 0.9772 or

97.72%

Example:

A firm has

normally distributed forecast of

usage with MAD = 60 units. It

desires a service level,

which

limits

the stock, outs to one

order cycle per

year.

(1)

How much safety stock

should be carried if the

order quantity is normally a

week's supply?

(2)

How much safety stock

should be carried if the

order quantity is weeks

supply.

Solution:

No.

of orders = 52/year.

1

stock out in 52 weeks means

a 98 % = (51/52) values

For

98% area, the value

of

Z

= 2.05 (from tables)

S

D = MAD/0.8 = 60/08

Z

= (S S - 0 )/S D= (S S - 0)/60/0.8

2.05

= (S S - 0 ) x 0.8/60

SS

= 2.05 x 60/0.8 = 154

units.

(a)

Number of orders =

52/5

1

stock out = (52/5 -

1)

Service

level = (47/5)/(52/5) = 47/52 =

0.904

Z

= 1.285 (for area = 0.404)

MAD = 60

1.285

= S S/75

S

S = 75 x 1.285 = 96 units.

78

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION