|

Inventory Control:Manufacturing model with no shortages |

| << Inventory Control:Purchasing model with shortages |

| Inventory Control:Manufacturing model with shortages >> |

Operations

Research (MTH601)

63

Rs.5�747�0.5

=

Shortage

cost

2�12

=

Rs.

77.75 per order

Total

cost per order

=

3857

+

400

+

77.75

+

322.14

=

Rs.

4656.89

Annual

cost =

Number

of orders/year �

cost

=

4.66

�

4656.89

=

Rs.

21701.

Model

3: Manufacturing model with no

shortages

In

this model the following

assumptions are made:

(1)

Demand

is at a constant rate (D).

All

cost coefficients (C1, C2,

C3)

are constants.

(2)

(3)

There

is no shortage cost, or C4 = 0.

(4)

The

replacement rate is finite

and greater than the

demand rate. This is also

called replenishment

rate

or

manufacturing rate, denoted by

R.

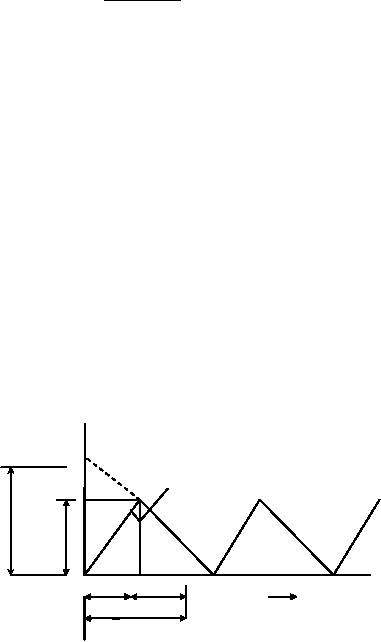

Schematically,

this model is illustrated in

fig 4

Slope=

(R-D)

Slope

= D

Q

Im

t2

Time

t1

t

Fig.

4

The

total cost of inventory per

period is the sum of three

components: item cost, order

cost and items holding

cost.

Let

Im be the

maximum inventory, t1 be

the time of manufacture and

t2 be

the time during which

there is no supply.

In

this model, all items

required for a cycle are

not stored at the beginning

as in Wilson's Model. The

items are

manufactured

at a higher rate than the

demand so that the

difference (RD)

is the existing inventory

till the items

are

exhausted.

Item

cost/period = C1Q

(32)

Order

cost/period = C2

(33)

63

Operations

Research (MTH601)

64

=

C

�

I

� (t1 +

t2 ) 2

Item

holding cost/period

(34)

m

3

=

C3 I

m � t

2

(35)

=

t

(

R

-

D)

(36)

I

1

m

t

=Q

R

(37)

But

1

=

(Q

R)(

R

-

D)

Therefore

(38)

I

m

Substituting

the value of Im, we get

the total cost of inventory

per period.

C′

= C

Q +

C2 +

C3 (Q

R)( R

-

D) �

t

2

(39)

1

Total

cost of inventory per unit

time

C

=

C′

t

(40)

t

+

C3 (Q

R)( R

-

D) �

t

=

C

Q t +C

(41)

2

1

2

But

t =

Q/D

Substituting

the value of t

we

get

C

=

C

D +

C

D Q +

C3 (Q

R) ( R-D)

2

(42)

1

2

Differentiating

C

with

respect to Q

and

setting equal to zero for

minimum C,

we get,

C

D C (

R-D)

dC

=

0-

2

+

3

=0

(43)

dQ

2R

Q2

Solving

equation (43), we get

2C2D

R

Q*

=

(44)

R-D

C3

This

gives the economic order

quantity and is a balance

between holding and set up

costs.

64

Operations

Research (MTH601)

65

Example:

The demand for an item in a

company is 18000 units/year

and the company can

produce at the rate

of

3000

per month. The cost of

one set up is Rs. 500

and the holding cost of 1

unit per month is 15 paisas.

Determine:

(a)

The

optimum manufacturing

quantity.

(b)

The

maximum inventory.

(c)

The

time between orders.

(d)

The

number of orders/year.

(e)

The

time of manufacture.

(f)

The

optimum annual cost if the

cost of the item per

unit is Rs. 2.

Assume

no shortages.

Solution

C1 = Rs. 2

per item.

C2 = Rs. 500

per order.

C3 = Rs. 0.15

per item per

month

D

= 18000/year =

1500/month

R

=

3000/month

a)

Optimum

manufacture quantity

2C2D

R

Q*

=

R-D

C3

2�500�1500�3000

=

=

4470

units

C

0.15(3000-1500)

b)

The

maximum inventory

=

Q

(

R-D)

R

=

4470

�

1500

3000 =

2235

units

I

m

c)

The

time between orders

t

=

Q

D =

4470

1500 =

2.98

months

3

months

d)

The

number of orders/year

N

=

12

3 =

4

e)

The

time of manufacture

t

=

Q

R =

4470

3000 =

1.490

months

1

f)

The

optimum annual cost

=

Item cost + Ordering cost +

Holding cost

65

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION