|

Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS) |

| << PERT / CPM:Exercises |

| Inventory Control:Purchasing model with shortages >> |

Operations

Research (MTH601)

51

3-5

Y

20

4

4-5

X

30

6

Resource

availability:

Number

of operators = 50

Equipments

X = 1, Y = 1, Z = 1

Segment

III: Inventory Control

Lectures

11 -16

51

Operations

Research (MTH601)

52

INVENTORY

AND CONTROL

Inventory

is the physical stock of

items held in any business

for the purpose of future

production

or

sales. In a production shop the

inventory may be in the form

of raw materials. When the

items

are

in production process, we have

the inventory as in-process

inventory and at the end of

the

production

cycle inventory is in the

form of finished goods. We

shall be dealing only with

the

finished

goods inventory. The problem

of determining inventory policies is

not a new concept

beginning.

It is only in he last two

decades that it has been

tackled with quantitative

techniques

and

mathematical models, a method amenable to

optimization.

Inventory

planning is the determination of

the type and quantity of

inventory items that would

be required at

future

points for maintaining

production schedules. Inventory

planning is generally based on

information from the

past

and

also on factors that would

arise in future. Once this

sort of planning is over,

the control process starts,

which

means

that actual and planned

inventory positions are

compared and necessary

action taken so that the

business

process

can function

efficiently.

In

inventory control, we are primarily

concerned with the inventory

cost control. The aim is

focussed to

bring

down the total inventory cost

per annum as much as

possible. Two important questions

are (1) how much

to

stock

or how much to buy and

(2) how often to buy or

when to buy. An answer to the

above questions is

usually

given

by certain mathematical models, popularly

known as `economic order

quantity models' or `economic

lot/batch

size

models (E.O.Q.).'

INVENTORY

COSTS

There

are four major elements of

inventory costs that should

be taken for analysis, such

as

Item

cost, Rs. C1/item.

(1)

(2)

Ordering

cost, Rs. C2/order.

Holding

cost Rs. C3/item/unit

time.

(3)

(4)

Shortage

cost Rs. C4/item/Unit

time.

Item

Cost (C1)

This

is the cost of the item

whether it is manufactured or purchased.

If it is manufactured, it includes

such

items

as direct material and

labour, indirect materials

and labour and overhead

expenses. When the item

is

purchased,

the item cost is the

purchase price of 1 unit.

Let it be denoted by Rs.

C1 per

item.

Purchasing

or Setup or Acquisition or Ordering

Cost (C2)

Administrative

and clerical costs are

involved in processing a purchase

order, expediting, follow up

etc., It

includes

transportation costs also.

When a unit is manufactured,

the unit set up cost

includes the cost of labour

and

materials

used in the set up and

set up testing and training

costs. This is denoted by

Rs. C2 per set up

or per order.

Inventory

holding cost (C3)

52

Operations

Research (MTH601)

53

If

the item is held in stock,

the cost involved is the

item carrying or holding

cost. Some of the costs

included

in

the unit holding cost

are

(1)

Taxes

on inventories,

(2)

Insurance

costs for inflammable and

explosive items,

(3)

Obsolescence,

(4)

Deterioration

of quality, theft, spillage

and damage to times,

(5)

Cost

of maintaining inventory

records.

This

cost is denoted by Rs.

C3/item/unit

time. The unit of time

may be days, months, weeks

or years.

Shortage

Cost (C4)

The

shortage cost is due to the

delay in satisfying demand

(due to wrong planning); but

the demand is

eventually

satisfied after a period of

time. Shortage cost is not

considered as the opportunity

cost or cost of lost

sales.

The

unit shortage cost includes

such items as,

(1)

Overtime

requirements due to

shortage,

(2)

Clerical

and administrative

expenses.

(3)

Cost

of expediting.

(4)

Loss

of goodwill of customers due to

delay.

(5)

Special

handling or packaging

costs.

(6)

Lost

production time.

This

cost is denoted by Rs.

C4 per item

per unit time of

shortage.

INVENTORY

MODELS (E.O.Q.

MODELS)

The

inventory control model can

be broadly classified into

two categories:

(1)

Deterministic inventory

problems.

(2)

Probabilistic or stochastic inventory

problems.

In

the deterministic type of

inventory control, the

parameters like demand,

ordering quantity cost, etc

are

already

known or have been

ascertained and there is no

uncertainty. In the stochastic

inventory control, the

uncertain

aspects

are taken into

account.

First

let us consider the

inventory control of the

deterministic type. There

are four EOQ models

which are

discussed

below. The first one is

the well-known Wilson's

inventory model.

Model

1: Purchasing

model with no shortages:

(Wilson's model)

The

following assumptions are

made in deriving the formula for

economic order quantity.

(1)

Demand

(D) is at a constant

rate.

(2)

Replacement

of items is instantaneous (lead

time is zero).

(3)

The

cost coefficients C1, C2,

and C3 are

constant.

There

is no shortage cost or C4 = 0.

(4)

This

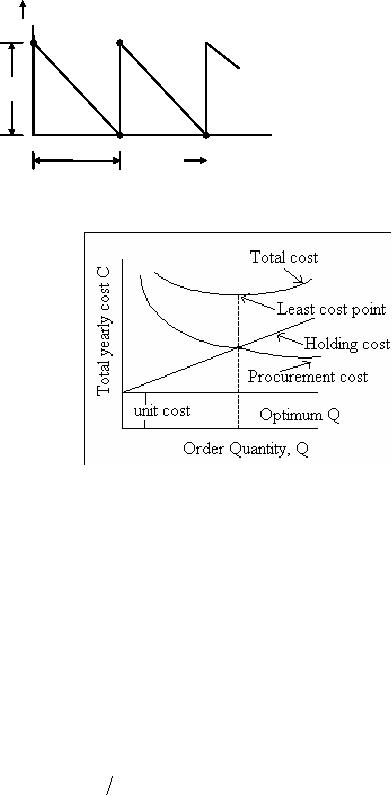

mode represented graphically in

fig. 1. This is also known

as a saw tooth model

(because of its

shape).

53

Operations

Research (MTH601)

54

Quantity

Q

=Im

t

Time

Fig.

1

Fig.

2

In

this model, at time

t

= 0, we order a

quantity Q

which is

stored as maximum inventory,

1m. The time

`t' denotes

the

time

of one period or it is the

time between orders or it is

the cycle time. During

this time, the items

are depleting and

reaching

a zero value at the end of

time t.

At time t

another

order of the same quantity

is to be placed to bring

the

stock

upto Q

again and

the cycle is repeated. Hence

this is a fixed order

quantity model.

The

total cost for this

model for one cycle is

made up of three cost

components.

Total

cost/period = (Item cost +

set up cost + holding

cost/period)

Item

cost per period = (Cost of

item) �

(number

of items ordered/period)

=

C1Q

(1)

Purchase

or set up cost per period =

C2 (only one

set up per period)

Item

holding cost per period =

(Holding cost) �

(average

inventory per period) �

(time

per period)

=

C3 Q

2

�

t

(2)

54

Operations

Research (MTH601)

55

Therefore

the total cost per

period (C ′) =

C

Q +

C

+

C

Q 2 �

t

(3)

1

2

3

But

the time for one

period t

=

Q

D

(4)

Therefore

the total cost per

unit time, C

=

C′

t

(5)

D

Q

C

+

C1D

+

C2

+C

(6)

3 2

Q

Substituting

the value of t,

we get C

=

C

D +

C

D Q +

C

Q 2

(7)

1

2

3

The

cost components of the above

equations can be represented as

shown in fig 2 and an

optimum order quantity

for

one

period is found when

Purchase

cost = Item holding

cost.

C2D

C3Q

=

Q

2

2C2D

2C2D

Q2 =

Q*

=

(8)

C3

C3

This

minimum inventory cost per

unit time can also be

found by differentiating C

with

respect to Q

and

equating it to

zero.

The derivative of the

equation is,

C3

dC

-C2 D

+

=0

=

(9)

dQ

Q

2

2

Solving

for Q,

we get

2C2D

Q*

=

(10)

C3

This

value of Q*

is the

economic order quantity and

any other order quantity

will result in a higher

cost.

The

corresponding period t*

is found

from

t*

=

Q*

D

(11)

The

optimum number of orders per

year is determined

from

N

*

=

D

Q*

where

D

is the

demand per year.

55

Operations

Research (MTH601)

56

56

Operations

Research (MTH601)

57

Example

1: The

demand rate for a particular

item is 12000 units/year.

The ordering cost is Rs.

100 per order

and

the

holding cost is Rs. 0.80

per item per month. If no

shortages are allowed and

the replacement is

instantaneous,

determine:

(1)

The

economic order

quantity.

(2)

The

time between orders.

(3)

The

number of orders per

year.

(4)

The

optimum annual cost if the

cost of item is Rs. 2 per

item.

Solution:

Note

that the holding cost is given

per month and convert the same

into cost per

year.

C1 = Rs.

2/item

C2 = Rs.

100/order

C3 = Rs.

0.80/item/month

=

Rs. 9.6/item/year

D

= 12000

items/year

a)

The

economic order

quantity

2C2 D

Q*

=

C3

2�100�12000

=

9.6

=

500

units

b)

The

time between orders

t*

=

Q*

D

=

500 /

12000 yr.

=

500

1000 month

=

0.5

month

c)

The

number of orders/year

N

=

D

Q*

=

12000

/ 500 =

24

d)

The

optimum annual cost

57

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION