|

STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT |

| << CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts |

| STATISTICAL PROCESS CONTROL….CONTD:Control Charts >> |

Total

Quality Management

MGT510

VU

Lesson

# 39

STATISTICAL

PROCESS CONTROL (SPC) FOR

CONTINUAL QUALITY

IMPROVEMENT

Variation

and Process

Control

In

a total quality setting,

consistency and predictability

are important. When a

process runs

consistently,

efforts

can begin to improve it by

reducing process variations, of

which there are two

kinds:

�

Common-cause

variation is the result of the sum of

numerous small sources of

natural variation

that

are always part of the

process.

�

Special-cause

variation is the result of factors that

are not part of the process

and that occur

only

in

special circumstances, such as a shipment of

faulty raw material or the

involvement of anew,

untrained

operator.

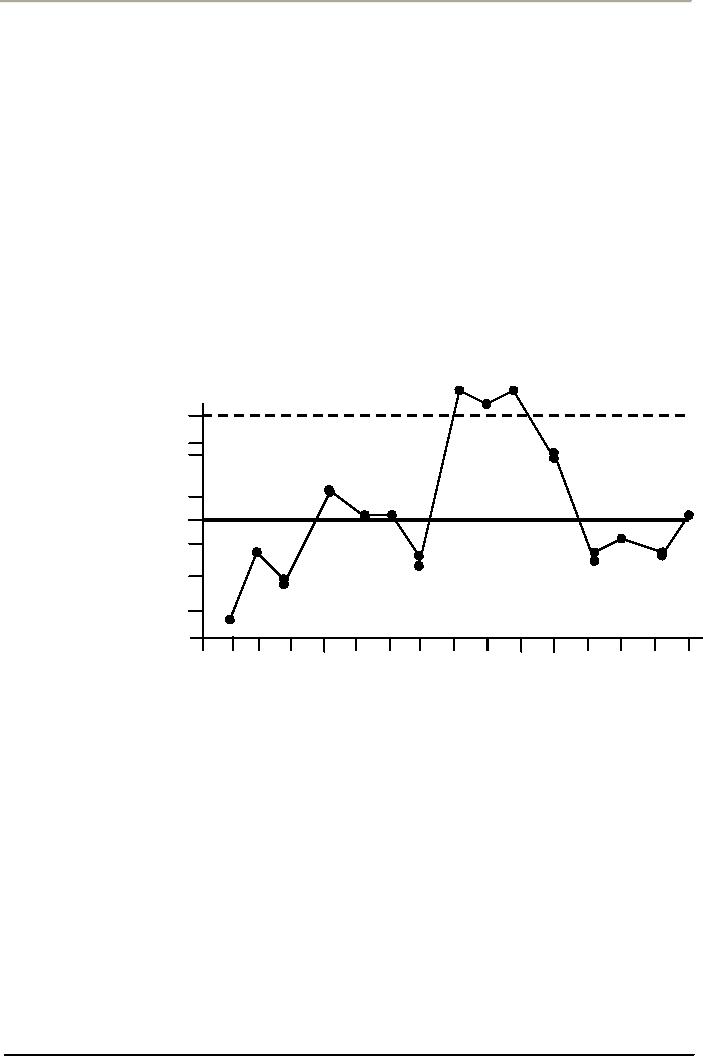

The

performance of a process that operates

consistently can be recorded and plotted

on a control chart

such

as the one in Figure below. The

sources of the variation in this

figure that fall within the

control

limits

are likely to be common causes.

The sources of variation in

this figure that fall

outside the control

limits

are likely to be special-causes

sources. In making decisions about the

process in question, it is

important

to separate common and special causes of

variation.

16

14

12

10

8

6

4

2

0

0

1

2

34

5

6

7

8

9

10

11

12

13

14

15

Control

Chart

If

you react to common-cause

variation as if it were due to special causes,

you will only make

matters

worse

and increase variation,

defects, and mistakes. If you

fail to notice the appearance of a

special

cause,

you will miss an opportunity

to search out and eliminate a

source of problems

Control

charting in SPC utilizes

in-process (sometimes called

on-line) sampling techniques to

help

monitor

a process. The purpose is to

indicate when the process is

functioning as intended

i.e.

statistically

under control and when to

take corrective action of

some type is necessary. Hence

SPC can

be

taken as a proactive and preventive

approach of quality improvement. An

in-control process is

considered

stable and out-of-control process is said

to be un-stable. Improvement in stable

system can

occur

only through system changes,

which are the responsibility of

management and empowered

employees.

Instability is created when a special

cause or disturbance is present. Once an

indication of a

process

shift is detected it is up to the operators,

engineers, and other technical people to

locate the

special

cause/s and take corrective

action.

163

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION