|

BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED |

| << QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION |

| HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER! >> |

Total

Quality Management

MGT510

VU

Lesson

# 36

BASIC

SQC IMPROVEMENT

TOOLS

Tools

for Continuous Improvement:

Many

tools have been created or

adapted from other

disciplines (such as operations research

and

industrial

engineering) to facilitate the process of

continuous improvement. Here we

learn the most

common

ones used in quality

improvement applications.

One

of the basic tenets of total

quality is management by facts.

Management by facts requires that

each

decision,

each solution to a problem, is

based on relevant data and

appropriate analysis. Problem

solving

and

decision making are

fundamental to total quality. On the one

hand, good decisions will decrease

the

number

of problems that occur. On the other

hand, the workplace will never be

completely problem

free.

Once

we get beyond the very small

business (in which the data

are always resident in the few

heads

involved,

anyway), most decision

points and problems will have many

impacting factors, and the

problem's

root cause or the best-course

decision will remain obscure

until valid data are

studied and

analyzed.

Collecting and analyzing data

can be difficult. The total

quality tools use will

assure better

decision

making, better solutions to problems, and

even Improvement of productivity and products

and

services.

Writing

about the use of statistical

methods in Japan, Dr.

Ishikawa said:

The

so-called seven indispensable tools . . .

that are being used by

everyone: company presidents,

company

directors, middle management, foremen,

and line workers. These

tools are also used in

a

variety

of [departments], not only in the

manufacturing [department] but

also in the [departments] of

planning,

design, marketing, purchasing, and technology."

No matter where you fit

into your

organization

today, you can use

some or all of these tools

to advantage, and they will serve

you well for

your

future prospects.

PROBLEM

SOLVING FOR TOTAL

QUALITY

If

you ask the typical manager

to describe his or her biggest

problem in today's work-place, the

response

will

probably include one or more of the

following:

�

We

spend all our time in

meetings trying to resolve

problems.

�

We

are constantly fighting problems, and

that doesn't leave us time

to do our real jobs, such

as

planning,

leading, and so

forth.

�

As

soon as we "put out one

fire," another pops

up.

�

We've

got more problems than we can

handle, and it bogs us

down.

The

actual words may vary, but the

message is the same. The

workplace can be so burdened

with

problems

that managers and others

spend so much time trying to

fix them that nothing gets done

right.

With

problem solutions leading to

process or products/service

improvement,

�

product

or service quality improves

�

costs

decrease (through less waste

and warranty action)

�

customer

satisfaction improves

�

competitiveness

improves, and

�

the

probability for success

improves

152

Total

Quality Management

MGT510

VU

Clearly

all of these outcomes are

desirable. And they are all

achievable by applying the total

quality

principles

to problem solving.

TOTAL

QUALITY TOOLS

DEFINED

Carpenters

use a kit of tools designed

for very specific functions.

Their hammers, for example,

are used

for

the driving of nails. Their

saws for the cutting of

wood. These and others enable a carpenter

to build

houses.

They are physical tools.

Total quality tools also

enable today's employees, whether engineers,

technologists,

production workers, managers, or

office staff, to do their

jobs. Virtually no one

can

function

in an organization that has

embraced total quality

without some or all of these

tools.

Unlike

those in the carpenter's kit,

these are intellectual

tools: they are not

wood and steel to be

used

with

muscle; they are tools

for collecting and displaying

information in ways to help the human

brain

grasp

thoughts and ideas. When

thoughts and ideas are

applied to physical processes, the

processes yield

better

results. When applied to

problem solving or decision

making, better solutions and decisions

are

developed.

The

seven tools discussed below

represent those generally

accepted as the basic total

quality tools. A

case

can be made that

just-in-time, statistical process

control, and quality

function deployment are

total

quality

tools. But these are more

than tools: they are

complete systems under the total

quality umbrella.

A

tool, like a hammer, exists to help do a

job. If the job includes

continuous improvement,

problem

solving,

or decision making, then

these seven tools fit the

definition. Each of these

tools is some form of

chart

for the collection and display of

specific kinds of data. Through the

collection and display

facility,

the

data become useful

information-information that can be

used to solve problems, enhance

decision

making,

keep track of work being done, even

predict future performance and problems.

The beauty of

the

charts is that they organize

data so that we can

immediately comprehend the message. This

would be

all

but impossible without the

charts, given the mountains of data

flooding today's workplace.

Tools

for Data Collection and

Analysis

Seven

simple statistically based

tools are used extensively

to gather and analyze data.

Unlike

the

seven advanced management and

planning tools, these tools

are visual in nature and

simple

enough

for anyone to understand.

These

seven basic tools of quality

are

1.

Flow-charts,

2.

Check

sheets,

3.

Histograms,

4.

Pareto

diagrams,

5.

Cause-and-Effect

diagrams,

6.

Scatter

diagrams, and

7.

Control

charts

Historically,

these tools preceded the

seven management and planning

tools and often

are

called

the "seven QC (Quality Control)

tools." The seven management

and planning tools

have

been referred to as the "new advanced

seven."

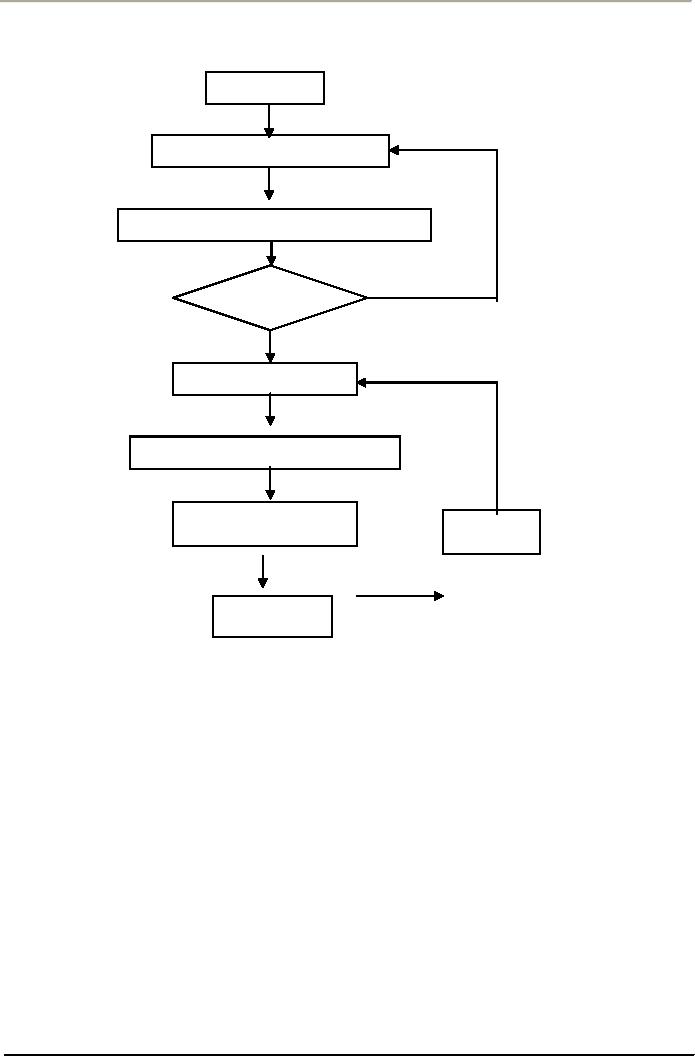

Flowcharts:

A

flowchart is a picture of a process

that shows the sequence of

steps performed. Flowcharts

are best

developed

by the people involved in the processemployees,

supervisors, managers, and customers.

A

facilitator

often is used to provide

objectivity, to ask the right questions,

and to resolve conflicts.

The

facilitator

can guide the discussion

through questions such as "What

happens next?" "Who makes

the

decision

at this point?" and "what

operation is performed

here?"

153

Total

Quality Management

MGT510

VU

Example

of a Flowchart for Training New

Printing Press Operators

Hire

Candidate

Training

with operator checklist

Safety,

quality, and procedures

testing

No

Test

d?

Yes

Four-week

evaluation

Solo

with lead operator

support

90-day

evaluation

Fail

Reevaluate

employee

Pass

Press-certifying

Flowcharts

help the people involved in the

process to understand it better. For

example,

employees

realize how they fit

into a processthat is, who their

suppliers and customers are.

By

helping

to develop a flowchart, workers

begin to feel a sense of

ownership in the process

and

become

more willing to work on improving

it. Using flowcharts to

train employees on standard

procedures

leads to more consistent

performance.

Once

a flowchart is constructed, it can be

used to identify quality problems as

well as areas for

improvement.

Questions such as "How does

this operation affect the customer?"

"Can we

improve

or element this operation?" or "Should we

control a critical quality characteristic

at this

point?"

help to identify such

opportunities. Flowcharts help

people to visualize simple

but

important

changes that could be made

in a process.

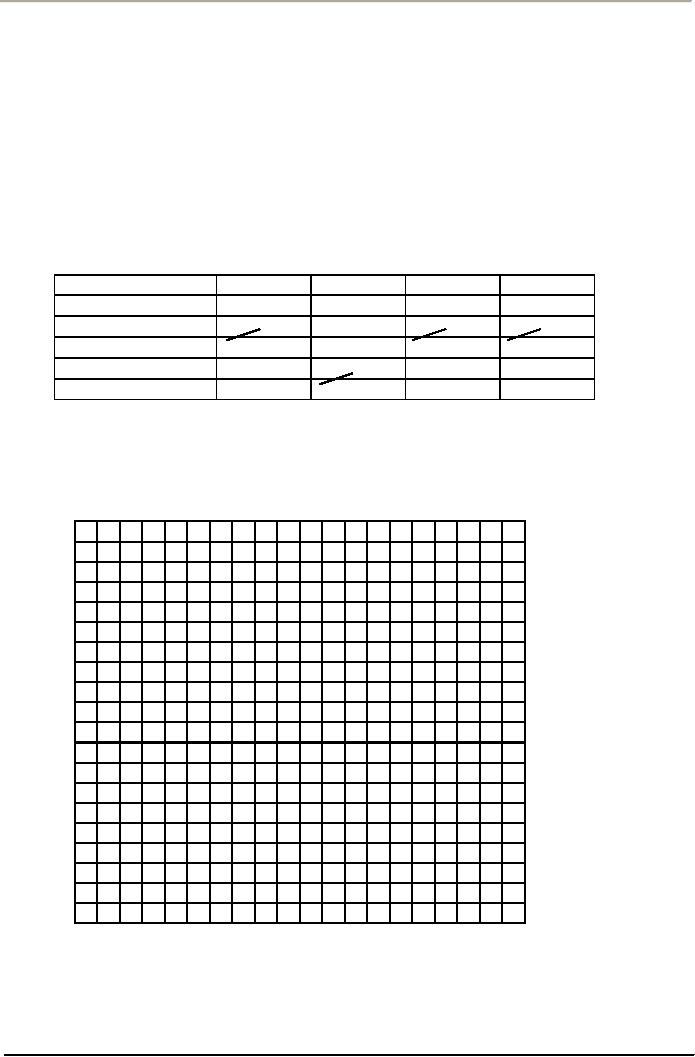

Check

Sheets

These

tools aid in data

collection. When designing a

process to collect data, one

must first ask

basic

questions such as:

�

What

question are we trying to

answer?

�

What

type of data will we need to

answer the question?

�

Where

can we find the data?

154

Total

Quality Management

MGT510

VU

�

Who

can provide the data?

�

How

can we collect the data with

minimum effort and minimum

chance of error?

Check

sheets are data collection

forms that facilitate the

interpretation of data.

Quality-related

data

are of two general typesattribute

and variable. Attribute data

are obtained by counting

or

from

some type of visual

inspection: the number of invoices that

contain errors, the number of

parts

that conform to specifications, and the

number of surface defects on an

automobile panel,

for

example. Variable data are

collected by numerical measurement on a

continuous scale.

Dimensional

characteristics such as distance,

weight, volume, and time

are common examples.

Figure

below is an example of an Attribute

data check sheet, and second

Figure below shows a

Variable

data check sheet.

Example

of a Check Sheet for Attribute

Data: Airline

Complaints

Type

Week

1

Week

2

Week

3

Week

4

⏐

⏐⏐

⏐

Lost

baggage

⏐⏐⏐

⏐

⏐⏐⏐⏐

⏐⏐⏐

⏐⏐⏐

⏐⏐⏐

Baggage

delay

⏐⏐

⏐

⏐⏐⏐

⏐

Missed

connection

⏐⏐⏐

⏐⏐⏐

⏐⏐⏐

⏐⏐⏐

Poor

cabin service

⏐

⏐

Ticketing

error

Example

of a Check Sheet for Variable

Data

Frequency

20

19

18

17

16

15

14

X

13

X

12

X

X

11

X

X

X

10

X

X

X

9

X

X

X

X

8

X

X

X

X

7

X

X

X

X

6

X

X

X

X

X

5

X

X

X

X

X

4

X

X

X

X

X

X

X

3

X

X

X

X

X

X

X

2

X

X

X

X

X

X

X

1

X

X

X

X

X

X

X

X

X

X

123456

7

8

9

10

11

12

13

14 15 16 17 18 19 20

Time

to process loan request

(days)

155

Total

Quality Management

MGT510

VU

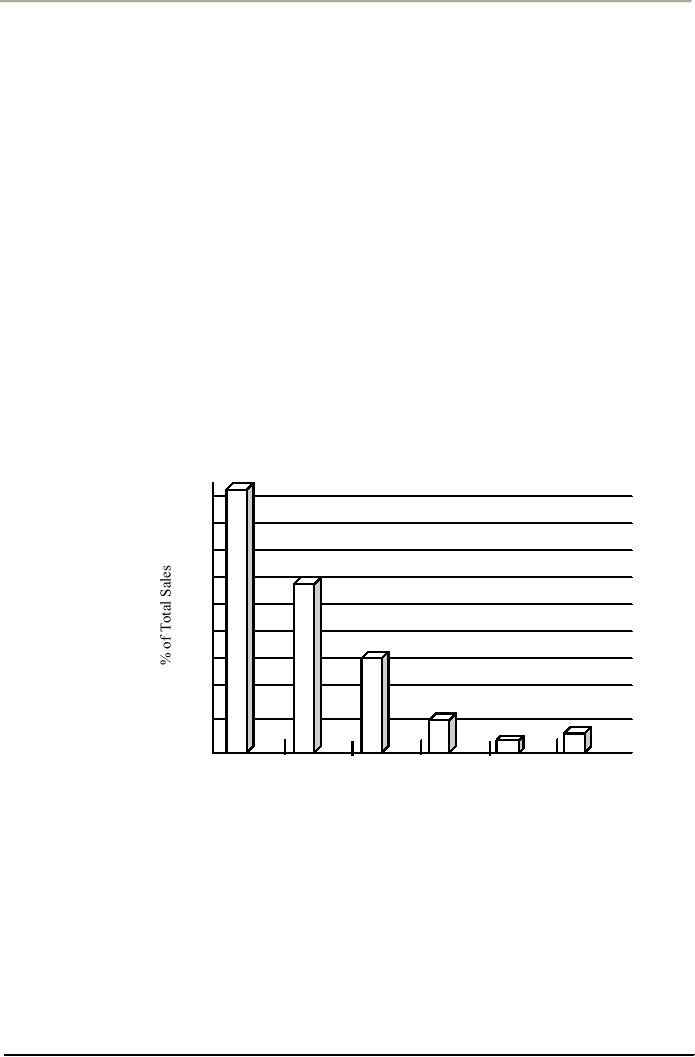

Pareto

Diagram

The

Pareto chart is a very useful

tool wherever one needs to

separate the important from the

trivial. The

chart,

first promoted by Dr. Joseph

Juran, is named after Italian

economist/sociologist Vilfredo

Pareto

(1848-1923).

He had the insight to recognize that in the

real world a minority of

causes lead to the

majority

of problems. This is known as the Pareto

principle. Pick a category, and the

Pareto principle

will

usually hold. For example,

in a factory you will find

that of all the kinds of problems

you can name,

only

about 20% of them will produce

80% of the product defects:

80% of the cost associated

with the

defects

will be assignable to only

about 20% of the total number of defect

types occurring. Examining

the

elements of this cost will

reveal that once again

80% of the total defect costs

will spring from

only

about

20% of the cost elements.

Charts have shown that approximately

20% of the pros on the tennis

tour

reap 80% of the prize money

and that 80% of the money

supporting churches in the United

States

comes

from 20% of the church membership.

Pareto

analysis is a technique for prioritizing

types or sources of problems. Pareto analysis

separates the

"vital

few" from the "trivial many"

and provides help in selecting directions

for improvement. The

Pareto

chart below labels a company's customers

A. B. C, D, E. and All Others. The bars

represent the

percentage

of the company's sales going to the

respective customers. Seventy-five

percent of this

company's

sales are the result of just

two customers. If one adds

customer C, 90% of its sales

are

accounted

for. All the other customers' together

account for only 10% of the

company's sales. Bear in

mind

that

"Other"

may include a very large

number of small customers. Which

customers are the ones who

should

be

kept happy? Obviously, A, B, and

perhaps C are the most

critical.

This

would suggest that customers

A, B, and Care the company's

core market and all the

other

customers

represent a marginal business. Decisions

on where to allocate resources should be

made

accordingly.

45

40

35

30

25

20

15

10

5

0

C

D

E

F

A

B

Pareto

Chart: Percentage of Total

Sales by Customer Customers

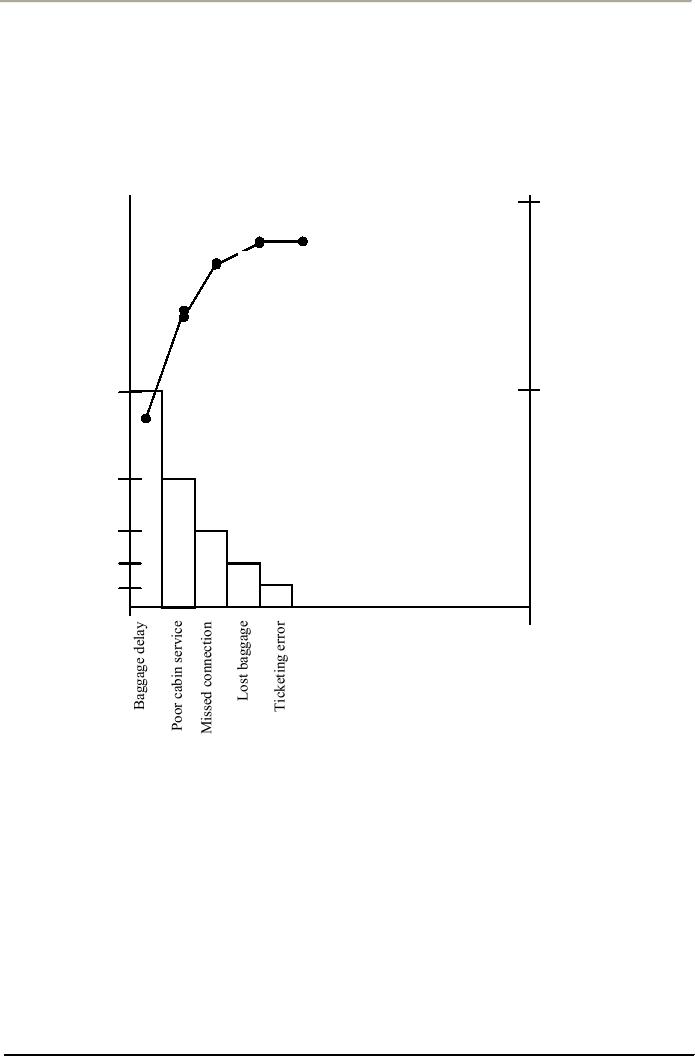

It

is often used to analyze the attribute

data collected in check

sheets. In a Pareto distribution

the

characteristics

are ordered from largest frequency to

smallest. For example, if the

airline attribute data

in

check

sheet above is placed in order of

decreasing frequency, the result

below is shown as a Pareto in

descending

order to focus on vital few

is

1.

Baggage

delay

2.

Poor

Cabin service

3.

Missed

connection

4.

Lost

baggage

5.

Ticketing

error

156

Total

Quality Management

MGT510

VU

A

Pareto diagram is a histogram of

these data, as shown in above Figure. A

cumulative frequency

curve

is

usually drawn on the histogram, as shown

above. Such pictures clearly show the

relative magnitude of

defects

and can be used to identify the

most promising opportunities

for improvement (the few

faults

which

causing 80% of problems.) They can

also show the results of improvement

projects over time by

drawing

Pareto after every project

is complete.

Example

of a Pareto Diagram

Frequency

Percent

100

Cumulative

Percent

23

50

14

7

4

2

157

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION