|

Total

Quality Management

MGT510

VU

Lesson

# 31

CREATING

QUALITY AT STRATEGIC, TACTICAL AND

OPERATIONAL LEVEL

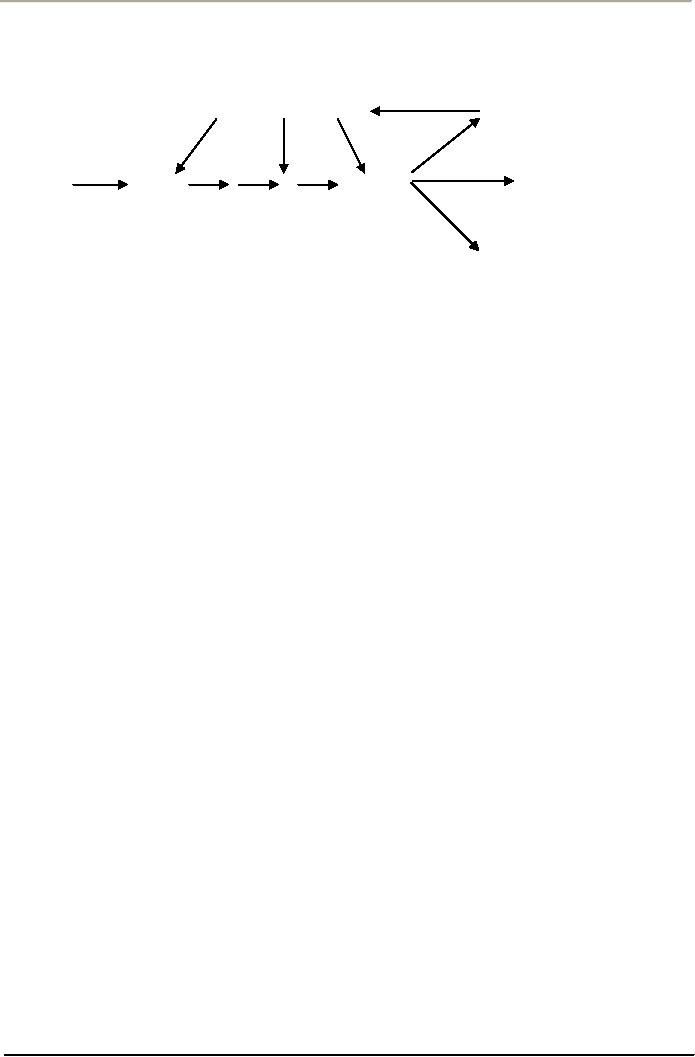

In

1950 Deming drew the

following picture on a blackboard

for a handful of Japanese

executives:

Consumer

Design

and redesign

research

Suppliers

Inputs

Outputs

Customers

Processes

Many

people see this as simply a

diagram of a typical Production or

Operation System that is

linked to

customers

and suppliers. Visionaries in the practice of TQ see

this as a new model of an

organization

chart

from a strategic perspective.

The

Functional Structure and

Operations

In

the functional structure, the organization is

divided into functions such

as operations, marketing, MIS

and

maintenance, each of which is headed by a

manager. In such organizations

communication occurs

vertically

up or down the chain of command, rather

than horizontally across

functions. Functional

structures

provide organizations with a clear

chain of command and allow

people to specialize in the

aspect

of the work for which they

are best suited. They also

make it easy to evaluate

people based on a

narrow

but clear set of responsibilities.

For these reasons functional

structures are common in

both

manufacturing

and service organizations at plant and

business unit levels.

Problems

with Functional Structure

Despite

its popularity, the functional structure

is designed primarily for the

administrative convenience

of

the organization, rather than

for providing high-quality service to

customers. From a TQ point

of

view,

the functional structure has several

inadequacies.

The

Functional Structure Separates Employees

from Customers

Few

employees in the functional organization have

direct contact with customers or even a

clear idea of

how

their work combines with the

work of others to satisfy

customers. The functional structure

tends to

insulate

employees from learning about

customer expectations and their degree of

satisfaction with the

service

or product the firm is providing.

Being insulated from

customers encourages in workers

a

narrow

conception of their responsibilities.

This is often expressed in

statements such as "It's not

my

job"

or "I just work here." Even

when such employees want to

help customers, they often

have such a

limited

understanding of how their

organizational system works

that they are unable to do

so. This often

results

in demotivated workers and poor

quality work.

131

Total

Quality Management

MGT510

VU

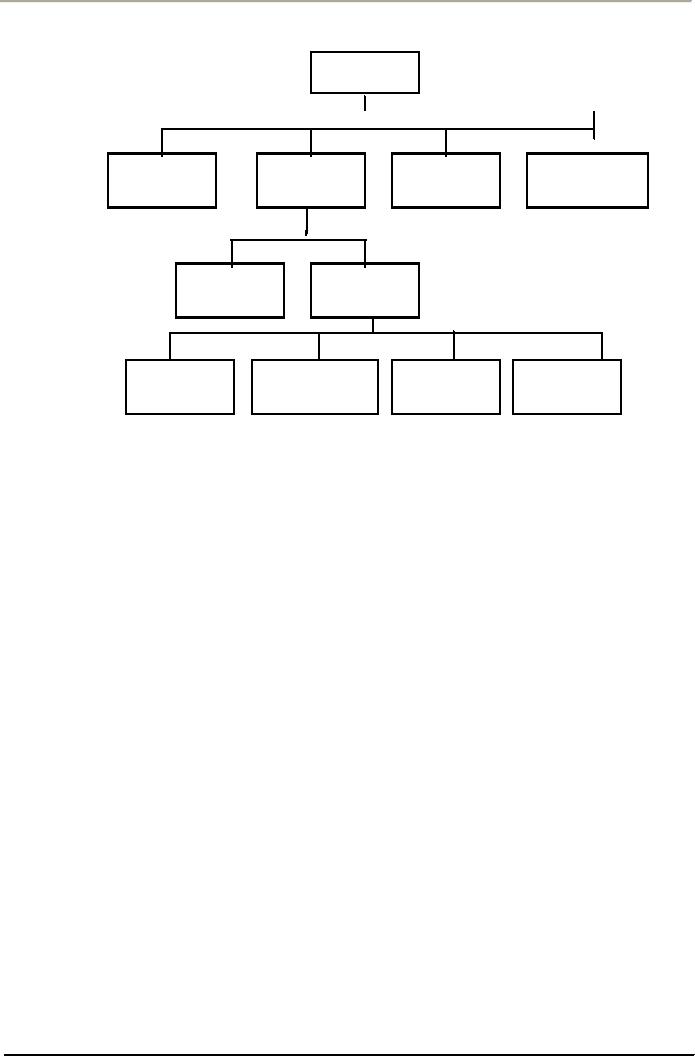

Functional

Structure for a Manufacturing

Company

President

Marketing

Production

Finance

Engineering

Director

Director

Director

Director

Manager

Manager

Plant

# 1

Plant

# 2

Operations

Quality

Control

Purchasing

Accounting

Manager

Manager

Manager

Manager

Most

of us have experienced this phenomenon when we

call a large organization

trying to get help and

get

switched to several different people

before (if we're lucky)

finding someone willing and

able to help

us.

If our needs as customers

relate to the product or service as a

whole, but the knowledge

and

responsibilities

of anyone with whom we deal

relate only to their

function, we are doomed to

disappointment.

The

Functional Structure Inhibits Process

Improvement

No

organizational unit has

control over a whole

processes, although most

processes involve a

large

number

of functions. This is because

the breakup of the organization

into functions is usually

unrelated

to

the processes used to deliver a

product to the customer. This structure is

likely to create

complex,

wasteful

processes, as people do things in

one area that must be redone

or undone, in another.

For

example, some organization

maintain a group of engineers whose

sole responsibility is to redesign

products

so that they can be manufactured

effectively. The engineers who design the

products in the

first

place worry only about

product performance, not

manufacturability. (For another example

of

problems

in coordinating design and manufacturing.)

Worse yet, if one function

tries to improve its

part,

it may well make things

worse (more wasted time and

effort, more cost) for another

part of the

process.

In this environment, continuous

process improvement doesn't

stand a chance. This

arrangement

obviously

stands in the way of continuous

process improvement. Organizations

pursuing TQ often

retain

their quality assurance

departments, but these units

act more as coaches or facilitators

to

employees,

rather than as the group with

primary responsibility for

quality. In summary, the

functional

organization

compromises total quality in several

ways: It distances people

from customers and

insulates

them from customer expectations. It promotes

complex and wasteful

processes and

inhibits

process

improvement. It separates the quality

function from the rest of

the organization, providing

people

with an excuse for not

worrying about

quality.

Redesigning

Organizations for Quality

Poor

organization design can be devastating to

a company. One of Deming's 14 Points is

to "break

down

barriers between departments" because "people in

various departments must

work as a team."

This

slogan captures in a nutshell what the TQ

philosophy entails for

organizational design. People

cannot

contribute to customer satisfaction and

continuous improvement if they

are confined to

132

Total

Quality Management

MGT510

VU

functional

prisons where they cannot see customers

or hear their voices. Some of the more

effective

ways

to break down these barriers

are to focus on processes, recognize

internal customers, create

a

team-based

organization, reduce hierarchy,

and use steering committees.

Focus

on Processes

A

process is how work creates

value for customers. Common

business process include

acquiring

customer

and market knowledge, fulfilling

customer orders, purchasing, developing

new products or

service,

strategic planning, production or service

delivery, distribution, research and

development,

information

management, performance measurement, and

training, to name just a

few. Individuals or

groups,

known as process owners, are accountable

for process performance and have the

authority to

manage

and improve their process.

Process owners may range from

high-level executives who

manage

cross-functional

processes to workers who run

machinery on the shop floor.

Assigning process owners

ensures

that someone is responsible to manage the

process and optimize its

effectiveness.

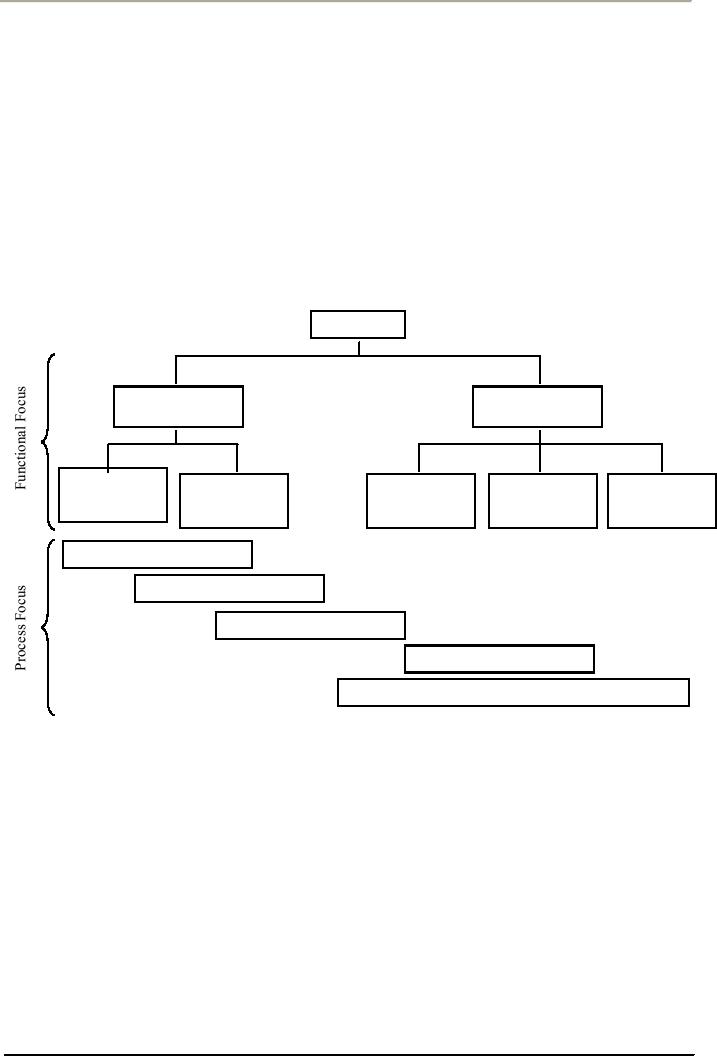

Process

versus Function

CEO

Vice

President

Vice

President

Department

Department

Department

Department

Department

Manager

Manager

Manager

Manager

Manager

Process

A

Process

B

Process

C

Process

D

Process

E

A

process focus, as opposed to the

functional structure, is shown below.

Nearly every major

activity

within

a business involves some

form of cross-functional cooperation. A

process perspective links

all

parts

of an organization together and increases

employee understanding of the entire

system, rather than

focusing

on only a small part. In

addition, it helps managers to recognize

that problems arise

from

processes,

not people. By aligning the structure of

an organization with the actual work

processes that

the

organization performs, customers may be

served more effectively. Process

management involves the

design

of processes to develop and deliver

products and services that

meet the needs of customers,

daily

control

so that they perform as

required, and their continual

improvement.

Create

a Team-Based Organization

As

more and more companies accept the

process view of organizations,

they are structuring the

quality

organization

around functional or cross-functional

teams, each of which has the

responsibility to carry

out

and improve one of the organization's

core processes. Depending on the

size of the organization

and

the

nature of the processes, teams may

include everyone who

contributes to a given process or

only a

representative

subset. Similarly, the tams

may meet continuously on a

crash basis until their

new

process

design is complete, after which they

may meet periodically or on an ad hoc

basis whenever

133

Total

Quality Management

MGT510

VU

necessary.

For example, Solectron

Corporation, a two-time Baldrige

recipient, has a customer

focus

team

for each customer that

includes personnel from quality,

manufacturing management,

project

engineering,

sales, production control,

test engineering, and a project

buyer and program manager.

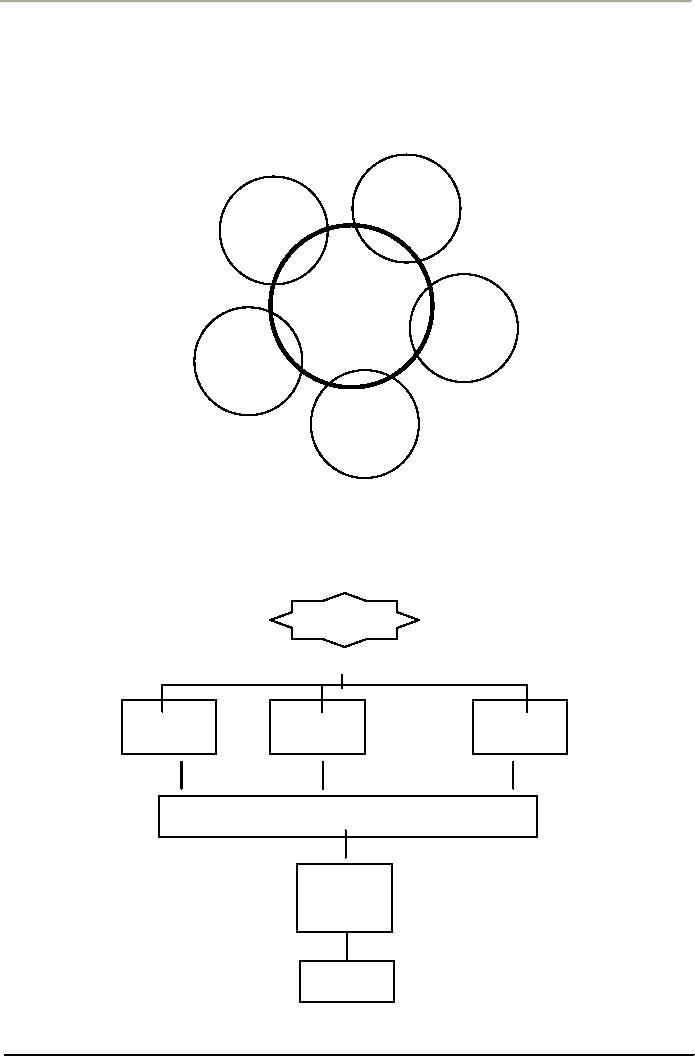

Team

based Organizational Structure at

one Plant

Team

Reps

Council

Safety

Team

Core

Process

Teams

Safety

Reps

Innovation

Team

Quality

Reps

Team-Based

Organizational Chart

Customers

Customer

Customer

Customer

Team

Team

Team

System

and Support Service

Executive

Steering

Committee

CEO

134

Total

Quality Management

MGT510

VU

Strategic

Planning and the Baldrige

Award

The

Baldrige Award recognizes the

importance of integrating total

quality principles with

overall

business

planning. The Strategic Planning

category addresses strategic business

planning and

deployment

of plans. It stresses tat customer-driven

quality and operational performance are

key

strategic

business issues that need to

be an integral part of overall company

planning, and emphasizes

that

improvement and learning must be

integral parts of company work

processes. The special role

of

strategic

planning is to align work

processes with the company strategic

directions, thereby

ensuring

that

improvement and learning reinforce

company priorities.

The

Strategic Planning category examines how

organizations.

�

Plan

for the long term, and understand the key

influences, risks, challenges, and

other

requirements

that might affect the

organization's future opportunities and

directions. This is to

help

ensure that short-term action plans

are aligned with the

organization's longer-term

strategic

directions.

�

Project

the future competitive environment to

help detect and reduce

competitive threats,

shorten

reaction time, and identify

opportunities.

�

Develop

action plans and deploy resources

particularly human resources to

achieve

alignment

and consistency, and provide a basis for

setting and communicating

priorities for

ongoing

improvement activities.

�

Ensure

that deployment will be

effective that a measurement

system enables tracking of

action

plan

achievement in all areas.

The

integration of quality planning

with business planning occurred in the

1995 criteria revision.

Most

symbolic

was the change in the category's

title from "Strategic

Quality Planning" to

"Strategic

Planning."

This change signaled a

"major emphasis on business strategy as

the most appropriate

view-

of-the-future

context for managing

performance." The integration of

quality and operational issues

with

business

planning became a dominant

theme, with a focus on "Performance,"

"Competitive position,"

"Customer-related,"

and "Operational"

themes.

The

ISO-9001 model has still to

work out ways how to

incorporate strategic planning into

business

planning;

however, it does take good

care of tactical and operational

quality control.

135

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION