|

DEVELOPING ISO QMS FOR CERTIFICATION:Process approach |

| << DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership |

| ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered >> |

Total

Quality Management

MGT510

VU

Lesson

# 22

DEVELOPING

ISO QMS FOR

CERTIFICATION

DEVELOPMENT,

IMPLEMENTATION AND

REGISTRATION

The

ISO 9000 standards

originally were intended to be advisory

in nature and to be used for

two-party

contractual

situations (between a customer and

supplier) and for internal

auditing. However,

they

quickly

evolved into criteria for

companies who wished to

"certify" their quality

management or

achieve

"registration" through a third-party

auditor, usually a laboratory or

some other

accreditation

agency

(called a registrar). This

process began in the United

Kingdom. Rather than a supplier

being

audited

for compliance to the standards by

each customer, the registrar certifies

the company, and this

certification

is accepted by all of the supplier's

customers.

The

registration process includes document

review by the registrar of the

quality system documents

or

quality

manual; pre-assessment, which

identifies potential noncompliance in the

quality system or in the

documentation;

assessment by a team of two or three

auditors of the quality system

and its

documentation;

and surveillance, or periodic re-audits to

verify conformity with the

practices and

systems

registered. During the assessment,

auditors might ask such

question as (using

management

responsibility

as an example): Does a documented policy

on quality exist? Have job descriptions

for

people

who manage or perform work

affecting quality been

documented? Are descriptions of

functions

that

affect quality been

documented? Are descriptions of functions

that affect quality

available? Has

management

designated a person or group with the

authority to prevent nonconformities in

products,

identify

and record quality problems, and recommend solutions?

What means are used to

verify the

solutions?

Re-certification

is required every three years.

Individual sites not

entire companies must

achieve

registration

individually. All costs are

borne by the applicant, so the process

can be quite

expensive.

Perspectives

on ISO 9000:2000

ISO

9000 provides a set of good

basic practices for

initiating a quality system, and is an

excellent

starting

point for companies with no

formal quality assurance

program. In fact, it provides

detailed

guidance

on process and product control. Thus,

for companies in the early

stages of developing a

quality

program,

the standards enforce the discipline of

control that is necessary

before they can

seriously

pursue

continuous improvement. The requirements

of periodic audits reinforce the stated

quality system

until

it becomes ingrained in the company.

Thus, using ISO 9000 as a

basis for a quality system

can

improve

discipline, process, productivity,

decrease costs, and increase

customer satisfaction.

ISO

9000 as a Quality Journey

and not as a Destination

How

to get started is always an issue

for organizations just

beginning their total

quality journey.

The

ISO 9000 development effort

will benefit by having the

following components: an

executive-level

steering

committee, a vision with the

guiding principles, a set of

broad objectives, baselines

on

employee

and customer satisfaction, an

objective view of the organization's

strengths and weaknesses,

and

an indication of which employees at all

levels can be counted on for support

during the

implementation.

In addition, the organization will have a

well thought out means of

communicating

with

employees and all other stakeholders to keep them

apprised of the changes taking place, why

they

are

happening, and what they

will mea to everyone.

The

development and implementation of an

organization's quality management

system is influenced by

its

varying needs, its

particular objectives, the products it

provides, and the processes it

employs. It is

not

the purpose of this ISO to

imply uniformity of quality

management systems.

81

Total

Quality Management

MGT510

VU

The

selection of the appropriate quality

related processes described in this

ISO Standard and the extent

to

which these processes are

adopted and applied by an organization

depends upon factors such as

its

size

and structure, the market being

served and the resources

available.

The

purpose of an organization

is:

a)

To

identify and meet the needs

and expectations of its customers and

other interested parties

(i.e.

employees, suppliers, owners, society), to achieve

competitive advantage, and to do this

in

an

effective and efficient manner;

b)

To

achieve, maintain, and improve overall

organizational performance and

capabilities.

The

application of quality management

principles not only provides

direct benefits but also

makes an

important

contribution to managing costs and risks.

Benefit, cost and risk

considerations are important

for

the organization, its customers and

other interested parties. These considerations on

overall

performance

may impact on the

following:

a}

Revenue

(turnover), profits and market

share; these may be

increased by such aspects

as

leadership,

increased efficiency, improved

employee performance, and employee

and customer

satisfaction;

b)

Costs

due to resources needed for

business; inadequate resource funding is

likely to cause

losses

and

be a competitive disadvantage through the

sale of deficient products.

Process

approach

The

ISO-9001(2000) Standard encourages the

adoption of a process approach to quality

management.

Any

activity which receives

inputs and converts them to outputs can be considered

as a process. For

organizations

to function effectively, they have to

identify and manage numerous

inter-linked processes.

Often

the output from one process

will directly form the input

into the next process. The

systematic

identification

and management of the processes employed

by an organization, and the

interactions

between

such processes, may be

referred to as the 'process

approach'.

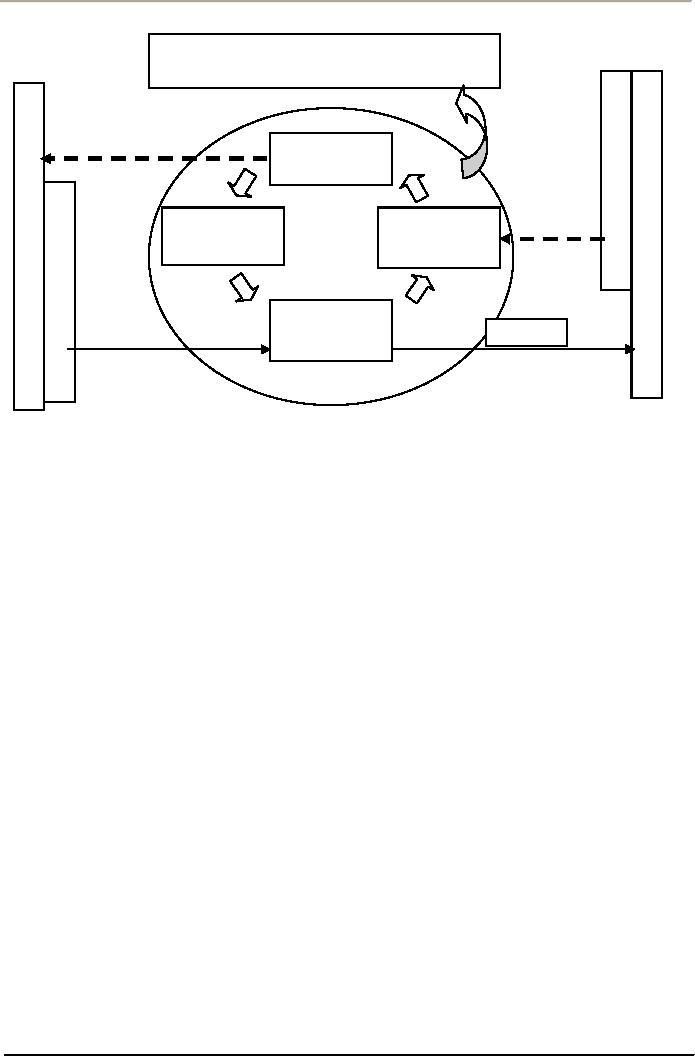

Following

Figure is a conceptual illustration of

one of the process approach. The

model recognizes that

customers

and other interested parties play a

significant role in defining

inputs. Monitoring the

satisfaction

of customers and other interested parties is

necessary to evaluate and validate

whether the

requirements

of customers and other interested parties have

been met. This model does

not reflect

processes

at a detailed level, but

covers all the contents of the

ISO Standard.

The

purpose of ISO 9001 is to

define the minimum Quality

Management System requirements

needed

to

achieve customer satisfaction by meeting

specified product requirements.

Compliance with ISO

9001

may

be used by an organization to demonstrate

its capability to meet

customer requirements.

82

Total

Quality Management

MGT510

VU

CONTINUAL

IMPROVEMENT OF THE

QUALITY

MANGEMENT SYSTEM

S

I

I

a

N

N

t

T

T

i

E

Management

`

E

s

R

Responsibility

R

f

E

E

a

S

R

S

c

T

e

T

Resource

Measurement,

t

E

q

E

analysis

Management

i

D

u

D

improvement

o

i

P

n

r

P

A

e

A

R

Product

m

Input

Output

R

T

realization

Product

e

T

I

n

I

E

t

E

S

s

S

Terms

and definitions

For

the purposes of this ISO

9001(2000) International Standard, the

terms and definitions given in

ISO

9000:2000,

are applied in following

way.

Supplier

--------- >Organization ----------

>Customer (Interested

Parties)

The

term "organization" replaces the

previously used term

"supplier", to mean the unit

to which

this

International Standard applies. The

term "supplier" is now used

instead of the previous

term

"subcontract".

The changes have been

introduced to reflect the vocabulary

used by

organizations.

Product

as a result of a Process

There

are four agreed generic

product categories as per

ISO-9000:

�

Hardware,

�

Software,

�

Services,

�

Processed

materials.

Most

products are combinations of some of the

four generic product categories.

Whether

the combined product is then

called hardware, processed material,

software or service depends

on

the dominant element.

Following

is one of the model methodology which

can be used to develop the

documentation for QMS

and

to get ready for certification by

implementing clause by clause

requirements (in the box) as given

in

ISO

9001(2000) as the minimum requirement

for certification and one can

also take help from

the

guidelines

given in ISO-9004(2000) as presented

below after the boxes.

83

Total

Quality Management

MGT510

VU

ISO

Quality Management System

Requirements/Guidelines

ISO

9001:2000 - Quality management systems

-.Requirements

General

requirements

The

organization shall establish, document,

implement, maintain a quality

management and continually

improve

its effectiveness in accordance with the

requirement of this International

Standard.

The

organization shall:

a)

Identify

the processes needed for the

quality management system and

their application

throughout

the organization (see

1.2)

b)

Determine

the sequence and interaction of these

processes;

c)

Determine

criteria and methods needed to

ensure that both the

operation and control of the

processes

are effective,

d)

Ensure

the availability of resources and

information necessary to support the

operation and

monitoring

of these processes;

e)

Measure,

monitor and analyze these

processes, and

f)

Implement

action necessary to achieve planned

results and continual improvement

these

processes.

These

processes shall be managed by the

organization in accordance with the

requirements of this

International

Standard.

Where

an organization chooses to outsource

any process that affects

product conformity

with

requirements,

the organization shall ensure

control over such

processes.

NOTE

Processes

needed for the quality

management system referred to above

should include

processes

for

management activities, provision of

resources, product realization and

measurement.

Quality

management system guidelines

Managing

systems and

processes

Leading

and operating an organization successfully requires

managing it in a systematic and

visible

manner.

Success should result from

implementing and maintaining a management

system that is

designed

to continually improve performance by

addressing the needs of all interested

parties.

Managing

an organization encompasses quality

management, among other management

disciplines.

The

quality management system of an

organization is an important part of the

overall management

system.

Organizations should define

their systems and the processes

contained within them to enable

the

systems

and processes to be clearly understood,

managed and improved. Management

should ensure

effective

operation and control of processes and

the measures and data used to

determine satisfactory

performance.

The management of the organization

should closely monitor the movement

toward

performance

improvement. The activities and

processes that can lead to

performance improvement

should

be described and defined by the

management. In general, to fulfill the requirements of

ISO

standard;

First,

Company should state

(write/document) what do they

want to do

Second,

do the work as was stated and

documented

Third,

check them, weather the work is being

carried out as was stated.

See if there are any gaps

.

Fourth,

Show and prove to an external

auditor that work is really

being done as was stated in the

first

place.

84

Total

Quality Management

MGT510

VU

So

what in terms of documentation

required is a manual altogether in one

volume to be called as

ISO

9000

QMS Manual or can be

separated into following

manuals:

1.

Quality

Policy Manual

2.

Quality

Procedures Manual

3.

Quality

Work Instructions

4.

Quality

Records Manual or Quality Data

Collection Manual

Documentation

and records may be in any

form or in any media suitable

for the needs of the

organization.

Requirements

for documentation and records

may arise from

�

contractual

requirements from the customer or other

interested parties,

�

acceptance

of international, national, regional

and industry sector

standards,

�

relevant

statutory and regulatory requirements,

or

�

decisions

by the organization.

ISO

9001:2000 Quality management

systems -Requirements

Documentation

Requirements

General

The

quality management system

documentation shall

include:

a)

Documented

statements of a quality policy and

quality objectives

b)

A

quality manual

c)

Documented

procedures required by this

International Standard;

d)

Documents

needed by the organization to ensure the

effective planning, operation and

control

Use

of quality management principles

ISO

9001:2000 Quality management

systems -Requirements

Documentation

Requirements

Quality

Manual

The

organization shall establish and maintain

a quality manual that

includes

a)

The

scope of the quality management

system, including details of and

justification for any

exclusions

(see 1.2),

b)

The

documented procedures established for the

quality management system, or reference

to

them,

and

c)

A

description of the interaction between the

processes of the quality management

system.

Control

of Documents

Documents

required by the quality management

system shall be controlled.

Records are a special

type

of

document and shall be controlled

according to the requirements given in

4.2.4.

A

documented procedure shall be established to define

the controls needed.

a)

to

approve documents for

adequacy prior to

issue,

b)

to

review and update as necessary and

re-approve documents,

85

Total

Quality Management

MGT510

VU

c)

to

ensure that changes and the

current revision status of

documents are

identified,

d)

to

ensure that relevant versions of

applicable documents are

available at points of

use,

e)

to

ensure that documents remain

legible and readily

identifiable,

f)

to

ensure that documents of

external origin are

identified and their distribution

controlled,

and

g)

to

prevent the unintended use of obsolete

documents, and to apply suitable

identification to

them

if they are retained for

any purpose.

Control

of Records

Records

shall be established and maintained to

provide evidence o conformity to requirements and

of

the

effective operation of the quality

management system. Records

shall remain legible,

readily

identifiable

and retrievable. A documented procedure shall be

established to define the controls

needed

for

the identification, storage, protection,

retrieval, retention time and

disposition of records.

Documentation

and Records

Management

should define the documentation

needed to support the quality management

system. The

nature

and extent of the documentation should

support the needs of tile organization.

The defined

documentation

should provide for

implementation, maintenance and improvement of the

system.

This

documentation typically

includes

�

policy

documents including the quality

manual

�

documentation

for control of

processes,

�

work

instructions for defined

tasks,

�

standard

formats for collection and reporting of

data and

�

quality

records.

The

primary purpose of quality

documentation is to express the

quality policy and to

describe the

quality

management system. This

documentation serves as the basis

for implementation

and

maintenance

of the system. Suitable documentation

should be available to achieve the

effective

operation

of the quality management

system.

Documentation

control should be defined and

implemented to ensure that correct

documents arc used.

All

obsolete documents should be promptly

removed from all points of

issue and use, or

otherwise

prevented

from unintended use.

Documents

to be retained, and records of quality

performance, should be controlled,

maintained and

protected.

The

organization should ensure

that sufficient records be

maintained to demonstrate conformance

to

requirements

and verify effective operation of the

quality management system.

These records can

also

provide

know1edge for maintenance and improvement

of the quality management

system.

Quality

records should be analyzed to

provide inputs for

corrective and preventive action, and

process

improvements.

Analysis of records may also

provide information for use

in the improvement of the

Quality

management system.

86

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION