|

Total

Quality Management

MGT510

VU

Lesson

# 02

TOTAL

QUALITY MANAGEMENT AND TOTAL ORGANIZATION

EXCELLENCE

TRADITIONAL

MANAGEMENT AND QUALITY

MANAGEMENT:

Twentieth-century

management has been strongly

influenced by Taylor's scientific

management and

Weber's

theory of bureaucracy. These approaches

have led managers to work

within functional

hierarchies,

with their responsibilities

divided according to specialized

activities, such as

accounting,

marketing,

engineering, and manufacturing.

Economic principles for

competing in well-defined

markets

emphasized

economies of scale, efficiencies,

mass production, and technological

innovation.

While

there had been competition, competitors

often played according to a

"live and let live"

strategy.

Because

monopolies were precluded by law,

companies had little

incentive to completely

drive

competitors

from the marketplace.

Even

when new product

technologies created new markets,

such as plastics in the 1950s,

management

practices

changed very little.

Managers set goals for

productivity, efficiency, and

profitability, using

management

set goals for productivity,

efficiency, and profitability, using

management by objectives

(MBO)

to link strategy and operations through the

hierarchy. Managers motivated employees

to fulfill

those

goals by inducements such as profit sharing, stock

options, and bonuses, or

other rewards such as

job

enrichment or participative management.

However, the job of management remained

much the

same:

set goals, define roles, provide

technologies, and motivate employees.

Accounting, marketing,

engineering,

and manufacturing practices also

did not change.

Occasionally, new techniques were

introduced

within the traditional functions,

such as quality control in

manufacturing. But such

changes

went

largely unnoticed by the rest of the

organization.

No

one challenged this approach to

management as long as it served

society well. While managers

in

Japan

were rewriting the rules of business practice and

management and planning to win the

world

markets

by focusing on quality management,

U.S. managers continued in the

stage of normality.

The

US,

and western society in general, was

focused on another agenda: the cold

war in the 1950s and

1960s.

The

Stage of Replacement: A New

Paradigm

The

stage of replacement means shifting to a

new paradigm. Managers must

shift to a new paradigm

for

managing

organizations because of the anomalies

that threaten their survival and

prosperity. To make

this

shift, however, they must

understand the new paradigm and how it

differs from the old

paradigm.

To

initiate this understanding, we

will contrast the new (but

still emerging) paradigm

with the old

paradigm.

Themes

of the New Paradigm

The

differences between the new

and the old paradigm are

organized around three

themes:

customer

value strategy, cross-functional systems,

and continuous

improvement.

Theme

1: Customer Value Strategy

Customer

value is defined as the combination of

benefits derived from using

a product ( or service) and

the

sacrifices required of the customer. The

customer value strategy is the business

plan for offering

value

to customers, including product

characteristics, attributes, mode of

delivery, support services, and

so

on. The theme of customer

value strategy may be addressed in

many topics, including

quality,

measurement,

positioning, key stakeholder, and

product design.

4

Total

Quality Management

MGT510

VU

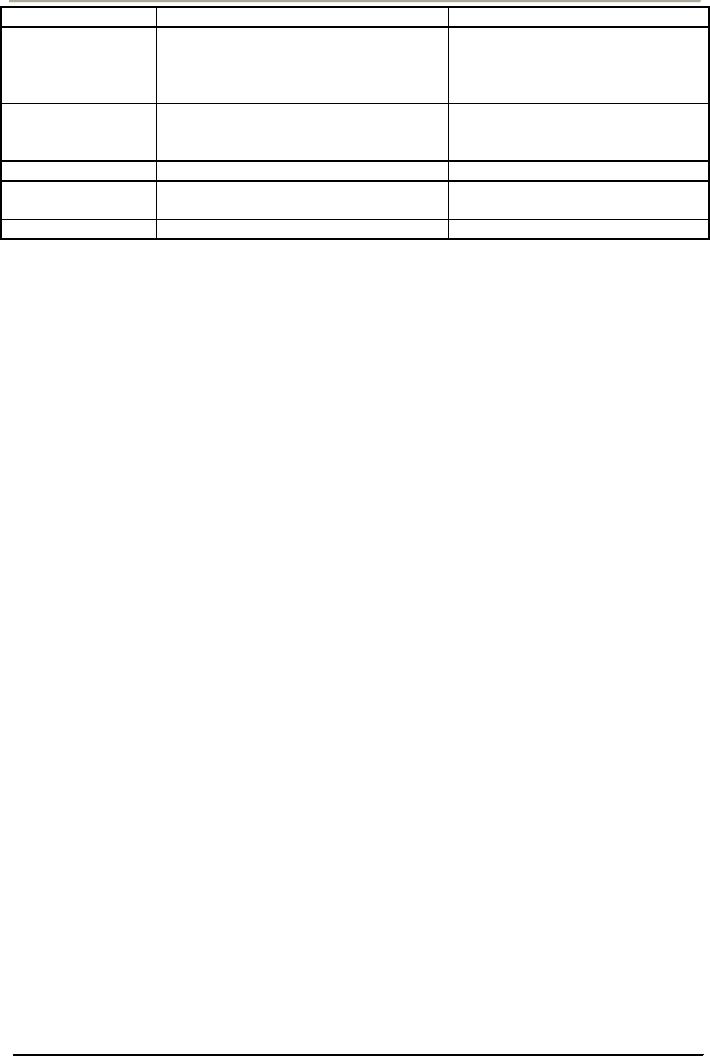

Topics

Old

Paradigm

New

(emerging) paradigm

Quality

Meeting

specifications, inspected into One

component of customer value,

product,

make tradeoffs among quality,

managed

into

process,

seek

cost,

schedule

synergies

among quality,

cost,

schedule.

Measurement

Internal

measures

of

efficiency,

All measures linked to

customer

productivity,

costs, and profitability, not

value

necessarily

linked to customers

Positioning

Competition

Customer

segments

Key

stakeholder

Stockholder,

boss

Customer

segments Customer

(other

stakeholders

are beneficiaries)

Product

design

Internal,

sell what we can

build

External,

build what customers

need

Quality

In

the old paradigm, managers

define quality in terms of

meeting specifications. Quality is

assured by

weeding

out the "bad" products before

they are shipped to customers.

Managers make tradeoffs among

quality,

cost, and scheduling under the assumption

that relationships among these

outcomes are fixed.

By

contrast, in the new paradigm, managers

recognize that product quality is

only one component of

customer

value, and managers seek

synergies among quality, cost, and

schedule, not just

tradeoffs. For

example,

improving quality by reducing

variation in outputs reduces defects,

reduces costs, and

makes

performance

to schedule more predictable. Further,

quality is more broadly defined

than just product

quality.

Quality applies to every

aspect of the organization. It must be

managed into processes

and

systems,

and not jut inspected into

products. System thinking included to

think of all

interdependent

parts

of the system into one

whole.

Measurement

In

the old paradigm, measurement

systems are focused on internal

measures of efficiency,

productivity,

costs,

and profitability. This is the tradition

of management by objectives. Managers do

not necessarily

understand

how these internally focused

measures are related to

customer value. In the new

paradigm,

managers

may use internally focused

measures, but they are

linked to customer value in a

broader

measurement

system. Managers interpret

measures in terms of the impact on

customer value in the

long

term

and short term.

Positioning

In

the old paradigm, managers make strategic

positioning decisions based primarily on

warfare models

on

the competition. In the new paradigm,

managers make strategic positioning decisions

with a focus

on

market segmentation and customer needs,

wants and demands.

Key

Stakeholder

In

the old paradigm, the key

external stakeholder is the stockholder, and the

key internal stakeholder

is

one's

boss. All other stakeholders, such as

customers, employees, suppliers, and business

partners, are

pawns

to serve the goals of the key stakeholders. In the

new paradigm, the key stakeholders

are

customers,

both internal and external

customers. Providing value to

customers is the key to serving

all

other

stakeholders over the long term.

Product

Design

In

the old paradigm, the product design

process is internally driven,

based on the assumption that

"we

know

what is bet for the customer."

Managers enact a "push" strategy

that aims to "sell what we

can

build."

In the new paradigm, managers

develop products after first

determining what customers

need.

5

Total

Quality Management

MGT510

VU

Managers

both react to improve products in

existing markets and

actively seek to create new

markets

with

new products.

Theme

2: Organizational Systems

Organizational

systems are the means that

provide customer value.

These systems broadly

include

material

and human inputs, process technology,

operating methods and work

practices, streams of

work

activity,

information flows, and decision

making. The approaches to

managing these systems in the

old

and

new paradigms are discussed

below.

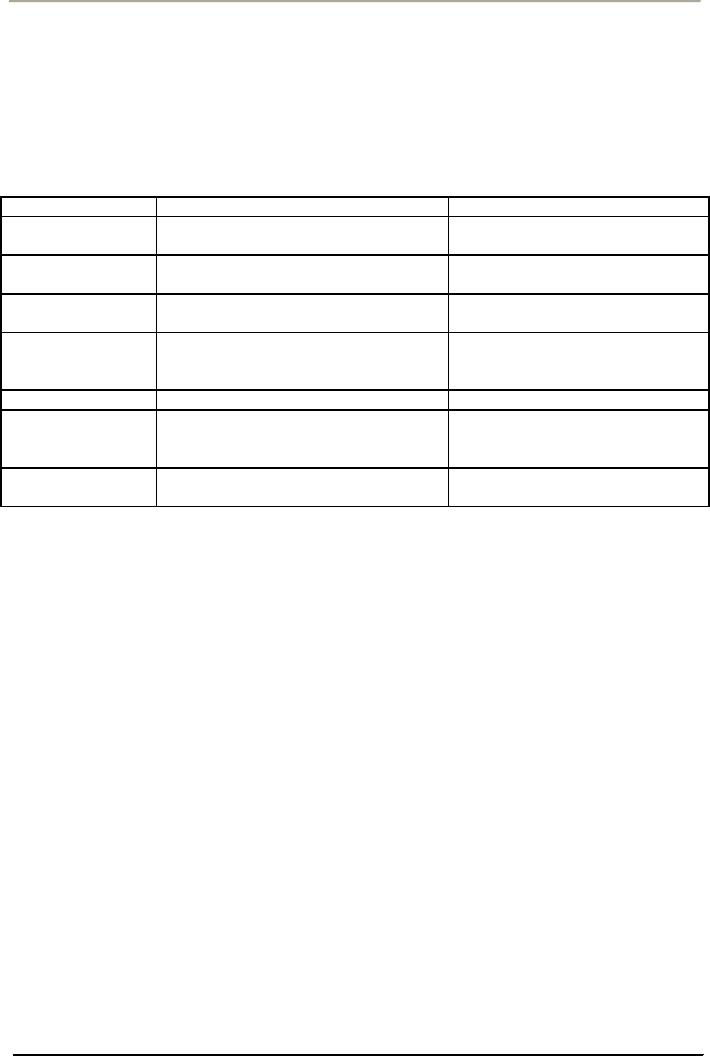

Topics

Old

Paradigm

New

(emerging) paradigm

Cross-functional

Negotiation

across functional interfaces

Cross-functional

systems defined,

approach

to

obtain cooperation

owned,

and optimized

Technology

To

deal with complexity, to

eliminate

To

reduce complexity, source

of

people

problems

optimization

for customer value

Employee

Focused

on hygiene factors

Focused

on strategic factors

involvement

Human

resource

Regarded

as a staff responsibility,

Regarded

as a critical resource,

management

administration

of personnel hiring, firing,

managed

as system input

handling

complaints

Role

definition

Task

and job descriptions set

limits

Vision

inspires flexibility

Culture

Social

and emotional issues

are

Connect

with individual sense

of

suppressed,

politics and power

dominate

purpose,

emotions, and social

meaning

Structure

Specialization,

tall hierarchy with

Integration,

flat hierarchy with

team

functional

emphasis

emphasis

Cross-Functional

Approach

The

old paradigm does not

acknowledge systems that cut

across functional or unit

boundaries.

Managers

simply negotiate across

functional interfaces to obtain minimal

cooperation. In the new

paradigm,

managers define, own, and

optimize cross-functional systems

for customer value.

Technology

In

the old paradigm, managers

use technology to help them

deal with the overly complex

systems that

have

grown up in the organization. Also,

they use technology to

eliminate people problems

(robots

don't

talk back). In the new

paradigm, managers prefer to

eliminate complexity rather than automate

it

or

computerize it. Managers use

technology only to optimize

systems for customer

value.

Employee

Involvement

In

the old paradigm, employee

involvement programs are implemented

without a focus to contribute to

systems.

Employee involvement in improvement

programs tends to focus on quality of

work life issues

and

some limited operational

changes. In the new paradigm,

employee involvement is

strategically

focused

and contributes to system

purposes.

Human

Resource Management

In

the old paradigm, managers regard human

resource management (HRM) as a

staff responsibility. HR

specialists

process paperwork to hire

and fire, and handle

personnel complaints. In the new

paradigm,

line

managers regard human resources as

critical resources and strategically

manage them as inputs to

systems.

6

Total

Quality Management

MGT510

VU

Role

Definition

In

the old paradigm, managers

use task and job descriptions to

prescribe and set limits to

personal

responsibilities.

In the new paradigm, managers

convey a vision to lead and

inspire flexibility.

Employees

participate in any activities

required to provide superior

value to customers.

Culture

In

the old paradigm, managers

suppress social and emotional

issues that are regarded as

irrational and

sources

of distraction away from goals and

objectives. Power and politics

dominate the culture,

with

individuals

jockeying for personal gain. In the

new paradigm, managers

connect organizational mission

and

purpose with each

individual's sense of purpose, emotions, and social

meaning. Individuals channel

their

needs for pride in

workmanship toward strategic

purposes.

Structure

In

the old paradigm, organizational

structure is based on specialization of

tasks. The hierarchy is

tall,

with

many levels of managers, and it

emphasizes functional lines of

authority. In the new paradigm,

the

hierarchy

is flat, with fewer levels

of managers, and it emphasizes teamwork

to serve super

ordinate

objectives.

Theme

3: Continuous Improvement

To

keep pace with the changes in the

external environment, managers have to

change the organization.

Managers

have always made improvements.

However, with rates of

change increasing in the

external

environment,

managers must improve

differently and more frequently

than in the past. They

must

pursue

continuous improvement, which is a

constant striving to change and

make things better.

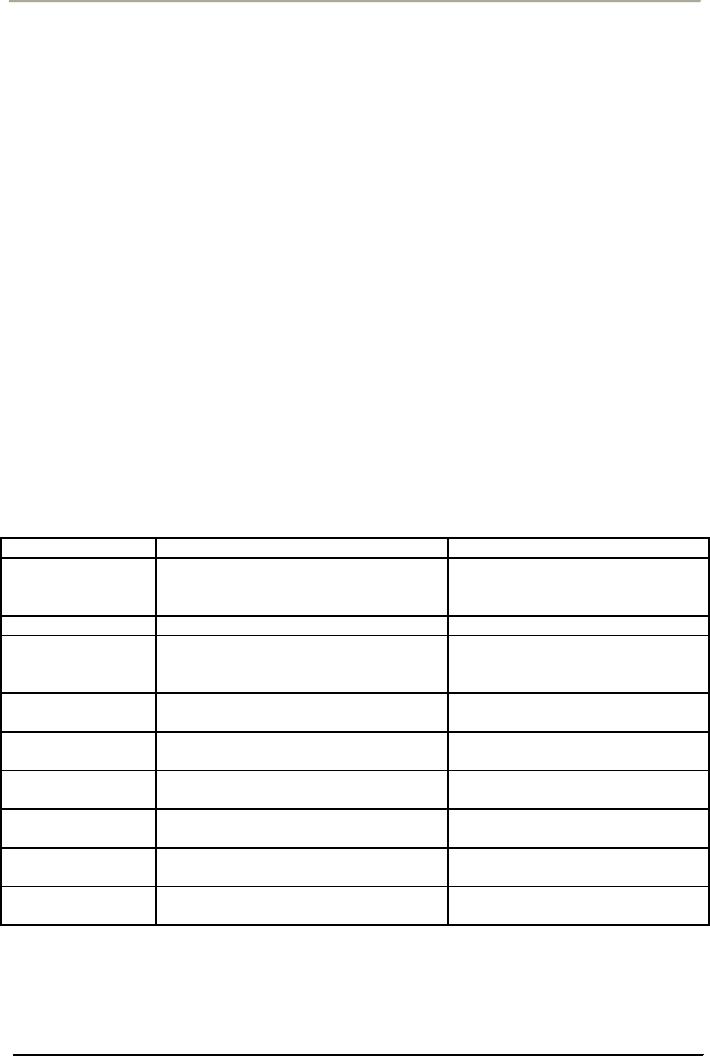

Topics

Old

Paradigm

New

(emerging paradigm

Occasion

Focused

new product

development,

Focused

on broader systems,

episodic,

reactive to problems, big

unending,

proactive to opportunities,

breakthroughs

only

big

breakthroughs and small

steps

Approach

Trial

and error

Scientific

method

Response

to error

Punish,

fear, cover-up, seek people

fix,

Learning,

openness,

seek

employees

are responsible

process/system

fix, management is

responsible

Decision-making

Individual

political expediency, short

Strategic,

long-term, purposeful

for

perspective

term

organization

Managerial

roles

Administer

and maintain status

quo,

Challenge

status quo,

prompt

control

other

strategic

improvement

Authority

Top-driven

via rules and policies

Customer-driven

through vision,

enablement,

and empowerment

Focus

Business

results through quotas

and

Business

results through

capable

targets

systems,

means tied to results

Control

Scoring,

reporting evaluating

Statistical

study of variation to

understand

causes

Means

Delegated

by managers to staff and

Owned

by managers who lead

staff

subordinates

and

subordinates

Occasion

In

the old paradigm, the occasions

for improvement were primarily

new product development

and

reaction

to salient problems. Mangers mostly

looked for big breakthroughs

to get improvement. In the

new

paradigm, the occasions for

improvement are everywhere,

every day. Managers

improve

7

Total

Quality Management

MGT510

VU

proactively

at every opportunity, even in the absence

of salient problems. Managers improve

all aspects

of

the organization's systems through

both big breakthroughs and

small steps.

Approach

In

the old paradigm, managers accomplish

improvements through trial and

error. In the new

paradigm,

managers

use the scientific method to study

proposed changes and their

effects.

Response

to Error

In

the old paradigm, if they

care at all, managers are

intolerant of error. They regard

error as a personal

failure,

and they respond with

punishment to instill fear in

those blamed. The result is

fear and cover-up

in

the future. In the new paradigm,

error is not desired; however,

managers view error as an

opportunity

for

learning. People openly acknowledge

error because managers do

not assign personal blame, but

seek

to

fix a process or system.

Decision-Making

Perspective

In

the old paradigm, managers

make decisions that are

politically expedient or that

serve short-term

personal

objectives. In the new paradigm,

managers make decisions that

serve long-term strategic

purposes.

Managerial

Roles

In

the old paradigm, managers

primarily administer existing

systems and maintain the status

quo. In the

new

paradigm, managers challenge the

status quo for strategic

improvement to meet future

demands. At

the

same time, they consistently

execute existing systems to

meet current demands.

Authority

In

the old paradigm, managers impose

authority from the top down

via rules and policies. In the

new

paradigm,

top managers still hold

authority but they impose it by

communicating a vision,

enabling

people

wit systems, and empowering them to

make the vision real.

Focus

In

the old paradigm, managers focus on

improving business results

through the imposition of quotas

and

targets.

They delegate responsibility, often

without giving real

authority to change broader systems

that

constrain

results. In the new paradigm,

managers focus on improving business

results through

improving

the capabilities of systems. They focus

on the means as well as the results,

because they have

retained

responsibility for improving

systems.

Control

In

the old paradigm, managers

control the organization through

scoring individual performance,

reviewing

regular reports, and evaluating performance as

either good or bad. In the new

paradigm,

managers

statistically study variation to

understand the causes of poor performance and

make changes

in

systems to improve performance.

Means

In

the old paradigm, managers delegate the

means of improvement to staff and

subordinates who must

figure

out how t meet established

targets. In the new paradigm,

managers assume responsibility

for the

means

of improvement. They lead

improvement by staff and

subordinates.

8

Total

Quality Management

MGT510

VU

The

Relationship between Quality and

Competitiveness

At

each successive level of

competition the quality of the competitors

increased. A similar phenomenon

happens

to businesses in the marketplace. Companies

that used to compete only on

a local, regional, or

national

level now find themselves

competing against companies from

throughout the world. Some

of

these

companies find the competition to be more

intense than any they have

ever encountered. Only

those

who are able to produce

world-class quality can

compete at this level. In

practical terms, it is

extremely

important for a country's

businesses to be able to compete

globally. When they can't,

jobs are

lost

and the quality of life in that

country declines correspondingly.

9

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION