|

Strategic

Management MGT603

VU

Lesson

35

PRODUCTION/OPERATIONS

CONCERNS

WHEN

IMPLEMENTING STRATEGIES

Learning

objectives

The

main objective of this chapter to enable

to students about production and

operation issue relating to

strategy

implementation.

Production/Operations

Concerns When Implementing

Strategies

Strategy

in action means implementation requires

complete transparent process.

Production/operations

department

that mainly concern with the

achievement of organization goals and

targets. Production

processes

typically constitute more than 70

percent of a firm's total assets.

Production department plays a

crucial

role for implemeting organization

strategy. Production-concerned decisions on

plant location, plant

size,

, product design, choice of equipment,

size of inventory, inventory

control, quality control,

cost

control,

use of standards, shipping and

packaging, and technological innovation,

job specialization,

employee

training, equipment and resource

utilization. All these

factors place an important

impact on

success

and failure of the

strategy.

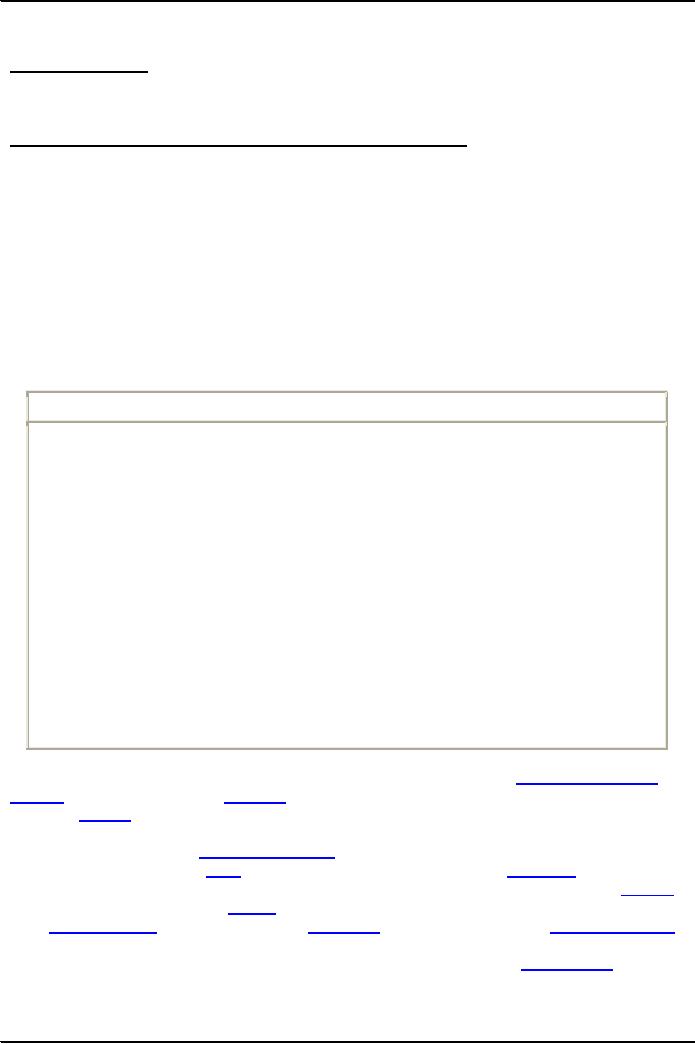

The

following examples of adjustments in

production systems that

could be required to implement

various

strategies

are provided in Table for

both for-profit and

nonprofit organizations. For

instance, note that

when

a bank formulates and selects a strategy

to add ten new branches, a

production-related

implementation

concern is site

location.

Strategy

Implementation and Production and Service

Management

Type

of

Strategy

Being

System

Adjustments

Organization

Implemented

Production

Hospital

Adding

a TB center (Product

Purchase

specialized equipment

Development)

and

add specialized people.

Bank

Opening

ten new branches

(Market

Perform

site location

analysis.

Development)

Computer

Purchasing

a retail distribution chain

Alter

the shipping, packaging, and

company

(Forward

Integration)

transportation

systems.

Steel

Acquiring

a fast-food chain

Improve

the quality control

manufacturer

(Conglomerate

Diversification)

system.

Just

In Time (JIT) is an

inventory strategy implemented to improve

the return

on investment of

a

business

by

reducing in-process inventory

and

its associated costs. The

process is driven by a series

of

signals,

or Kanban

that

tell production processes to

make the next part. Kanban

are usually simple

visual

signals,

such as the presence or absence of a

part on a shelf. JIT can

lead to dramatic improvements in a

manufacturing

organization's return

on investment,

quality, and efficiency when implemented

correctly.

New

stock is ordered when stock

reaches

the re-order level. This saves warehouse

space

and costs.

However,

one drawback of the JIT

system is that the re-order level is determined by

historical demand.

If

demand

rises above the historical average

planning

duration demand, the firm could

deplete inventory and

cause

customer

service issues.

To meet a 95% service

rate a

firm must carry about 2

standard

deviations of

demand

in safety stock. Forecasted

shifts in demand should be planned for

around the Kanban until

trends

can be established to reset the

appropriate Kanban level. In recent years

manufacturers

have

touted

a

trailing 13 week average is a better

predictor than most

forecasters could provide.

126

Strategic

Management MGT603

VU

Philosophy

Just-in-time

(JIT) inventory systems are

not just a simple method

that a company has to buy in

to; it has a

whole

philosophy that the company

must follow. The ideas in

this philosophy come from

many different

disciplines

including; statistics, industrial

engineering, production management

and behavioral science. In

the

JIT inventory philosophy

there are views with

respect to how inventory is

looked upon, what it

says

about

the management within the company,

and the main principle

behind JIT.

First

off inventory is seen as

incurring costs instead of adding

value, contrary to traditional

thinking.

Therefore,

under the philosophy businesses are

encouraged to eliminate inventory that

doesn't add value

to

the product. Secondly, it sees

inventory as a sign of sub

par management as it is simply there to

hide

problems

within the production system.

These problem are many, they

include: backups at work

centers,

lack

of flexibility for employees

and equipment, and inadequate

capacity among other

things.

In

short, the just-in-time inventory system

is all about having "the right

material, at the right time, at

the

right

place, and in the exact

amount."

Just

in time (JIT) production approaches

have withstood the test of time.

JIT significantly reduces the

costs

of implementing strategies. With JIT,

parts and materials are

delivered to a production site just

as

they

are needed, rather than being stockpiled

as a hedge against later

deliveries

The

factors that must be study

while pacing a pant are:

transportation costs related to shipping

and

receiving,

the location of major markets,

availability of major resources,

availability of skilled labor ,

wage

rates,

political risks in the area or

country.

For

high-technology companies, production

costs may not be as

important as production

flexibility

because

changes in a product are

needed often. Industries such as

biogenetics and plastics rely

on

production

systems that must be

flexible enough to allow frequent

changes and rapid

introduction of new

products.

They

too slowly realize that a

change in product strategy

alters the tasks of a production

system. These

tasks,

which can be stated in terms

of requirements for cost,

product flexibility, volume

flexibility, product

performance,

and product consistency,

determine which manufacturing policies

are appropriate. As

strategies

shift over time, so must

production policies covering the location

and scale of manufacturing

facilities,

the choice of manufacturing process, the

degree of vertical integration of each

manufacturing

facility,

the use of R&D units, the control of the

production system, and the

licensing of technology.

Cross-training

of employees, can

facilitate strategy implementation and

can yield many

benefits.

Employees

gain a better understanding of the whole

business and can contribute

better ideas in planning

sessions.

It some time create problems

both for manager and

employee

1.

It can necessitate substantial

investments in training and

incentives.

2.

It can be very time-consuming.

3.

Skilled workers may resent unskilled

workers who learn their

jobs.

4.

It can thrust managers into

roles that emphasize

counseling and coaching over

directing and

enforcing.

5.

Older employees may not want

to learn new skills.

Human

Resource Concerns When

Implementing Strategies

The

other important concern

while implementing the strategy is human

resource. Human resource is

the

backbone

of any organization with out

efficient human resource organization

can not perform well

and

fail

to achieve the organizational strategy. Staffing

need of the organization and its

cost is an important

function

of the human resource manager.

The other main concerns

include health, safety and security

of

the

workers. The plan must

also include how to motivate

employees and managers

during a time when

layoffs

are common and workloads are

high.

The

human resource department must develop

performance

incentives that

clearly link performance

and

pay

to strategies. The process of empowering

managers and employees

through involvement in

strategic-

management

activities yields the greatest benefits

when all organizational members

understand clearly

how

they

will benefit personally if the

firm does well. Linking

company and personal benefits is a major

new

strategic

responsibility of human resource

managers. Other new responsibilities

for human resource

managers

may include establishing and

administering an employee

stock ownership plan (ESOP),

are

corporations

owned

in whole or in part by their employees.

Employees are usually given a

share of the

127

Strategic

Management MGT603

VU

corporation

after a certain length of employment or they

can buy shares at any time.

A corporation owned

entirely

by its employees (a worker

cooperative)

will not, therefore, have

its shares sold on public

stock

markets.

Employee-owned corporations often adopt profit

sharing where

the profits of the corporation

are

shared with the employees.

These types of corporations also

often have boards of

directors elected

directly

by the employees.

A

well-designed strategic-management system

can fail

If

insufficient attention is given to the

human resource dimension. Human

resource problems that

arise

when

businesses implement strategies can

usually be traced to one of

three causes:

(1)

Disruption of social and

political structures,

(2)

Failure to match individuals' aptitudes

with implementation

tasks

(3)

Inadequate top management support for

implementation activities.

Inadequate

support from strategists for

implementation activities often

undermines organizational success.

Chief

executive officers, small business

owners, and government agency

heads must be

personally

committed

to strategy implementation and

express this commitment in highly visible

ways. Strategists'

formal

statements about the importance of

strategic management must be

consistent with actual

support

and

rewards given for activities completed

and objectives reached.

Otherwise, stress created

by

inconsistency

can cause uncertainty among

managers and employees at

all levels.

Perhaps

the best method for

preventing and overcoming human

resource problems in

strategic

management

is to actively involve as many managers

and employees as possible in the

process. Although

time-consuming,

this approach builds understanding, trust, commitment,

and ownership and

reduces

resentment

and hostility. The true

potential of strategy formulation

and implementation resides in

people.

128

Table of Contents:

- NATURE OF STRATEGIC MANAGEMENT:Interpretation, Strategy evaluation

- KEY TERMS IN STRATEGIC MANAGEMENT:Adapting to change, Mission Statements

- INTERNAL FACTORS & LONG TERM GOALS:Strategies, Annual Objectives

- BENEFITS OF STRATEGIC MANAGEMENT:Non- financial Benefits, Nature of global competition

- COMPREHENSIVE STRATEGIC MODEL:Mission statement, Narrow Mission:

- CHARACTERISTICS OF A MISSION STATEMENT:A Declaration of Attitude

- EXTERNAL ASSESSMENT:The Nature of an External Audit, Economic Forces

- KEY EXTERNAL FACTORS:Economic Forces, Trends for the 2000’s USA

- EXTERNAL ASSESSMENT (KEY EXTERNAL FACTORS):Political, Governmental, and Legal Forces

- TECHNOLOGICAL FORCES:Technology-based issues

- INDUSTRY ANALYSIS:Global challenge, The Competitive Profile Matrix (CPM)

- IFE MATRIX:The Internal Factor Evaluation (IFE) Matrix, Internal Audit

- FUNCTIONS OF MANAGEMENT:Planning, Organizing, Motivating, Staffing

- FUNCTIONS OF MANAGEMENT:Customer Analysis, Product and Service Planning, Pricing

- INTERNAL ASSESSMENT (FINANCE/ACCOUNTING):Basic Types of Financial Ratios

- ANALYTICAL TOOLS:Research and Development, The functional support role

- THE INTERNAL FACTOR EVALUATION (IFE) MATRIX:Explanation

- TYPES OF STRATEGIES:The Nature of Long-Term Objectives, Integration Strategies

- TYPES OF STRATEGIES:Horizontal Integration, Michael Porter’s Generic Strategies

- TYPES OF STRATEGIES:Intensive Strategies, Market Development, Product Development

- TYPES OF STRATEGIES:Diversification Strategies, Conglomerate Diversification

- TYPES OF STRATEGIES:Guidelines for Divestiture, Guidelines for Liquidation

- STRATEGY-FORMULATION FRAMEWORK:A Comprehensive Strategy-Formulation Framework

- THREATS-OPPORTUNITIES-WEAKNESSES-STRENGTHS (TOWS) MATRIX:WT Strategies

- THE STRATEGIC POSITION AND ACTION EVALUATION (SPACE) MATRIX

- THE STRATEGIC POSITION AND ACTION EVALUATION (SPACE) MATRIX

- BOSTON CONSULTING GROUP (BCG) MATRIX:Cash cows, Question marks

- BOSTON CONSULTING GROUP (BCG) MATRIX:Steps for the development of IE matrix

- GRAND STRATEGY MATRIX:RAPID MARKET GROWTH, SLOW MARKET GROWTH

- GRAND STRATEGY MATRIX:Preparation of matrix, Key External Factors

- THE NATURE OF STRATEGY IMPLEMENTATION:Management Perspectives, The SMART criteria

- RESOURCE ALLOCATION

- ORGANIZATIONAL STRUCTURE:Divisional Structure, The Matrix Structure

- RESTRUCTURING:Characteristics, Results, Reengineering

- PRODUCTION/OPERATIONS CONCERNS WHEN IMPLEMENTING STRATEGIES:Philosophy

- MARKET SEGMENTATION:Demographic Segmentation, Behavioralistic Segmentation

- MARKET SEGMENTATION:Product Decisions, Distribution (Place) Decisions, Product Positioning

- FINANCE/ACCOUNTING ISSUES:DEBIT, USES OF PRO FORMA STATEMENTS

- RESEARCH AND DEVELOPMENT ISSUES

- STRATEGY REVIEW, EVALUATION AND CONTROL:Evaluation, The threat of new entrants

- PORTER SUPPLY CHAIN MODEL:The activities of the Value Chain, Support activities

- STRATEGY EVALUATION:Consistency, The process of evaluating Strategies

- REVIEWING BASES OF STRATEGY:Measuring Organizational Performance

- MEASURING ORGANIZATIONAL PERFORMANCE

- CHARACTERISTICS OF AN EFFECTIVE EVALUATION SYSTEM:Contingency Planning