|

Project

Management MGMT627

VU

LESSON

38

QUALITY

IMPROVEMENT TOOLS

BROAD

CONTENTS

Seven

Basic Tools of Statistical Process

Control

38.1

Seven

Basic Tools of Statistical Process

Control (SPC):

They

are as follows:

1.

Data Tables

2.

Cause-and Effect

Analysis

3.

Histograms

4.

Pareto Analysis

5.

Scatter Diagrams

6.

Trend Analysis

7.

Process Control

Charts

Quality

Improvement Tools:

Over

the years, statistical methods have

become prevalent throughout

business, industry, and

science.

With the availability of advanced, automated

systems that collect,

tabulate, and analyze

data;

the practical application of these

quantitative methods continues to grow.

Statistics today

plays

a major role in all phases

of modern business.

More

important than the quantitative

methods themselves is their

impact on the basic

philosophy

of business. The statistical

point of view takes decision

making out of the

subjective

autocratic

decision-making arena by providing the

basis for objective decisions

based on

quantifiable

facts.

This

change provides some very

specific benefits:

�

Improved

process information

�

Better

communication

�

Discussion

based on facts

�

Consensus

for action

�

Information

for process changes

Statistical

Process Control (SPC) takes

advantage of the natural characteristics of

any process.

All

business activities can be

described as specific processes

with known tolerances

and

measurable

variances. The measurement of these

variances and the resulting

information

provide

the basis for continuous

process improvement. The

tools presented here provide

both a

graphical

and measured representation of process data.

The systematic application of

these tools

empowers

business people to control products

and processes to become

world-class

competitors.

The

basic tools of statistical

process control are data

figures, Pareto analysis,

cause-and-effect

analysis,

trend analysis, histograms, scatter diagrams, and

process control charts.

These basic

tools

provide for the efficient

collection of data, identification of

patterns in the data, and

measurement

of variability.

281

Project

Management MGMT627

VU

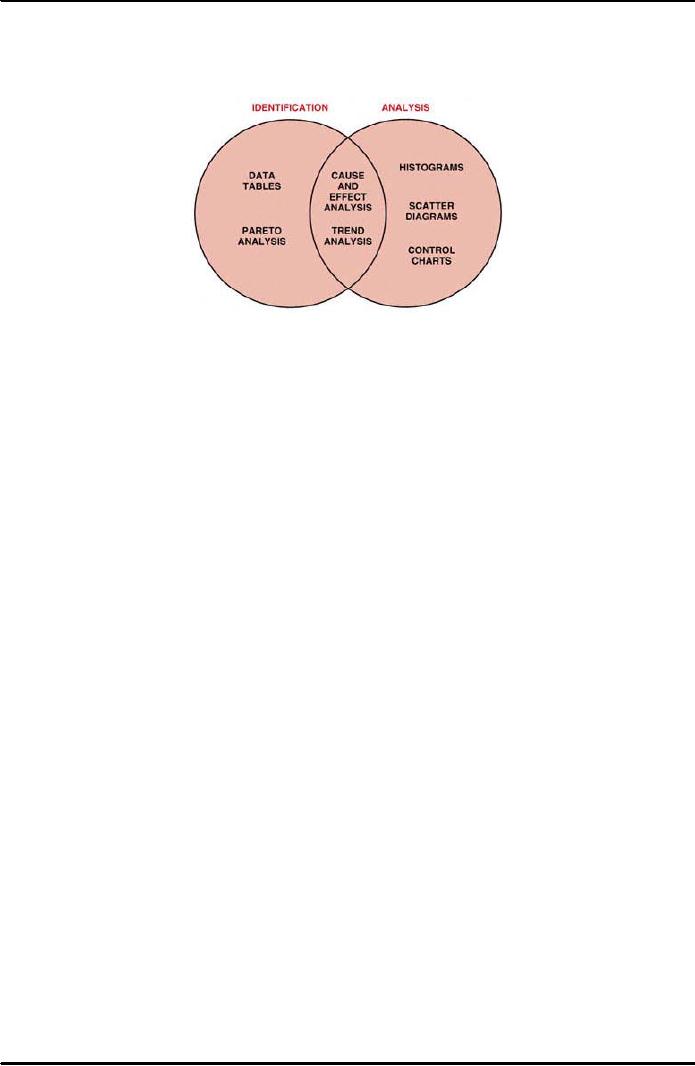

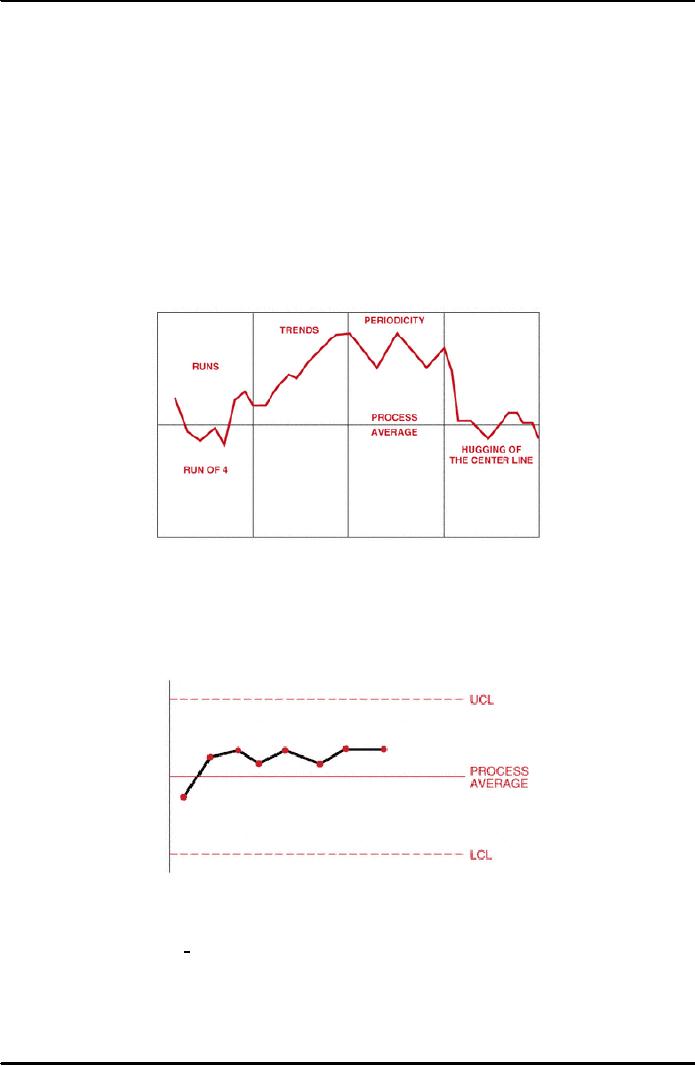

The

following Figure 38.1 shows

the relationships among these seven

tools and their use

for the

identification

and analysis of improvement opportunities. We

will review these tools

and

discuss

their implementation and

applications.

Figure

38.1: Seven

Quality Improvement

Tools

38.1.1

Data Tables:

Data

tables or data arrays

provide a systematic method

for collecting and

displaying

data.

In most cases, data tables

are forms designed for the

purpose of collecting

specific

data.

These tables are used most

frequently where data is available

from automated

media.

They provide a consistent, effective, and

economical approach to gathering

data,

organizing

them for analysis, and displaying them

for preliminary review. Data

tables

sometimes

take the form of manual check

sheets where automated data are

not

necessary

or available. Data figures and check

sheets should be designed to

minimize

the

need for complicated entries.

Simple-to-understand, straightforward tables

are a key

to

successful data

gathering.

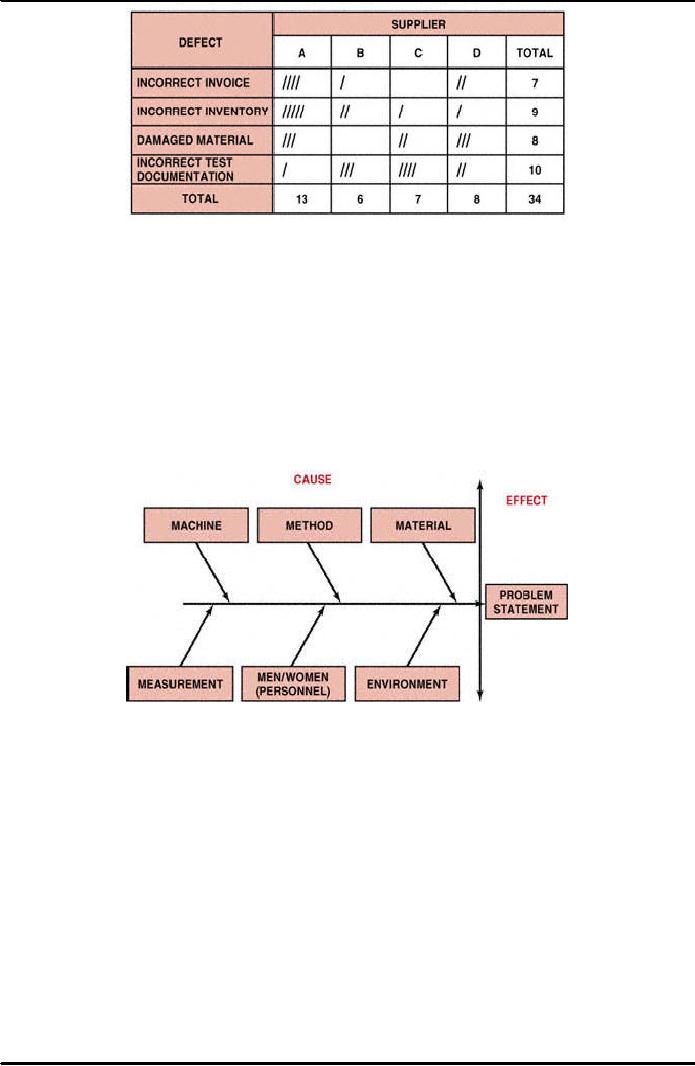

Figure

38.2 is an example of an attribute

(pass/fail) data figure for

the correctness of

invoices.

From this simple check

sheet several data points

become apparent. The

total

number

of defects is 34. The

highest number of defects is from

supplier A, and the

most

frequent

defect is incorrect test documentation.

We can subject this data to

further

analysis

by using Pareto analysis, control

charts, and other

statistical tools.

In

this check sheet, the

categories represent defects

found during the material

receipt

and

inspection function. The

following defect categories provide an

explanation of the

check

sheet:

�

Incorrect

invoices: The

invoice does not match the

purchase order.

�

Incorrect

inventory: The

inventory of the material does

not match the

invoice.

�

Damaged

material: The

material received was

damaged and rejected.

�

Incorrect

test documentation: The

required supplier test

certificate was not

received

and

the material was rejected.

282

Project

Management MGMT627

VU

Figure

38.2: Check

Sheet for "Material Receipt and

Inspection"

38.1.2

Cause-and -Effect Analysis (C

and EA)

"Fishbone":

After

identifying a problem, it is necessary to

determine its cause. The

cause-and-effect

relationship

is at times obscure. A considerable amount of analysis

often is required to

determine

the specific cause or causes of the

problem.

Cause-and-effect

analysis uses diagramming techniques to

identify the relationship

between

an effect and its causes.

Cause-and-effect

diagrams are also known

as

fishbone

diagrams.

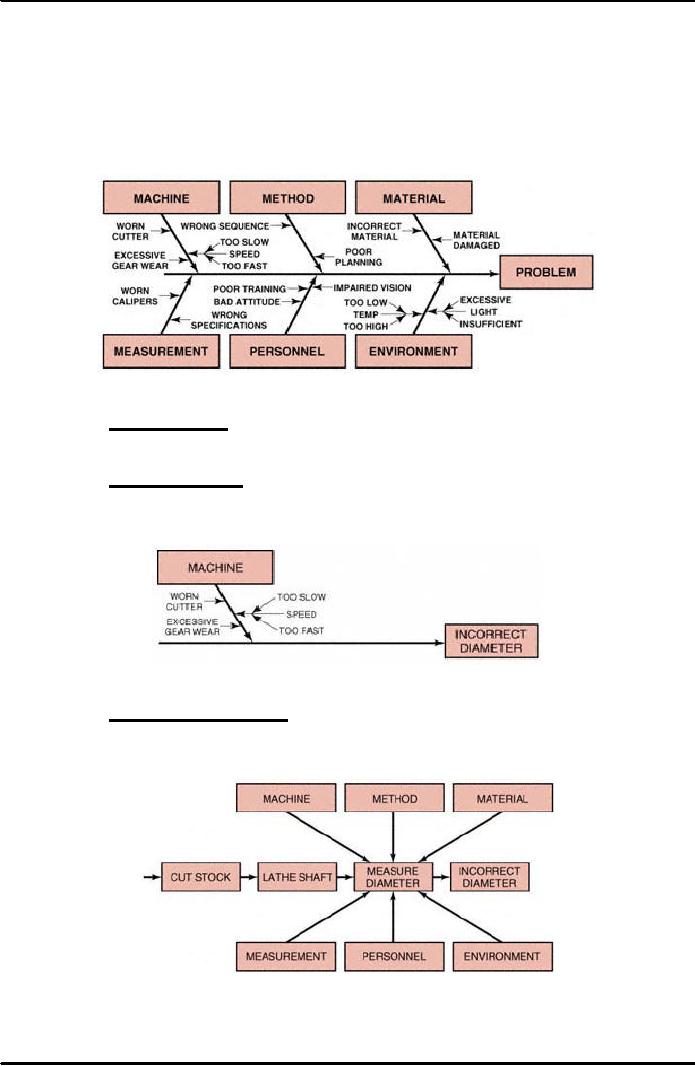

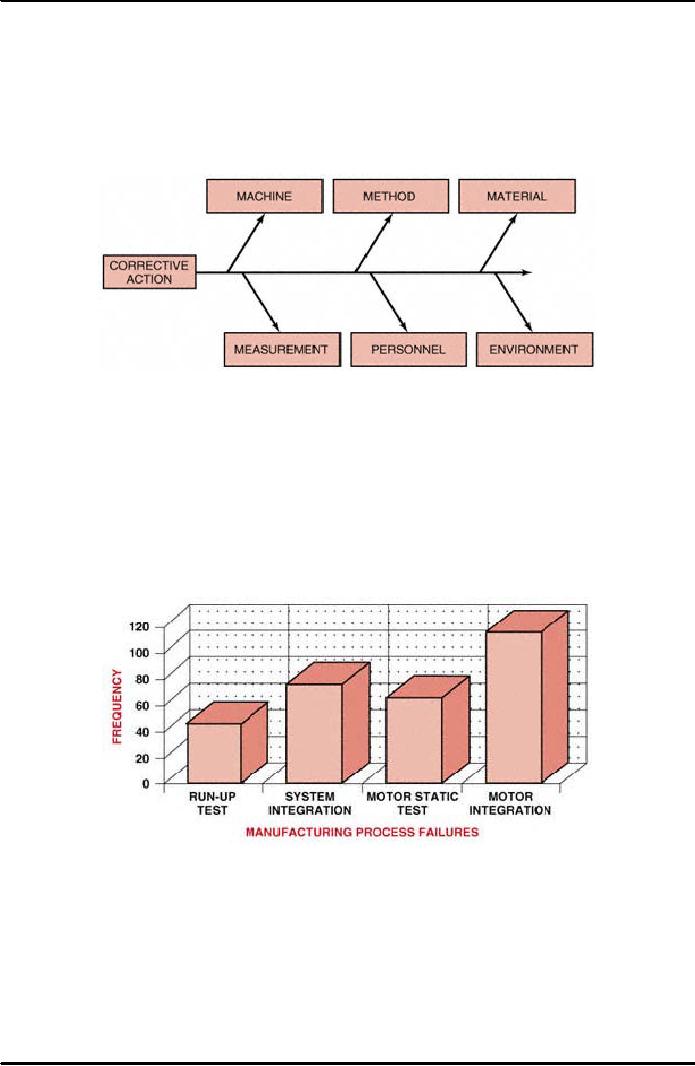

Figure 38.3 demonstrates the

basic fishbone diagram. Six

steps are

used

to perform a cause-and-effect analysis.

Figure

38.3: Cause-and-Effect

Diagram

Step

1 Identify the

problem:

This

step often involves the use

of other statistical process

control tools, such as

Pareto

analysis,

histograms, and control charts, as

well as brainstorming. The

result is a clear,

concise

problem statement.

Step

2 Select interdisciplinary brainstorming

team:

Select

an interdisciplinary team, based on the

technical, analytical, and

management

knowledge

required determining the causes of the

problem.

Step

3 Draw problem box and

prime arrow:

The

problem contains the problem statement

being evaluated for cause

and effect. The

prime

arrow functions as the foundation

for their major

categories.

Step

4 Specify major

categories:

Identify

the major categories contributing to the

problem stated in the problem

box. The

six

basic categories for the

primary causes of the problems are

most frequently

283

Project

Management MGMT627

VU

personnel,

method, materials, machinery,

measurements, and environment, as shown

in

Figure

38.3. Other categories may

be specified, based on the needs of the

analysis.

Step

5 Identify defect

causes:

When

you have identified the major

causes contributing to the problem,

you can

determine

the causes related to each of the

major categories. There are

three approaches

to

this analysis: the

random method, the systematic method, and

the process analysis

method.

Figure

38.4: Random

Method

Random

method: List

all six major causes

contributing to the problem at the same

time.

Identify

the possible causes related to each of

the categories, as shown in Figure

38.4.

Systematic

method: Focus

your analysis on one major category at a

time, in descending

order

of importance. Move to the next

most important category only

after completing

the

most important one. This

process is diagrammed in Figure

38.5.

Figure

38.5: Systematic

Method

Process

analysis method: Identify

each sequential step in the process and

perform

cause-and-effect

analysis for each step, one

at a time. Figure 38.6

represents this

approach.

Figure

38.6: Process

Analysis Methods

284

Project

Management MGMT627

VU

Step

6 Identify corrective

action:

Based

on (1) the cause-and-effect analysis of the problem

and (2) the determination of

causes

contributing to each major

category, identify corrective

action.

The

corrective action analysis is performed

in the same manner as the

cause-and-effect

analysis.

The cause-and-effect diagram is simply

reversed so that the problem

box

becomes

the corrective action box.

Figure 38.7 displays the method

for identifying

corrective

action.

Figure

38.7: Identify

Corrective Action

38.1.3

Histogram-(HG):

A

histogram is a graphical representation of

data as a frequency distribution.

This tool

is

valuable in evaluating both

attribute (pass/fail) and

variable (measurement)

data.

Histograms

offer a quick look at the

data at a single point in

time; they do not

display

variance

or trends over time. A

histogram displays how the

cumulative data looks

today.

It is useful in understanding the

relative frequencies (percentages) or

frequency

(numbers)

of the data and how that

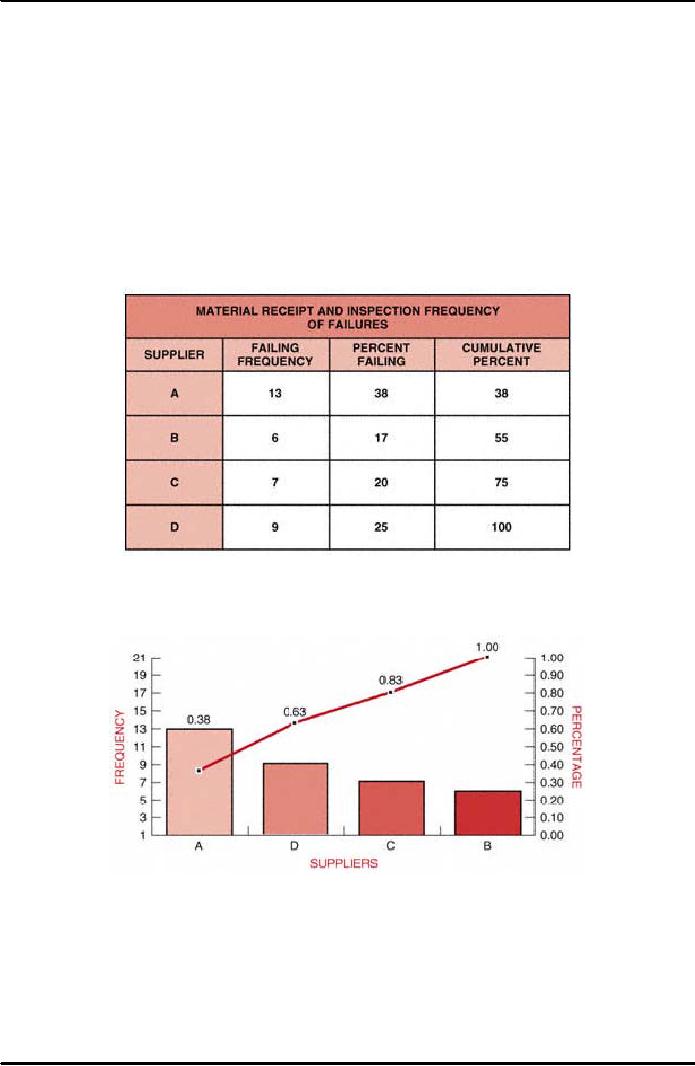

data are distributed. Figure

38.8 illustrates a

histogram

of the frequency of defects in a

manufacturing process.

Figure

38.8: Histogram

for Variables

38.1.4

Pareto Analysis

(PA):

A

Pareto diagram is a special type of

histogram that helps us to identify and

prioritize

problem

areas. The construction of a

Pareto diagram may involve

data collected from

data

figures, maintenance data, repair

data, parts scrap rates, or

other sources. By

identifying

types of nonconformity from any of

these data sources, the

Pareto diagram

directs

attention to the most frequently

occurring element.

285

Project

Management MGMT627

VU

There

are three uses and types of

Pareto analysis:

1.

The basic Pareto analysis

identifies the vital few

contributors that account

for most

quality

problems in any system.

2.

The comparative Pareto analysis

focuses on any number of program

options or

actions.

3.

The weighted Pareto analysis

gives a measure of significance to

factors that may

not

appear significant at first--

such additional factors as cost,

time, and criticality.

The

basic Pareto analysis chart provides an

evaluation of the most frequent

occurrences

for

any given data set. By

applying the Pareto analysis steps to the

material receipt and

inspection

process described in Figure 38.9, we

can produce the basic Pareto

analysis

demonstrated

in Figure 38.10. This basic

Pareto analysis quantifies and graphs

the

frequency

of occurrence for material

receipt and inspection and further

identifies the

most

significant, based on

frequency.

Figure

38.9: Material

Receipt and Inspection Frequency of

Failures

Figure

38.10: Basic

Pareto Analysis

A

review of this basic Pareto

analysis for frequency of occurrences

indicates that

supplier

A is experiencing the most rejections

with 37 percent of all the

failures.

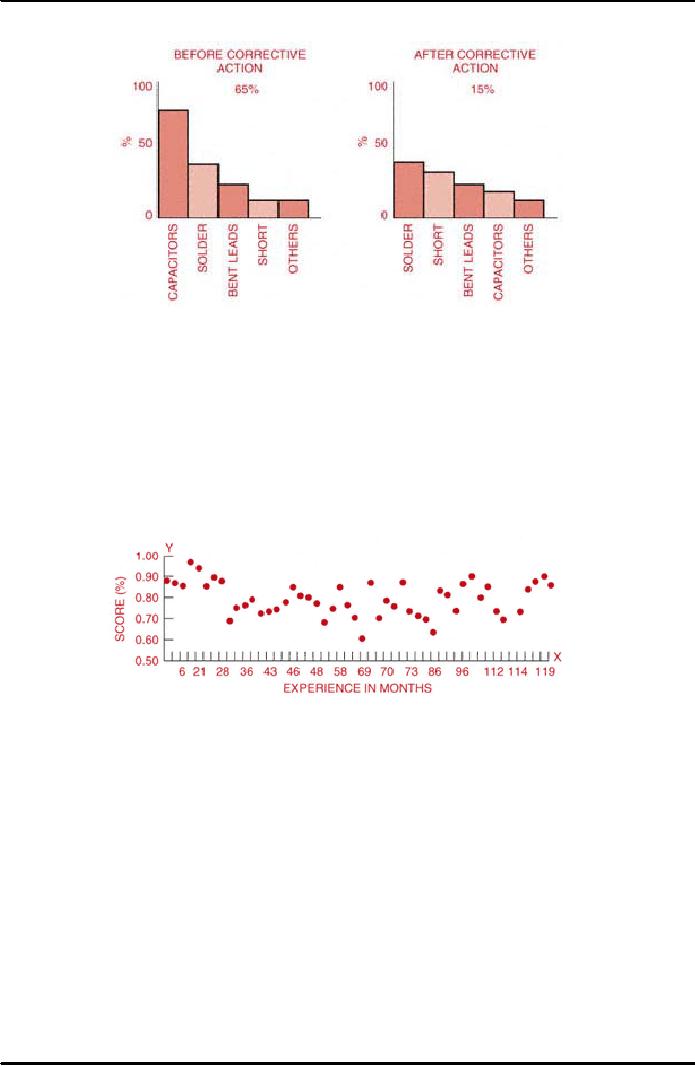

Pareto

analysis diagrams are also used to

determine the effect of corrective

action, or to

analyze

the difference between two or more

processes and methods. Figure

38.11

286

Project

Management MGMT627

VU

displays

the use of this Pareto method to

assess the difference in defects

after corrective

action.

Figure

38.11: Comparative

Pareto Analysis

38.1.5

Scatter Diagrams:

Another

pictorial representation of process

control data is the scatter

plot or scatter

diagram.

A scatter diagram organizes data

using two variables: an

independent variable

and

a dependent variable. These data

are then recorded on a simple

graph with X

and

Y

coordinates

showing the relationship between the

variables. Figure 38.12

displays the

relationship

between two of the data elements

from solder qualification test

scores. The

independent

variable, experience in months, is listed on the

X-axis.

The dependent

variable

is the score, which is recorded on the

Y-axis.

Figure

38.12: Solder

Certification Test

Score

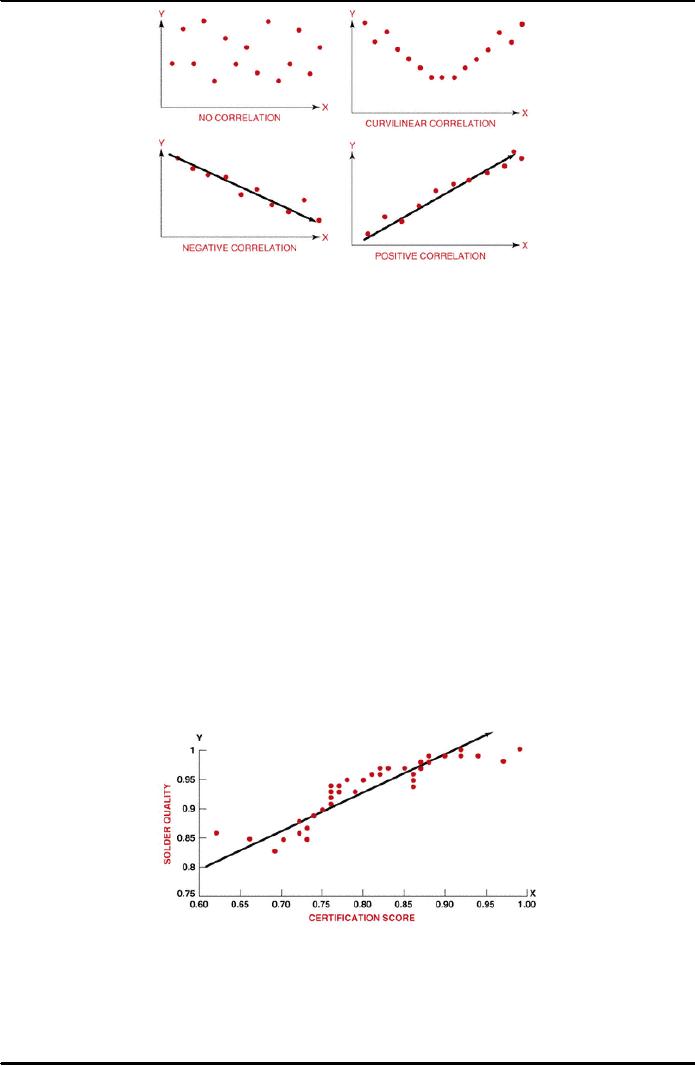

These

relationships fall into several

categories, as shown in Figure 38.13

below. In the

first

scatter plot there is no correlation--

the data points are widely

scattered with no

apparent

pattern.

287

Project

Management MGMT627

VU

Figure

38.13: Scatter

Plot Correlation

The

second scatter plot shows a

curvilinear correlation demonstrated by

the U shape

of

the graph. The third scatter

plot has a negative

correlation, as indicated by the

downward

slope. The final scatter

plot has a positive

correlation with an

upward

slope.

From

Figure 38.12 we can see

that the scatter plot for

solder certification testing is

somewhat

curvilinear. The least and

the most experienced employees scored

highest,

whereas

those with an intermediate

level of experience did relatively

poorly. The next

tool,

trend analysis, will help

clarify and quantify these

relationships.

38.1.6

Trend Analysis (T/A):

Trend

analysis is a statistical method for

determining the equation that

best fits the

data

in a scatter plot. Trend analysis

quantifies the relationships of the

data,

determines

the equation, and measures

the fit of the equation to the data.

This

method

is also known as curve

fitting or least

squares.

Trend

analysis can determine optimal

operating conditions by providing an

equation

that

describes the relationship between the dependent

(output) and independent

(input)

variables. An example is the data

set concerning experience and scores on

the

solder

certification test (see

Figure 38.14).

Figure

38.14: Scatter

Plot Solder Quality and

Certification Score

The

equation of the regression line, or

trend line, provides a clear and

understandable

measure

of the change caused in the output

variable by every incremental

change of the

input

or independent variable. Using

this principle, we can

predict the effect of

changes

in

the process.

288

Project

Management MGMT627

VU

One

of the most important contributions

that can be made by trend

analysis is

forecasting.

Forecasting enables us to predict what is

likely to occur in the future.

Based

on

the regression line we can

forecast what will happen as the

independent variable

attain

values beyond the existing data.

38.1.7

Process Control Charts

(C/C):

The

use of control charts

focuses on the prevention of defects,

rather than their

detection

and rejection. In business, government,

and industry, economy and

efficiency

are always best served by

prevention. It costs much more to produce

an

unsatisfactory

product or service than it does to

produce a satisfactory one. There

are

many

costs associated with

producing unsatisfactory goods

and services. These

costs

are

in labor, materials, facilities, and the

loss of customers. The cost

of producing a

proper

product can be reduced

significantly by the application of

statistical process

control

charts.

�

Control

Charts and the Normal

Distribution:

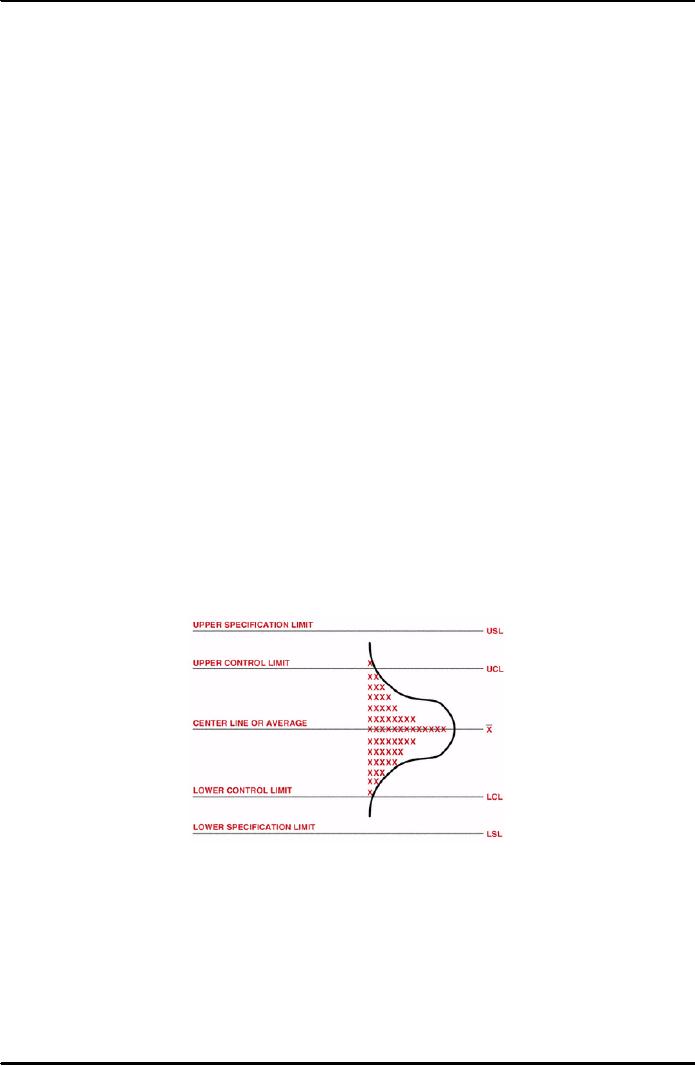

The

construction, use, and interpretation of

control charts is based on the

normal

statistical

distribution as indicated in Figure

38.15. The centerline of the

control

chart

represents the average or mean of the

data ( ). The upper

and lower control

limits

(UCL and LCL),

respectively, represent this

mean plus and minus

three

standard

deviations of the data either

the lowercase s

or

the Greek letter (sigma)

represents

the standard deviation for

control charts.

The

normal distribution and its

relationship to control charts

are represented on the

right

of the figure. The normal

distribution can be described

entirely by its mean

and

standard deviation. The

normal distribution is a bell-shaped

curve (sometimes

called

the Gaussian distribution) that is

symmetrical about the mean,

slopes

downward

on both sides to infinity,

and theoretically has an

infinite range. In the

normal

distribution 99.73 percent of all

measurements lie within and;

this is why

the

limits on control charts are

called three-sigma limits.

Figure

38.15: The

Control Chart and Normal

Curve

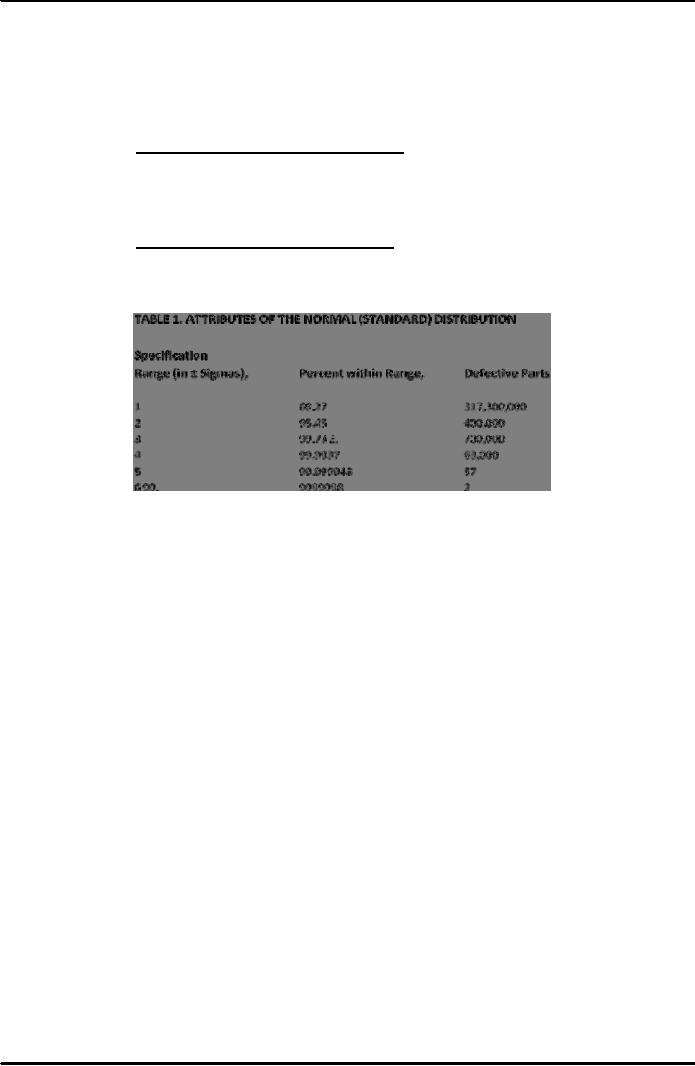

Companies

like Motorola have embarked upon a

six-sigma limit rather than

a three-

sigma

limit. The benefit is shown in

Table 38.1 below. With a

six-sigma limit, only

two

defects per billion are

allowed. The cost to

maintain a six-sigma limit

can be

extremely

expensive unless the cost

can be spread out over, say,

1 billion units

produced

Control

chart analysis determines whether the inherent

process variability and

the

process

average are at stable levels, whether

one or both are out of

statistical control

289

Project

Management MGMT627

VU

(not

stable), or whether appropriate action

needs to be taken. Another

purpose of

using

control charts is to distinguish between

the inherent, random variability of

a

process

and the variability attributed to an

assignable cause. The

sources of random

variability

are often referred to as common

causes. These are the

sources that

cannot

be changed readily, without

significant restructuring of the process.

Special

cause

variability, by contrast, is subject to correction

within the process

under

process

control.

Common

cause variability or variation:

This

source of random variation is

always

present

in any process. It is that

part of the variability inherent in the

process itself.

The

cause of this variation can

be corrected only by a management

decision to

change

the basic process.

Special

cause variability or variation:

This

variation can be controlled at the

local

or

operational level. Special

causes are indicated by a

point on the control chart

that

is

beyond the control limit or by a

persistent trend approaching the control

limit.

Table

38.1: Attributes

of the Normal (Standard)

Distribution

To

use process control

measurement data effectively, it is

important to understand

the

concept of variation. No two

product or process characteristics

are exactly alike,

because

any process contains many

sources of variability. The

differences between

products

may be large, or they may be

almost immeasurably small, but

they are

always

present. Some sources of

variation in the process can

cause immediate

differences

in the product, such as a change in

suppliers or the accuracy of an

individual's

work. Other sources of

variation, such as tool

wear, environmental

changes,

or increased administrative control,

tend to cause changes in the

product

or

service only over a longer

period of time.

To

control and improve a process, we

must trace the total

variation back to its

sources.

Again the sources are common

cause and special cause

variability.

Common

causes are the many sources

of variation that always

exist within a

process

that is in a state of statistical

control. Special causes (often

called assignable

causes)

are any factors causing

variation that cannot be adequately

explained by any

single

distribution of the process output, as

would be the case if the

process were in

statistical

control. Unless all the special causes of

variation are identified

and

corrected,

they will continue to affect

the process output in unpredictable

ways.

The

factors that cause the most

variability in the process are the

main factors found

on

cause-and-effect analysis charts: people,

machines, methodology, materials,

measurement,

and environment. These

causes can either result

from special causes

or

be common causes inherent in the

process.

290

Project

Management MGMT627

VU

The

theory of control charts

suggests that if the source of

variation is from

chance

alone,

the process will remain

within the three-sigma limits. When the

process goes

out

of control, special causes exist.

These need to be investigated and

corrective

action

must be taken.

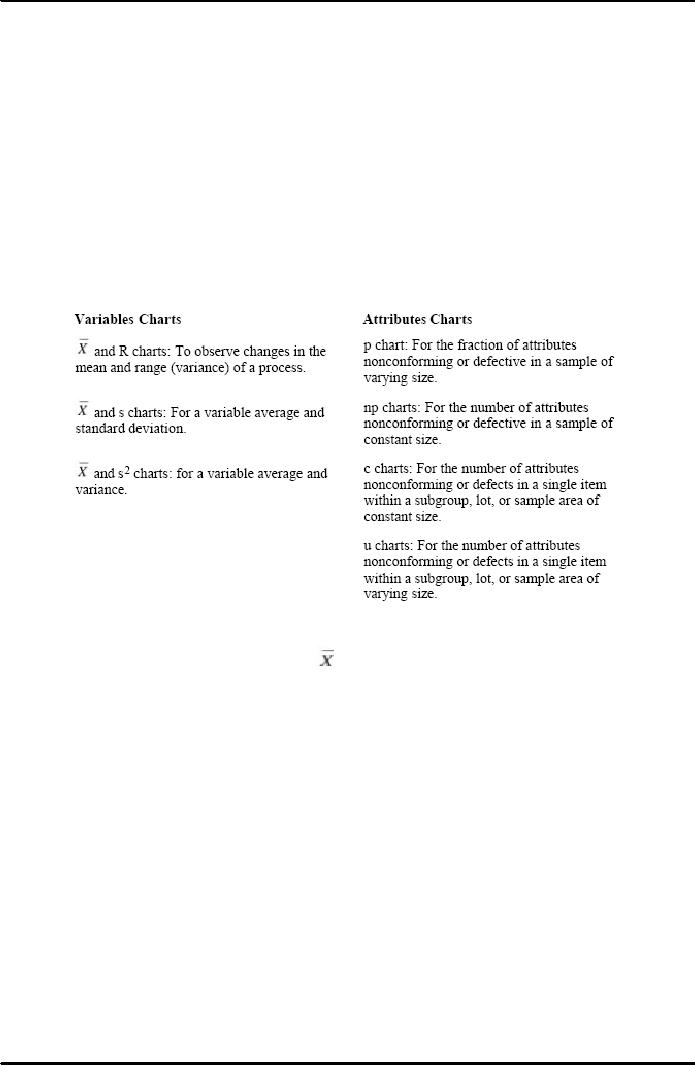

�

Control

Chart Types:

Just

as there are two types of data,

continuous and discrete, there are

two types of

control

charts: variable charts for

use with continuous data and

attribute charts for

use

with discrete data. Each

type of control chart can be

used with specific types

of

data.

Table 38.2 provides a brief

overview of the types of control charts

and their

applications.

Variables

charts: Control

charts for variables are

powerful tools that we can

use

when

measurements from a process

are variable. Examples of variable

data are the

diameter

of a bearing, electrical output, or the

torque on a fastener.

Table

38.2: Types

of Control Charts and

Application

As

shown in Table 38.2, and R

charts are used to measure

control processes

whose

characteristics are continuous

variables such as weight,

length, ohms, time,

or

volume. The p and NP charts

are used to measure and

control processes

displaying

attribute characteristics in a sample. We

use p charts when the number

of

failures

is expressed as a fraction, or NP charts

when the failures are

expressed as a

number.

The c and u charts are used

to measure the number or portion of

defects in

a

single item. The c control

chart is applied when the sample

size or area is

fixed,

and

the u chart when the sample size or

area is not fixed.

Attribute

charts: Although

control charts are most

often thought of in terms

of

variables,

there are also versions for

attributes. Attribute data have

only two values

(conforming/nonconforming,

pass/fail, go/no-go, present/absent),

but they can

still

be

counted, recorded, and analyzed. Some

examples are: the presence of a

required

label,

the installation of all required

fasteners, the presence of solder drips,

or the

continuity

of an electrical circuit. We also

use attribute charts for

characteristics

that

are measurable, if the results

are recorded in a simple yes/no fashion,

such as

the

conformance of a shaft diameter when

measured on a go/no-go gauge, or

the

acceptability

of threshold margins to a visual or gauge

check.

It

is possible to use control charts

for operations in which attributes

are the basis for

inspection,

in a manner similar to that

for variables but with

certain differences. If

291

Project

Management MGMT627

VU

we

deal with the fraction rejected

out of a sample, the type of

control chart used is

called

a p chart. If we deal with the actual number rejected,

the control chart is

called

an NP chart. If articles can have more than one

nonconformity, and all

are

counted

for subgroups of fixed size,

the control chart is called a c chart.

Finally, if

the

number of nonconformities per unit is the

quantity of interest, the control

chart

is

called a u chart.

The

power of control charts (Shewhart

techniques) lies in their ability to

determine

if

the cause of variation is a special cause

that can be affected at the

process level,

or

a common cause that requires a change at

the management level.

The

information

from the control chart can

then be used to direct the

efforts of

engineers,

technicians, and managers to achieve preventive or

corrective action.

The

use of statistical control

charts is aimed at studying specific

ongoing processes

in

order to keep them in satisfactory control. By

contrast, downstream inspection

aims

to identify defects. In other words,

control charts focus on prevention

of

defects

rather than detection and

rejection. It seems reasonable, and it

has been

confirmed

in practice, that economy and efficiency

are better served by

prevention

rather

than detection.

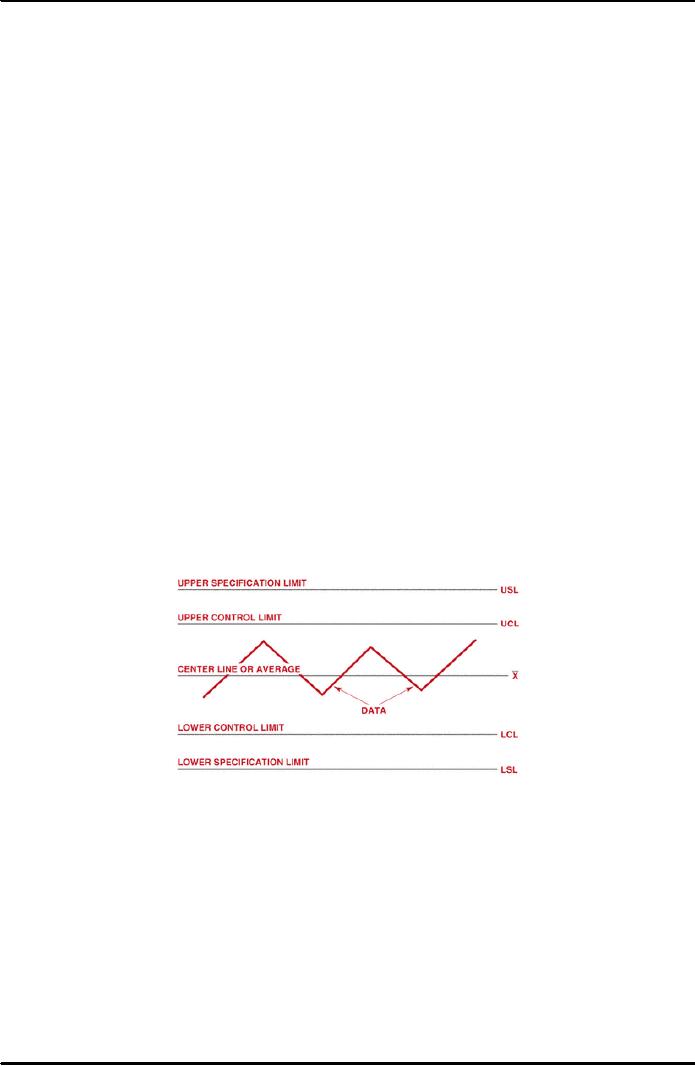

�

Control

Chart Components:

All

control charts have certain

features in common (Figure 38.16).

Each control

chart

has a centerline, statistical

control limits, and the calculated

attribute or

control

data. Additionally, some control

charts contain specification

limits.

The

centerline is a solid (unbroken)

line that represents the

mean or arithmetic

average

of the measurements or counts. This

line is also referred to as the X bar

line

(

). There are two statistical

control limits: the upper

control limit for values

greater

than

the mean and the lower control

limit for values less than

the mean.

Figure

38.16: Control

Chart Elements

Specification

limits are used when

specific parametric requirements exist

for a

process,

product, or operation. These

limits usually apply to the

data and are the

pass/fail

criteria for the operation.

They differ from statistical

control limits in

that

they

are prescribed for a process, rather

than resulting from the

measurement of the

process.

The

data element of control charts varies

somewhat among variable and

attribute

control

charts. We will discuss

specific examples as a part of the

discussion on

individual

control charts.

292

Project

Management MGMT627

VU

�

Control

Chart Interpretation:

There

are many possibilities for

interpreting various kinds of

patterns and shifts on

control

charts. If properly interpreted, a

control chart can tell us

much more than

simply

whether the process is in or out of

control. Experience and

training can lead

to

much greater skill in extracting

clues regarding process

behavior, such as

that

shown

in Figure 38.17. Statistical guidance is

invaluable, but an

intimate

knowledge

of the process being studied is

vital in bringing about

improvements.

A

control chart can tell us

when to look for trouble,

but it cannot by itself tell

us

where

to look, or what cause will

be found. Actually, in many

cases, one of the

greatest

benefits from a control chart is

that it tells when to leave

a process alone.

Sometimes

the variability is increased unnecessarily

when an operator keeps

trying

to

make small corrections, rather than

letting the natural range of

variability

stabilize.

The following paragraphs

describe some of the ways the

underlying

distribution

patterns can behave or misbehave.

Figure

38.17: Control

Chart Interpretation

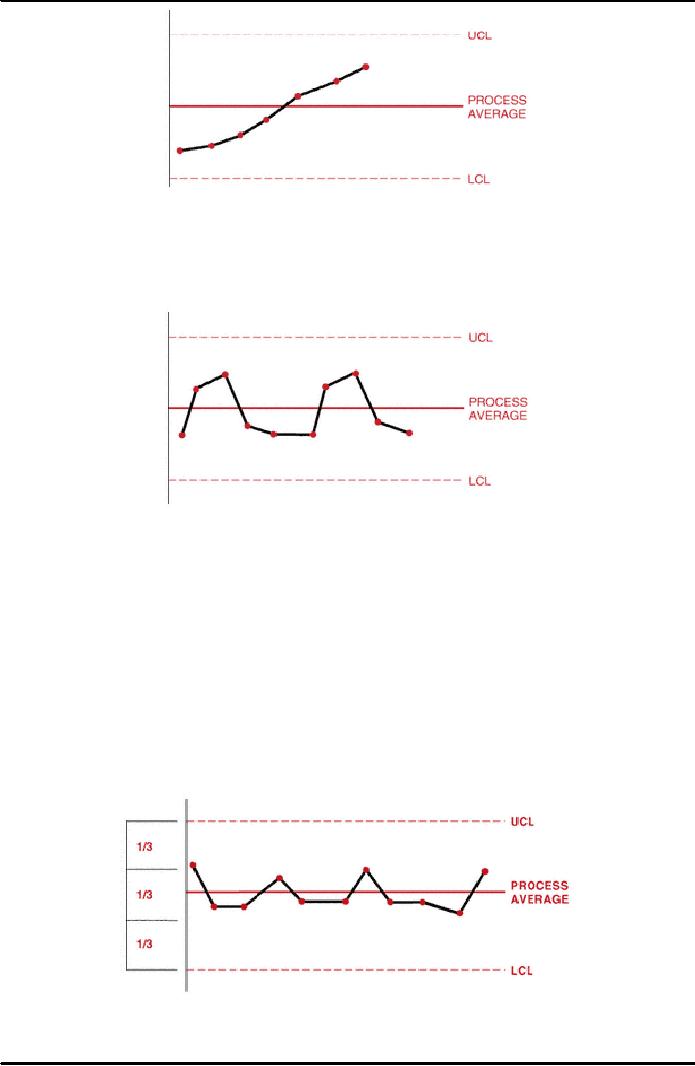

Runs:

When

several successive points line up on

one side of the central

line, this

pattern

is called a run. The number of

points in that run is called

the length of the

run.

As a rule of thumb, if the run

has a length of seven

points, there is an

abnormality

in the process. Figure 38.18

demonstrates an example of a

run.

Figure

38.18: Process

Run

Trends: If

there is a continued rise of all in a

series of points, this

pattern is called a

trend.

In general, if seven consecutive points

continue to rise or fall, there is

an

abnormality.

Often, the points go beyond one of the

control limits before

reaching

seven.

Figure 38.19 demonstrates an

example of trends.

293

Project

Management MGMT627

VU

Figure

38.19: Control

Chart Trends

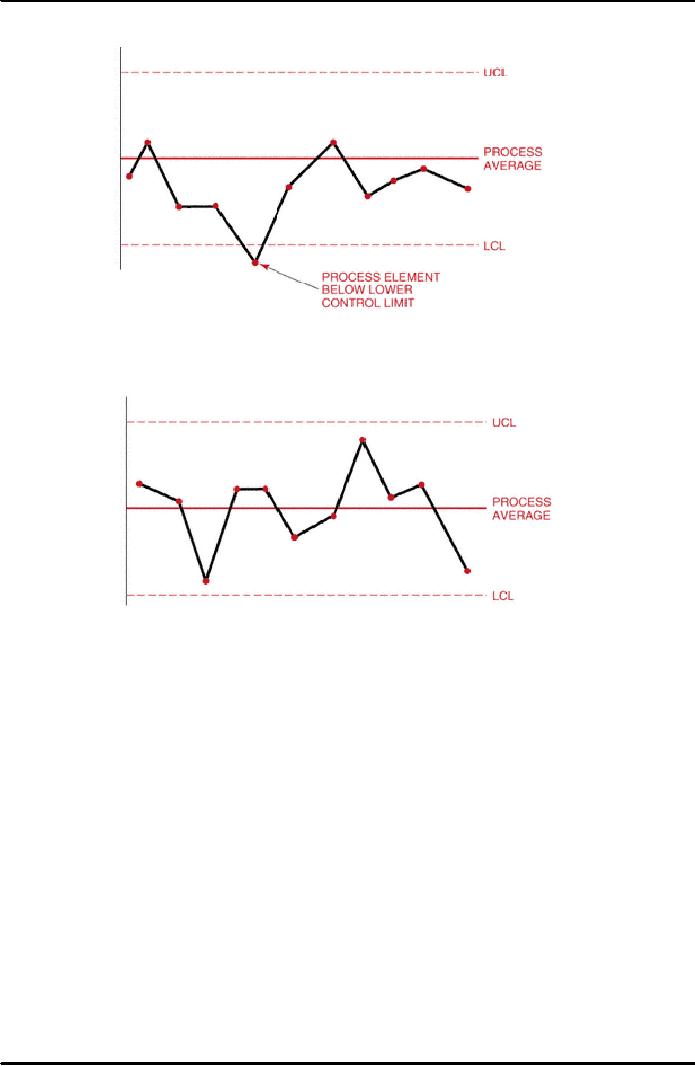

Periodicity:

Points

that show the same pattern of

change (rise or fall)

over

equal

intervals denote periodicity. Figure

38.20 demonstrates an example

of

periodicity.

Figure

38.20: Control

Chart Periodicity

Hugging

the centerline or control limit.

Points on the

control chart that are close

to

the

central line or to the control

limit are said to hug the

line. Often, in this

situation,

different types of data or data

from different factors have been

mixed into

the

subgroup. In such cases it is necessary

to change the sub-grouping,

reassemble

the

data, and redraw the control chart. To decide

whether there is hugging of the

center

line, draw two lines on the

control chart, one between the centerline

and the

UCL

and the other between the center line and

the LCL. If most of the points

are

between

these two lines, there is an

abnormality. To see whether there is

hugging of

one

of the control limits; draw

line two-thirds of the distance between

the center

line

and each of the control lines.

There is abnormality if 2 out of 3

points, 3 out of

7

points, or 4 out of 10 points

lie within the outer

one-third zone. The

abnormalities

should

be evaluated for their

cause(s) ad the corrective action

taken. Figure 38.21

demonstrates

data hugging the LCL.

Figure

38.21: Hugging

the Centerline

294

Project

Management MGMT627

VU

Out

of control: An

abnormality exists when data

points exceed either

the

upper

or lower control limits.

Figure 38.22 illustrates

this occurrence.

Figure

38.22: Control Chart Out of

Control

In

control: No

obvious abnormalities appear in the

control chart. Figure

38.23

demonstrates

this desirable process

state.

Figure

38.23: Process

in Control

295

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles