|

Project

Management MGMT627

VU

LESSON

35

QUALITY

IN PROJECT MANAGEMENT

(CONTD.)

BROAD

CONTENTS

The

Quality Movement

Quality

Development Stages

Quality

Audit

Deming

Philosophy

35.1

THE

QUALITY MOVEMENT:

During

the past 100 years, the

views of quality have changed

dramatically. Prior to World

War

I,

quality was viewed

predominantly as inspection, sorting

out the good items from the

bad.

Emphasis

was on problem identification.

Following World War I and up to the

early 1950s,

emphasis

was still on sorting good

items from bad.

However,

quality control principles were

now emerging in the form

of:

�

Statistical

and mathematical techniques

�

Sampling

tables

�

Process

control charts

From

the early 1950s to the late 1960s,

quality control evolved into

quality assurance, with

its

emphasis

on problem avoidance rather

than problem detection.

Additional quality

assurance

principles

emerged, such as:

�

The

cost of quality

�

Zero-defect

programs

�

Reliability

engineering

�

Total

quality control

35.2

DEVELOPMENT

OF QUALITY STAGES:

This

comprises of the following "five

level model":

1.

Inspection

2.

Quality

Control

3.

Quality

Assurance

4.

Quality

Management

5.

Total

Quality Management

1.

Inspection:

"Activity

such as measuring, examining, testing, or

gauging one or more

characteristics

of

an entity and comparing the

results with specified requirements in

order to establish

whether

conformity is achieved for each

characteristic" (ISO

8402)

2.

Quality

Control:

Quality

control is a collective term for

activities and techniques, within the

process, that

are

intended to create specific

quality characteristics. Such

activities include

continually

monitoring

processes, identifying and

eliminating problem causes,

use of statistical

255

Project

Management MGMT627

VU

process

control to reduce the variability

and to increase the efficiency of

processes.

Quality

control certifies that the

organization's quality objectives

are being met.

Quality

control is also referred to as the

technical aspect of quality

management. They

set

up the technical processes and

procedures that ensure that

each step of the

project

provides

a quality output from design and

development through implementation

and

maintenance.

Each step's output must

conform to the overall quality

standards and

quality

plans, thus ensuring that

quality is achieved.

A

good quality control system

will:

�

Select

what to control

�

Set

standards that provide the

basis for decisions regarding possible

corrective

action

�

Establish

the measurement methods

used

�

Compare

the actual results to the quality

standards

�

Act

to bring nonconforming processes and

material back to the standard based

on

the

information collected

�

Monitor

and calibrate measuring devices

�

Include

detailed documentation for

all processes

3.

Quality

Assurance:

Quality

assurance is the collective term

for the formal activities and

managerial

processes

that are planned and

undertaken in an attempt to ensure that

products and

services

that are delivered are at

the required quality level.

Quality assurance

also

includes

efforts external to these

processes that provide

information for improving

the

internal

processes. It is the quality assurance

function that attempts to

ensure that the

project

scope, cost, and time

functions are fully

integrated.

The

Project Management Institute

Guide to the Body of Knowledge

(PMBOK) refers to

quality

assurance as the management section of

quality management. This is the

area

where

the project manager can have the

greatest impact on the quality of

his project.

The

project manager needs to establish the

administrative processes and

procedures

necessary

to ensure and, often, prove

that the scope statement conforms to the

actual

requirements

of the customer. The project manager

must work with his

team to

determine

which processes they will

use to ensure that all

stakeholders have confidence

that

the quality activities will be

properly performed. All relevant

legal and regulatory

requirements

must also be met.

A

good quality assurance

system will:

�

Identify

objectives and

standards.

�

Be

multifunctional and prevention

oriented.

�

Plan

for collection and use of

data in a cycle of continuous

improvement.

�

Plan

for the establishment and maintenance of performance

measures.

�

Include

quality audits.

4.

Quality

Management:

During

the past twenty years, there

has been a revolution toward

improved quality. The

improvements

have occurred not only in product

quality, but also in quality

leadership

and

quality project management.

Unfortunately, it takes an economic

disaster or a

recession

to get management to recognize the need

for improved quality. Prior

to the

recession

of 19791982, Ford, General

Motors, and Chrysler viewed

each other as the

256

Project

Management MGMT627

VU

competition

rather than the Japanese. Prior to the

recession of 19891994,

high-tech

engineering

companies never fully recognized the

need for shortening

product

development

time and the relationship between project

management, total

quality

management,

and concurrent engineering. The push

for higher levels of quality

appears

to

be customer driven. Customers

are now demanding:

�

Higher

performance requirements

�

Faster

product development

�

Higher

technology levels

�

Materials

and processes pushed to the

limit

�

Lower

contractor profit margins

�

Fewer

defects/rejects

One

of the critical factors that can

affect quality is market expectations.

The variables

that

affect market expectations

include:

�

Salability:

the balance between quality and

cost

�

Produceability:

the ability to produce the product with

available technology

and

workers,

and at an acceptable

cost

�

Social

acceptability: the degree of conflict

between the product or process and

the

values

of society (i.e., safety,

environment)

�

Operability:

the degree to which a product

can be operated safely

�

Availability:

the probability that the product,

when used under given

conditions,

will

perform satisfactorily when

called upon

�

Reliability:

the probability of the product performing

without failure under

given

conditions

and for a set period of

time

�

Maintainability:

the ability of the product to be retained

in or restored to a

performance

level when prescribed maintenance is

performed

Customer

demands are now being

handled using total quality

management (TQM).

Total

quality management is an ever-improving

system for integrating

various

organizational

elements into the design, development,

and manufacturing efforts,

providing

cost-effective products or services that

are fully acceptable to the

ultimate

customer.

Externally, TQM is customer oriented and

provides for more

meaningful

customer

satisfaction. Internally, TQM reduces

production line bottlenecks

and

operating

costs, thus enhancing product

quality while improving

organizational morale.

5.

Total

Quality Management

(TQM):

For

this, we first explain what

"total

quality" is.

Total Quality means:

�

Quality

of work

�

Quality

of Service

�

Quality

of information

�

Quality

Process

�

Quality

of Organization

�

Quality

of People

�

Quality

of Company

�

Quality

of Objectives

Mature

organizations today readily

admit that they cannot accurately

define quality.

The

reason for this is because

quality is defined by the customer. The

Kodak definition

of

quality is those products and services

that are perceived to meet

or exceed the needs

and

expectations of the customer at a cost

that represents outstanding

value.

257

Project

Management MGMT627

VU

The

ISO 9000 definition is "the

totality of feature and characteristics

of a product or

service

that bears on its ability to

satisfy stated or implied needs."

Terms such as fitness

for

use, customer satisfaction,

and zero defects are goals

rather than definitions.

Most

organizations

today view quality more as a

process than a product. To be more

specific,

it

is a continuously improving process where

lessons learned are used to

enhance future

products

and services in order

to:

�

Retain

existing customers

�

Win

back lost customers

�

Win

new customers

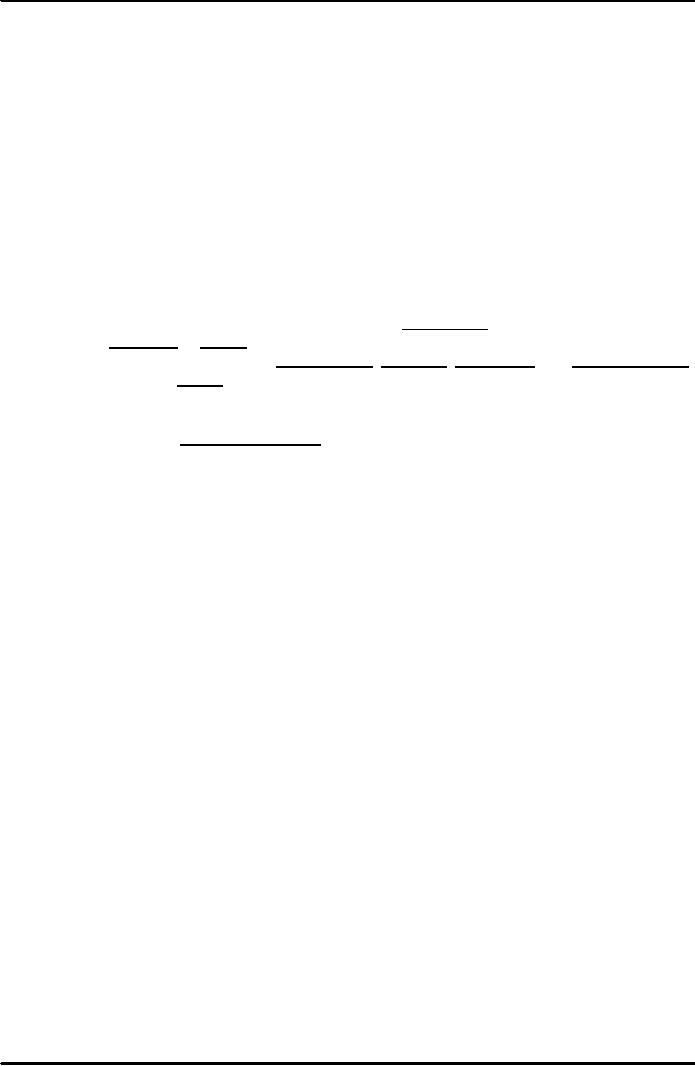

Therefore,

companies today are

developing quality improvement

processes. Figure

35.1

shows

the five quality principles

that support Kodak's quality

policy. Figure 35.2

shows

a

more detailed quality improvement

process.

Total

Quality Management (TQM) is

a management strategy aimed at

embedding

awareness

of quality in all organizational

processes. Total Quality

Management (TQM)

has

been widely used in

manufacturing, education, government, and

service industries,

as

well as NASA space and

science programs.

Total

Quality provides an umbrella

under which everyone in the

organization can

strive

and

create customer satisfaction at

continually lower real

costs.

Total

Quality Management (TQM) is the

management of total quality. We

know that

management

consists of planning, organizing,

directing, control, and assurance.

Then,

one

has to define "total

quality". Total quality is

called total

because

it consists of the

following

three qualities:

1.

Quality

of

return to satisfy the needs of the

shareholders

2.

Quality

of

products and services to satisfy some

specific needs of the

consumer

(end

user)

3.

Quality

of

life - at work and outside

work - to satisfy the needs of the

people in the

organization.

This

is achieved with the help of upstream and

downstream partners of the enterprise.

To

this, we have to add the corporate

citizenship, that is the

social,

technological,

economical,

political, and ecological (STEPE)

responsibility

of the enterprise

concerning

its internal (its people)

and external (upstream and downstream)

partners,

and

community. Therefore, total

quality management goes well

beyond satisfying the

customer,

or merely offering quality products

(goods and/or services). Note

that we use

the

term consumer or end customer. The reason

is that in a Supply Chain

Management

approach,

we do not have to satisfy our

customers' needs but the

needs of our

customers'

customers' all the way to

the end customer, the consumer of a

product and/or

service.

258

Project

Management MGMT627

VU

Figure

35.1: Kodak's

Five Quality

Principles

Figure

35.2: The

Quality Improvement

Process

These

two figures (35.1 and

35.2) seem to illustrate

that organizations are

placing more emphasis on the

quality

process than on the quality

product and, therefore, are

actively pursuing quality

improvements

through

a continuous cycle.

35.3

QUALITY

AUDIT:

A

quality audit is an independent

evaluation performed by qualified

personnel that ensures

that

the

project is conforming to the project's

quality requirements and is following the

established

quality

procedures and policies.

A

good quality audit will

ensure that:

�

The

planned quality for the

project will be met.

�

The

products are safe and fit

for use.

�

All

pertinent laws and regulations are

followed.

�

Data

collection and distribution systems

are accurate and

adequate.

259

Project

Management MGMT627

VU

�

Proper

corrective action is taken

when required.

�

Improvement

opportunities are

identified.

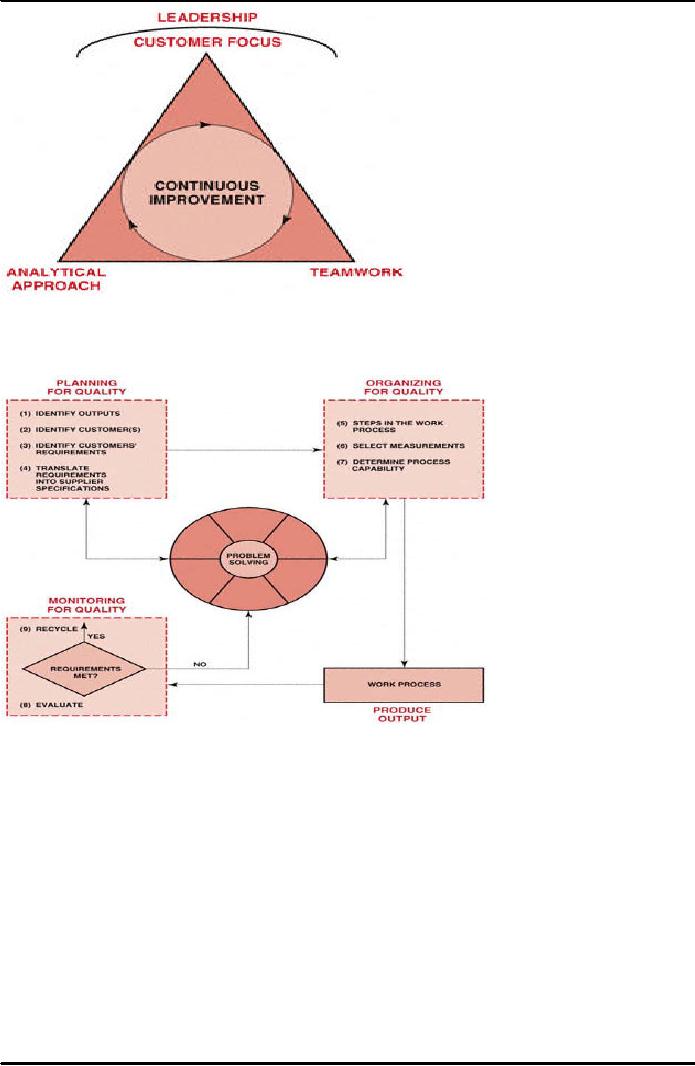

Figure

35.3: The

Result of Total Quality

35.4

DEMING'S

PHILOSOPHY:

Deming

postulated that 85 percent of all quality

problems required management to take

the

initiative

and change the process. Only 15 percent

of the quality problems could be

controlled

by

the workers on the floor. As an example,

the workers on the floor were

not at fault because

of

the poor quality of raw materials

that resulted from management's

decision to seek out

the

lowest

cost suppliers. Management had to change

the purchasing policies and

procedures.

Management

had to develop long-term relationships

with vendors.

�

Dr.

Deming's Dreadful

Diseases:

1.

Looking

elsewhere for examples, or concluding

that "our problems are

different.

2.

"Creative

accounting" rather than

"commitment"

3.

Purchasing

to an "acceptable level of

quality.

4.

Management's

failure to delegate

responsibility.

5.

That

employees cause all the problems.

6.

Quality

can be "assured by

inspection".

7.

False

starts: no organization-wide

commitment.

Although

many experts have contributed to the

success of the quality movement; the

three most

influential

contributors in this country and

internationally are W. Edwards Deming,

Joseph M.

Juran,

and Phillip B. Crosby. Dr.

Deming pioneered the use of

statistics and sampling

methods

from

1927 to 1940 at the U.S.

Department of agriculture. Dr.

Deming applied Dr.

Shewhart's

Plan/Do/Check/Act

cycle to clerical tasks.

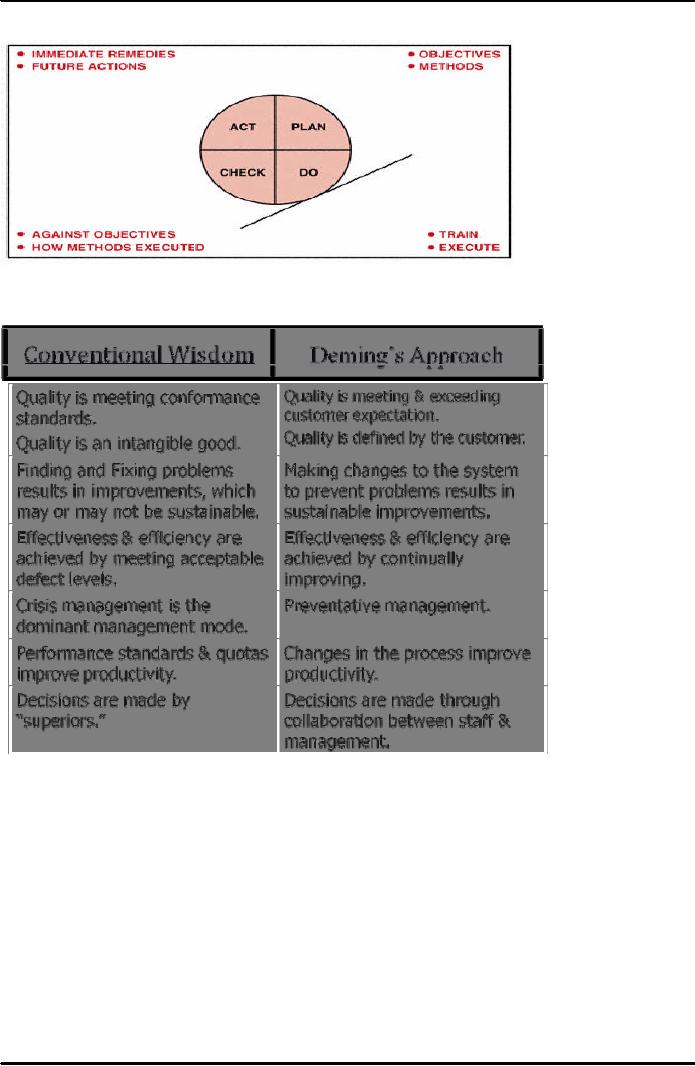

Figure 35.4 shows the Deming

Cycle for

Improvement.

Deming

contended that workers simply cannot do

their best. They had to be shown

what

constitutes

acceptable quality and that

continuous improvement is not

only possible, but

necessary.

For this to be accomplished, workers

had to be trained in the use of

statistical process

control

charts. Realizing that even

training required management's

approval, Deming's lectures

became

more and more focused toward management

and what they must

do.

260

Project

Management MGMT627

VU

Figure

35.4: The

Deming Cycle for

Improvement

Table

35.1

261

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles