|

Project

Management MGMT627

VU

LESSON

30

NETWORK

SCHEDULING TECHNIQUES

BROAD

CONTENTS

Estimating

Activity Time

Estimating

Total Program Time

Total

PERT/CPM Planning

Crash

Times

PERT/CPM

Problem Areas

Alternative

PERT/CPM Model

30.1

Estimating

Activity Time:

In

order to determine the elapsed

time between events requires that

responsible functional

managers

evaluate the situation and

submit their best estimates.

The calculations for

critical

paths

and slack times in the previous sections

were based on these best

estimates.

Thus,

in this ideal situation, the

functional manager would have at

his disposal a large

volume

of

historical data from which

to make his estimates.

Obviously, the more historical

data

available,

the more reliable the estimate would

be. Many programs, however,

include events

and

activities that are

non-repetitive.

In

this case, the functional

managers must submit their

estimates using three possible

completion

assumptions:

�

Most

optimistic completion

time:

This

time assumes that everything

will go according to plan and

with a minimal amount of

difficulties.

This should occur approximately 1 percent

of the time.

�

Most

pessimistic completion

time:

This

time assumes that everything

will not go according to

plan and that the

maximum

potential

difficulties will develop.

This should also occur

approximately 1 percent of the

time.

�

Most

likely completion time:

This

is the time that, in the mind of the

functional manager, would most

often occur should

this

effort be reported over and

over again.

Two

assumptions must be made

before these three times can be

combined into a

single

expression

for expected time. The first

assumption is that the standard

deviation, , is one-sixth

of

the time requirement range. This

assumption stems from probability

theory, where the end

points

of a curve are three standard

deviations from the mean.

The second assumption requires

that

the probability distribution of time

required for an activity be expressible

as a beta

distribution.

The

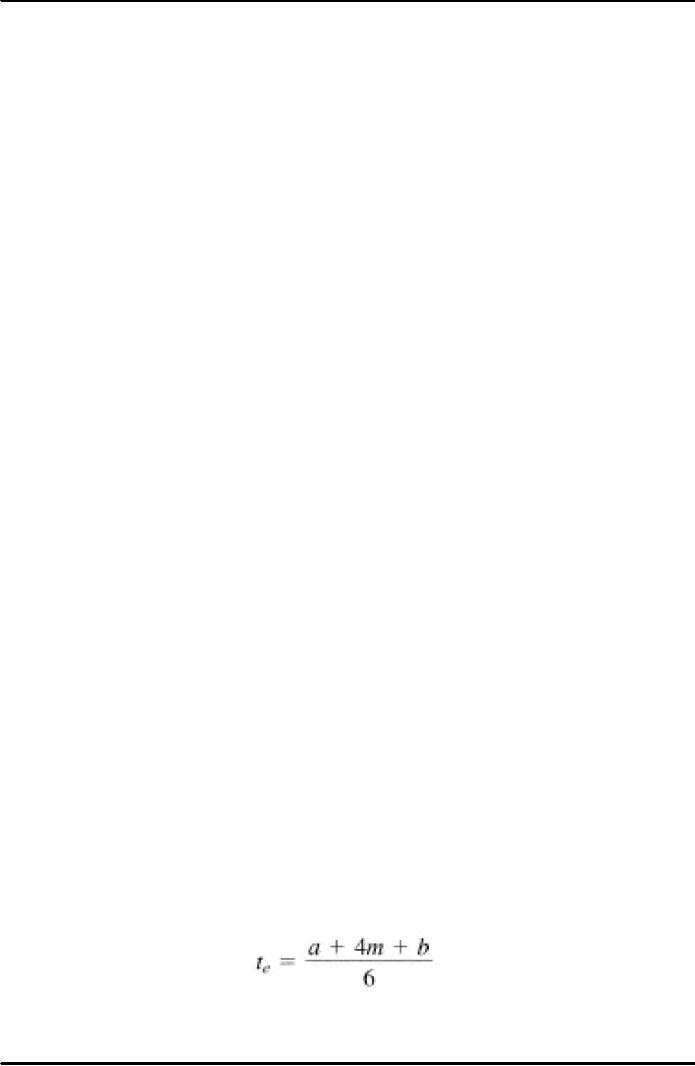

expected time between events can be

found from the expression:

In

this, te

=

expected time, a

=

most optimistic time,

b

=

most pessimistic time, and m =

most

likely

time.

213

Project

Management MGMT627

VU

Here

we take an example. If a

=

3, b

=

7, and m

=

5 weeks, then the expected time,

te,

would be

5

weeks. This value for

te

would

then be used as the activity

time between two events in

the

construction

of a PERT chart. This method for

obtaining best estimates contains a

large degree

of

uncertainty. If we change the variable

times to a

=

2, b

=

12, and m

=

4 weeks, then te

will

still

be 5 weeks. The latter case,

however, has a much higher

degree of uncertainty because

of

the

wider spread between the optimistic

and pessimistic times. Care must be

taken in the

evaluation

of risks in the expected times.

30.2

Estimating

Total Program

Time:

It

is important to know that in

order to calculate the probability of

completing the project on

time,

the standard deviations of each

activity must be known. This

can be found from

the

expression:

is

the standard deviation of the expected

time, te.

Another useful expression is the

Where

variance,

, which is the square of the

standard deviation. The

variance is primarily useful

for

comparison

to the expected values.

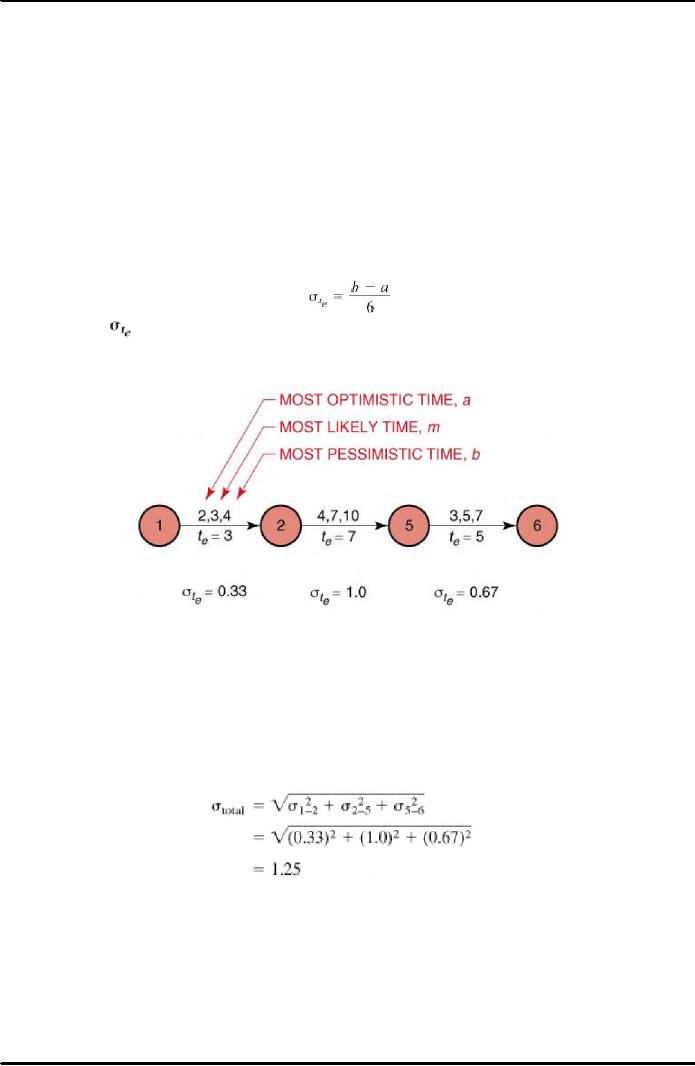

Figure

30.1: Expected

Time Analysis for Critical

Path Events in Figure 29.1

(Lecture 29)

However,

the standard deviation can be

used just as easily, except

that we must identify

whether

it

is a one, two, or three sigma limit

deviation. Figure 30.1 above

shows the critical path

of

Figure

29.1 (lecture 29), together

with the corresponding values from

which the expected times

were

calculated, as well as the standard

deviations. The total path

standard deviation is

calculated

by the square root of the sum of the

squares of the activity standard

deviations using

the

following expression:

30.3

Total

PERT/CPM Planning:

It

is necessary to discuss the methodology

for preparing PERT

schedules, before we

continue

further.

PERT scheduling is a six-step

process.

Steps

one and two begin with the

project manager laying out a

list of activities to be

performed

and

then placing these

activities in order of precedence,

thus identifying the

interrelationships.

These

charts drawn by the project

manager are called logic

charts, arrow diagrams, work

flow,

214

Project

Management MGMT627

VU

or

simply networks. The arrow

diagrams will look like

Figure 29.1 (lecture 29)

with two

exceptions:

The activity time is not

identified, and neither is the critical

path.

The

next step that is step three

is reviewing the arrow diagrams

with the line managers (that

is,

the

true experts) in order to obtain

their assurance that neither

too many nor too

few activities

are

identified, and that the

interrelationships are correct.

In

step four, the functional

manager converts the arrow

diagram to a PERT chart by

identifying

the

time duration for each

activity. It should be noted

here that the time estimates

that the line

managers

provide are based on the

assumption

of unlimited resources because

the calendar

dates

have not yet been

defined.

Fifth

step is the first iteration on the

critical path. It is here

that the project manager

looks at the

critical

calendar dates in the definition of the project's

requirements. If the critical path does

not

satisfy

the calendar requirements, then the project

manager must try to shorten the

critical path

using

methods explained earlier or by

asking the line managers to

take the ''fat" out of

their

estimates.

Step

six is often the most

overlooked step. Here the

project manager places calendar

dates on

each

event in the PERT chart, thus, converting

from planning under

unlimited resources to

planning

with limited

resources.

Even though the line manager

has given you a time

estimate,

there

is no guarantee that the correct

resources will be available

when needed. That is why

this

step

is crucial. If the line manager cannot

commit to the calendar dates, then

replanning will be

necessary.

Most companies that survive

on competitive bidding lay

out proposal

schedules

based

on unlimited resources. After contract

award, the schedules are analyzed

again because

the

company now has limited

resources.

The

question arises that after

all, how can a company bid

on three contracts simultaneously

and

put

a detailed schedule into

each proposal if it is not

sure how many contracts, if

any, it will

win?

For this reason customers

require that formal project

plans and schedules be provided

thirty

to ninety days after contract

award.

Finally,

PERT re-planning should be an ongoing

function during project

execution. The best

project

managers are those

individuals who continually

try to assess what can go

wrong and

perform

perturbation analysis on the schedule.

(This should be obvious

because the constraints

and

objectives of the project can

change during execution.)

Primary objectives on a

schedule

are:

�

Best

time

�

Least

cost

�

Least

risk

In

addition to this, the secondary

objectives include:

�

Studying

alternatives

�

Optimum

schedules

�

Effective

use of resources

�

Communications

�

Refinement

of the estimating process

�

Ease

of project control

�

Ease

of time or cost

revisions

It

is quite obvious that these

objectives are limited by

such constraints as:

�

Calendar

completion

215

Project

Management MGMT627

VU

�

Cash

or cash flow

restrictions

�

Limited

resources

�

Management

approvals

30.4

Crash

Times:

So

far no distinction was made

between PERT and CPM. The

basic difference between PERT

and

CPM lies in the ability to calculate

percent complete. PERT is used in Research

and

Development

or just development activities, where a

percent-complete determination is almost

impossible.

Therefore,

PERT is event oriented rather than

activity oriented. In PERT,

funding is normally

provided

for each milestone (i.e.,

event) achieved because incremental

funding along the

activity

line has to be based on percent complete.

CPM, on the other hand, is activity

oriented

because,

in activities such as construction,

percent complete along the activity line

can be

determined.

CPM can be used as an arrow

diagram network without

PERT. The difference

between

the two methods lies in the

environments in which each one

evolved and how each

one

is

applied.

In

addition, the CPM (activity-type

network) has been widely

used in the process industries,

in

construction,

and in single-project industrial

activities. Common problems include no place

to

store

early arrivals of raw materials and

project delays for late

arrivals.

Project

managers can consider the cost of

speeding up, or crashing, certain phases

of a project

using

strictly the CPM approach. In order to

accomplish this, it is necessary to calculate

a

crashing

cost per unit time as well

as the normal expected time

for each activity. CPM

charts,

which

are closely related to PERT

charts, allow visual representation of

the effects of crashing.

There

are these following

requirements:

�

For

a CPM chart, the emphasis is on

activities, not events.

Therefore, the PERT chart

should

be redrawn with each circle

representing an activity rather than an

event.

�

In

CPM, both time and

cost of each activity are

considered.

�

Only

those activities on the critical

path are considered, starting

with the activities for

which

the

crashing cost per unit time is the

lowest.

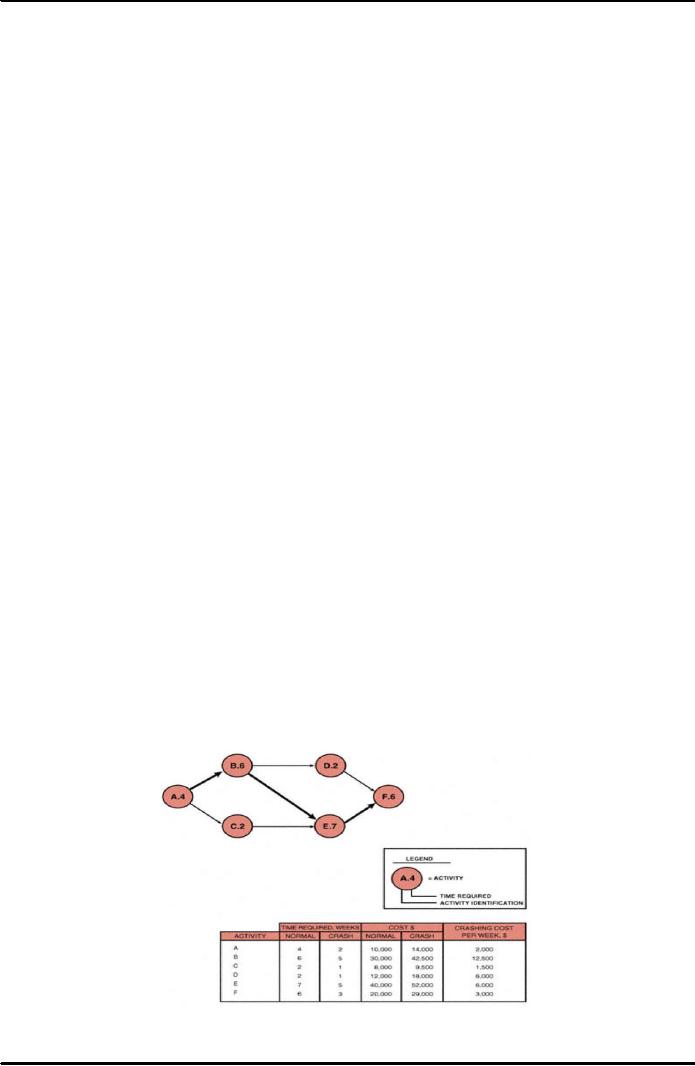

The

following Figure 30.2 below

shows a CPM network with the

corresponding crash time

for

all

activities both on and off the

critical path. The

activities are represented by circles

and

include

an activity identification number and the estimated

time. The costs expressed in

it are

usually

direct costs only.

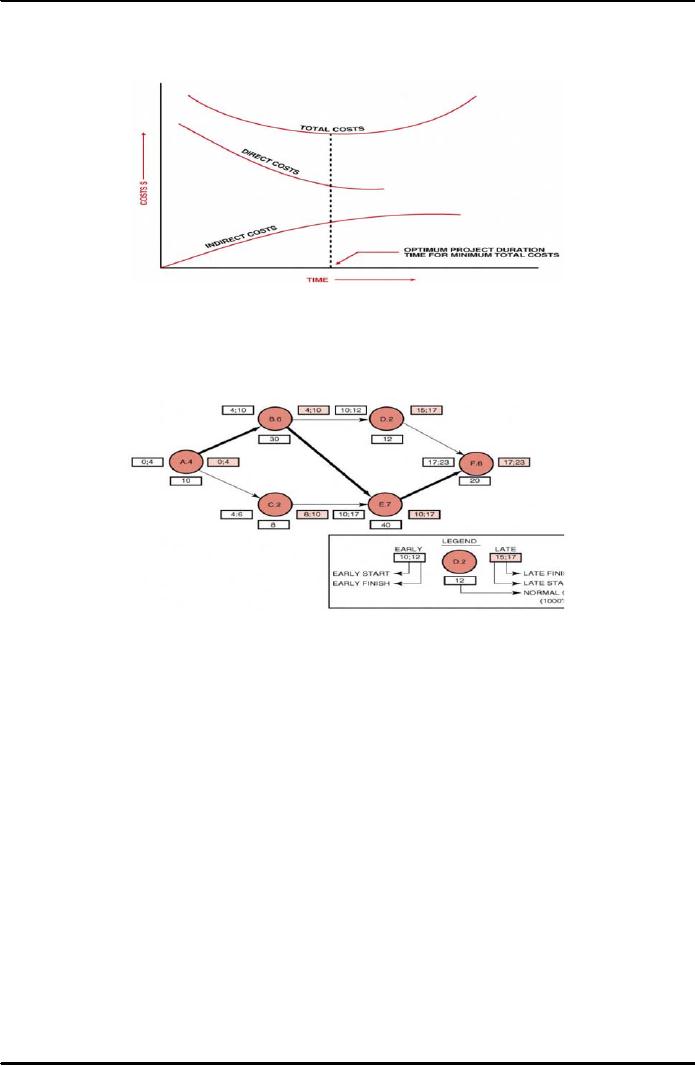

Figure

30.2: CPM

Network

216

Project

Management MGMT627

VU

As

shown in the figure 30.2, in order to

determine crashing costs we begin

with the lowest

weekly

crashing cost, activity A, at $2,000 per

week. Although activity C

has a lower crashing

cost,

it is not on the critical path.

Only critical path

activities are considered for

crashing.

Activity

A will be the first to be crashed

for a maximum of two weeks

at $2,000 per week.

The

next

activity to be considered would be F at

$3,000 per week for a

maximum of three weeks.

These

crashing costs are additional

expenses above the normal

estimates.

It

is important to remember a word of

caution concerning the selection and

order of the

activities

that are to crash: There is

a good possibility that as

each activity is crashed, a

new

critical

path will be developed. This

new path may or may

not include those elements

that were

bypassed

because they were not on the

original critical

path.

In

the same Figure 30.2 (and

assuming that no new

critical paths are

developed), activities A, F,

E,

and B would be crashed in that

order. The crashing cost

would then be an increase

of

$37,500

from the base of $120,000 to

$157,500. The corresponding

time would then be

reduced

from

twenty-three weeks to fifteen

weeks. This is shown in Figure

30.3 below to illustrate

how

a

trade-off between time and

cost can be obtained. Also

shown in it is the increased cost

of

crashing

elements not on the critical

path.

Figure

30.3: CPM

Crashing Costs

Crashing

these elements would result

in a cost increase of $7,500

without reducing the

total

project

time. There is also the

possibility that this figure

will represent unrealistic

conditions

because

sufficient resources are not

or cannot be made available for the

crashing period.

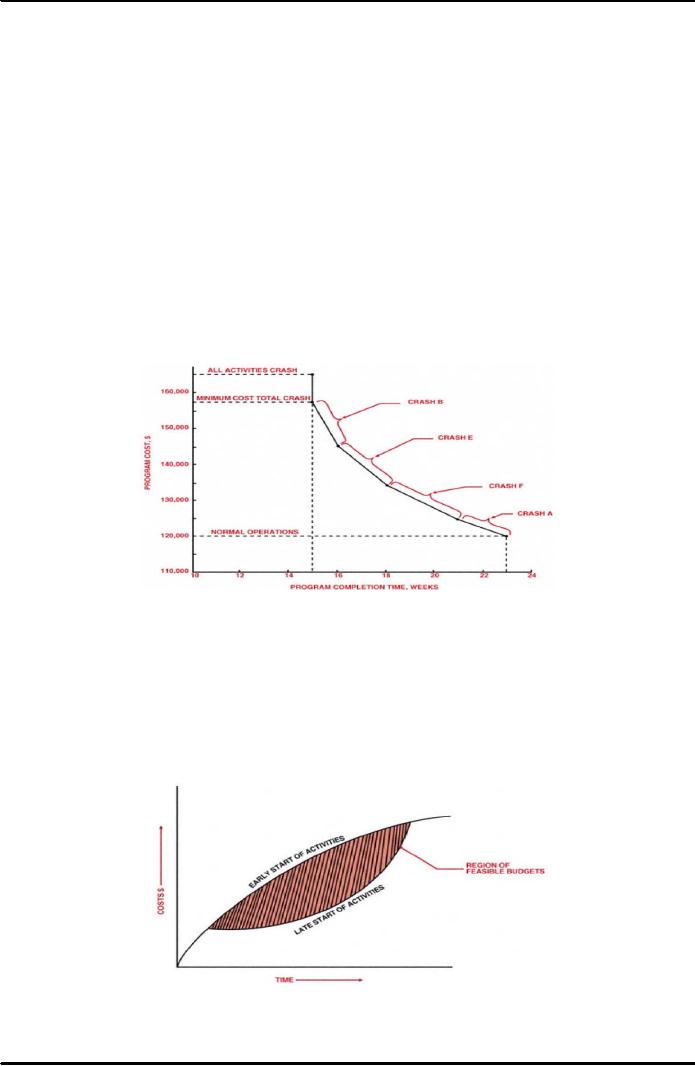

Importantly,

the purpose behind balancing

time and cost is to avoid

the useless waste of

resources.

If the direct and indirect

costs can be accurately obtained,

then a region of

feasible

budgets

can be found, bounded by the

early-start (crash) and late-start (or

normal) activities.

This

is shown in Figure 30.4

below.

Figure

30.4: Region

of Feasible Budgets

217

Project

Management MGMT627

VU

Since

the direct and indirect costs

are not necessarily expressible as linear

functions, timecost

trade-off

relationships are made by

searching for the lowest possible

total cost (that is,

direct

and

indirect) that likewise satisfies

the region of feasible budgets.

This method is shown in

Figure

30.5 below.

Figure

30.5: Determining

Project Duration

Note

that like PERT, CPM

also contains the concept of slack time,

the maximum amount of

time

that a job may be delayed

beyond its early start

without delaying the project

completion

time.

Figure 30.6 below shows a

typical representation of slack time

using a CPM chart.

Figure

30.6: CPM

Network with Slack

This

figure also shows how

target activity costs can be

identified. It can be modified to

include

normal

and crash times as well as normal and

crash costs. In this case,

the cost box in the

figure

would

contain two numbers: The

first number would be the normal

cost, and the second

would

be

the crash cost. These

numbers might also appear as

running totals.

30.5

PERT/CPM

Problem Areas:

Even

the largest organizations with years of

experience in using PERT and CPM have the

same

ongoing

problems as newer or smaller companies. Thus, PERT/CPM

models are not

without

their

disadvantages and problems.

Due

to its characteristics, many

companies have a difficult time

incorporating PERT systems

because

PERT is end-item oriented.

Many upper-level managers

feel that the adoption

of

PERT/CPM

remove a good part of their

power and ability to make decisions.

This is

particularly

evident in companies that have

been forced to accept

PERT/CPM as part of

contractual

requirements.

In

addition to this, there exists a distinct

contrast in PERT systems between the planners

and the

doers.

This human element must be accounted

for in order to determine where the

obligation

actually

lies. In most organizations

PERT planning is performed by the

program office and

functional

management. Yet once the

network is constructed, the planners and

managers

become

observers and rely on the

doers to accomplish the job within

time and cost

limitations.

218

Project

Management MGMT627

VU

Management

must convince the doers that

they have an obligation toward the

successful

completion

of the established PERT/CPM plans.

It

is important to note that

unless the project is repetitive, there

usually exists a lack of

historical

information

on which to base the cost

estimates of most optimistic,

most pessimistic, and most

likely

times. Problems can also involve

poor predictions for overhead

costs, other indirect

costs,

material

and labor escalation factors, and

crash costs. It is also possible

that each major

functional

division of the organization has

its own method for

estimating costs. Engineering,

for

example,

may use historical data,

whereas manufacturing operations may

prefer learning

curves.

PERT

works best if all

organizations have the same method for

predicting costs and

performance.

PERT

networks are based on the

assumption that all

activities start as soon as possible.

This

assumes

that qualified personnel and

equipment are available.

Regardless of how well we

plan,

there

almost always exist differences in

performance times from what would

normally be

acceptable

for the model selected. For

the selected model, time and

cost should be well-

considered

estimates, not a spur-of-the-moment

decision.

Another

problem is that of cost

control. It presents a problem in

that the project cost and

control

system

may not be compatible with

company fiscal planning policies.

Project-oriented costs

may

be meshed with non-PERT-controlled

jobs in order to develop the

annual budget. This

becomes

a difficult chore for cost

reporting, especially when

each project may have its

own

method

for analyzing and controlling

costs.

Furthermore,

many people have come to expect

too much of PERT -type

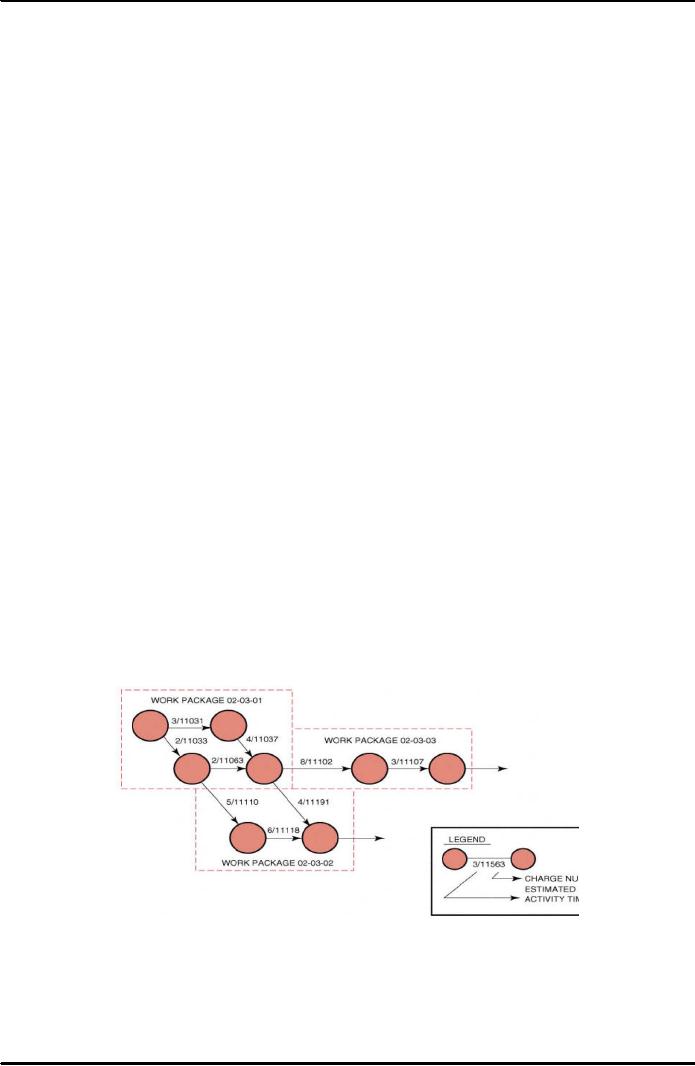

networks. Figure 30.7

below

illustrates a PERT/CPM network

broken down by work packages

with identification of

the

charge numbers for each

activity. Large projects may

contain hundreds of charge

numbers.

Subdividing

work packages (which are

supposedly the lowest element) even further

by

identifying

all sub activities has the

advantage that direct charge

numbers can be easily

identified,

but the time and cost for

this form of detail may be

prohibitive. PERT/CPM

networks

are

tools for program control,

and managers must be careful

that the original game plan

of using

networks

to identify prime and supporting

objectives is still met.

Additional detail may

mask

this

all-important purpose. Remember, networks

are constructed as a means for

understanding

program

reports. Management should not be

required to read reports in order to

understand

PERT/CPM

networks.

Figure

30.7: Using

PERT for Work Package

Control

30.6

Alternative

PERT/CPM Models:

Numerous

industries have found applications

for this form of network,

because of the many

advantages

of PERT/time. A partial list of

these advantages includes

capabilities for:

219

Project

Management MGMT627

VU

�

Trade-off

studies for resource

control

�

Providing

contingency planning in the early

stages of the project

�

Visually

tracking up-to-date performance

�

Demonstrating

integrated planning

�

Providing

visibility down through the

lowest levels of the work

breakdown structure

�

Providing

a regimented structure for control

purposes to ensure compliance

with the work

breakdown

structure and the statement of

work

�

Increasing

functional members' ability to

relate to the total program, thus,

providing

participants

with a sense of

belonging

Remember

that even with these

advantages, in many situations

PERT/time has proved

ineffective

in controlling resources. Earlier we have

defined three parameters necessary

for the

control

of resources: time, cost, and

performance. With these factors in mind,

companies began

reconstructing

PERT/time into PERT/cost and

PERT/performance models.

In

addition, PERT/cost is an extension of

PERT/time and attempts to overcome the

problems

associated

with the use of the most

optimistic and most pessimistic time

for estimating

completion.

PERT/cost can be regarded as a cost

accounting network model

based on the work

breakdown

structure and capable of being subdivided

down to the lowest elements, or

work

packages.

The advantages of PERT/cost are

that it:

�

Contains

all the features of

PERT/time

�

Permits

cost control at any Work

Breakdown Structure (WBS)

level

Note

that the primary reason for

the development of PERT/cost was so that

project managers

could

identify critical schedule slippages

and cost overruns in time

for corrective action to

be

taken.

In

this regard, many attempts have

been made to develop

effective PERT/schedule models. In

almost

all cases, the charts are

constructed from left to right. An

example of such

current

attempts

is the Accomplishment/Cost

Procedure (ACP).

Summing

up our discussion, unfortunately, the

development of PERT/schedule techniques is

still

in its infancy. Although

their applications have been

identified, many companies

feel

locked

in with their present method of

control, whether it is PERT,

CPM, or some other

technique.

220

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles