|

Project

Management MGMT627

VU

LESSON

29

NETWORK

SCHEDULING TECHNIQUES

BROAD

CONTENTS

Slack

Terminology

Slack

Time Calculation

Slack

Identification

Network

Re-planning

29.1

Slack

Terminology:

Slack

can be defined as the difference between

the latest allowable date and the

earliest

expected

data based on the nomenclature

below:

TE

=

the earliest time (date) on which an

event can be expected to take

place

TL

=

the latest date on which an event

can take place without

extending the completion date

of

the

project

Slack

time = TL

TE

29.2

Slack

Time Calculation:

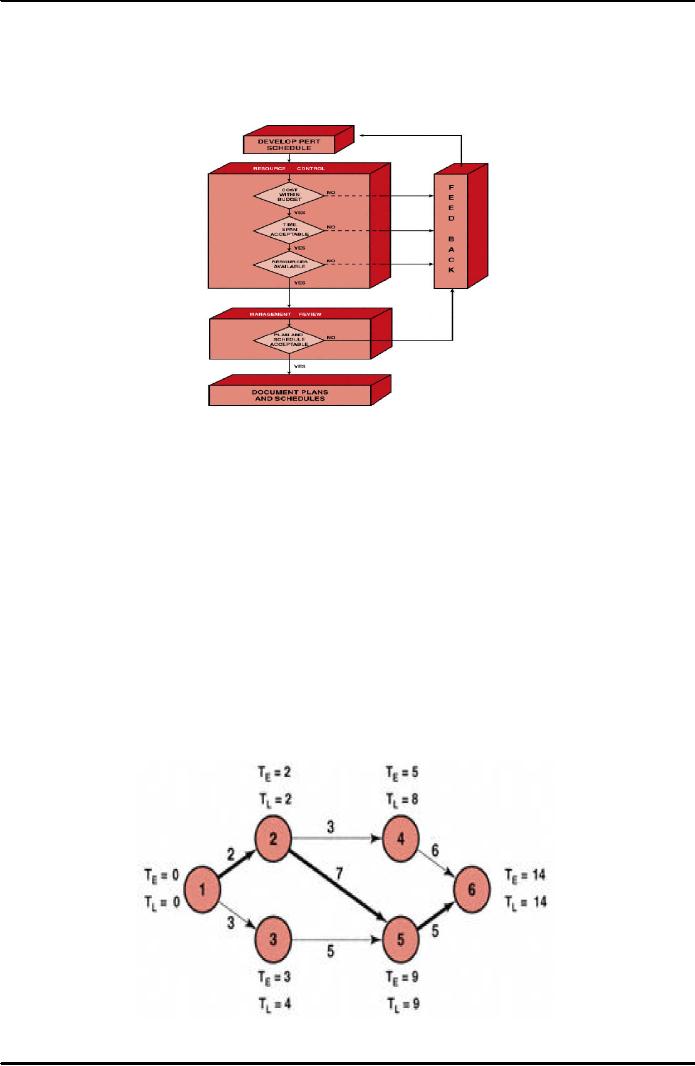

As

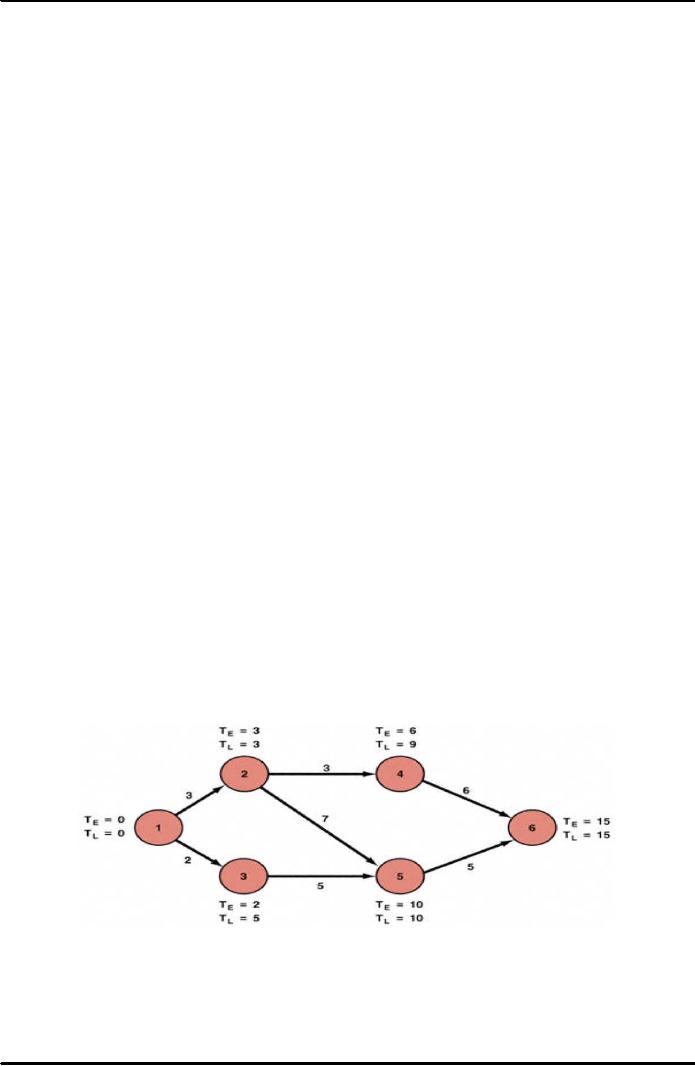

shown in Figure 29.1 below, the

calculation for slack time is

performed for each event in

the

network,

by identifying the earliest expected date

and the latest starting date.

For event 1, TL

TE

=

0. Event 1 serves as the reference point

for the network and could

just as easily have

been

defined

as a calendar date. As before, the

critical path is represented as a

bold line. The

events

on

the critical path have no slack (i.e.,

TL

=

TE)

and provide the boundaries for the

non-critical

path

events. Since event 2 is critical,

TL

=

TE

�

3 + 7 = 10 for event 5. Event 6

terminates the

critical

path with a completion time

of fifteen weeks.

The

earliest time for event 3,

which is not on the critical

path, would be two weeks

(TE

=

0 + 2

=

2), assuming that it started

as early as possible. The latest

allowable date is obtained

by

subtracting

the time required to complete the

activity from events 3 to 5

from the latest starting

date

of event 5.

Figure

29.1: PERT

Network with Slack

Time

Therefore,

TL

(for

event 3) = 10 5 = 5 weeks. Event 3

can now occur anywhere

between

weeks

2 and 5 without interfering with the

scheduled completion date of the

project. This same

procedure

can be applied to event 4, in

which case TE

=

6 and TL

=

9.

205

Project

Management MGMT627

VU

The

same figure 29.1 contains a

simple PERT network, and

therefore the calculation of slack

time

is not too difficult. For

complex networks containing

multiple paths, the earliest

starting

dates

must be found by proceeding

from start to finish through

the network, while the latest

allowable

starting date must be calculated by

working backward from finish

to start.

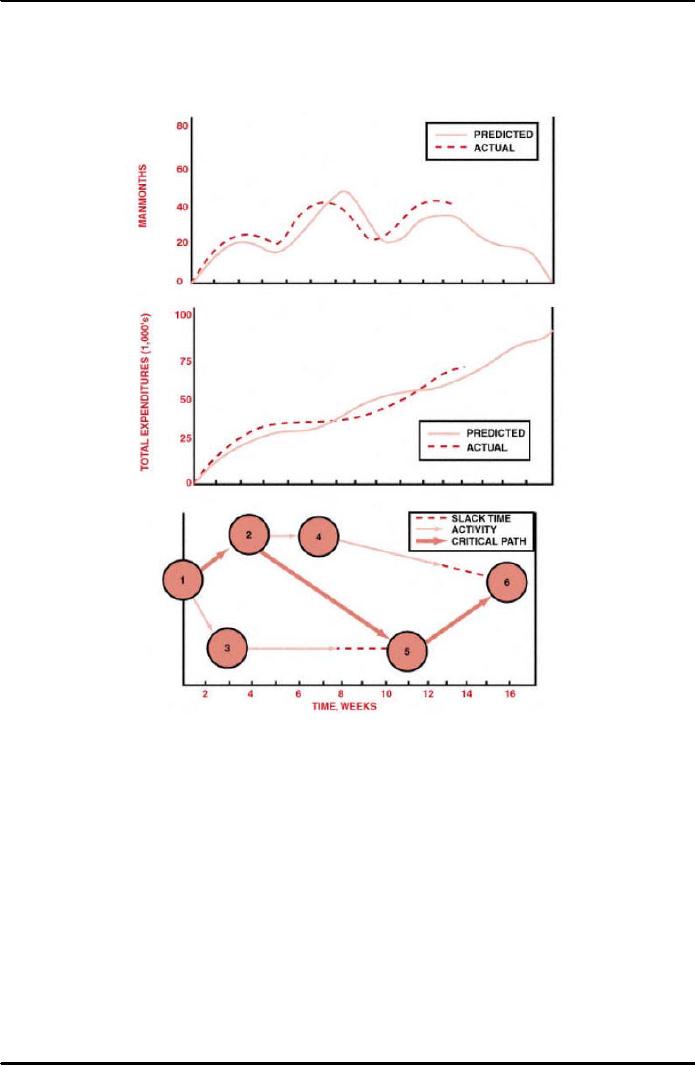

Figure

29.2: Comparison

Models for a Time- Phase

PERT Chart

We

must understand that the importance of

knowing exactly where the slack exists cannot

be

overstated.

Proper use of slack time permits better

technical performance. Donald Marquis

has

observed

that those companies making

proper use of slack time were 30 percent

more

successful

than the average in completing

technical requirements.

PERT

networks are often not

plotted with a time scale,

because of these slack times.

Planning

requirements,

however, can require that

PERT charts be reconstructed with time

scales, in

which

case a decision must be made

as to whether we wish early or

late time requirements

for

slack

variables. This is shown in Figure

29.2 above for comparison with

total program costs

and

manpower

planning. Early time requirements

for slack variables are

utilized in this

figure.

Note

that the earliest times and late times

can be combined to determine the

probability of

successfully

meeting the schedule. A sample of the

required information is shown in Table

29.1

below.

The earliest and latest times are considered as random

variables. The original

schedule

refers

to the schedule for event

occurrences that were established at the

beginning of the project.

206

Project

Management MGMT627

VU

The

last column in this table

gives the probability that the earliest

time will not be greater

than

the

original schedule time for

this event.

Table

29.1: PERT

Control Output

Information

In

the example shown in Figure 29.1, the

earliest and latest times were calculated for

each

event.

Some people prefer to calculate the

earliest and latest times for each

activity instead.

Also,

the earliest and latest times were identified

simply as the time or date

when an event can

be

expected to take place. To make full

use of the capabilities of PERT/CPM, we

could identify

the

following four

values:

�

The

earliest time when an activity

can start (ES)

�

The

earliest time when an activity

can finish (EF)

�

The

latest time when an activity

can start (LS)

�

The

latest time when an activity

can finish (LF)

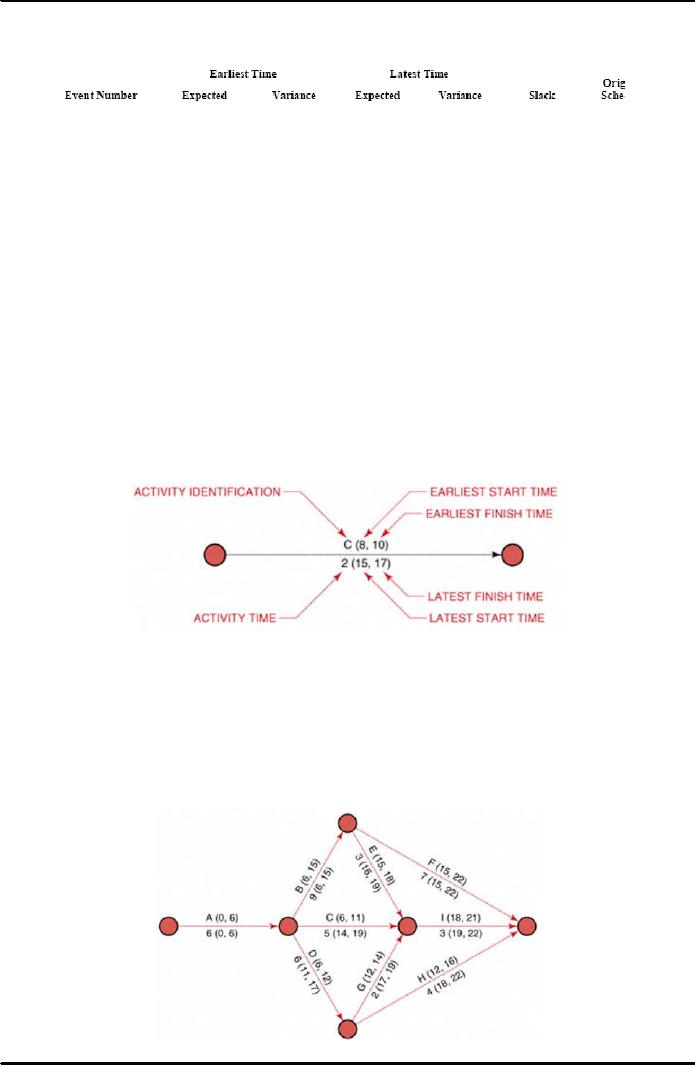

The

following Figure 29.3 below

shows the earliest and latest times identified on the

activity.

In

order to calculate the earliest starting times, we

must make a forward pass

through the

network

(that is, left to right).

The earliest starting time of a

successor activity is the latest of

the

earliest

finish dates of the predecessors.

The latest starting time is the

total of the earliest

starting

time and the activity

duration.

Figure

29.3: Slack

Identification

It

is important to note that to calculate

the finishing times we must make a

backward

pass

through

the network by calculating the latest

finish time. Since the activity

time is known, the

latest

starting time can be calculated by

subtracting the activity time

from the latest finishing

time.

The latest finishing time

for an activity entering a node is the

earliest finishing time of

the

activities

exiting the node.

Figure

29.4 below shows the earliest

and latest starting and

finishing times for a

typical

network.

Figure

29.4: A

Typical PERT Chart with

Slack Times

207

Project

Management MGMT627

VU

29.3

Slack

Identification:

Its

significance is that the identification

of slack time can function as an

early warning system

for

the project manager. As an example, if the

total slack time available begins to

decrease from

one

reporting period to the next,

that could indicate that

work is taking longer than

anticipated

or

that more highly skilled

labor is needed. A new

critical path could be

forming.

By

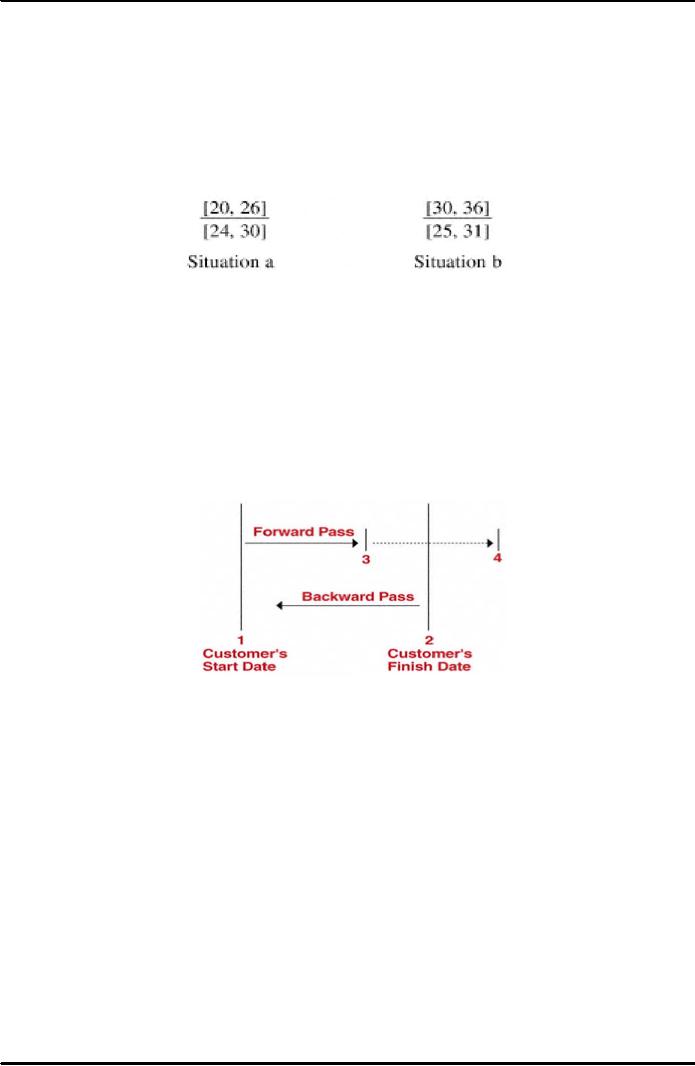

looking at the earliest and latest start

and finish times, we can

identify slack. As an example,

look

at the two situations

below:

According

to these, in Situation

a,

the slack is easily identified as four

work units, where the

work

units can be expressed in hours,

days, weeks, or even months. In Situation

b,

the slack is

negative

five

units of work. This is

referred to as negative slack or negative

float.

Here

the question arises, what

can cause the slack to be negative?

Look at Figure 29.5

below.

When

performing a forward pass

through a network, we work

from left to right beginning

at the

customer's

starting milestone (position

1). The backward pass,

however, begins at the

customer's

end date milestone (position

2), not

(as

is often taught in the classroom) where

the

forward

pass ends. If the forward

pass ends at position 3,

which is before the customer's end

date,

it is possible to have slack on the critical

path.

Figure

29.5: Slack

Time

This

slack is often called reserve

time and

may be added to other

activities or filled

with

activities

such as report writing so

that the forward pass will

extend to the customer's

completion

date.

Note

that negative slack usually

occurs when the forward pass

extends beyond the

customer's

end

date, as shown by position 4 in the figure.

However, the backward pass is

still measured

from

the customer's completion date,

thus creating negative slack.

This is most likely to

result

when:

�

The

original plan was highly

optimistic, but

unrealistic

�

The

customer's end date was

unrealistic

�

One

or more activities slipped during

project execution

�

The

assigned resources did not

possess the correct skill

levels

�

The

required resources would not

be available until a later

date

In

any event, negative slack is an

early warning indicator that

corrective action is needed

to

maintain

the customer's end date.

208

Project

Management MGMT627

VU

29.4

Network

Re-planning:

We

know that once constructed, the

PERT/CPM charts provide the

framework from which

detailed

planning can be initiated and

costs can be controlled and

tracked. Much

iteration,

however,

are normally made during the

planning phase before the

PERT/CPM chart is finished.

Figure

29.6: Iteration

Process for PERT Schedule

Development

This

iteration process is shown in the Figure

29.6 above. The slack times form the

basis from

which

additional iterations, or network

replanning, can be performed.

Network replanning is

performed

either at the conception of the program

in order to reduce the length of the

critical

path,

or during the program, should the

unexpected occur. If all were to go

according to

schedule,

then the original PERT/CPM chart

would be unchanged for the duration of

the

project.

But, how many programs or

projects follow an exact schedule from

start to finish?

Let

us again consider Figure 29.1.

Suppose that activities

12 and 13 in it require

manpower

from

the same functional unit.

Upon inquiry by the project manager, the

functional manager

asserts

that he can reduce activity

12 by one week if he

shifts resources from

activity 13 to

activity

12. Should this happen,

however, activity 13

will increase in length by one

week.

Reconstructing

the PERT/CPM network as shown in Figure

29.7 below, the length of

the

critical

path is reduced by one week, and the

corresponding slack events are

likewise changed.

Figure

29.7: Network

Replanning of Figure

29.1

209

Project

Management MGMT627

VU

29.4.1

Network Replanning Techniques:

There

are two network replanning

techniques based almost entirely upon

resources:

resource

leveling and resource

allocation.

�

Resource

leveling is an attempt to eliminate the manpower

peaks and valleys by

smoothing

out the period-to-period resource

requirements. The ideal situation is

to

do

this without changing the end date.

However, in reality, the end date

moves out

and

additional costs are

incurred.

�

Resource

allocation is an attempt to find the

shortest possible critical path

based

upon

the available or fixed resources.

The problem with this

approach is that the

employees

may not be qualified

technically to perform on more than

one activity in

a

network.

Not

all PERT/CPM networks permit

such easy rescheduling of

resources. Project

managers

should make every attempt to reallocate

resources so as to reduce the

critical

path,

provided that the slack was

not intentionally planned as a safety

valve.

It

is important to note here

that transferring resources

from slack paths to more

critical

paths

is only one method for reducing expected

project time. Several other

methods are

available.

These are as follows:

�

Elimination

of some parts of the

project

�

Addition

of more resources

�

Substitution

of less time-consuming components or

activities

�

Parallelization

of activities

�

Shortening

critical path

activities

�

Shortening

early activities

�

Shortening

longest activities

�

Shortening

easiest activities

�

Shortening

activities that are least

costly to speed up

�

Shortening

activities for which you

have more resources

�

Increasing

the number of work hours per day

In

this regard, under the ideal

situation, the project start and end

dates are fixed, and

performance

within this time scale

must be completed within the

guidelines described

by

the statement of work. Should the

scope of effort have to be reduced in

order to meet

other

requirements, the contractor incurs a serious

risk in that the project may

be

canceled,

or performance expectations may no longer be

possible.

However,

adding resources is not

always possible. If the activities

requiring these added

resources

also call for certain

expertise, then the contractor may

not have qualified or

experienced

employees, and may avoid the risk.

The contractor might still

reject this

idea,

even if time and money were

available for training new

employees, because on

project

termination he might not have

any other projects to which to

assign these

additional

people. However, if the project is the

construction of a new facility,

then the

labor-union

pool may be large enough

that additional experienced manpower can

be

hired.

Another

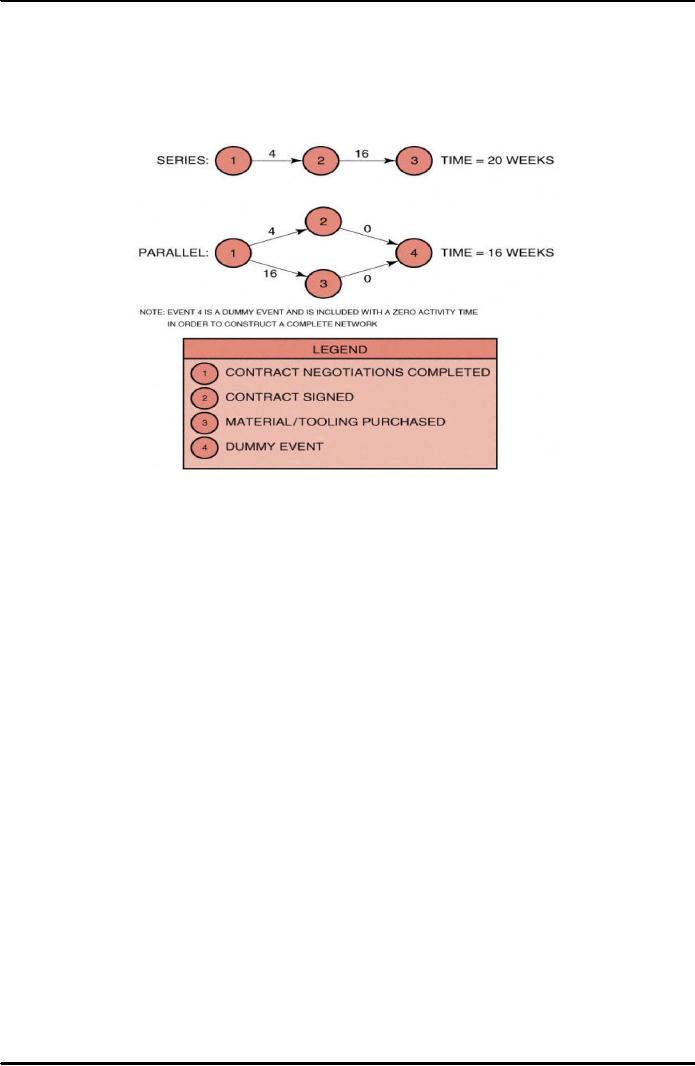

aspect is parallelization of activities.

It can be regarded as accepting a risk

by

assuming

that a certain event can

begin in parallel with a

second event that

would

normally

be in sequence with it. This

is shown in Figure 29.8 below.

One of the biggest

headaches

at the beginning of any project is the

purchasing of tooling and

raw

materials.

As shown in Figure below, four

weeks can be saved by sending

out purchase

210

Project

Management MGMT627

VU

orders

after contract negotiations are

completed, but before the one-month

waiting

period

necessary to sign the contract. Here the

contractor incurs a risk. Should the

effort

be

canceled or the statement of work

change prior to the signing of the

contract, the

customer

incurs the cost of the termination

liability expenses from the vendors.

This

risk

is normally overcome by the issuance of a

long-lead procurement letter

immediately

following contract negotiations.

Figure

29.8: Parallelization

of PERT Activities

In

addition to this, there are

two other types of risk that

are common. In the first

situation,

engineering has not yet

finished the prototype, and manufacturing

must order

the

tooling in order to keep the end date

fixed. In this case,

engineering may

finally

design

the prototype to fit the

tooling.

In

the second situation, the subcontractor

finds it difficult to perform

according to the

original

blueprints. In order to save

time, the customer may allow

the contractor to work

without

blueprints, and the blueprints are

then changed to represent the

as-built end-

item.

As

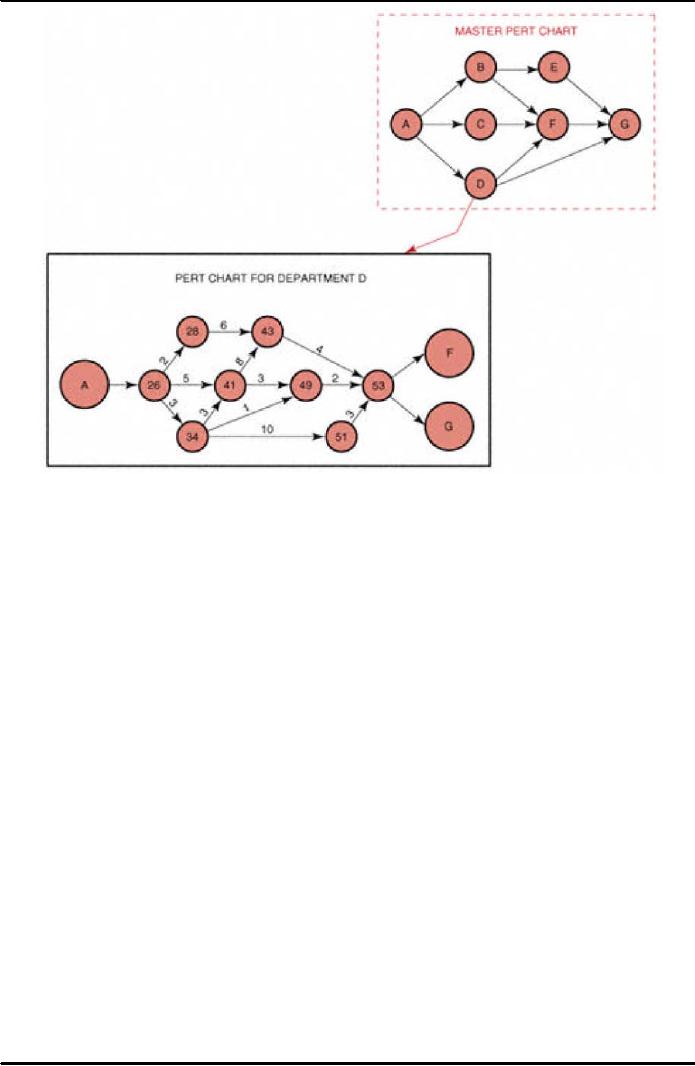

a result of the complexities of large

programs, network re-planning becomes

an

almost

impossible task when

analyzed on total program

activities. It is often better

to

have

each department or division that develops

its own PERT/CPM networks,

on

approval

by the project office, and based on the

work breakdown structure.

The

individual

PERT charts are then

integrated into one master chart to

identify total

program

critical paths, as shown in Figure

29.9 below. It should not be

inferred from

this

figure that department D does

not interact with other

departments or that

department

D is the only participant for

this element of the project.

In

addition, segmented PERT

charts can also be used

when a number of contractors

work

on the same program.

Each

contractor (or subcontractor) develops his

own PERT chart. It then

becomes the

responsibility

of the prime contractor to integrate

all of the subcontractors' PERT

charts

to

ensure that total program

requirements can be met.

211

Project

Management MGMT627

VU

Figure

29.9: Master

PERT chart breakdown by department

212

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles