|

Production

and Operations Management

MGT613

VU

Lesson

05

Productivity

Productivity

is a measure of the effective use of

resources, usually expressed as the

ratio of output to

input

.Also called Efficiency at

times

�Productivity

ratios are used

for

Planning

workforce requirements

Scheduling

equipment

Financial

analysis

Productivity

Partial

measures is output/(single

input)

Multi-factor

measures is output/(multiple

inputs)

Total

measure is the output/(total

inputs)

Productivity

Growth = Current

Period Productivity Previous

Period Productivity

Previous

Period Productivity

Productivity

Growth = Unit less

Quantity

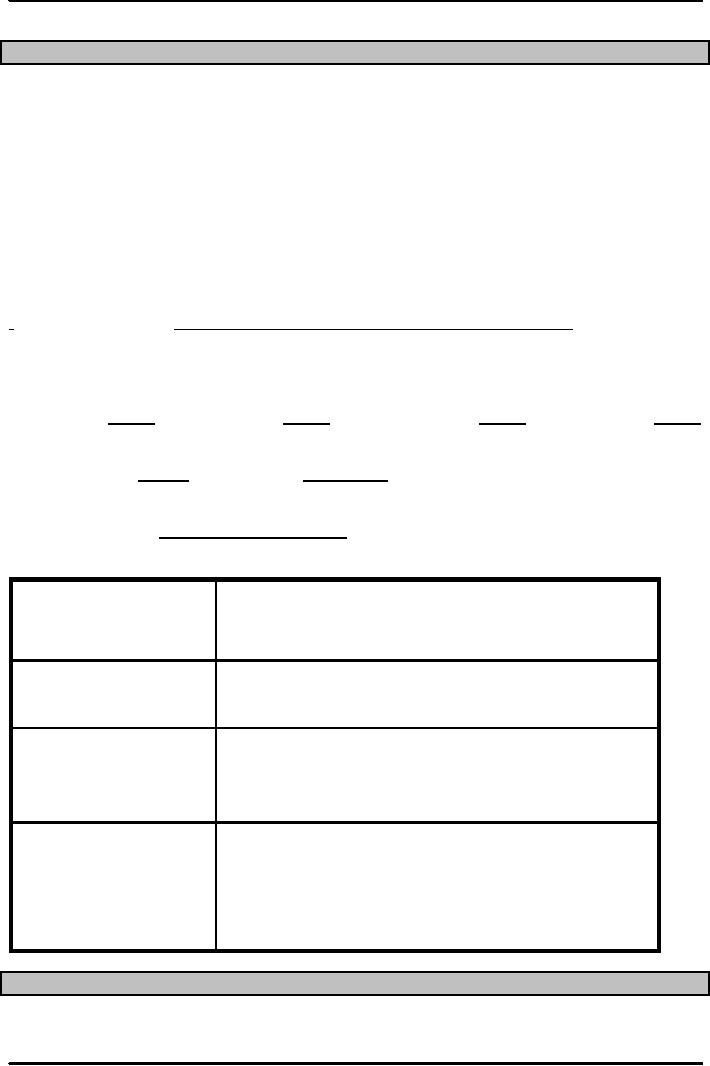

Partial

Output

Output

Output

Output

measures

Labor

Machine

Capital

Energy

Multifactor

Output

Output

measures

Labor

+ Machine

Labor

+ Capital + Energy

Total

=

Goods

or Services Produced

measure

All

inputs used to produce them

Units

of output per labor

hour

Labor

Productivity

Units

of output per shift

Value-added

per labor hour

Machine

Productivity Units of output

per machine hour

Units

of output per Rs.

input

Capital

Productivity

Dollar

value of output per Rs.

input

Units

of output per

kilowatt-hour

Energy

Productivity

Rupee

value of output per

kilowatt-hour

Example

What

is the multifactor productivity "MFP"? if

7500 Units Produced and Sold

for Rs.10/unit with

Cost

of labor of Rs.10,000, Cost of materials: Rs.5,000

and Cost of overhead:

Rs.20,000.

19

Production

and Operations Management

MGT613

VU

Output

MFP

=

Solution

Labor

+ Materials + Overhead

MFP

=

(7500

units)*(100)

10,000

+ 5,000 + 20,000

MFP

=

(750,000)

35,000

MFP

= 21.420

Factors

Affecting Productivity

Productivity

stands tall on four

important pillars of Capital,

Quality, Management and

Technology.

These

pillars are also responsible

for positively as well as

negatively affecting the Productivity

of

the

Organization.

1.

CAPITAL An existing machine or facility

if it is not functioning up to full

capacity or turning

out

products which are not

acceptable can lower

productivity. A new machine or repair

of

existing

machine would require capital

input.

2.

QUALITY Poor quality products would not

meet customer requirements and would

need

repairs

and reworks on the product to meet the

standards.

3.

MANAGEMENT With better scheduling,

planning, coordinating and controlling

activities of

management

the machine operations can be carried to

improve productivity.

4.

TECHNOLOGY Technological improvements

have increased productivity. A machine of

today

would

outperform machine of yesterday but may

not withstand machines of

tomorrow.

CAUTION:

Without careful planning

technology can reduce

productivity as it often leads

to

increased

costs, inflexibility or mismatched

operations. All leads to reduction in

value.

Other

Factors Affecting

Productivity

Standardization

We

live in a world where for the

sake of convenience, reliability and

safety,

majority

of the products and services have been

standardized. If for a moment any process

whether

it

relates to manufacturing or services is

made standard less, the

vital concept of

compatibility

would

be lost. Think for a moment if there is a

fire at a Montessori school or at a

crowded stadium,

if

there is no standardization of fire hose

attached to the fire truck and

fire hydrant present at

the

site,

no effort would succeed in

putting out the fire and

saving the lives of the

people.

Use

of Internet .Use of

Internet/Extranet especially for the

services side, even though there

are

knowledge

base applications available

for the manufacturing side as

well but primarily it has

the

been

the services side which has

been able to exploit the

resourcefulness of the Internet.

Computer

viruses. A

lot of time IT based

services industry have fallen a

prey to computer viruses

and

hackers.

Searching

for lost or misplaced

items.

This speaks low about the

coordinating activities and

can

lead

to loss in production time and

increase in idle time. Often

this also leads to increase

in

replacement

costs

Scrap

rates Any

aberration in the raw materials or

processed product can lead

to increase in scrap.

The

increase in scrap rate in fact

can decrease the utilization of

resources in general and

raw

material

New

workers Organizations

spend millions of Rupees

every year to train their

employees. A

trained

workforce is not only

reliable and dependable but also

ensures good

Host

of other Factors Affecting

Productivity:

Safety

Shortage

of IT Trained Workers

Layoffs

Labor

turnover

20

Production

and Operations Management

MGT613

VU

Design

of the workspace

Incentive

plans that reward

productivity

E.

Bottleneck Operation

Bottleneck

is one process in a chain of

processes, such that its

limited capacity ( increased

time

of

completion, or increased labour

requirement) reduces the capacity of the

whole chain

A

related concept is critical

path (see Project

Management) and the Theory of Constraints

(from

the

field of Industrial Engineering and

Operations management).

Theory

of constraints (TOC) is a body of

knowledge on the effective management of

(mainly

business)

organizations, as systems.

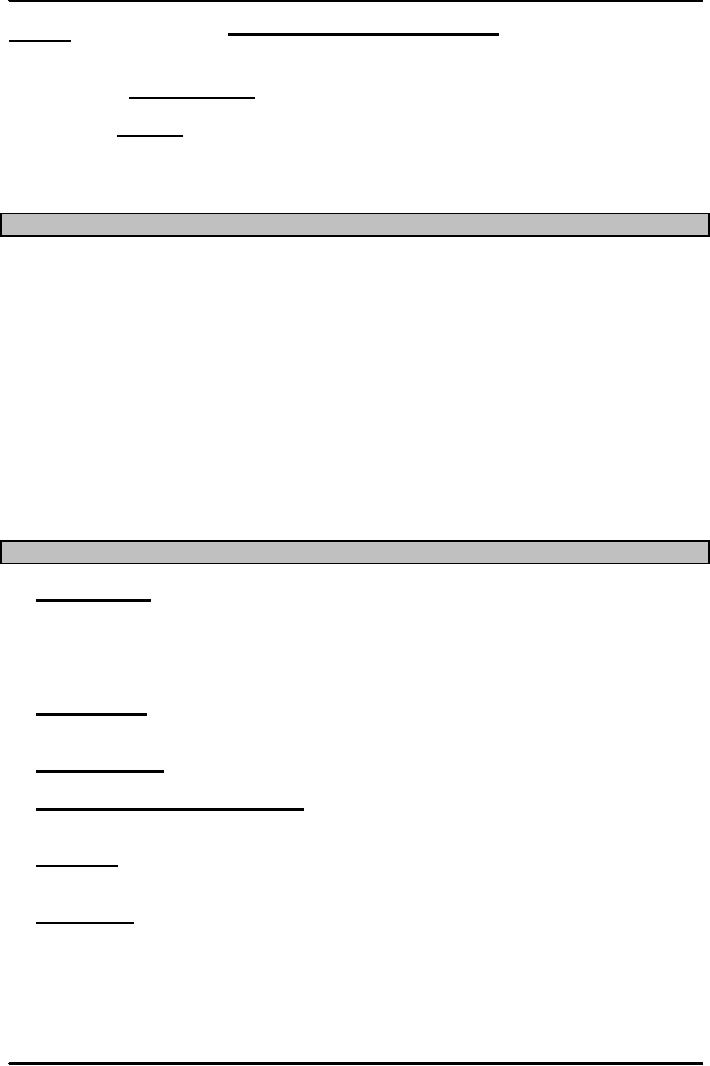

The

figure below clearly shows

that a machine requiring 12 hours to complete the

job is the real

bottleneck.

A manufacturing bottle neck like

this normally leads to

delayed completion and extended

time

for job. Similar bottlenecks

are observed in the Service side as

well.

10/hr

Machine

A

10/hr

Machine

B

Bottleneck

30/hr

Operation

Machine

C

10/hr

Machine

D

10/hr

Develop

productivity measures

Determine

and isolate critical (bottleneck)

operations

Develop

methods for productivity

improvements

Establish

reasonable goals

Get

management support

Measure

and publicize

improvements

Clearly

differentiate between productivity and

efficiency

Example

of Productivity Measurement

You

have just determined that

your 20 Operations ( Service) department employees

have used a total of

2200

hours of labor this week to

process 480 insurance forms.

Last week the same crew used

only 2000

hours

of labor to process 400

forms.

Which

productivity measure should be

used?

Answer:

Could be classified as a Total

Measure or Partial Measure and

Time/Labor productivity.

Is

productivity increasing or

decreasing?

Answer:

Last week's productivity =

400/2000 = 0.2, and this

week's productivity is = 480/2200 =

0.22.

So,

productivity is increasing

slightly.

21

Production

and Operations Management

MGT613

VU

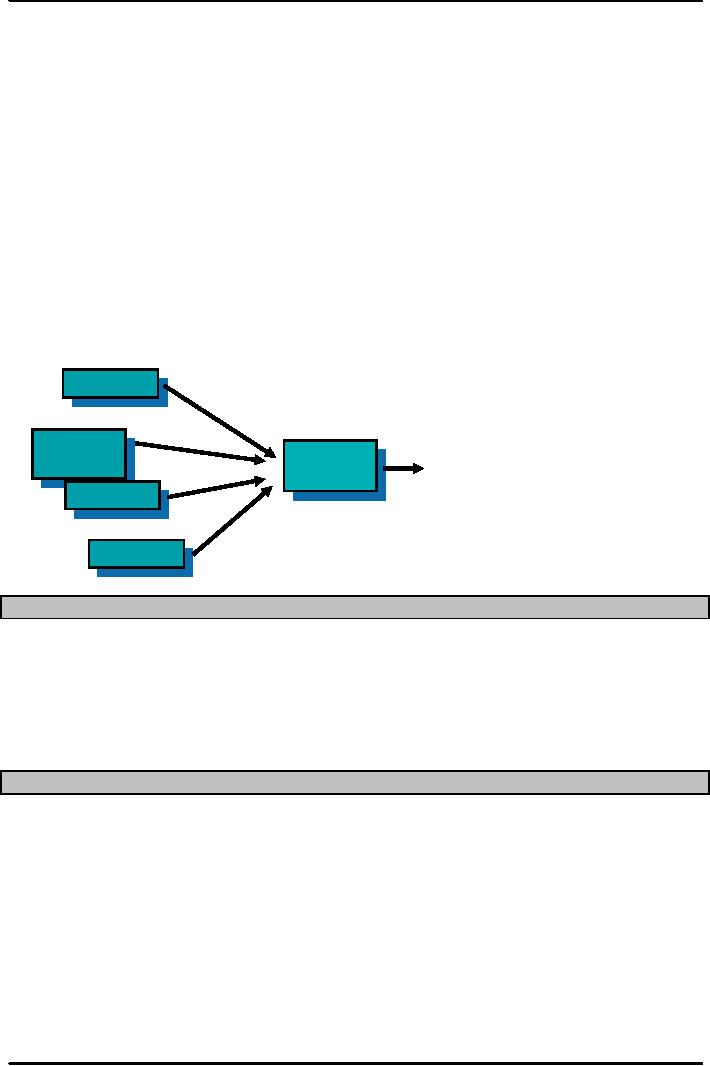

Pakistani

Productivity Example 1

Calculate

the change in productivity of Pakistani

Textile Industry between the years

2003-04 and 2004-

05?

(Installed Capacity)

Parameter

2003/4

2004/5

Change

Number

of mills

399

426

6.77

Spindles

(000)

9286.8

9815.5

5.69

Rotors(000)

145.6

151.6

4.12

Pakistani

Productivity Example2

Calculate

the change in productivity of Pakistani

Textile Industry between the years

2003-04 and 2004-

05?

( Working Capacity)

Parameter

2003/4

2004/5 % Change

Number

of Looms(000)

4.3

4.9

13.95

Spindles

(000)

7710.0

8531.0

10.65

Rotors(000)

67.3

75.1

11.59

Textile

Productivity Example 3

Calculate

the Productivity of Pakistani Textile

Industry between the years 2003-04 and

2004-05?

(Weaving

Sector Capacity)

Parameter

Installed

Working

%

Effectiveness

I

W

W/I

Power

Loom Sector

225258

220447

Independent

Weaving Unit

26034

25500

Integrated

Textile Unit

10249

4947

Total

261541

220447

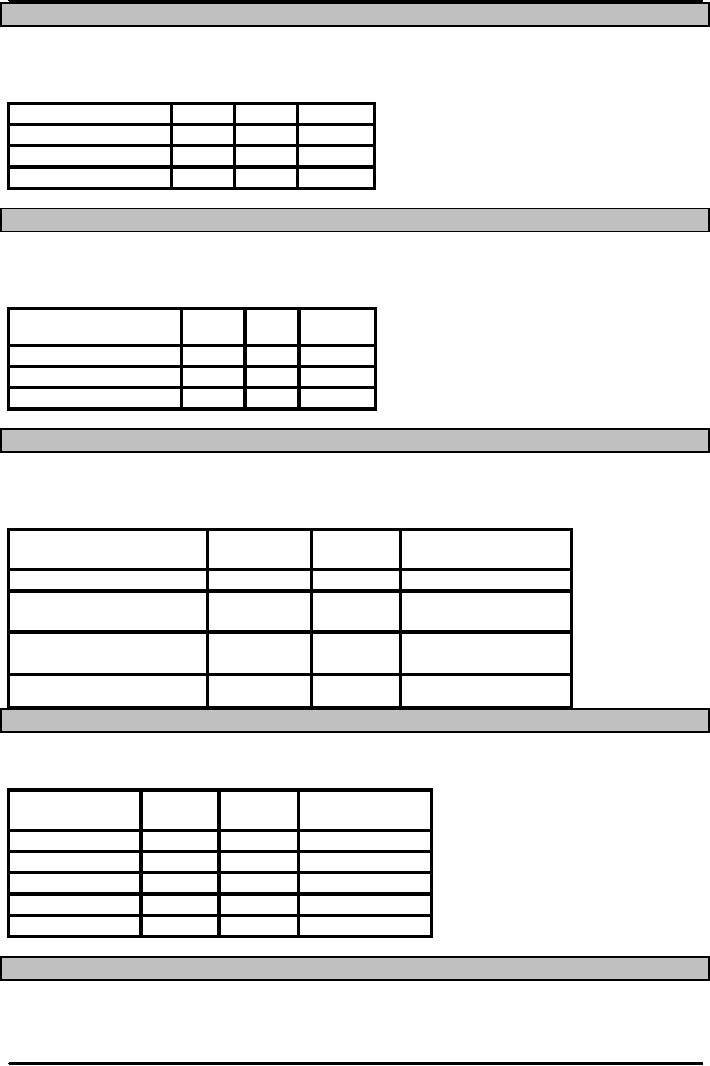

Pakistan

Automobile Industry

Calculate

the Productivity Change for

Pakistani Automobile Industry between the

years 2003-04 and

2004-05?

Type

2003-04

2004-05

%

change in

Productivity

Cars

79,655

100,213

Motorcycles

263,149

386,589

Trucks

1,669

1,999

Buses

1,151

1,503

Tractors

28,583

35,308

How

countries/nations can improve

productivity

As

students of Operations Management in Pakistan we

need to know and understand how the

concepts

of

productivity can help nation

improve its quality of life

and economy.

22

Production

and Operations Management

MGT613

VU

Increase

capital formation by saying no to

foreign goods. This would

increase savings and

decrease

consumption. Foreign goods

only make why to a market if

there is high consumption.

BE

PAKISTANI BUY PAKISTANI

Decrease

in administrative ( non productive)

regulations of the government. Self

explanatory.

Right

balance between Services and

Manufacturing activities. In the city of

Lahore, there is an

availability

of surplus services, which is often

less productive than

manufacturing operations

An

emphasis on both long term

and short term objective based

performance. (Closely monitor

and

audit the variances between planed and actual

results).

Exploit

the inherent resources of domestic market

.Let it be known to all that

the best

productive

market for Pakistani Producer is

Pakistani market.

SUMMARY

The

important concepts of Productivity,

Competitiveness and Strategy when considered in

cohesion

enhance

the overall performance of any service

based or manufacturing organization.

Organizations

formulate

operational and organizational strategies

to achieve competitive advantage over

its

competitors.

Different types of competencies allow

organizations to formulate time or

quality based

strategies

to achieve competitive

advantage

and increase their revenues.

The same concepts find

equal application for a

country to gain

competitive

advantage over other countries.

23

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model