|

Waiting Lines:Queuing Analysis, System Characteristics, Priority Model |

| << PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management |

Production

and Operations Management

MGT613

VU

Lesson

45

Waiting

Lines

Learning

Objectives

After

completing the lecture, we should be

able to explain the formation of

waiting lines in

unloaded

systems,

identify the goal of queuing (

waiting line) analysis, list the

measures of system performance

that

are used in queuing analysis. We

should be able to understand the

importance of simulation and at

the

same time we should look

beyond the Production Operations

Management class as

business

graduate

professionals adding value to the

society.

Visit

to a Cricket Stadium

1.

Waiting in lines does not

add enjoyment

2.

Waiting in lines does not

generate revenue

3.

Waiting

Lines

4.

Waiting lines are non-value

added occurrences

5.

Are formed at airports,

cricket stadiums, post

offices.

6.

Formed due to non scheduled random

arrivals

7.

Often regarded as poor service

quality

Waiting

Line Examples

1.

Orders

waiting to be filled

2.

Trucks

waiting to be loaded or

unloaded

3.

Job

waiting to be processed

4.

Equipment

waiting to be loaded

5.

Machines

waiting to be repaired.

Service

Station as a Waiting Line

Example

Service

station is usually designed to provide

service on average service time. At macro

level system is

unloaded

at micro level the system is

overloaded a Paradox

Customers

arrive at random rate

Service

requirements vary only oil

change or even tuning or maintenance

activity in order to change

oil

Waiting

Lines

Queuing

theory: Mathematical approach to the analysis of

waiting lines.

1.

Goal of queuing analysis is to minimize

the sum of two costs

Customer waiting costs

and

Service

capacity costs.

2.

Waiting lines are non-value

added occurrences

Implications

of Waiting Lines

1.

Cost to provide waiting

space

2.

Loss of business

a.

Customers leaving

b.

Customers refusing to

wait

3.

Loss of goodwill

4.

Reduction in customer

satisfaction

5.

Congestion may disrupt other

business operations

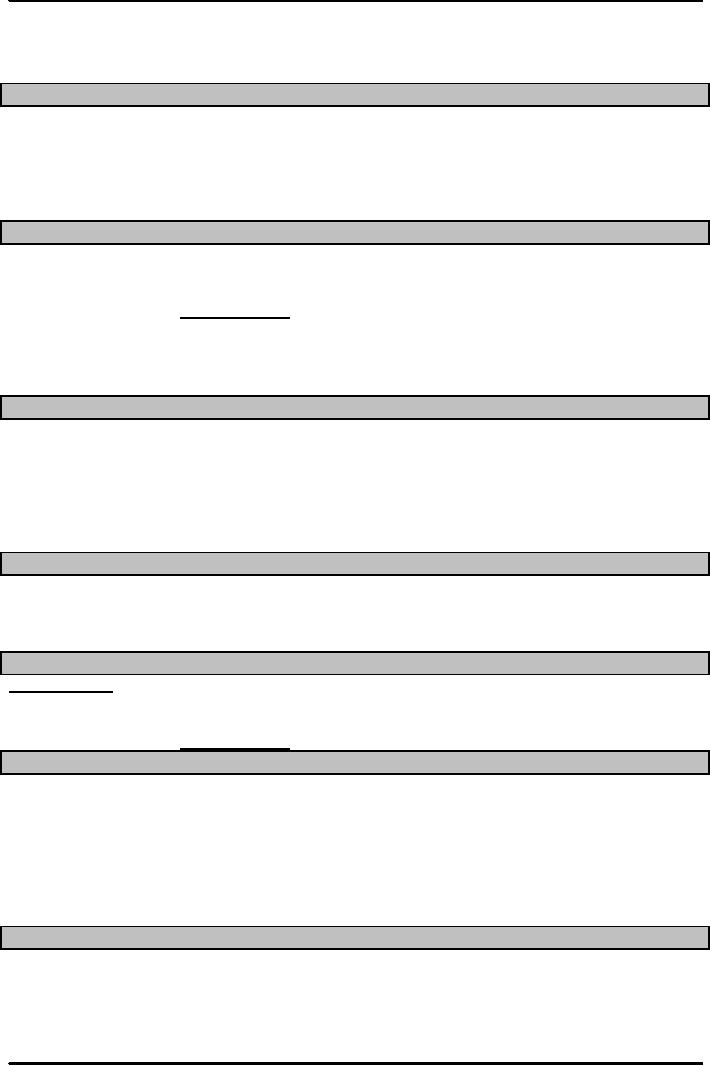

Queuing

Analysis

Organizations

carry out queuing analysis to

ensure that they are

able to balance the service levels

with

costs

which the organization can

incur. The ultimate goal of

queuing analysis is to minimize the sum

of

213

Production

and Operations Management

MGT613

VU

two

costs that is the service capacity

cost ( represented on x axis) and

customer waiting

Capacity

Total

Customer

=

+

waiting

cost

cost

cost

Cost

Total

cost

Cost

of

Service

Capacity

Cost

of

Customers

Waiting

Service

capacity

Optimum

costs.

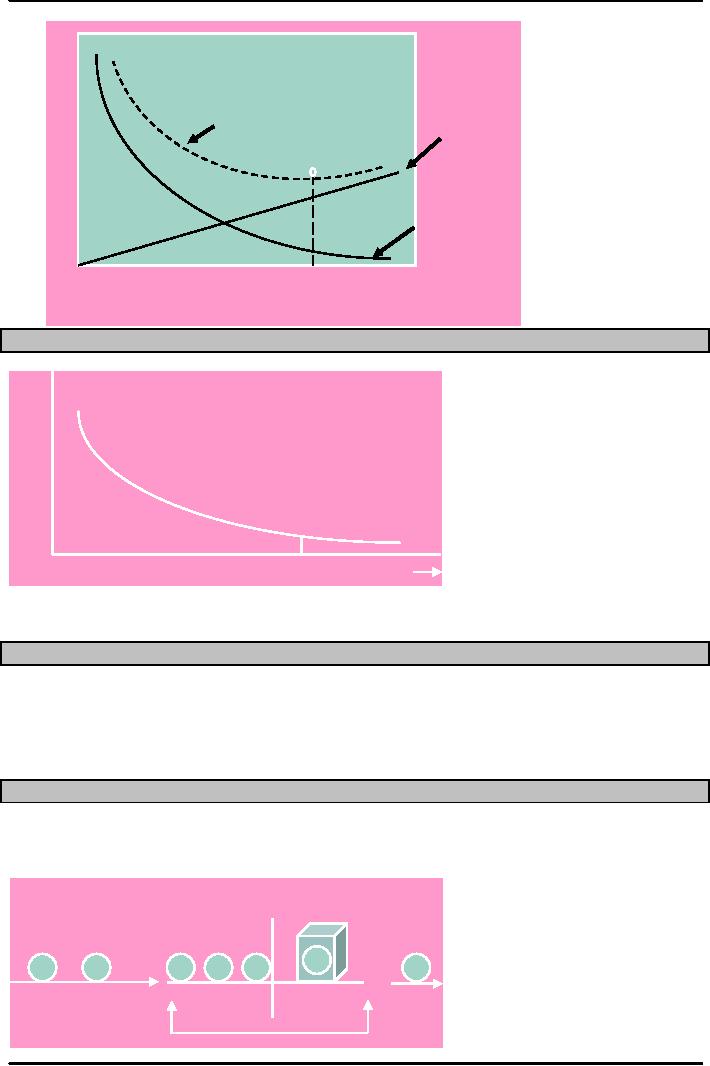

Negative

Exponential Distribution: Another

example of Common Queuing

System

F(t)

Pt≥T)=.RN

(

0

T

t

Queue

discipline is considered to be a primary

requirement in service systems. However

hospital

emergency

rooms, rush orders in a

factory and main frame computer

processing of jobs do not

follow

Queue

Discipline.

System

Characteristics

1.

Population Source

a.

Infinite source: customer

arrivals are unrestricted

b.

Finite source: number of potential

customers is limited

2.

Number of observers (channels)

3.

Arrival and service patterns

4.

Queue discipline (order of

service)

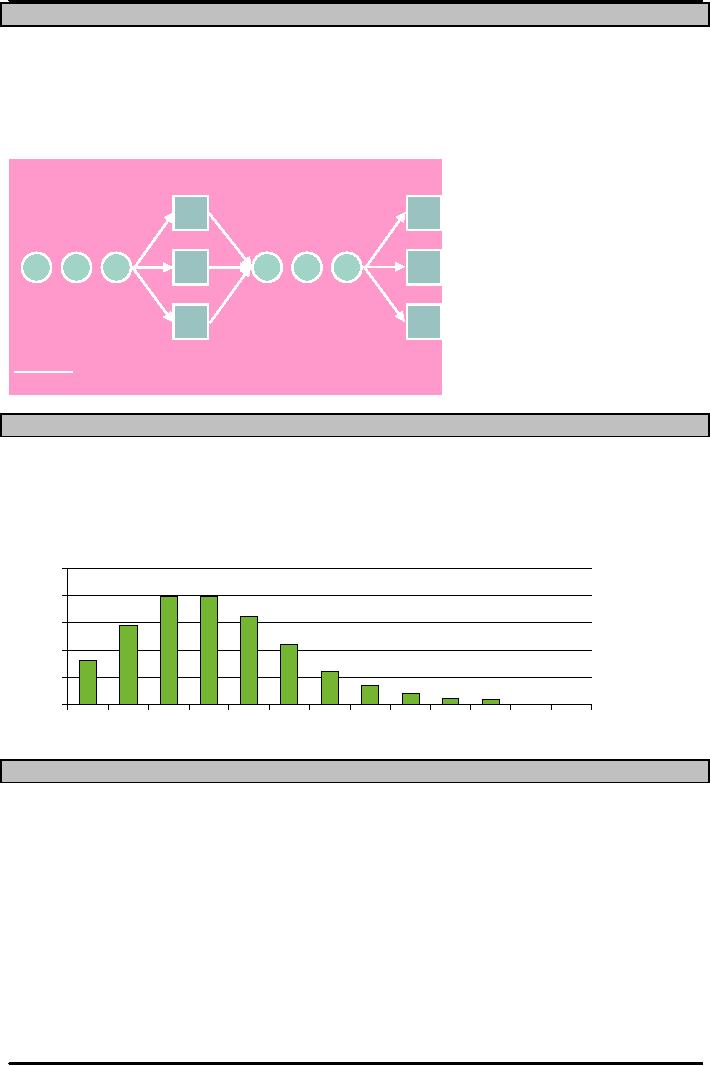

Elements

of Queuing System

Population

Source, Arrivals, Waiting

Lines, Processing Order, Service,

System and Exit are

the

common

identifiable elements of a Queuing

System.

Processing

Order

Waiting

Arrivals

Service

Exit

Line

System

214

Production

and Operations Management

MGT613

VU

Queuing

Systems

The

System characteristics

are

1.

Population Source

2.

Number of Servers( Channels)

3.

Arrival and Service

Patterns

4.

Queue Discipline

Multiple

Channels

Multiple

Phases

Channel:

A

server in a service system

Poisson

Distribution

Poisson

distribution is a

discrete probability distribution

and expresses the probability of a number

of

events

occurring in a fixed period of

time if these events occur

with a known average rate, and

are

independent

of the time since the last

event.

0.25

0.2

0.15

0.1

0.05

0

0

1

2

3

4

5

6

7

8

9

10

11

12

Waiting

Line Models

As

a student of Operations Management we can

identify the following types of Waiting

Line Models in

our

day to day routine

activities.

1.

Patient

:Customers enter the waiting

line and remain until

served

2.

Reneging:

Waiting customers grow

impatient and leave the

line

3.

Jockeying:

Customers may switch to another

line

4.

Balking:

Upon arriving, decide the line is

too long and decide not to

enter the line

Waiting

Time vs. Utilization

The

figure represents an increase in

system utilization at the expense of

increase in both length of

the

waiting

line and average waiting

time. These values increase as the

utilization approaches 100

percent.

The

implication is that under

normal circumstances, 100 percent

utilization is not a realization

goal.

215

Production

and Operations Management

MGT613

VU

Average

number

on

time waiting

in

line

0

100

System

Waiting

Time vs. Utilization

System

Performance

1.

Average number of customers

waiting

2.

Average time customers

wait

3.

System utilization

4.

Implied cost

5.

Probability that an arrival

will have to wait

Example

Service Station

Queuing

Models: Infinite-Source

1.

Single channel, exponential service

time

2.

Single channel, constant service

time

3.

Multiple channel, exponential service

time

4.

Multiple priority service, exponential

service time

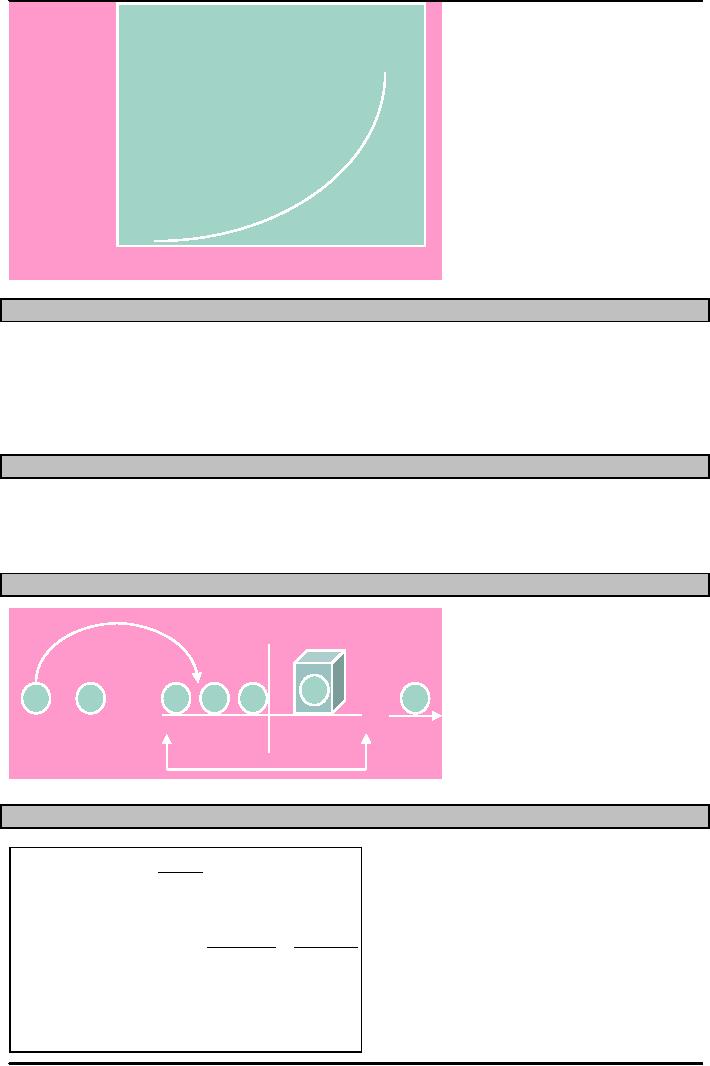

Priority

Model

Processing

order

1

3

2

1

1

Waiting

Arrival

Exit

Service

line

Arrivals

are assigned

System

a

priority as they

arrive

Finite-Source

Formulas

T

Service

Factor X =

T

+U

Average

Number Waiting L =

N

(1

-

F

)

L(T +

U

)

T

(1

-

F

)

AverageWaiting

TimeW =

=

N

-L

XF

Average

Number Running J =

NF

(1

-

X

)

Average

Number being Served H =

FNX

Number

in Population N =

J

+

L

+

H

216

Production

and Operations Management

MGT613

VU

Finite-Source

Queuing

Not

waiting or

Being

Waiting

being

served

served

J

L

H

U

W

T

Where

we use the

formula

Other

Approaches Non Mathematical

Approaches

1.

Reduce

perceived waiting

time

J

+H

F=

2.

Magazines

in waiting rooms

J

+L+H

3.

Radio/television

4.

In-flight

movies

5.

Filling

out forms

6.

Derive

benefits from waiting

7.

Place

impulse items near checkout

8.

Advertise

other goods/services

Simulation

Simulation:

a descriptive technique that

enables a decision maker to evaluate the

behavior of a model

under

various conditions.

1.

Simulation models complex

situations

2.

Models are simple to use and

understand

3.

Models can play "what if"

experiments

4.

Extensive software packages

available

Simulation

Process

1.

Identify the problem

2.

Develop the simulation

model

3.

Test the model

4.

Develop the experiments

5.

Run the simulation and evaluate

results

6.

Repeat 4 and 5 until results

are satisfactory

Monte

Carlo Simulation

Monte

Carlo method: Probabilistic

simulation technique used

when a process has a random

component

1.

Identify a probability

distribution

2.

Setup intervals of random numbers to

match probability

distribution

3.

Obtain the random numbers

4.

Interpret the results

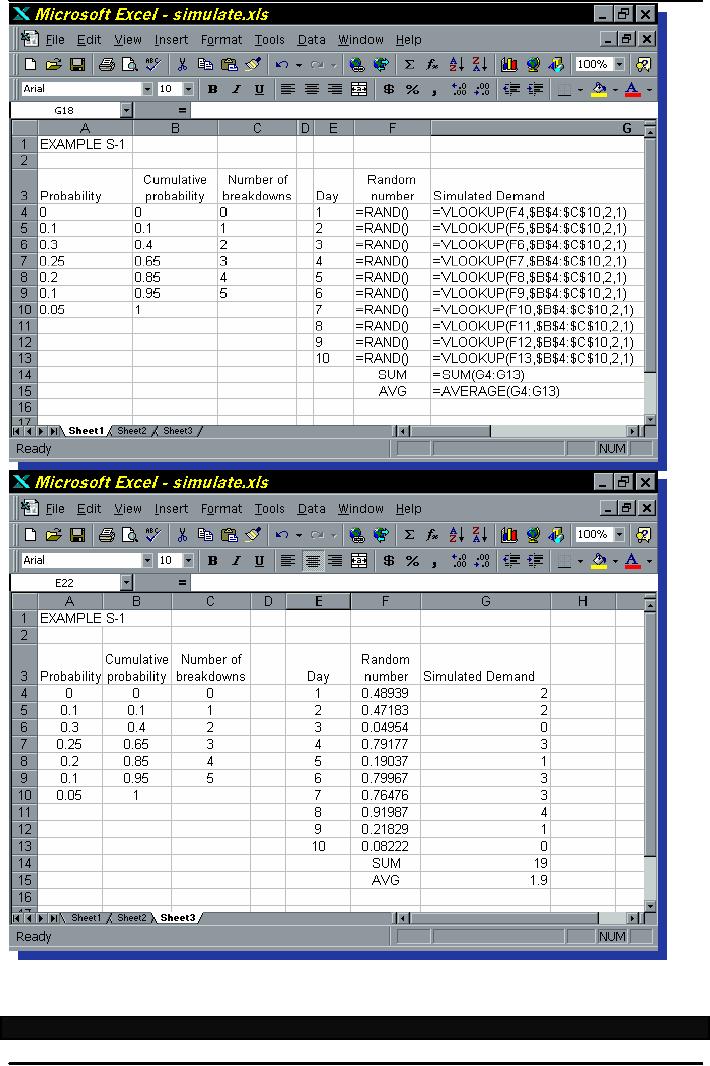

Example

Showing the use of Microsoft

Excel

An

Operations Manager makes best

use of the power of Microsoft

Excel by carrying out

simulation.

The

first picture below shows a

snapshot which carries the

formulae and the second

picture represents

the

actual values.

217

Production

and Operations Management

MGT613

VU

Simulating

Distributions commonly used

are the Poisson and Normal

Distributions.

Poisson

Distribution: Mean of distribution is

required

Normal

Distribution: Need to know the

mean and standard

deviation

Stimulated

Value= Mean + Random Number

X Standard Deviation

218

Production

and Operations Management

MGT613

VU

Uniform

Distribution

F(x)

0

a

b

x

Stimulated

Value= a+ (b-a)(Random number as a

percentage)

Computer

Simulation

Simulation

languages

1.

SIMSCRIPT II.5

2.

GPSS/H

3.

GPSS/PC

4.

RESQ

Advantages

of Simulation

1.

Solves problems that are difficult or

impossible to solve

mathematically

2.

Allows experimentation without

risk to actual system

3.

Compresses time to show long-term

effects

4.

Serves as training tool for

decision makers

Limitations

of Simulation

1.

Does not produce optimum

solution

2.

Model development may be

difficult

3.

Computer run time may be

substantial

4.

Monte Carlo simulation only

applicable to random systems

Why

Simulation is necessary

1.

Mathematics involved is too

complicated

2.

Easier to manipulate than

reality

3.

Software and hardware permit

modeling

Simulation

Steps

1.

Problem formulation

2.

Model building

3.

Data acquisition

4.

Model translation

5.

Verification & validation

6.

Experiment planning &

execution

7.

Analysis

8.

Implementation & documentation

Operations

Strategy

1.

The central idea for

formulating an Operations Strategy for

Waiting Line concept is

designing a

service

system to achieve a balance between service

capacity and customer

waiting time.

219

Production

and Operations Management

MGT613

VU

2.

The operations strategy should be able to

identify an appropriate and

acceptable level of service

capacity

as well as quality so waiting

lines are not formed or

formed which are manageable

and

acceptable

to the customers.

3.

Often Organizations when

challenged by lack of practical

solutions or space constraints opt

for

a

more tangible quality based

solutions by engaging the waiting

customers in activities

which

give

the customers not only an

opportunity to make use of the

time but also to make the

waiting

time

less painful and more

pleasant.

Summary

Analysis

of waiting lines can be an

important milestone in the design of

improved service systems.

Waiting

lines have a tendency to form in even

those systems which in a

macro sense are under

loaded or

unloaded.

The

arrival of customers at random times and

variability of service times combine to

create temporary

overloads.

When this happens, waiting

lines appear.

A

major consideration in the analysis of the

queuing systems is whether the number of

potential

customers

is limited (finite source) or

whether entry to the system is

unrestricted (infinite source).Of the

5

models we studied, 4 dealt with

infinite source and 1 with

finite source

population.

As

a rule, the models assume that

customer arrival rates are

described by Poisson distribution

and

service

time can be described by a

negative exponential

distribution.

220

Production

and Operations Management

MGT613

VU

POMA

Strategies beyond the final

exam

1.

In the long run (when factors of

production change, any or

combination of the factors of

labor,

land,

technology), productivity growth is

almost everything if not

everything.

2.

Do not create artificial non

operational management strategies

means to balance capacity

to

demand

(It can cause competitive

advantage to shift towards your

competitor and your

organization

losing the competition.

3.

How much does it really

cost to manufacture a product or develop

a service ( refer to the

concept

of total costs, which we

learnt in our discussions on

inventory management,

alternative

capacity,

quality, maintenance and waiting

lines)

4.

Competitive advantage in operational and

organization strategy creates a win

win situation for

the

organization.

5.

Operations Manager should learn to

think at the margin (an addition in

cost by 1 Rupee(unit

cost)

would increase or decrease the revenue by

1 Rupee(unit revenue/benefit)).

6.

How we as Operations Manager can

play a part in minimization of

costs of most important

of

services

in Pakistan i.e. education and medical.

Trade off between Effectiveness and

quality.

7.

How and why Project

Management concepts are

equally important to Production

Operations

Management

and vice versa.

8.

The importance of coordinating,

planning, controlling, budgeting

operations and project

activities

in achieving our firms short and

long term objectives.

9.

The concepts of strategy, competitiveness

and productivity, design of product and

services,

design

of work systems and facilities,

concept of quality and system

improvement as applicable

in

organizations be applied to

Pakistan.

10.

How as Operations Manager we can

communicate to masses the importance of

Pakistani

domestic

markets and how they help in

capital formation. If we say no to

foreign goods

consumption,

foreign good would not

come to our place and we can

generate a well

deserved

saving.

That saving can be channelized to

provide clean and drinkable

water, better health

care,

education

or even used for infrastructural

issues. e.g. if 1 % of Pakistani

population saves Rs.

10

per

week for 1 year alone we

would have almost 780 million

rupees or 12 to 13 Million US

dollars

by which we can set biogas plants or

waste incinerator boiler

based power generation

or

clean

drinking waters or even institutions of

higher learning.

221

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model