|

Production

and Operations Management

MGT613

VU

Lesson

42

SEQUENCING

Learning

Objectives

After

completing today's lecture, the

students should be able to

develop a comprehensive

understanding

of

scheduling and sequencing operations with the

help of Hungarian Methods and

Johnson Rules. The

students

would be able to understand the priority

rules along with the need of

effective scheduling and

sequencing.

The students would be able

to develop an Operations Strategy with

respect to both

Scheduling

and Sequencing.

Sequencing

Sequencing:

Determine the order in which

jobs at a work center will

be processed.

Requires

order for sequencing at all

work centers as well as sequencing at

individual work

centers.

Workstation:

An area where one person works,

usually with special equipment, on a

specialized job.

Sequencing

Job

time:

Time needed for setup and

processing of a job.

Priority

rules:

Simple heuristics (Commonsense rules)

used to select the order in

which jobs will be

processed.

1.

Local Rules ( pertaining to

single workstation)

2.

Global Rules( pertaining to multiple

workstation)

3.

Job processing times and due dates are

important pieces of

information.

4.

Job time consists of processing

time and setup times

Priority

Rules

1.

FCFS - First Come, First

Served: Jobs are processed in the

order in which they arrive

at a

machine

or work center.

2.

SPT- Shortest Processing

Time: Jobs are processed

according to processing time at

a

machine

or work center, shortest job

first.

3.

DD - Due Date: Jobs are

processed according to due

date, earliest due date

first.

4.

CR - critical ratio: Jobs

are processed according to

smallest ratio of time

remaining until

due

date to processing time

remaining.

5.

S/O - slack per operation: Jobs

are processed according to

average slack time (time

until

due

date minus remaining time to

process). Compute by dividing slack time

by dividing

slack

time by number of remaining operations

including the current one.

6.

Rush emergency: Emergency or Preferred Customers

first.

Assumptions

to Priority Rules

1.

The set of jobs is known, no

new jobs arrive after

processing begins and no jobs

are

canceled.

2.

Setup time is

deterministic

3.

Processing times are deterministic rather

than variables.

4.

There will be no interruptions in

processing such as machine breakdowns ,

accidents or

worker

illnesses.

Definitions

Job

Flow Time: The length of

time a job is in the shop at a

particular workstation or work

center.

Job

Lateness: This is the length of

time the job completion

date is expected to exceed the date

the

job

was due or promised to a customer.

189

Production

and Operations Management

MGT613

VU

Makespan:

This is the total time

needed to complete a group of jobs. It is

the length of time between

the

start of the first job in the

group and the completion of the last job

in the group.

Average

Number of Jobs: Jobs that

are considered in a shop are considered

to be work in process

inventory.

Mathematically

Average

Number of Jobs= Total Flow

Time / Makespan

Example

Determine

the sequence of jobs, average

time flow, average days

late and average number of jobs

at

the

work center, for each of

these rules

FCFS

SPT

DD

CR

Example

Data

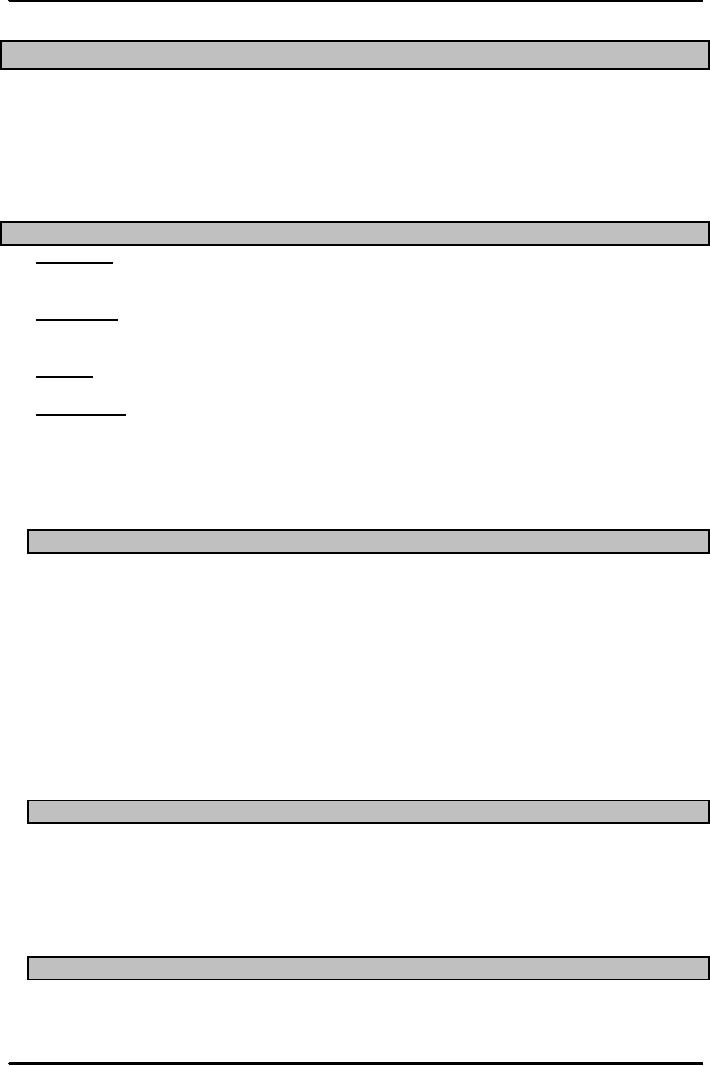

JOB

Processing

Time

Due

Date

A

2

7

B

8

16

C

4

4

D

10

17

E

5

15

F

12

18

Part

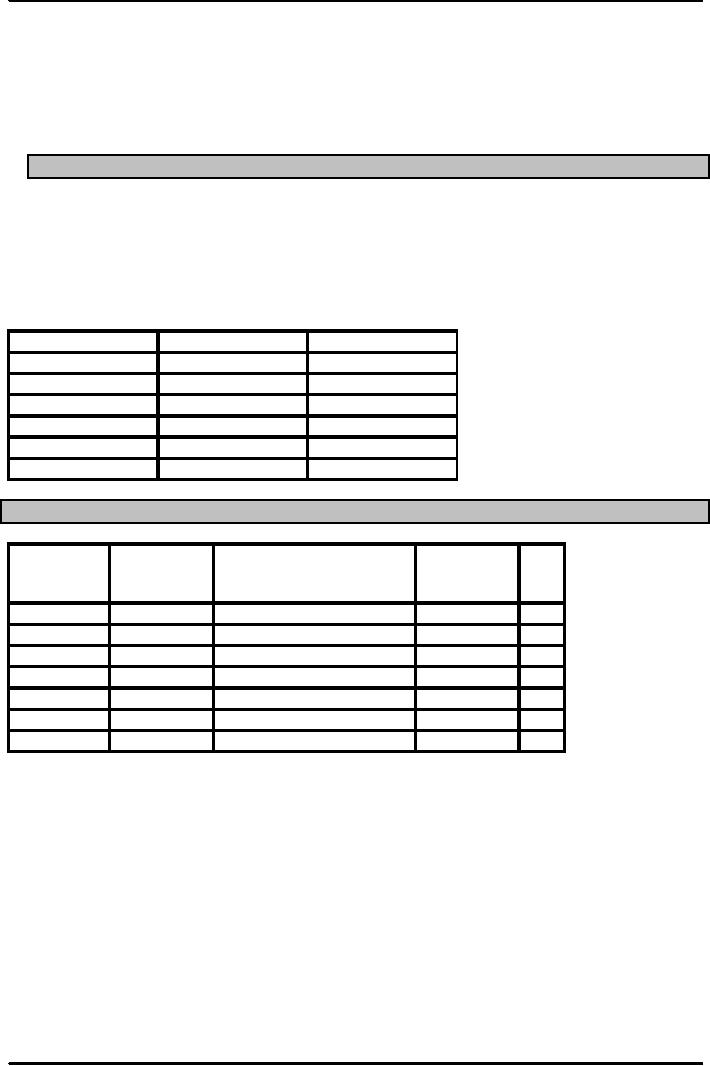

A. FCFS

Assume

Jobs arrived in the following

order 1. A-B-C-D-E-F

Processing

JOB

Flow

Time ( cumulative

Due

Date (2)-

Sequences

Time

processing

time) (2)

(3)

(3)

(1)

A

2

2

7

0

B

8

10

16

0

C

4

14

4

10

D

10

24

17

7

E

5

29

15

14

F

12

41

18

22

41

120

54

Part

A. FCFS

Average

Flow time= Total Flow

Time/Number of Jobs=120/6=20 days

Average

Tardiness=54/6=9

The

makespan =41 days

Average

Number of Jobs at

workstation=

120/41=2.93

jobs per workstation

SPT,

the sequence is A-C-E-B-D-F

190

Production

and Operations Management

MGT613

VU

Part

B SPT rule

JOB

Processing

Flow

Time ( cumulative

Due

(2)-(3)

Sequences

Time

processing

time)

Date

(1)

(2)

(3)

A

2

2

7

0

C

4

6

4

2

E

5

11

15

0

B

8

19

16

3

D

10

29

17

12

F

12

41

18

23

41

108

40

Average

Flow time= Total Flow

Time/Number of Jobs=108/6=18 days

Average

Tardiness=40/6=6.67days

The

makespan =41 days

Average

Number of Jobs at

workstation=

108/41=2.63

jobs per workstation

Summary

Part A,B,C and D

Average

Average Average Number of

Jobs of

JOB

Flow

Lateness

the Work Center

Sequences

Time

(Days)

Rule

(Days)

FCFS

20.00

9.00

2.93

SPT

18.00

6.67

2.63

DD

18.33

6.33

2.68

CR

26.67

14.17

3.9

Summary

Part A,B,C and D

1.

Generally Speaking FCFS and

CR rule seems to be the least

effective.

2.

CR is the worst in each aspect of

measurement.

3.

The primary limitation of

FCFS is that long jobs

will tend to delay other

jobs.

4.

However in scheduling of service systems,

the FCFS has the advantage of

simplicity,

inherent

fairness (first come first

served) but also due to non

availability of realistic

estimates

of processing times for individual

jobs.

Johnson's

Rule (Two Work Center

Sequencing)

Johnson's

Rule:

technique for minimizing

completion time for a group

of jobs to be processed on

two

machines or at two work

centers.

1.

Minimizes total idle

time

2.

Several conditions must be

satisfied

Johnson's

Rule Conditions

1.

Job

time must be known and

constant

2.

Job

times must be independent of

sequence

3.

Jobs

must follow same two-step

sequence

4.

Job

priorities cannot be used

5.

All

units must be completed at the first

work center before moving to

second

Johnson's

Rule Optimum Sequence

1.

List the jobs and their times at

each work center

191

Production

and Operations Management

MGT613

VU

2.

Select the job with the

shortest time

3.

Eliminate the job from

further consideration

4.

Repeat steps 2 and 3 until

all jobs have been

scheduled

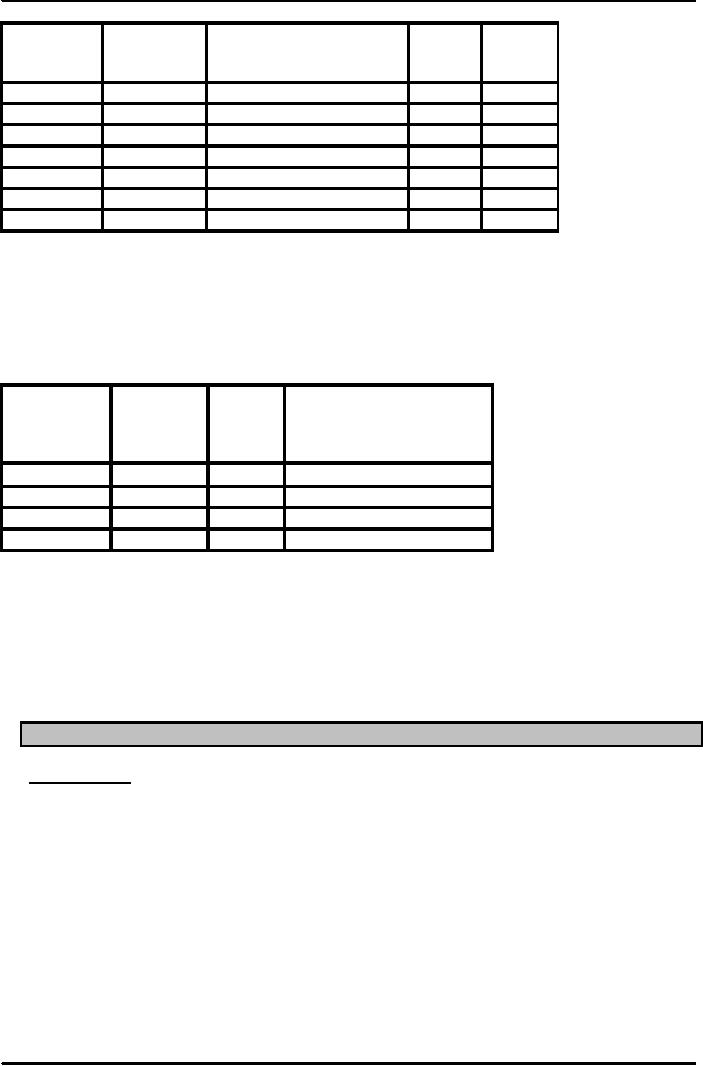

Johnson's

Rule Example

PROCESSING

TIMES ( HOURS)

JOB

Work

Center 1

Work

Center2

A

5

5

B

4

3

C

8

9

D

2

7

E

6

8

F

12

15

1.

Select the job with shortest

processing time. In our case

it is Job D

2.

Eliminate the row of JOB D &

proceed further to select the

next job with

shortest

processing

time which is B in our case

and that too at work

center2

3.

Similarly sequencing other jobs at

work centers, we follow that

if there is tie of no of hours,

we

can sequence it at the beginning or the

end.

4.

Construct a chart to determine the throughput

time and idle times at the

work centers. We

have

5.

1st D,2nd E,3rd C,4th F,5th A and

6th B

Scheduling

Difficulties

1.

Variability in

a.

Setup times

b.

Processing times

c.

Interruptions

d.

Changes in the set of

jobs

2.

No method for identifying optimal

schedule

3.

Scheduling is not an exact

science

4.

Ongoing task for a

manager

Minimizing

Scheduling Difficulties

1.

Set realistic due

dates

2.

Focus on bottleneck operations

3.

Consider lot splitting of large

jobs

Scheduling

Service Operations

1.

Appointment systems

a.

Controls customer arrivals

for service

2.

Reservation systems

a.

Estimates demand for

service

3.

Scheduling the workforce

a.

Manages capacity for service

4.

Scheduling multiple

resources

a.

Coordinates use of more than one

resource

Cyclical

Scheduling

1.

Hospitals,

police/fire departments, restaurants,

supermarkets

2.

Rotating

schedules

3.

Set

a scheduling horizon

4.

Identify

the work pattern

5.

Develop

a basic employee

schedule

192

Production

and Operations Management

MGT613

VU

6.

Assign employees to the schedule

Service

Operation Problems

1.

Cannot store or inventory

services

2.

Customer service requests are

random

3.

Scheduling service involves

a.

Customers

b.

Workforce

c.

Equipment

Maintenance

Maintenance:

All activities that maintain

facilities and equipment in good

working order so that

a

system

can perform as

intended

Breakdown

maintenance: Reactive approach; dealing with

breakdowns or problems when they

occur

Preventive

maintenance: Proactive approach; reducing breakdowns

through a program of

lubrication,

adjustment, cleaning, inspection, and replacement of

worn parts

Maintenance

Reasons

Reasons

for keeping equipment

running

1.

Avoid production

disruptions

2.

Not add to production

costs

3.

Maintain high quality

4.

Avoid missed delivery

dates

Breakdown

Consequences

Some

of the Important consequences are:

1.

Production capacity is reduced :

Orders are delayed

2.

No production: Overhead continues

3.

Cost per unit increases:

Quality issues

4.

Product may be damaged

5.

Safety issues

a.

Injury to employees

b.

Injury to customers

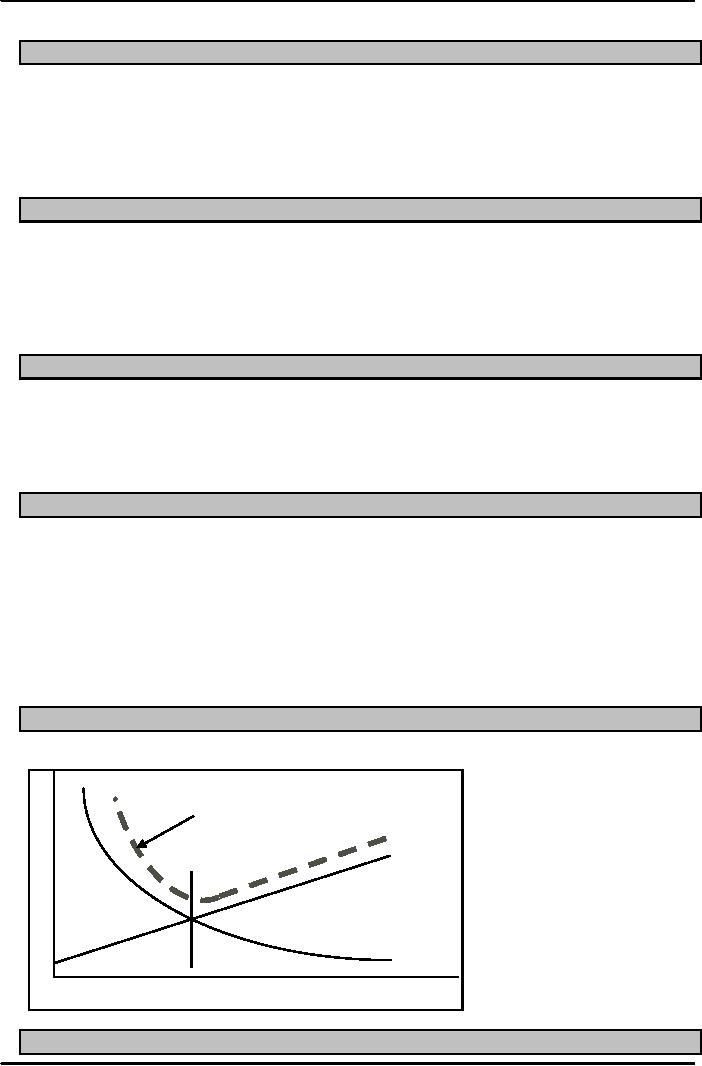

Total

Maintenance Cost

Total

Cost

Preventive

maintenance

cost

Breakdown

and

repair

cost

Optimum

Amount of

Preventive

Maintenance

Preventive

Maintenance

193

Production

and Operations Management

MGT613

VU

Preventive

maintenance:

goal is to reduce the incidence of

breakdowns or failures in the plant

or

equipment

to avoid the associated

costs

1.

Preventive maintenance is periodic

2.

Result of planned inspections

3.

According to calendar

4.

After predetermined number of

hours

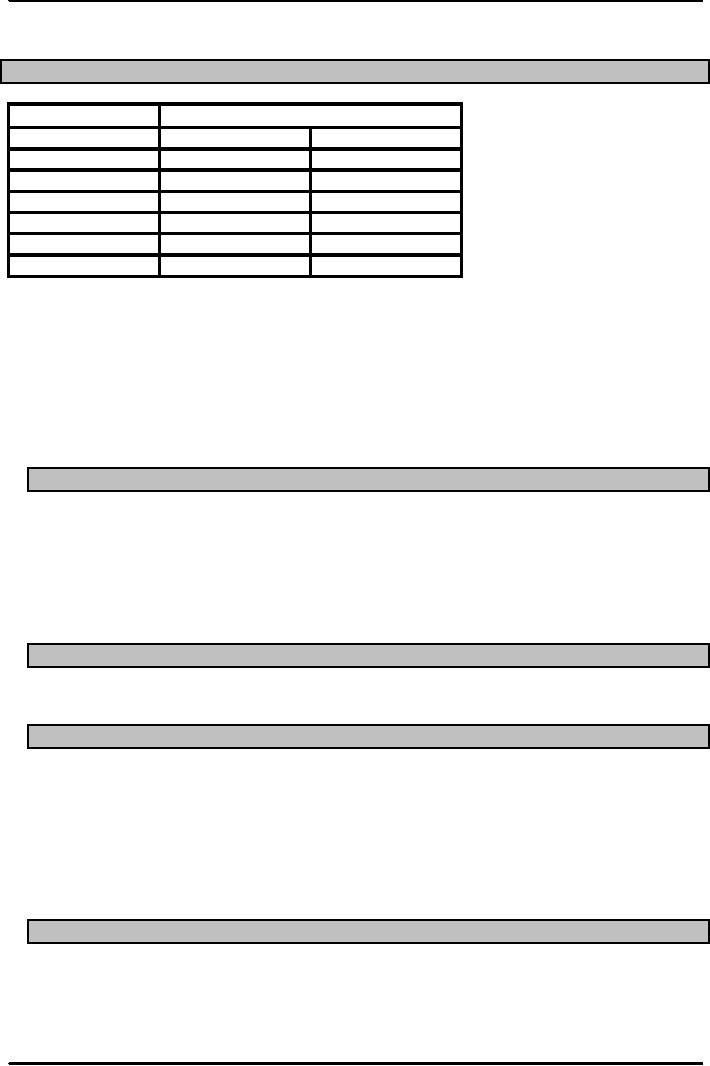

Example

1

Frequency

of breakdown

1

2

3

Number

of breakdowns

0

Frequency

of occurrence

.20

.30 .40 .10

If

the average cost of a breakdown is

Rs.10,000, and the cost of preventative

maintenance is

Rs.12,500

per month, should we use

preventive maintenance?

Example

1 Solution

Number

of

Frequency

Expected

Breakdowns

of

number

of

Occurrence

Breakdowns

0

.20

0

1

.30

.30

2

.40

.80

3

.10

.30

1.00

1.40

Expected

cost to repair = 1.4 breakdowns per

month X Rs.10,000

=

Rs.14,000

Preventive

maintenance = Rs.12,500.

PM

results in savings of Rs.1500 per

month

Predictive

Maintenance

Predictive

maintenance: An attempt to determine when best to

perform preventive maintenance

activities

Total

productive maintenance: JIT approach where

workers perform preventive maintenance on

the

machines

they operate

Breakdown

Programs

1.

Standby

or backup equipment that can

be quickly pressed into

service

2.

Inventories

of spare parts that can be

installed as needed

3.

Operators

who are able to perform

minor repairs

4.

Repair

people who are well

trained and readily available to diagnose

and correct problems

with

equipment

Replacement

1.

Trade-off

decisions

2.

Cost

of replacement vs. cost of continued

maintenance

3.

New

equipment with new features

vs. maintenance

4.

Installation

of new equipment may cause

disruptions

5.

Training

costs of employees on new

equipment

6.

Forecasts

for demand on equipment may

require new equipment

capacity

7.

When

is it time for

replacement?

194

Production

and Operations Management

MGT613

VU

Operations

Strategy

1.

Scheduling can hinder or

help the Operations Strategy.

2.

An on time delivery of a product or

service is only possible if the Operations Managers

is

able

to do effective scheduling.

3.

An ineffective scheduling would

result in inefficient use of

resources and possible

dissatisfied

customers.

4.

Scheduling as an Operations Strategy can

provide an organization a competitive

advantage

over

its competitors.

5.

Time based competition

depends on good

scheduling.

6.

Good design, superior quality and

other elements of a well run

organization are

meaningless

if

effective scheduling is absent

from Operations Management

Strategy.

7.

Scheduling is that bank

balance which may seem great

in numbers but if not

used

effectively

would not make any

sense.

Summary

Scheduling

involves timing and coordination of

operations. Scheduling is different for

high volume,

intermediate

volume and low volume.

Scheduling for job shops is

very complex, because of

variety

jobs

that need to be processed.

The two major problems in

Scheduling is the assigning of jobs to

the

machines

(work centers) and sequence of operations

at a machine.

Gantt

Load charts are used to

help managers visualize the

work load situation.

Scheduling

of service systems require appointment or

reservation systems, although

all systems are

not

amenable to this. When

multiple resources are

involved, the balancing can be

difficult.

Maintenance

Activities ensure that

sequence activities are

completed on time and as per

schedule.

Maintenance

adds to revenue and not to

costs.

195

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model