|

SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method |

| << SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks |

| SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations >> |

Production

and Operations Management

MGT613

VU

Lesson

41

SCHEDULING

Learning

Objectives

After

completing the introductory discussion on

Scheduling, the students would be

able to understand

what

scheduling is and how important it is to

high volume and intermediate

volume systems. It

would

also

help them to learn how to

address scheduling needs in Job

shops. The students would

also learn the

use

and interpretation of Gantt Charts.

They would also use

Assignment method for loading

along with

common

Priority Rules. They would

also learn the common and unique

scheduling problems in Service

Systems.

Scheduling

Scheduling:

Scheduling is an important tool

for manufacturing and service industries

where it can have

a

major impact on the productivity of a

process. In manufacturing, the purpose of

scheduling is to

minimize

the production time and costs, by

telling a production facility

what to make, when, with

which

staff,

and on which equipment. Similarly,

scheduling in service industries, such as

airlines and public

transport,

aim to maximize the efficiency of the

operation and reduce

costs.

Scheduling

Modern

computerized scheduling tools greatly

outperform older manual

scheduling methods.

This

provides

the production scheduler with powerful

graphical interfaces which can be

used to visually

optimize

real-time work loads in various

stages of the production, and

pattern recognition allows

the

software

to automatically create scheduling

opportunities which might

not be apparent without this

view

into

the data. For example, an airline

might wish to minimize the number of

airport gates required for

its

aircraft,

in order to reduce costs, and

scheduling software can allow the

planners to see how this can

be

done,

by analyzing time tables, aircraft

usage, or the flow of

passengers.

Scheduling

Companies

use backward and forward

scheduling to plan their human

and material resources.

Backward

scheduling

is planning the tasks from the due

date to determine the start

date and/or any changes

in

capacity

required, whereas forward

scheduling is planning the tasks

from the start date to

determine the

shipping

date or the due date.

Benefits

of Scheduling

Scheduling:

Establishing the timing of the use of

equipment, facilities and human

activities in an

organization

1.

Effective scheduling can

yield

2.

Cost savings

3.

Increases in productivity

The

benefits of production scheduling

include:

1.

Process change-over reduction

2.

Inventory reduction,

leveling

3.

Reduced scheduling

effort

4.

Increased production efficiency

5.

Labor load leveling

6.

Accurate delivery date

quotes

7.

Real time information

High-Volume

Systems

1.

Flow system: High-volume

system with Standardized equipment and

activities

2.

Flow-shop scheduling: Scheduling

for high-volume flow

system

184

Production

and Operations Management

MGT613

VU

Work

Center #1

Work

Center #2

Output

Scheduling

Manufacturing Operations

High-volume

Intermediate-

volume

Low-volume

Service

operations

High-Volume

Success Factors

Process

and product design

Preventive

maintenance

Rapid

repair when breakdown

occurs

Optimal

product mixes

Minimization

of quality problems

Reliability

and timing of supplies

Intermediate-Volume

Systems

Outputs

are between standardized high-volume

systems and made-to-order job

shops

Run

size, timing, and sequence

of jobs

Economic

run size:

2DS

p

Q0 =

p-u

H

Scheduling

Low-Volume Systems

Loading

-

assignment of jobs to process

centers

Sequencing

-

determining the order in which

jobs will be

processed

Job-shop

scheduling

Scheduling

for low-volume

systems

with many

variations

in

requirements

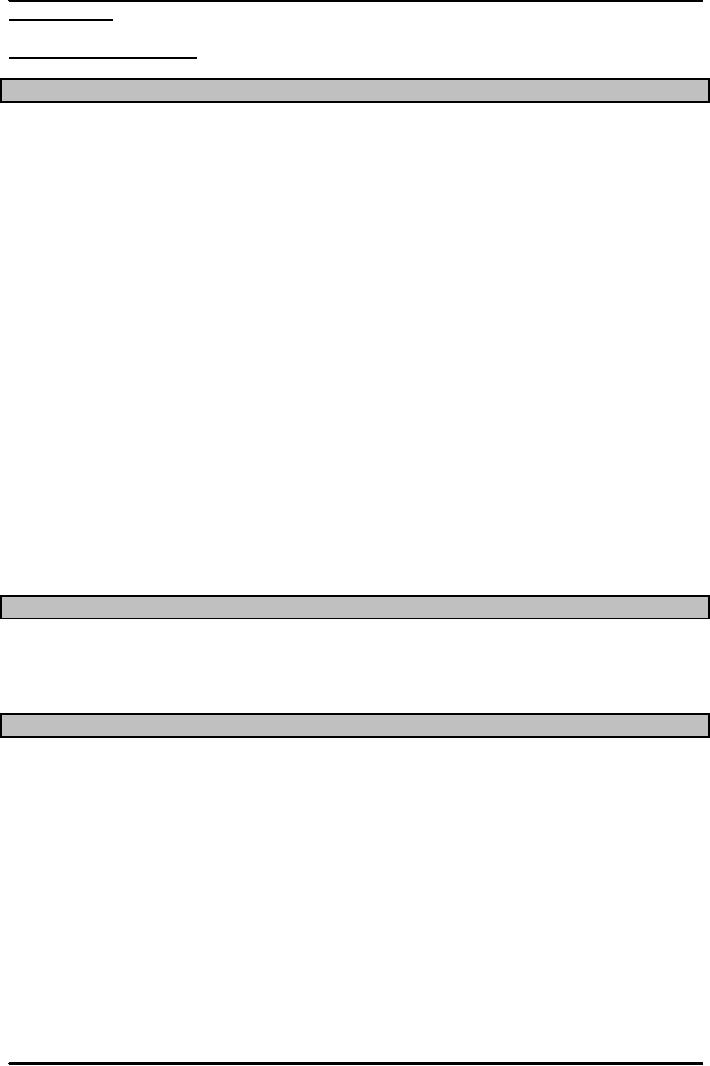

Gantt

Load Chart

Gantt

chart -

used as a visual aid for

loading and scheduling

Load

Chart

Load

chart A

type of Gantt Chart that

shows the loading and idle

times for a group of machines or

list

of

departments

Work

Mon.

Tues.

Wed.

Thurs.

Fri.

Center

1

Job

3

Job

4

2

Job

3

Job

7

3

Job

1

Job

6

Job

7

4

Job

10

185

Production

and Operations Management

MGT613

VU

Schedule

chart A

type of Gantt Chart that

shows the orders or jobs in

progress and whether they

are

on

schedule or not.

Input/Output

Control Chart A

type of Control Chart that

shows management of work

flow and queues

at

the work centers

Loading

Types

The

common types of loading include the

following

1.

Infinite loading

2.

Finite loading

3.

Vertical loading

4.

Horizontal loading

5.

Forward scheduling

6.

Backward scheduling

7.

Schedule chart

We

now briefly discuss these

type of Loading

1.

Infinite loading. Jobs are

assigned to work centers

without regard to the capacity of the

work

center.

2.

Finite loading Jobs are

assigned to work centers

with regard to the capacity of the work

center

and

job processing times.

3.

Vertical loading: Loading

jobs at a work center, job by

job, usually according to

some priority

criterion,

using infinite loading i.e.

Jobs are assigned to work

centers without regard to the

capacity

of the work center.

4.

Horizontal loading: Loading

each job on all work

centers it will require,

then the next job on

all

work

centers, according to some

priority, using finite

loading i.e. Jobs are

assigned to work

centers

with regard to the capacity of the work

center and job processing

times.

5.

Forward scheduling: Scheduling

ahead, from some point in

time

6.

Backward scheduling: Scheduling by

working backwards from the due

date

7.

Schedule chart A Gantt chart that shows

the orders or jobs in progress and

whether they are on

schedule

or not.

Assignment

Method of Linear

Programming

Assignment

Model is a type of linear

programming model for

optimal assignment of tasks and

resources

Hungarian

method is the method of assigning jobs by a one for

one matching to identify the lowest

cost

solution

Let's

take a step by step approach to

understand and make use of Hungarian

Method

Hungarian

Method

First

of all, acquire the relevant cost

information and arrange it in tabular

form

Second,

obtain the Row Reduction;

this is obtained by subtracting the

smallest number in each

row

from

every number in the row. Enter the

results in a new

table.

Third,

Obtain the Column Reduction by

subtracting the smallest number in each

column of the new

table

from every number in the

column.

Fourth,

test whether an optimum

assignment can be made. You do

this by determining the

minimum

number

of lines needed to cover (

i.e.) cross out all

zeros. If the number of lines equal the

numbers

of

row, an optimum assignment is possible.

IN that case move to final

step.

Fifth,

if the numbers of lines is less

than the number of rows, modify the table

in the following

manner

o

Subtract the

smallest uncovered number from every

uncovered number in the table.

186

Production

and Operations Management

MGT613

VU

Add

the smallest uncovered number to the numbers at the

intersections of covering

o

lines

Numbers

crossed out but not at

intersections of cross out lines

carry over unchanged to

o

the

next table.

Sixth,

Repeat steps fourth and

fifth unless an Optimal

table is obtained

Seventh,

make the assignments. Begin

with rows or columns with only

one zero. Match items

that

have

zeros, using only one match

for each row and

each column. Cross out

both the row and

column

for

each row.

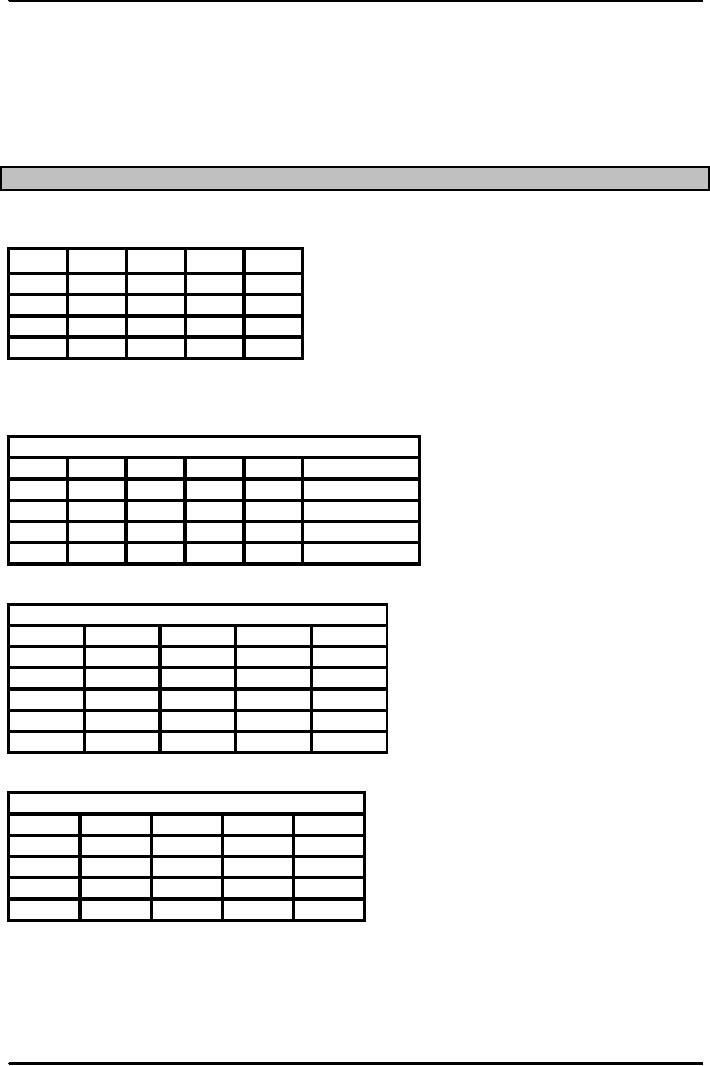

Hungarian

Method Example

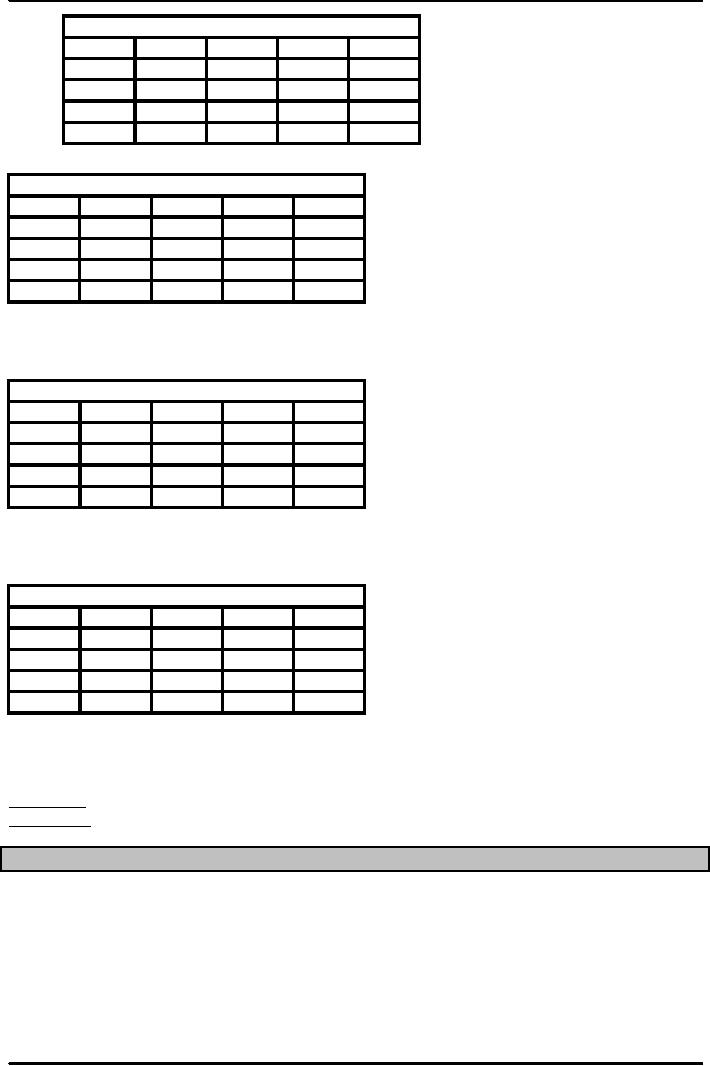

Please

refer to the matrix which

shows Jobs 1,2,3 and 4 with

Machines A, B, C and D.

JOBS

A

B

C

D

1

8

6

2

4

2

6

7

11

10

3

3

5

7

6

4

5

10

12

9

Please

apply the Hungarian Method to make

appropriate assignments.

Select

the Row Minimum

MACHINE

JOBS

A

B

C

D

ROW

MIN

1

8

6

2

4

2

2

6

7

11

10

6

3

3

5

7

6

3

4

5

10

12

9

5

Subtract

the smallest number in reach

row

To

form a new table and select

column minimum

MACHINE

JOBS

A

B

C

D

1

6

4

0

2

2

0

1

5

4

3

0

2

4

3

4

0

5

7

4

COL

MIN

0

1

0

2

Subtract

the smallest number in reach column &

Enter the results to form a

new table

MACHINE

JOBS

A

B

C

D

1

6

3

0

0

2

0

0

5

2

3

0

1

4

1

4

0

4

7

2

Determine

the minimum number of lines needed to

cross Out all zeros.

Here we have three lines

only

and

rows are 4, so the solution is not

optimal

Hungarian

Method Example

Subtract

the smallest value that has

not been crossed out

from every number that has

not been crossed

out

(1 here) and add this to numbers that

are at intersections of covering

lines

187

Production

and Operations Management

MGT613

VU

MACHINE

JOBS

A

B

C

D

1

6

3

0

0

2

0

0

5

2

3

0

1

4

1

4

0

4

7

2

MACHINE

JOBS

A

B

C

D

1

6+1=7

3

0

0

2

0+1=1

0

5

2

3

0

0

3

0

4

0

3

6

1

Determine

the minimum number of lines needed to

cross Out all 0 ( 4),

since this equals the number

of

rows

, we obtain the optimum

assignment.

MACHINE

JOBS

A

B

C

D

1

7

3

0

0

2

1

0

5

2

3

0

0

3

0

4

0

3

6

1

Make

the assignments, start with rows

and columns with Only one 0.

Match jobs with machines

that

have

0 costs.

MACHINE

JOBS

A

B

C

D

1

7

3

0

0

2

1

0

5

2

3

0

0

3

0

4

0

3

6

1

The

assignment according to Hungarian

Method is therefore

A4,

2B,1C AND 3D

Sequencing

Sequencing:

Determine the order in which

jobs at a work center will

be processed.

Workstation:

An area where one person works,

usually with special equipment, on a

specialized job.

Summary

Scheduling

is the timing and coordination of Operations.

Scheduling problems differ in nature

because

of

the system being designed for

high volume, intermediate or

low volume flow. In our

next lecture we

will

discuss its complementary and

supplementary concept of Sequencing.

188

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model