|

SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks |

| << SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning |

| SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method >> |

Production

and Operations Management

MGT613

VU

Lesson

40

SUPPLY

CHAIN MANAGEMENT

Learning

Objective

In

this lecture we will focus on

certain important parameters of

Supply Chain Management. We

will

discuss

the Supply Chain Operational

Reference Metrics and Collaborative

Planning Forecasting

and

Replenishment Process, which would

help us analyze the Supply chains.

This would also

help

us

an operation manager to design effective

supply chains. We will try

to understand the concepts of

Velocity

and Bullwhip effect and how

they pose a serious

challenge to the effectiveness of the

Supply

Chain.

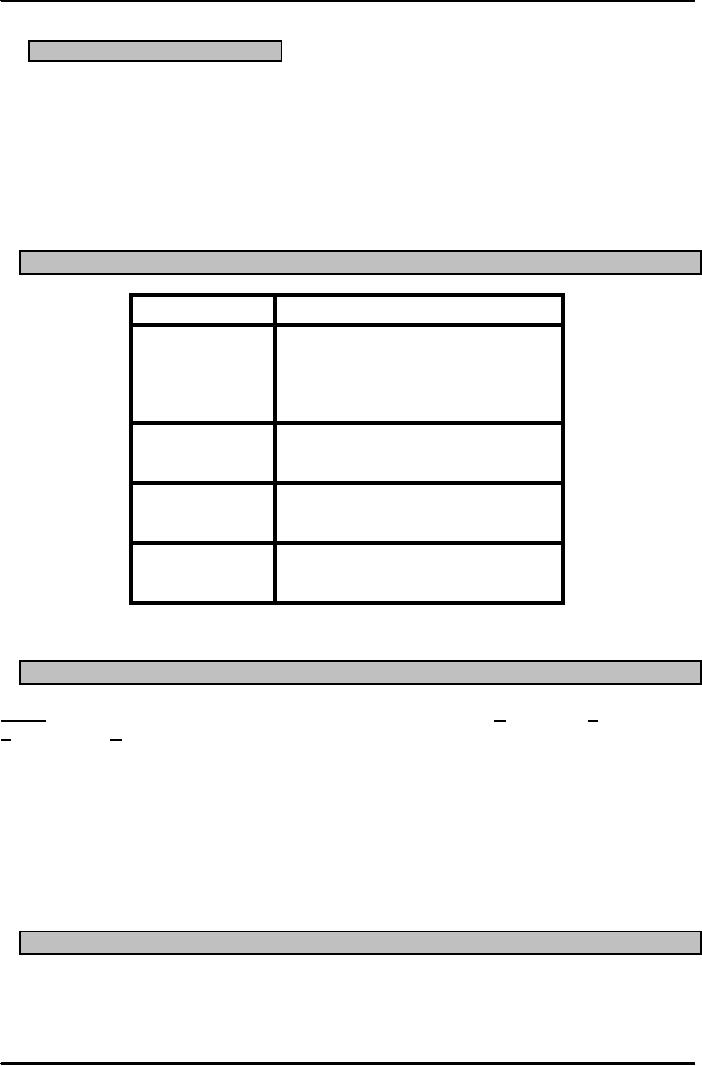

Supply

Chain Operational Reference (SCOR)

Metrics

Perspective

Metrics

Reliability

On-time

delivery

Order

fulfillment lead time

Fill

rate (fraction of demand met

from

stock)

Perfect

order fulfillment

Flexibility

Supply

chain response time

Upside

production flexibility

Agility

to obtain competitiveness

Expenses

Supply

chain management

costs

Warranty

cost as a percent of revenue

Value

added per employee

Assets/utilization

Total

inventory days of

supply

Cash-to-cash

cycle time

Net

asset turns

Supply

chain response time often

makes or breaks a supply

chain.

CPFR

CPFR

is an acronym derived from the

first letters of the following phrase:

Collaborative Planning,

Forecasting

and Replenishment.

1.

Focuses on information sharing among

trading partners.

2.

Forecasts can be frozen and

then converted into a

shipping plan.

3.

Eliminates typical order

processing.

CPFR

Process consists of the following

steps.

Step

1 Front-end agreement

Step

2 Joint business

plan

Steps

3-5 Sales

forecast

Steps

6-8 Order forecast

collaboration

Step

9 Order generation/delivery

execution

Creating

an Effective Supply

Chain

1.

Develop

strategic objectives and

tactics.

2.

Integrate

and coordinate activities in the internal

supply chain.

3.

Coordinate

activities with suppliers with

customers.

4.

Coordinate

planning and execution

across the supply

chain.

181

Production

and Operations Management

MGT613

VU

5.

Form strategic partnerships.

Supply

Chain Performance Drivers

1.

Quality

2.

Cost

3.

Flexibility

4.

Velocity

5.

Customer service

Velocity

1.

Inventory velocity: The rate at

which inventory (material)

goes through the supply

chain.

2.

Information velocity: The rate at

which information is communicated in a

supply chain.

Challenges

to an Effective Supply Chain

Management

1.

Barriers to integration of

organizations

2.

Getting top management on

board

3.

Dealing with

trade-offs

4.

Small businesses

5.

Variability and uncertainty

6.

Long lead times

Trade-offs

1.

Cost-customer service

a.

Disintermediation

2.

Lot-size-inventory

a.

Bullwhip effect

3.

Inventory-transportation costs

a.

Cross-docking

4.

Lead time-transportation

costs

5.

Product variety-inventory

a.

Delayed differentiation

Bullwhip

effect represents the real

life time situation that

Inventories are

progressively

larger

moving backward through the

supply chain.

Cross-docking

represents the fact that the

goods arriving at a warehouse

from a supplier are

unloaded

from the supplier's truck

and loaded onto outbound

trucks. Avoids warehouse

storage.

Delayed

differentiation relates to the Production

of standard components and

subassemblies,

which are held until

late in the process to add

differentiating features.

Disintermediation

is reducing one or more steps in a supply

chain by cutting out one

or

more

intermediaries.

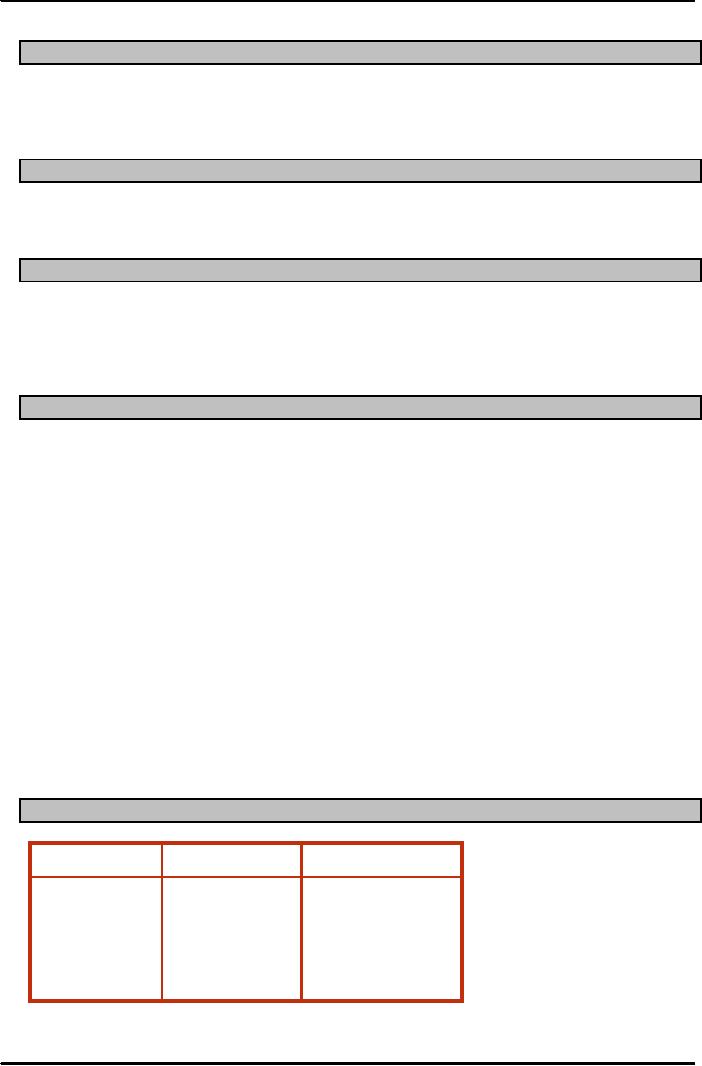

Supply

Chain Issues

Strategic

Issues

Tactical

Issues

Operating

Issues

Design

of the

Inventory

policies

Quality

control

supply

chain,

Purchasing

policies

Production

planning and

partnering

Production

policies

control

Transportation

policies

Quality

policies

182

Production

and Operations Management

MGT613

VU

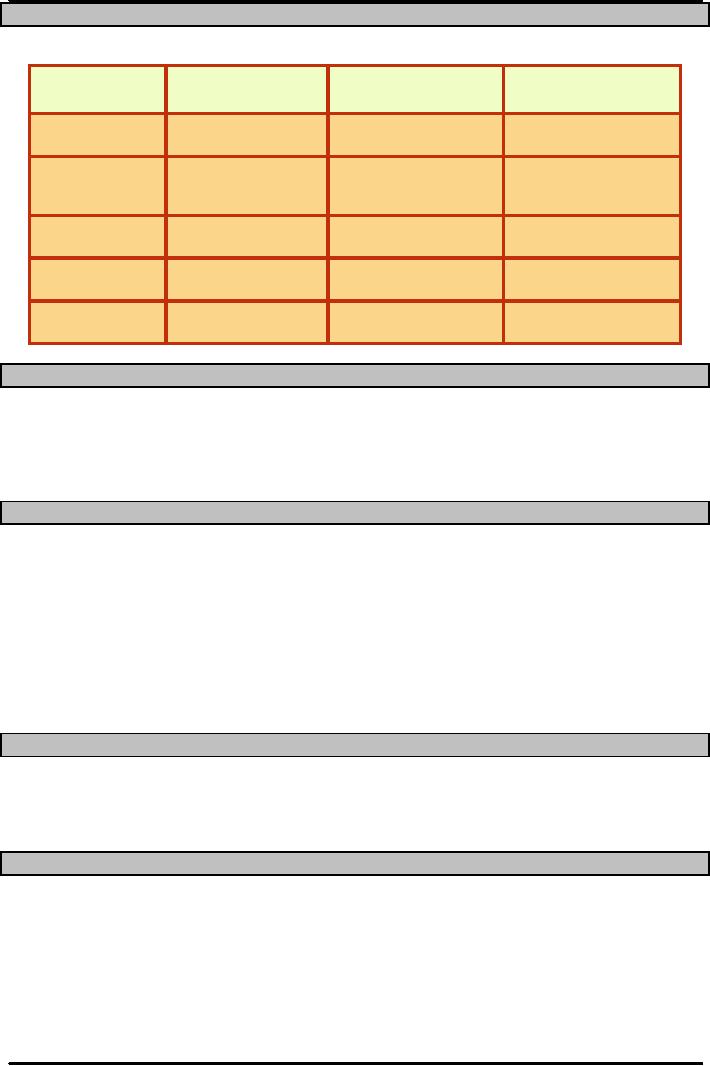

Supply

Chain Benefits and Drawbacks

Problem

Potential

Benefits

Possible

Improvement

Drawbacks

Large

Smaller,

more

Reduced

holding

Traffic

congestion

inventories

frequent

deliveries

costs

Increased

costs

Long

lead times

Delayed

Quick

response

May

not be feasible.

differentiation

May

need absorb

Disintermediation

functions

Large

number

Modular

Fewer

parts

Less

variety

of

parts

Simpler

ordering

Cost

Outsourcing

Reduced

cost, higher

Loss

of control

Quality

quality

Variability

Shorter

lead times,

Able

to match supply

Less

variety

better

forecasts

and

demand

Supplier

Partnerships

Ideas

from suppliers could lead to

improved competitiveness

1.

Reduce cost of making the

purchase

2.

Increase Revenues

3.

Enhance Performance

Critical

Issues

1.

Technology management

a.

Benefits

b.

Risks

2.

Strategic importance

a.

Quality

b.

Cost

c.

Agility

d.

Customer service

e.

Competitive advantage

Operations

Strategy

1.

SCM creates value through

changes in time, location and

quantity.

2.

SCM creates competitive advantage by

integrating and streamlining the diverse

range of

activities

that involve purchasing, internal

inventory, transfers and physical

distribution.

Summary

Supply

Chain Management dynamics allow an

Operations Manager to evolve an effective

strategy that

creates

value. Logistics and purchasing alone

can allow an operations manager to

effectively control the

flow

of information and materials with in and to and

fro from the organization.

Organizations aiming

for

SCM

implementation often fail

because of lack of training of

their employees as well as

top

managements

commitment.

183

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model