|

Production

and Operations Management

MGT613

VU

Lesson

39

SUPPLY

CHAIN MANAGEMENT

Supply

Chain: The

sequence of organization's facilities,

functions, and activities

that are involved in

producing

and delivering a product or

service.

Need

for Supply Chain

Management

1.

Improve

operations

2.

Increasing

levels of outsourcing

3.

Increasing

transportation costs

4.

Competitive

pressures

5.

Increasing

globalization

6.

Increasing

importance of e-commerce

7.

Complexity

of supply chains

8.

Manage

inventories

Benefits

of Supply Chain

Management

1.

Lower

inventories

2.

Higher

productivity

3.

Greater

agility

4.

Shorter

lead times

5.

Higher

profits

6.

Greater

customer loyalty

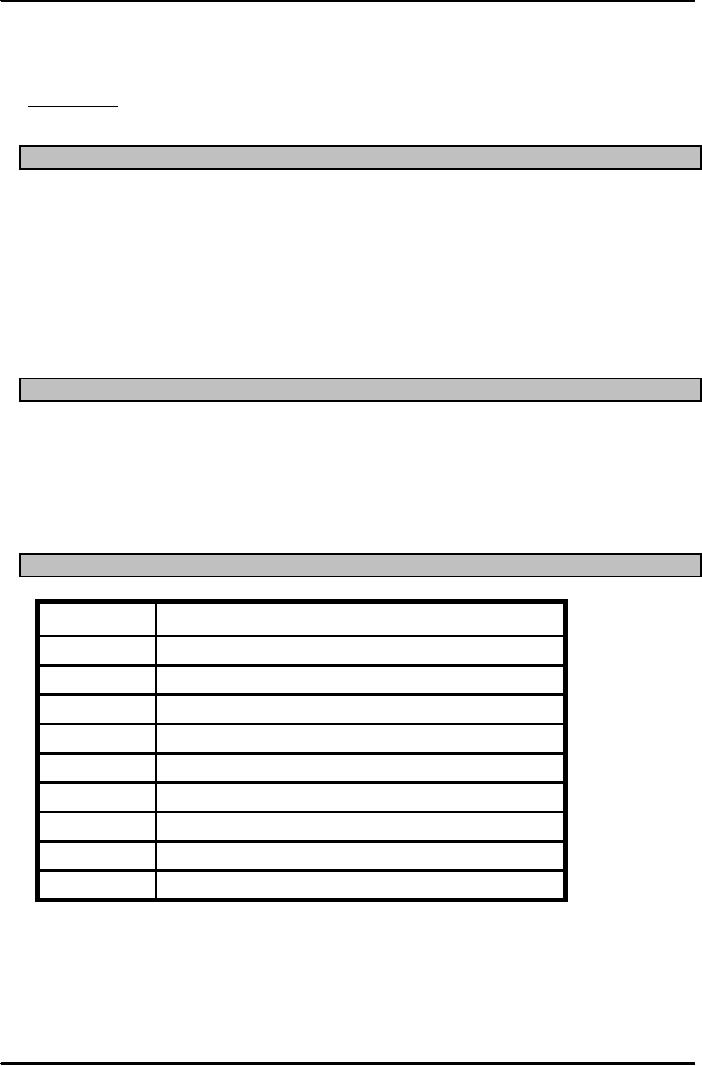

Elements

of Supply Chain

Management

Element

Typical

Issues

Customers

Determining

what customers want

Forecasting

Predicting

quantity and timing of

demand

Incorporating

customer wants, mfg., and

time

Design

Processing

Controlling

quality, scheduling work

Inventory

Meeting

demand while managing

inventory costs

Purchasing

Evaluating

suppliers and supporting

operations

Suppliers

Monitoring

supplier quality, delivery, and

relations

Location

Determining

location of facilities

Logistics

Deciding

how to best move and store

materials

177

Production

and Operations Management

MGT613

VU

Logistics

The

goal of logistic work is to

manage the completion of project

life cycles, supply chains

and

resultant

efficiencies. Often Logistics is termed

as the art and science of

managing and controlling

the

flow of goods, energy, information and

other resources like products,

services, and people,

from

the

source of production to the

marketplace.

It

also refers to the movement of materials and

information within a facility and to

incoming and

outgoing

shipments of goods and materials in a

supply chain.

Logistics

is the time related positioning of

resources and is commonly

seen as a branch of

engineering

which creates "people

systems" rather than

"machine systems. It involves

the

integration

of information, transportation,

inventory, warehousing, material

handling, and

packaging.

.

Important

Characteristics of Logistics

1.

Movement

within the facility

2.

Bar

coding

3.

Incoming

and outgoing shipments

4.

EDI

(Electronic Data Interchange)

5.

Distribution

6.

JIT

Deliveries

Logistics:

Evaluating Shipping

Alternatives

A

situation that arises

frequently in some businesses in

making a choice between quicker(

expensive)

shipping alternatives such as

overnight or 2 day air and

slower but cheaper

alternatives.

The decision in such cases

often focuses on the cost

savings of alternatives

versus

the increased holding cost

that result from using

slower alternative.

Often

the supplier gets paid on

delivery of the product through

EDI the very same time

the

order

reaches its

destination.

The

Incremental Holding cost

incurred by using the slower

alternative is computed as

follows:

Incremental

Holding Cost= H (

d/365)

Where

H=Annual Holding cost for

the item.

d

= Time savings in days and

d/365 is fraction of year

saved.

Logistics

Example

Determine

the shipping alternative ( with in

Pakistan) for a Karachi based

Montessori toy

manufacturer,1

days or 5 days are best

when the holding cost of the

item is Rs. 100,000 per year

and

the

1 day shipping cost is Rs

1500. and 3 day shipping

cost is

Rs.

600

Rs.

500

178

Production

and Operations Management

MGT613

VU

Solution

H=

Rs. 100,000 per year

Time

savings = 2 days using 1 day

alternative

Holding

cost for additional 2

days

=

100,000 X ( 2/365)

=

Rs. 547.95=548.

Or

Holding cost per day = Rs.

274

Alternative

A

Cost

savings = Rs. (1500-600)= Rs.

900, because the actual cost of savings

of Rs 900 is more than

the

holding cost of Rs. 548,

use the 3 day option.

Cost

savings = Rs. (1500-500)= Rs.

1000, because the actual cost of savings

of Rs 1000 is greater

than

the holding cost of Rs.548,

use the 3 day option.

Distribution

Requirements Planning

Distribution

requirements planning (DRP) is a system

for inventory management and

distribution

planning.

Extends the concepts of MRPII.

Uses

of DRP

Management

uses DRP to plan and

coordinate:

1.

Transportation

2.

Warehousing

3.

Workers

4.

Equipment

5.

Financial

flows

Electronic

Data Interchange

EDI

is the direct transmission of inter-organizational

transactions, computer-to-computer,

including

purchase

orders, shipping notices, and debit or

credit memos.

Electronic

Data Interchange gives an organization

the following benefits and

advantages.

1.

Increased

productivity

2.

Reduction

of paperwork

3.

Lead

time and inventory

reduction

4.

Facilitation

of just-in-time systems

5.

Electronic

transfer of funds

6.

Improved

control of operations

7.

Reduction

in clerical labor

8.

Increased

accuracy

179

Production

and Operations Management

MGT613

VU

Efficient

Consumer Response

Efficient

consumer response (ECR) is a

supply chain management

initiative specific to the

food

industry.

ECR reflects companies' efforts to achieve

quick response using EDI and

bar codes.

E-Commerce:

is the use of electronic technology to

facilitate business transactions.

Successful

Supply Chain

1.

Trust

among trading partners

2.

Effective

communications

3.

Supply

chain visibility

4.

Event-management

capability

a.

The ability to detect and

respond to unplanned

events

5.

Performance metrics

Summary

Supply

Chain Management is primarily the

flow of information which

ensures the effective flow

of

materials

throughout the value chain.

The chain extends from the

Suppliers to the organization and

from

the

organization to the customers. Operations

Managers should be able to

identify that the strength of

the

Supply Chain is the strength of its

weakest link. If an organization

fails to make use of the

customer

feed

back it not only looses its

customer base but also

weakens its supply chain and

loses its business to

its

customers. Suppliers normally

come at the upstream of the organization

and customers at the

downstream

to complete the Supply Chain. Many

Software are available to

ensure that Supply chain

is

managed

effectively by the organization. Supply

Chain Management is now

gaining popularity in

Pakistan.

180

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model