|

Production

and Operations Management

MGT613

VU

Lesson

38

JUST

IN TIME PRODUCTION SYSTEMS

Just

In Time system provides an

organization a robust structure by improving the

relationship between

the

organization and the supplier by

constituting a strategic alliance network

between the organization

and

the suppliers. At the intra organization

level, JIT forms a healthy

alliance between the management

and

the workforce, all this

contributes in elimination of

waste.

JUST

IN TIME

Just-In-Time

(JIT): JIT can be defined as

an integrated set of activities designed

to achieve

high-volume

production using minimal

inventories (raw materials, work in

process, and

finished

goods).

JIT

also involves the elimination of

waste in production

effort.

JIT

also involves the timing of

production resources (i.e.,

parts arrive at the

next

workstation

"just in time").

Just-in-time

(JIT): A

highly coordinated processing

system in which goods move

through the

system,

and services are performed,

just as they are needed. As

operations managers we should

remember

this point onwards

that

1.

JIT is also known as lean

production

2.

JIT is the true pull (demand)

system

3.

JIT operates with very

little "fat"

.

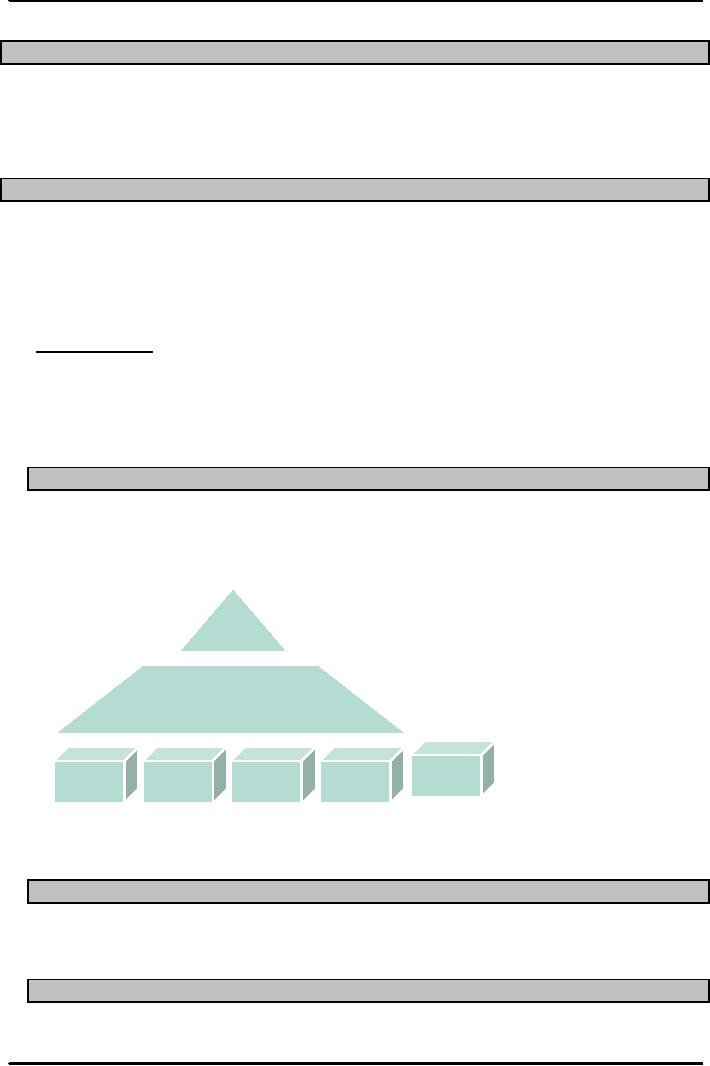

Summary

JIT Goals and Building

Blocks

Goal

of JIT: The ultimate goal of

JIT is a balanced system. JIT

achieves a smooth, rapid flow

of

materials

through the system. The

ultimate as well as supporting goals

are represented below in

the

form

of a pyramid.

Ultimate

A

Goal

balanced

rapid

flow

Supporting

Goals

Eliminate

disruptions

Eliminate

waste

Make

the system flexible

Building

Product

Process

Personnel

Manufactur-

Blocks

Design

Design

Elements

ing

Planning

We

need to pay special attention on

building blocks along with

secondary blocks as absence of

one

or

more objectives can seriously harm the

JIT production structure for

any manufacturing or service

based

organization.

Secondary

Goals

1.

Eliminate disruptions

2.

Make system flexible

3.

Eliminate waste, especially

excess inventory

Big

vs. Little JIT

1.

Big JIT broad focus (

Includes Internal as well as

External)

a.

Vendor relations

174

Production

and Operations Management

MGT613

VU

b.

Human relations

c.

Technology management

d.

Materials and inventory

management

2.

Little JIT narrow focus

Internal to organization

a.

Scheduling materials

b.

Scheduling services of

production

JIT

Building Blocks

1.

Product design

2.

Process design

3.

Personnel/organizational elements

4.

Manufacturing planning and

control

The

Lean Production

System

Based

on two philosophies:

1.

Elimination of waste

2.

Respect for people

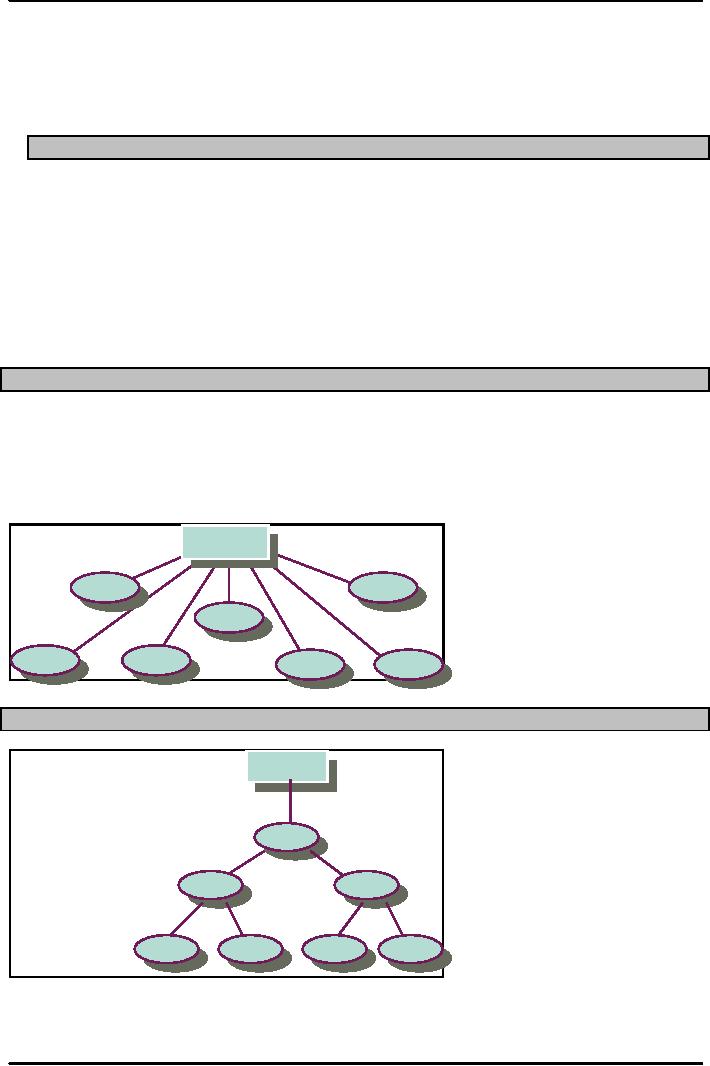

Traditional

Supplier Network

1.

The organizations make its

suppliers compete against each

other.

2.

Also the suppliers can supply the

same component or raw material to the

organizations

competitors

thus harming the organizations

business.

3.

Organizations tend to waste

resources and a lot of time

looses its suppliers to the

competitors.

4.

Suppliers too end up absorbing

poor order placement from the

organizations.

5.

The whole network faces

sluggishness or inertia.

Buyer

Supplier

Supplier

Supplier

Supplier

Supplier

Supplier

Supplier

Tiered

Supplier Network

Buyer

First

Tier Supplier

Supplier

Second

Tier Supplier

Supplier

Supplier

Third

Tier Supplier

Supplier

Supplier

Supplier

Supplier

1.

The suppliers work as a strategic

alliance to provide components to the

organization.

2.

Inventory costs as well as the

overall time involved are

reduced.

175

Production

and Operations Management

MGT613

VU

3.

Order execution is improved and

organizations do not face the

challenge of loosing its

suppliers

to

the competitors.

4.

There is little or no rivalry between the

suppliers

Transitioning

to a JIT System

1.

Get top management

commitment

2.

Decide which parts need

most effort

3.

Obtain support of workers

4.

Try to reduce scrap

material

5.

Start by trying to reduce setup

times

6.

Incorporate quality

7.

Gradually convert operations

8.

Convert suppliers to JIT

9.

Prepare for obstacles

Obstacles

to Conversion

1.

Management may not be

committed

2.

Workers/management may not be

cooperative

3.

Suppliers may resist

JIT

in Services

The

basic goal of the demand

flow technology in the service

organization is to provide

optimum

response

to the customer with the highest

quality service and lowest possible

cost.

1.

Eliminate disruptions

2.

Make system flexible

3.

Reduce setup and lead

times

4.

Eliminate waste

5.

Simplify the process

JIT

in Services (Examples)

1.

Upgrade Quality

2.

Clarify Process Flows

3.

Develop Supplier

Networks

4.

Introduce Demand-Pull

Scheduling

5.

Reorganize Physical Configuration

6.

Eliminate Unnecessary

Activities

7.

Level the Facility

Load

JIT

II

JIT

II: a supplier representative works right

in the company's plant,

making sure there is an

appropriate

supply on hand.

Benefits

of JIT Systems

1.

Reduced inventory

levels

2.

High quality

3.

Flexibility

4.

Reduced lead times

5.

Increased productivity

Summary

JIT

systems allow an organization to achieve

a balanced smooth flow of production,

more system

flexibility

with reduction in wastes and

lead time. Proper emphasis on the

process and product design

along

with personnel management can

provide the necessary control and

reward of achievement of JIT

or

Lean Production

systems.

176

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model