|

Production

and Operations Management

MGT613

VU

Lesson

37

JUST

IN TIME PRODUCTION

SYSTEMS

We have

progressed our discussion on

Lean Production Systems and

Just In Time Systems and we

will

now

focus our attention upon

Lean Systems in Services,

Operational Benefits associated

with JIT. We

will

also note some of the common

Implementation Issues along

which the Organizational face

while

implementing

JIT. We also need to know

what single Kanban System is

and solve some

examples.

Characteristics

of Lean Systems:

Just-in-Time

Continuous

Improvement with the help of

Lean Systems is possible if Operations

Managers are able

to

focus on some of the common characteristics of

Lean Systems, which

include:

1.

Pull

method of materials flow

2.

Consistently

high quality

3.

Small

lot sizes

4.

Uniform

workstation loads

5.

Standardized

components and work

methods

6.

Close

supplier ties

7.

Flexible

workforce

8.

Line

flows

9.

Maintenance

10.

Automated

production

11.

Preventive

maintenance

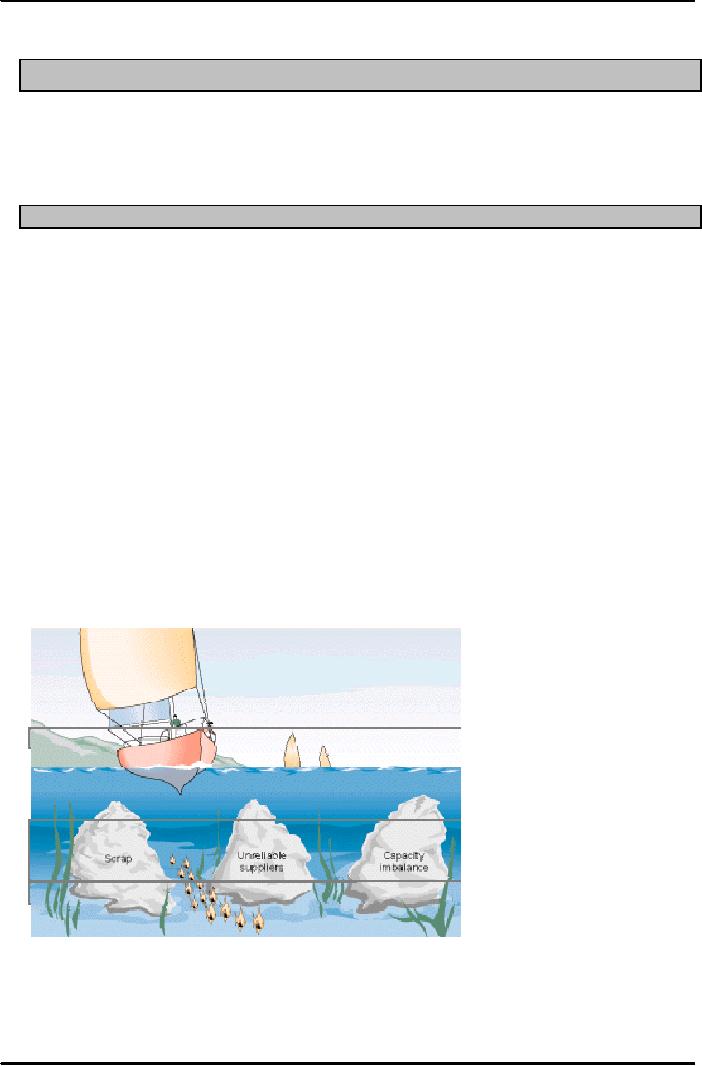

The

figure below of a ship

sailing through waters is a great

representation of an organization

carrying

its business with hidden

rocks (barriers) like scrap,

unreliable suppliers and capacity

imbalance,

carrying the threat of sinking the ship.

With proper and effective

lean production

system

philosophy

in place, this can be avoided and

organization can continue to

sail through smooth

and

calm

waters.

Unreliable

Capacity

Scrap

suppliers

imbalance

170

Production

and Operations Management

MGT613

VU

Lean

Systems in Services

1.

Consistently

high quality

2.

Uniform

facility loads

3.

Standardized

work methods

4.

Close

supplier ties

5.

Flexible

workforce

6.

Automation

7.

Preventive

maintenance

8.

Pull

method of materials flow

9.

Line

flows

Operational

Benefits

1.

Reduce

space requirements

2.

Reduce

inventory investment

3.

Reduce

lead times

4.

Increase

labour productivity

5.

Increase

equipment utilization

6.

Reduce

paperwork and simple planning

systems

7.

Valid

priorities for

scheduling

8.

Workforce

participation

9.

Increase

product quality

Implemental

Issues

1.

Organizational considerations

a.

Human cost of JIT

systems

b.

Cooperation and trust

c.

Reward systems and labour

classifications

2.

Process considerations

3.

Inventory and

scheduling

a.

MPS stability

b.

Setups

c.

Purchasing and logistics

Kanban

Production Control

System

Kanban:

Card or other device that

communicates demand for work

or materials from the preceding

station.

Kanban

is the Japanese word meaning

"signal" or "visible

record".

Paperless

production control

system.

Authority

to pull, or produce comes from a

downstream process.

Kanbans

also govern the assembly or Parts'

movement authorization

Kanban

Formula

We

can mathematically construct the Kanban

Formula, If we designate the following

alphabets

N

= Total number of containers ( Or Kanban

Cards)

D

= Planned usage rate of using work

center

T

= Average waiting time for

replenishment of parts

plus

average production time for

a

container

of parts

171

Production

and Operations Management

MGT613

VU

X

= Policy variable set by

management

-

possible inefficiency in the system often

called Alpha

C

= Capacity of a standard

container

DT(1+X)

N

=

C

Often

the same formula above is

used with the following

parameters in mind

N=

# cards

D=

usage

T

= wait + process time

X

= efficiency rating

C

= bin capacity

Example

A

company in Gujranwala is making rubber

tyres and tubes. The operations manager

has just

completed

his MBA from VU and has

observed the that factory has

inefficient machine group. He

records

that the daily demand for

21" tube is 1000 units.

The average waiting time

for a container of

the

same part is 0.5 day.

The processing time for the

tyre tube container is 0.25

day. A container can

hold

500 units, currently there

are 20 containers for this

item.

Calculate

1.

What is the value of policy

variable ALPHA?

2.

What is the total planned

inventory (work in process and

finished goods) for the tyre

tube?

3.

Suppose that the policy

variable Alpha is 0, how

many containers would be needed?

what is

the

effect of policy variable in

this problem?

Solution

The

given data is

d

is 1000 units, w bar = 0.5

day.

P

bar= 0.25 day. K= 500

units and Alpha is to be

calculated.

We

use the equation and substitute

values

d(

w

+

p

)(

1 +α

)

k=

c

Then

with 20 containers in the system and

since each container can

hold 500 units, the total

planned

inventory

is 20 (500)= 10,000

units

If

Alpha is 0 then on substituting values we

have

1000(0.5

+0.25 )( 1 + α )

500

=

20

(1

+ a

)=500

X 20 / 1000 (0.75)

(1

+ a

)=10,000/750=13.33

a

=12.33

172

Production

and Operations Management

MGT613

VU

Then

with 20 containers in the system and

since each container can

hold 500 units, the

total

planned

inventory is 20 ( 500)= 10,000

units

If

Alpha is 0 then on substituting values we

have

1000(0.5

+0.25 )( 1 + 0 )

k=

500

1000(0.75

)( 1 )

k=

500

K=

750/500= 1.5 or more correctly 2

containers.

Single-Card

Kanban System

1.

Each

container must have a

card.

2.

Assembly

always withdraws from

fabrication (pull

system).

3.

Containers

cannot be moved without a

kanban.

4.

Containers

should contain the same number of

parts.

5.

Only

good parts are passed

along.

6.

Production

should not exceed

authorization.

Summary

Organizations

use different methods and

means to signal the need for

material replenishment and

production,

in this lecture we studied the

effective kanban system and

learnt how a single card

Kanban,

JIT

System can be used to

control production

flow.

173

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model