|

Production

and Operations Management

MGT613

VU

Lesson

35

MRP

II/ ERP

Learning

Objectives

Discuss

benefits and requirements of MRP.

Explain

how an MRP system is useful

in Capacity Requirements

Benefits

and shortcomings of MRP

MRP

II and MRP.

MRP:

A Recap

1.

Material

Requirements Planning (MRP) is a

software focusing on production

planning and

inventory

control system used to

manage manufacturing

processes.

2.

An MRP system is intended to

simultaneously meet three

objectives:

1.

Ensure materials and products are

available for production and

delivery to customers.

2.

Maintain the lowest possible level of

inventory.

3.

Plan manufacturing activities,

delivery schedules and purchasing

activities.

MRP

Processing

1.

Gross requirements

a.

Total expected demand.

2.

Scheduled receipts

a.

Open orders scheduled to

arrive.

3.

Planned on hand

a.

Expected inventory on hand at the beginning of

each time period.

4.

Net requirements

a.

Actual amount needed in each

time period.

5.

Planned-order receipts

a.

Quantity expected to be received at the

beginning of the period.

b.

Offset by lead time.

6.

Planned-order releases

a.

Planned amount to order in each time

period.

Updating

the MRP Systems

1.

Regenerative system

a.

Updates MRP records

periodically.

2.

Net-change system

a.

Updates MPR records

continuously.

MRP

in Services

1.

Food catering service

2.

End item => catered

food

3.

Dependent demand => ingredients for

each recipe, i.e. bill of

materials

4.

Hotel renovation

5.

Activities and materials "exploded" into

component parts for cost

estimation and scheduling

6.

Benefits

of MRP

1.

Low levels of in-process

inventories

2.

Ability to track material

requirements

3.

Ability to evaluate capacity

requirements

4.

Means of allocating production

time

164

Production

and Operations Management

MGT613

VU

Requirements

of MRP

1.

Computer and necessary

software

2.

Accurate and up-to-date

3.

Master schedules

4.

Bills of materials

5.

Inventory records

6.

Integrity of data

MRP

II

1.

Expanded MRP with emphasis

placed on integration

2.

Financial planning

3.

Marketing

4.

Engineering

5.

Purchasing

6.

Manufacturing

Capacity

Planning

Capacity

requirements planning: The process of

determining short-range capacity

requirements.

Load

reports: Department or work center reports

that compare known and expected

future capacity

requirements

with projected capacity

availability.

Time

fences: Series of time

intervals during which order

changes are allowed or

restricted.

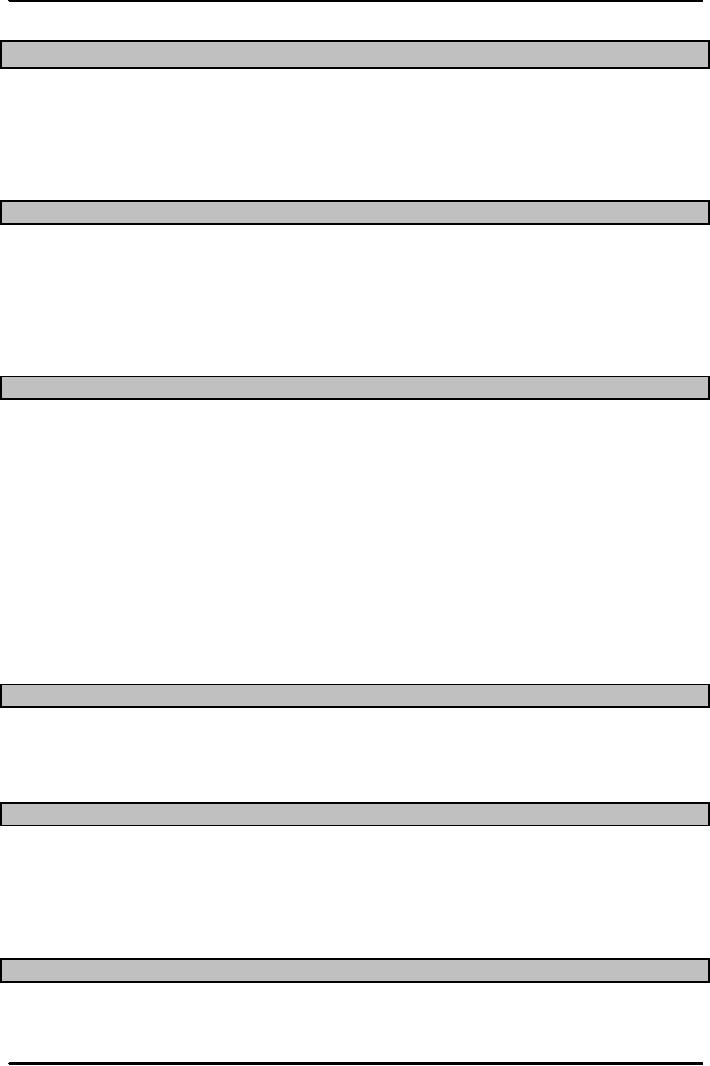

Develop

a tentative

Use

MRP to

master

production

simulate

material

schedule

requirements

Revise

tentative

Convert

material

master

production

requirements

to

schedule

resource

requirements

No

Can

Is

shop

capacity

be

No

capacity

changed

to meet

adequate?

requirements

Yes

Yes

Firm

up a portion

Change

of

the MPS

capacity

As

an operations manager we should be able

to identify the process of Capacity

Planning. Infact the

Capacity

requirements planning process determines short-range

capacity requirements. The

necessary

inputs

are:

1.

Planned order releases for

MRP

2.

The current shop

load

3.

Routing information

4.

Job times

Outputs

include load reports for

each work center.

Load

reports: Department or

work center reports that

compare known and expected future

capacity

requirements

with projected capacity

availability.

An

organization generates a Master Schedule

in terms of what is needed and

not in terms of what

is

possible

or available.

An

over view of the capacity

planning process includes the

following.

1.

The Master schedule is first

tested for feasibility and

possibly adjusted before it

becomes

permanent.

2.

The proposed schedule is processed

using MRP to ascertain the materials

requirements the

schedule

would generate.

165

Production

and Operations Management

MGT613

VU

3.

These are then translated

into capacity requirements in the form of

load reports for each

departments

or work centers.

The

initial schedule may or may

not be feasible given the

limits of production or availability

of

materials.

Also, with the aid of Time

fences ( the series of time

intervals during which order

changes are

allowed

or restricted) a feasible schedule may be

finalized.

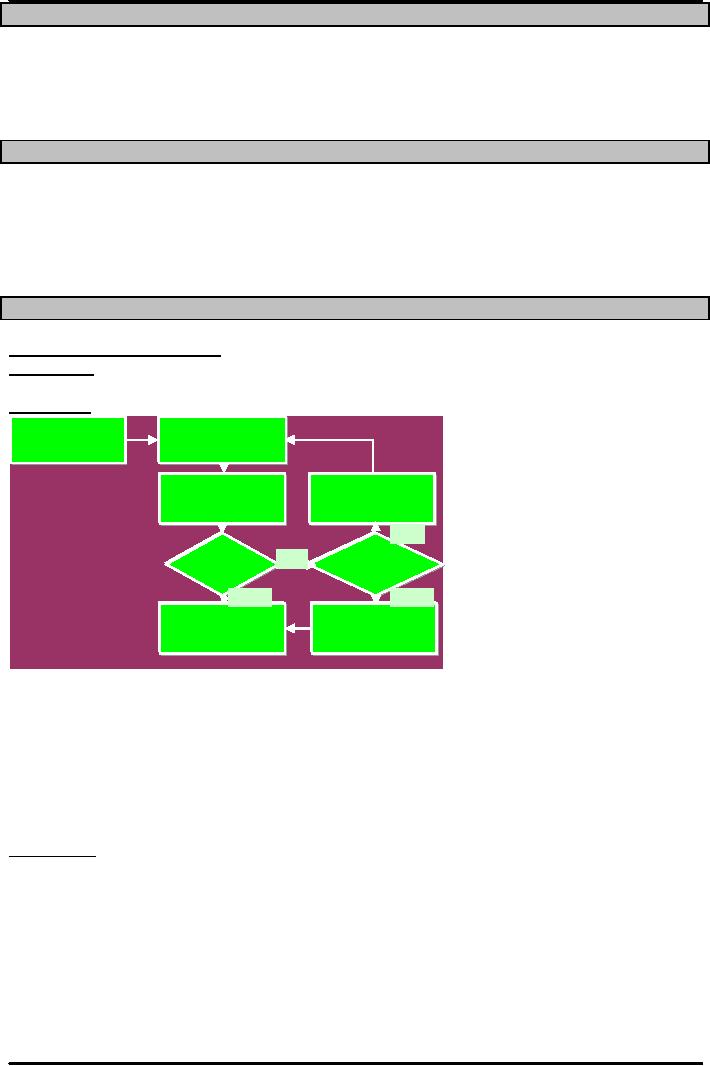

A

listing of all raw materials, parts,

subassemblies,

and assemblies needed to

produce

one unit

P

d

T

f

I

evel X

L

X

0

B(2)

C

1

2

D(3)

E

E(2)

F(2)

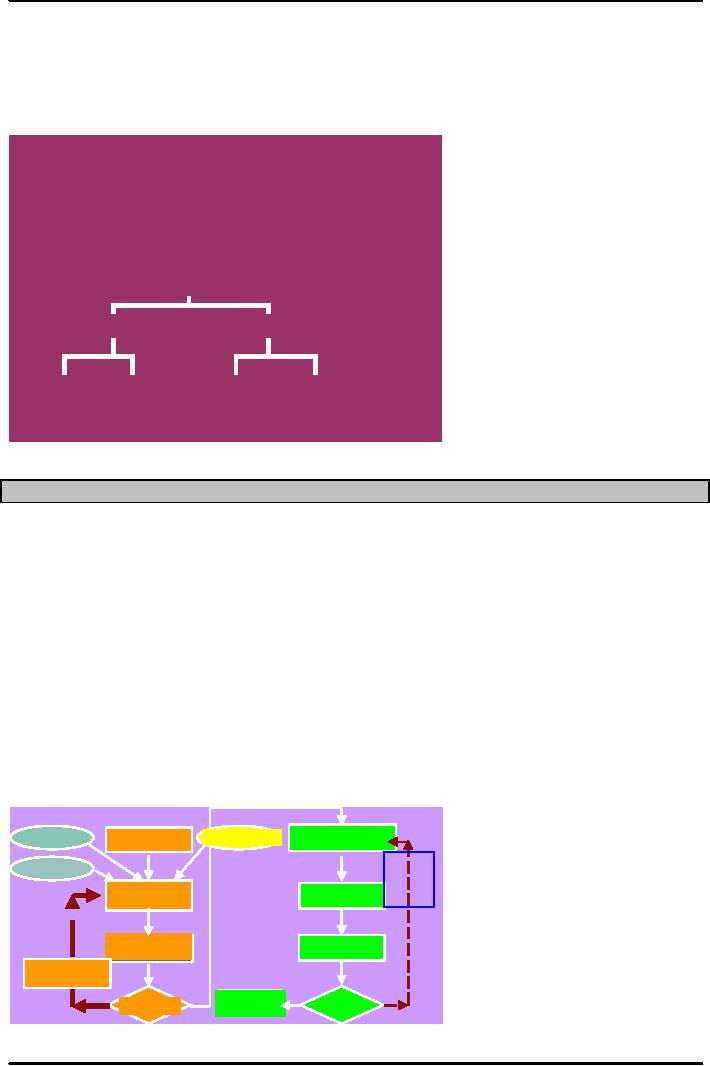

MRP

II

Manufacturing

Resource Planning (MRP

II) is

defined and accepted by professionals as

a method for

the

effective planning of all

resources of a manufacturing

company.

Ideally,

it should answer operational

planning in units, financial

planning in rupees, and has

a simulation

capability

to answer "what-if" questions. and

extension of closed-loop

MRP.

This

is not exclusively a software

function, but a merger of people

skills, dedication to data

base

accuracy,

and computer resources. It is a total

company management concept for

using human resources

more

productively.

Accounting

and finance departments get accurate

costs and predict cash

flows. Operations and

Engineering

departments audit and feed in

accurate data on production

methods in detail, such

as:

1.

Bill of Materials

2.

Quality Control based

operational and functional data.

Master

Market

Manufacturin

Financ

Production

schedule

Deman

Adjust

Marketin

master

schedule

Productio

MR

n

Rough-cut

Capacit

capacity

planning

y

Adjust

production

N

Ye

Requirements

N

Ye

Problems

Problems

schedules

166

Production

and Operations Management

MGT613

VU

ERP

Enterprise

resource planning (ERP):

often called the rightful

next step in an evolution

that began with

MPR

and evolved into MRPII.

Integration of financial, manufacturing,

and human resources on a single

computer

system.

ERP

Strategy Considerations

1.

High

initial cost

2.

High

cost to maintain

3.

Future

upgrades

4.

Training

Summary

Materials

Requirements Planning (MRP) is an

information Systems used to

handle ordering of

dependent

demand items ( components of assembled

products)

The

planning process begins with

customer orders, which are

used along with any back

orders

to

develop a Master Schedule that indicates

timing and quantity of finished

goods.

The

end items are exploded using the

bill of materials; Material

Requirement Plans are

developed

show quantity and timing for

ordering or producing

components.

The

main features of MRP are the

time phasing of requirements, calculating

component

requirements

and planned order

releases.

To

be successful MRP requires a computer

program and accurate master

production schedules,

bills

of materials and inventory data.

Firms

can only implement MRP if

they have accurate

records

MRP

II links business planning,

production planning and the

MPS. ERP's are more refined

as

well

as comprehensive versions of MRP.

167

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model