|

Production

and Operations Management

MGT613

VU

Lesson

32

INVENTORY

MANAGEMENT

Learning

Objectives

Inventory

Management is the procurement, use and

distribution of Inventory; some

text books use the

work

Inventory control for the

same concept. The word

control ensures that inputs,

the process itself

and

the

outputs are all manageable. This

inventory control concept helps us to

understand two important

concepts

of Operations Management i.e. Supply

Chain Management and Just In

Time Production

Systems.

In this lecture we will

study the ABC classification

System, Inventory Ordering

and Holding

Costs

and Economic Order Quantity

Model.

Key

Inventory Terms

The

Key Inventory Terms we

should know are Lead

time, Holding (carrying)

costs, Ordering ( Set

up)

Costs and Shortage(Stock out)

costs

1.

Lead time: Time interval

between ordering and receiving the

order.

2.

Holding (carrying) costs:

Cost to carry an item in

inventory for a length of

time, usually a year.

Costs

include Interest, insurance, taxes,

depreciation, obsolescence,

deterioration, pilferages,

breakage,

warehousing costs and Opportunity

costs. Holding (carrying)

costs: Holding costs

are

stated

in two ways

a.

Percentage of unit price

or

b.

Rupee

3.

Ordering costs: Costs of

ordering and receiving inventory.

These are the actual costs

that vary

with

the actual placement of the order.

4.

Shortage costs: Costs when

demand exceeds

supply.

ABC

Classification System

An

important aspect of Inventory

Management is that items held in

inventory are not of

equal

importance

in terms of rupees invested,

profit potential, sales or

usage volume.

ABC

Classification System controls

inventories by dividing items into 3

groups A, B and C

respectively.

1.

Group A consists of High

Rupee (Monetary) Value,

which account for a small

portion about

10%

of the total inventory

usage.

2.

Group B consists of Medium

Rupee (Monetary) Value,

which account for about

20% of the

total

inventory usage.

3.

Group C consists of Low

Rupee (Monetary) Value,

which account for a large

portion about

70%

of the total inventory

usage.

4.

The level of control reflects

cost benefit

concerns.

5.

Group A items are reviewed on a

regular basis.

6.

Group B items are reviewed at a

less frequency than Group A

items but more than Group

C

items.

7.

Group C items are not

reviewed and order is placed

directly.

147

Production

and Operations Management

MGT613

VU

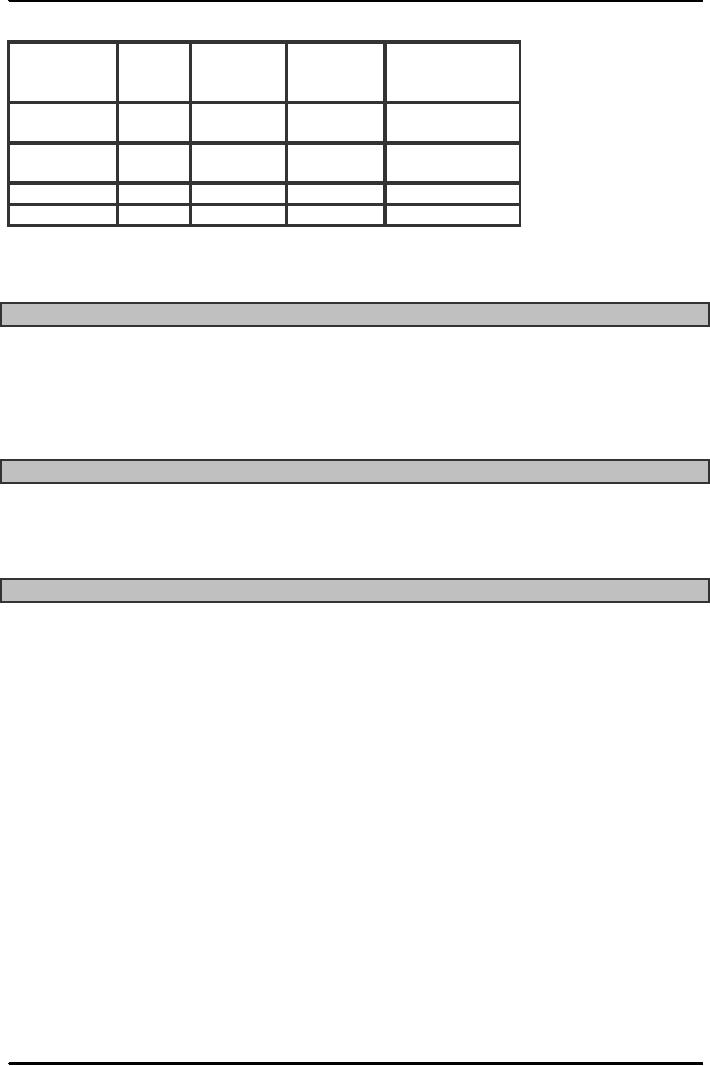

Example.

Item

Dema

Unit

Annual

Classification

nd

Cost

Value

(

Rupees)

PC

10

Rs.20,000

200,000

B

( up to Rs.

500,000)

Monitor

5

5000

25,000

C(

Up to Rs.

50,000)

Processor

25

5000

125,000

B

RAM

1000

2000

2,000,000

A

Classify

inventory

according to ABC classification

system, Rupee value up to

50K and 500K

represent

C and B respectively.

Cycle

Counting

1.

A

physical count of items in

inventory.

2.

Cycle

counting management:

3.

How

much accuracy is

needed?

4.

When

should cycle counting be

performed?

5.

Who

should do it?

Economic

Order Quantity Models

1.

Economic order quantity

model

2.

Economic production

model

3.

Quantity discount

model

Assumptions

of EOQ Model

1.

Only

one product is involved.

2.

Annual

demand requirements known.

3.

Demand

is even throughout the year.

4.

Lead

time does not

vary.

5.

Each

order is received in a single

delivery.

6.

There

are no quantity discounts.

148

Production

and Operations Management

MGT613

VU

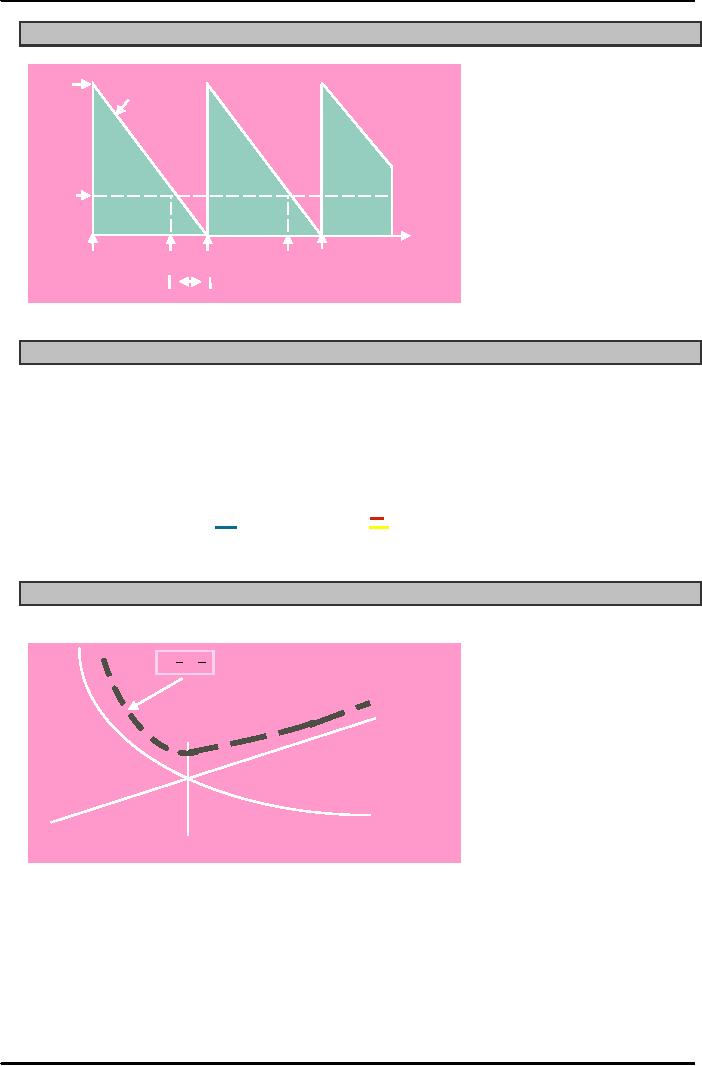

The

Inventory Cycle

Profile

of Inventory Level Over

Time

Q

Usage

rate

Quantity

on

hand

Reorder

point

Time

Place

Receive

Receive

Place

Receive

order

order

order

order

order

Lead

time

Total

Cost

Annual

Annual

carrying

ordering

+

Total

cost =

cost

cost

Q

D

S

H

TC

=

+

2

Q

Cost

Minimization Goal

Q

D

TC

=

H+

S

A

2

Q

n

n

u

Holding

al

Costs

C

o

st

Ordering

Costs

Order

Quantity

QO(optimal order

quantity)

(Q)

149

Production

and Operations Management

MGT613

VU

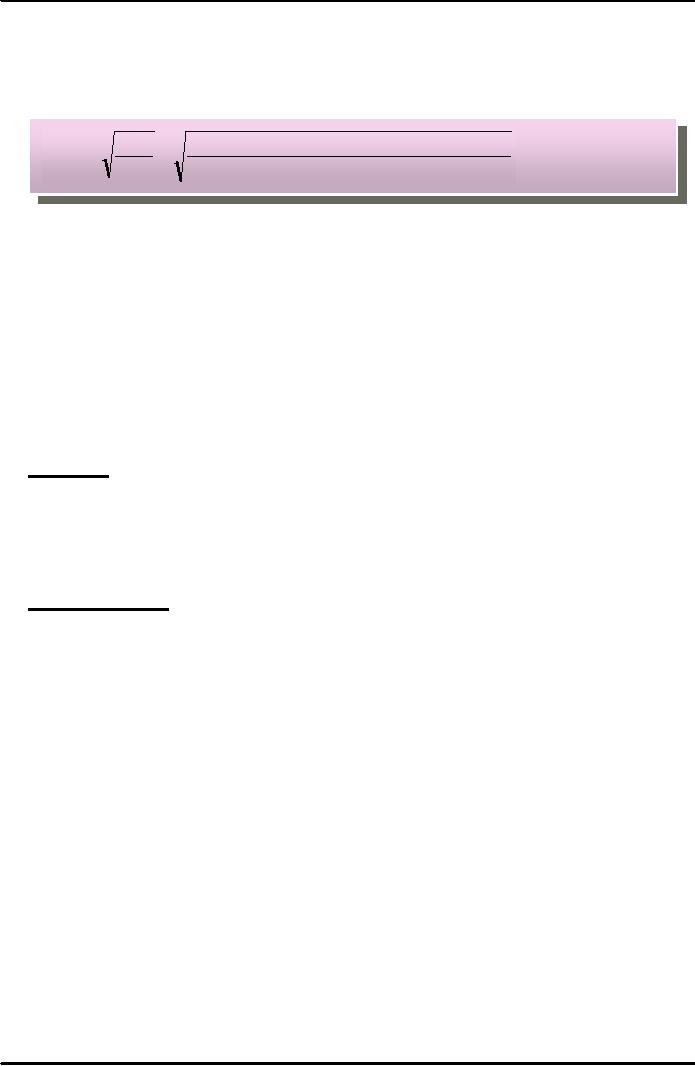

Deriving

the EOQ

Using

calculus, we take the derivative of the

total cost function and

set the derivative (slope)

equal

to

zero and solve for Q.

2DS

2(Annual

Demand)(O rder or Setup

Cost)

Q

OPT =

=

H

Annual

Holding Cost

Minimum

Total Cost

The

total cost curve reaches

its minimum where the carrying

and ordering costs are

equal.

Example

2

A

local distributor for an

international aerobic exercise machine manufacturer

expects to sell

approximate

10,000 machines. Annual

carrying cost is Rs. 2500

per machine and Order cost is

Rs.

10,000.

The distributor Operates 300

days a year.

1.

Find EOQ?

2.

The number of times the store will

reorder?

3.

Length of an Order

Cycle?

4.

Total Annual Cost if EOQ is

ordered?

Given

Data

D=10,000

machines.

H=

Annual carrying cost is Rs.

2500 per machine.

S=Order

cost is Rs. 10,000.

No

of The distributor Operates

300 days a year.

Calculation

of EOQ

Q0= Sq

Root of (2 DS)/H=

Sq

Root (2 X 10,000 X 10,000

)/2500

=Sq

Root (80,000)

=283

machines per year

The

number of times the store will

reorder?

D/Q0=10,000/283=35.34

=

35 Times

The

Length of an Order

Cycle

Q0/D=283/10.000=0.0283 of a year=

0.0283 X 300= 8.49

days

The

Total Annual Cost, if EOQ is

ordered

TC=

Carrying Cost + Ordering

Cost

=Q0/2 ( H) +

D/Q0 (S)

=283/2

(2500) + 10.000/283

(10,000)

=353,750

+ 353,353

=

Rs. 707,107

150

Production

and Operations Management

MGT613

VU

Summary

Inventory

Management is simply the procurement, use

and distribution of Inventory. In our

subsequent

discussions

on Inventory as well as Supply

Chain Management we will

find some similarities

between

the

two important concepts of

Inventory Management and Supply

Chain Management. When

we

combine

Inventory Management (Control)

with Production and Purchasing we are

more or less focusing

on

the Japanese Philosophy of Just In

Time Production. Also, the

basic EOQ Model minimizes the

sum

of

carrying or holding costs as

well as setup or ordering

cost.

151

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model