|

Production

and Operations Management

MGT613

VU

Lesson

30

AGGREGATE

PLANNING

Learning

Objectives

In

this lecture we will cover the basic

aggregate planning strategies,

Assumptions for

Aggregate

Planning,

different Aggregate Planning

Relationships, Master Schedule

and Master Scheduler. We

will

study

desegregating the aggregate plans

for production control. This

discussion would prepare us

to

take

a deeper look into Inventory Management

and MRP/ERP. All this

would allow us to

become

effective

operations manager to work

for improving the operations as

well as the systems of the

organizations

we will work for.

Basic

Strategies

Level

capacity strategy: Maintaining a

steady rate of regular-time output

while meeting

variations

in demand by a combination of

options.

Chase

demand strategy: Matching

capacity to demand; the planned output

for a period is set

at

the

expected demand for that

period.

Chase

Approach

Advantages

1.

Investment in inventory is

low

2.

Labor utilization in

high

Disadvantages

1.

The cost of adjusting output

rates and/or workforce

levels

Level

Approach

Advantages

1.

Stable output rates and

workforce

Disadvantages

1.

Greater inventory costs

2.

Increased overtime and idle

time

3.

Resource utilizations vary

over time

Techniques

for Aggregate

Planning

1.

Determine

demand for each

period

2.

Determine

capacities for each

period

3.

Identify

policies that are

pertinent

4.

Determine

units costs

5.

Develop

alternative plans and

costs

6.

Select

the best plan that satisfies

objectives. Otherwise return to step

5.

Assumptions

for Aggregate

Planning

1.

The regular output capacity

is the same for all

periods.

2.

Cost (Back Order, Inventory,

Subcontracting etc) is a linear function

composed of unit cost

and

number

of units. ( In reality cost is more of a

step function)

3.

Plans are feasible ( There

is sufficient inventory exists to

accommodate a plan,

subcontractors

would

provide quality products and outsourcers

would be secure)

4.

Assumptions for Aggregate

Planning

5.

All costs associated with a

decision option can be

represented by a lump sum or by

unit costs

that

are independent of the quantity

involved.

6.

Cost figures can be reasonably

estimated and are constant

over the planning

horizon.

138

Production

and Operations Management

MGT613

VU

7.

Inventories are built up and

draw down at a uniform rate and

output occurs at a uniform

rate

throughout

each period. Backlogs are

treated as if they exist for the

entire period, even

though

in

reality they tend to build

up towards the end of the period

Aggregate

Planning Relationships

1.

Number of workers in a period

equals Number of Workers at the end of

the previous period

PLUS

Number of new Workers at the

start of the current period -

Number of laid off Workers

at

the

start of the current

period

2.

NOTE: SINCE the organization

would not hire and layoff

simultaneously, so at least one of

the

last

two terms will be

"0".

3.

Inventory at the end of a ( current)

period equals Inventory at the end of the

previous period

PLUS

Production in the current period

Amount used to satisfy the

demand in the current

period

4.

NOTE :The average

Inventory for a period is

equal to (Beginning Inventory

Plus Ending

Inventory)/2

Average

Inventory

Aggregate

Planning Relationships

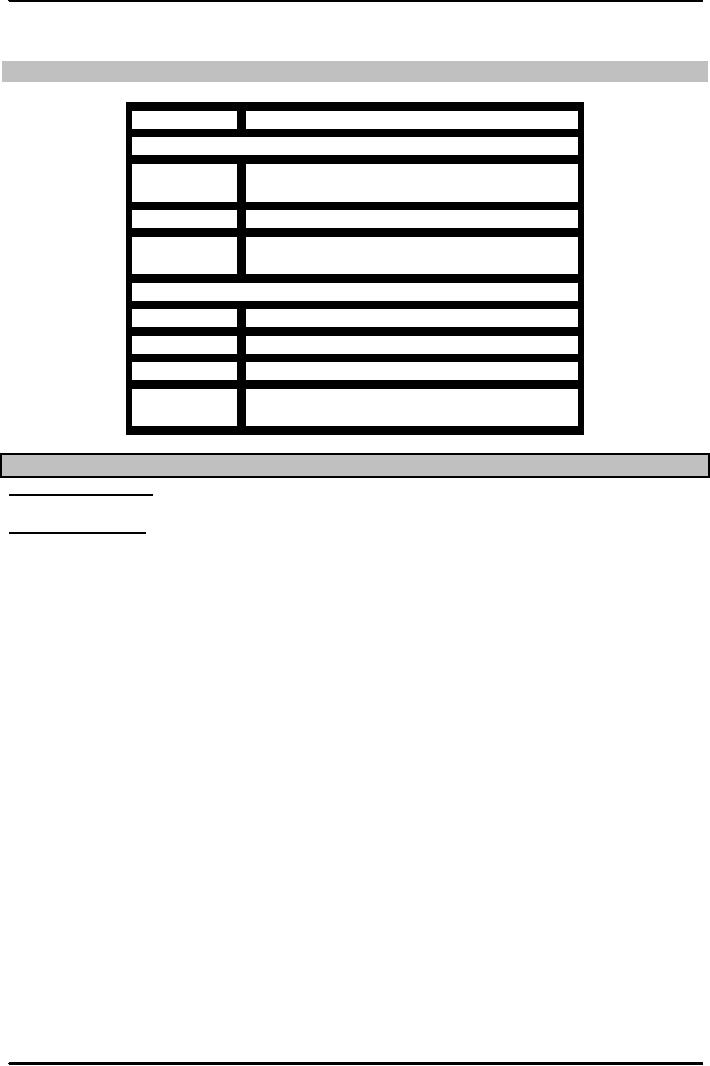

�Cost

for a ( current) period

equals Output Cost ( Regular

+OT+ Subcontract) + Hire/Layoff

Cost+

Inventory

Cost + Backorder Cost

NOTE

The

cost of a particular plan

for a given period can be

determined by summing the appropriate

costs

139

Production

and Operations Management

MGT613

VU

Aggregate

Planning Relationships

Type

of Costs

How

to Calculate

Output

Regular

Regular

Cost per Unit X Quantity of

Regular

Output

Overtime

Overtime

Cost per Unit X Overtime

Quantity

Subcontract

Subcontract

Cost per Unit X Subcontract

Quantity

Hire/Layoff

Hire

Cost

Per Hire X Number

Hired

Layoff

Cost

per Layoff X Number laid

off

Inventory

Carrying

Cost per Unit X Average

Inventory

Back

Order

Back

Order Cost Per Unit X

Number of

Backorder

Units

Mathematical

Techniques

Linear

programming:

Methods for obtaining

optimal solutions to problems involving

allocation of

scarce

resources in terms of cost

minimization.

Linear

decision rule:

Optimizing technique that

seeks to minimize combined

costs, using a set of

cost-

approximating

functions to obtain a single

quadratic equation.

140

Production

and Operations Management

MGT613

VU

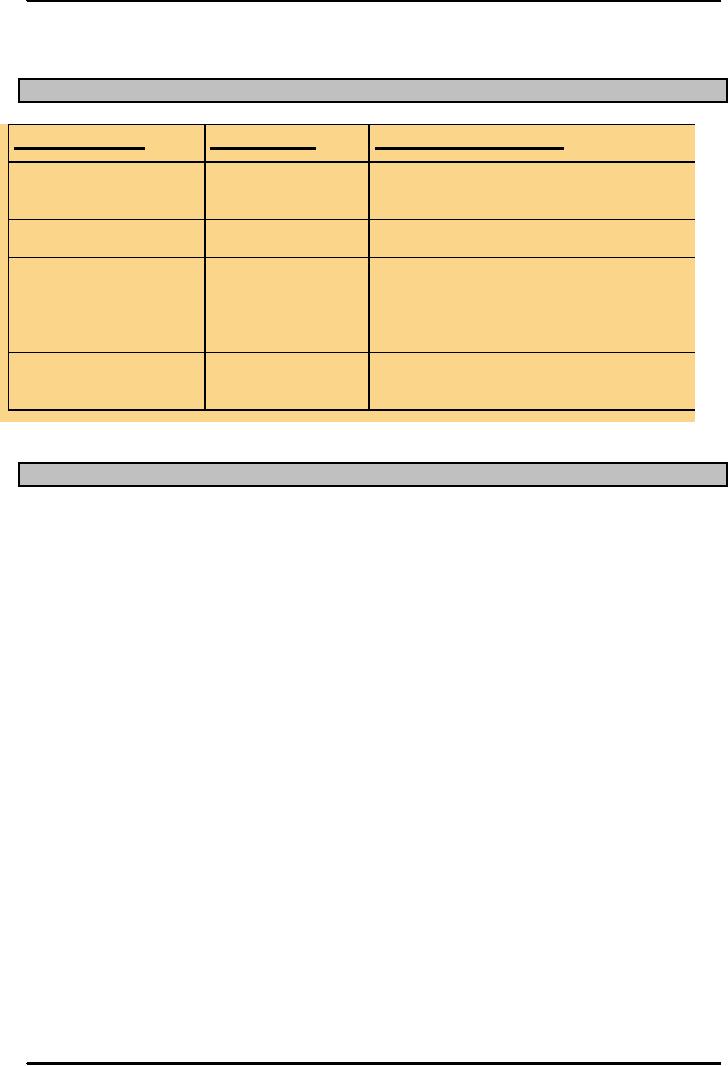

Summary

of Planning Techniques

Technique

Solution

Characteristics

Graphical/charting

Trial

and

Intuitively

appealing, easy to

error

understand;

solution not

necessarily

optimal.

Linear

Optimizing

Computerized;

linear assumptions

not

always valid.

programming

Linear

Optimizing

Complex,

requires considerable

decision

rule

effort

to obtain pertinent cost

information

and to construct

model;

cost assumptions not

always

valid.

Simulation

Trial

and

Computerized

models can be

error

examined

under a variety of

conditions.

Aggregate

Planning in Services

1.

Services occur when they are

rendered .Unlike most manufacturing

output, most services

cannot

be

inventoried. Services such as

financial planning, tax

counseling and oil changes

cant be

inventoried/stockpiled.

This removes the option of

building up the inventories during a

slow

period

in anticipation of future

demand.

2.

Demand for service can be difficult to

predict .The volume of

demand for services is

often

variable.

In some situations, customers

may need prompt service . e.g.

police, fire, medical

emergency

while in others they may

not need prompt service and

may be willing to find

some

other

service provider.

3.

Capacity Availability can be

difficult to predict. Processing

requirements for services

can

sometimes

be quite variable, similar to the

variability of work in a job

shop setting.

4.

Demand for service can be difficult to

predict It is difficult to measure the

capacity of a person

rendering

a service, a dentist, a Montessorian, a

bank teller in anticipation of

future demand).

5.

Labor Flexibility can be advantage in

Services Labor often

comprises a significant portion

of

service

compared to manufacturing. That

coupled with the fact that

service providers are

often

able

to handle a fairly wide

variety of service requirements means

that to some extent,

planning

is

easier than

manufacturing

141

Production

and Operations Management

MGT613

VU

Aggregate

Plan to Master Schedule

Aggregat

e

Dissaggregatio

Master

Schedul

Disaggregating

the Aggregate Plan

The

Aggregate Plan is broken

down into Master Schedules

and Rough Cut Capacity

Planning charts

respectively.

Master

schedule: The

result of disaggregating an aggregate

plan; shows quantity and

timing of

specific

end items for a scheduled

horizon.

Rough-cut

capacity planning:

Approximate balancing of capacity

and demand to test the

feasibility

of

a master schedule.

WE

WILL DISCUSS IT IN DETAIL WHEN WE COVER

OUR MRP LECTURE

E.g.

Suppose the organization is making

500 aggregate units of Air

conditioners for the month

of

March

and April with breakup being

200 for window types, 300

type split units with

further tonnage

capacities.

A

master schedule shows the

planned output for

individual products rather than an entire

product

group,

along with the timing of

production.

With

Rough cut capacity planning we

can check capacities of

production and warehouses

constraints

exist. This means checking

capacities of production and warehouse

facilities, labor and

vendors

to ensure that no gross

deficiencies exist that will

render master schedule unworkable.

The

master

schedule then serves as the

basis for short range

planning.

MS

is disaggregated in stages or phases,

which may cover weeks or

months.

Master

schedule: Determines quantities needed to

meet demand

Interfaces

with

1.

Marketing

2.

Capacity planning

3.

Production planning

4.

Distribution planning

142

Production

and Operations Management

MGT613

VU

Master

Scheduling

A

Master schedule indicates the quantity

and timing ( i.e. delivery times)

for a product, or a

group

of

products, but it does not show

planned production. For a

master schedule may call

for delivery of

500

Air conditioners on April 1. But it

may not require any

production because of availability

of

1000

air conditioners in inventory. Or if

there are only 400 Air

conditioners, 100 would be

planned

for

production.

Master

Scheduler

Evaluates

impact of new orders

Provides

delivery dates for

orders

Deals

with problems

Production

delays

Revising

master schedule

Insufficient

capacity

Projected

On-hand Inventory

Projected

on-hand

Inventory

from

Current

week's

-

=

inventory

previous

week

requirements

Stabilizing

the Master Schedule

Changes

to a master schedule can be

disruptive, particularly changes to the

early, or near,

portions

of

the schedule.

Typically

the further out in the future a

change is, the less the tendency to cause

problems.

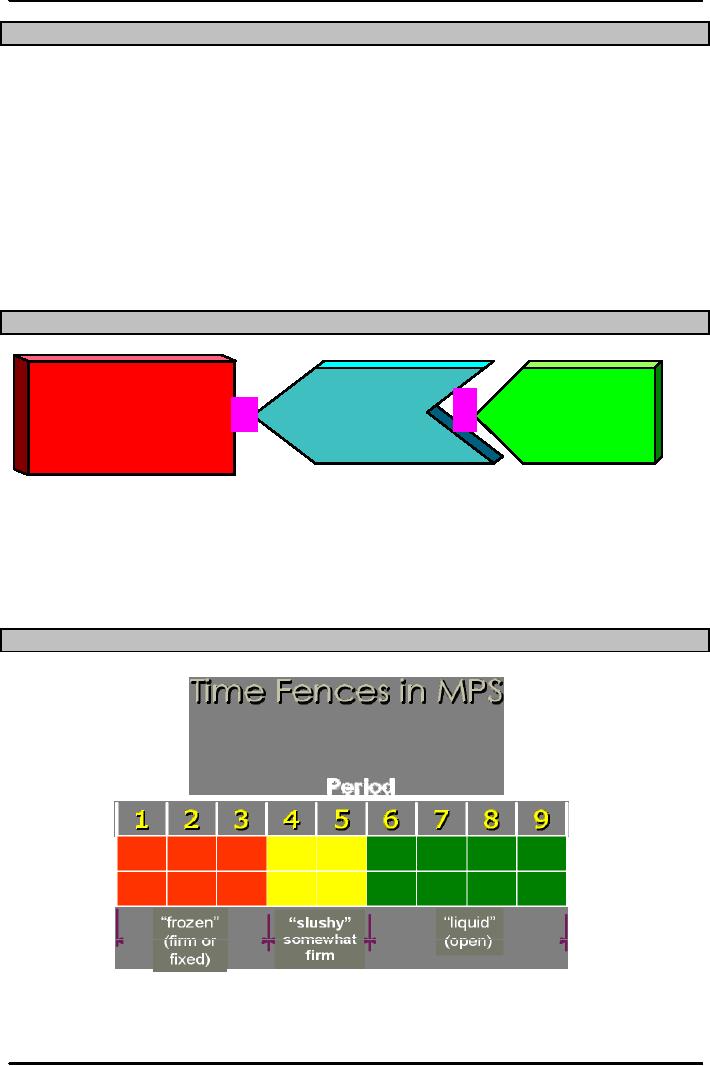

Master

Production Schedules are

often divided into 4 stages

or phases. The dividing

lines between

phases

are sometimes referred to as

time fences.

Time

Fences in MPS

In

the first phase, usually the

first few periods of the schedule,

changes can be quite

disruptive.

143

Production

and Operations Management

MGT613

VU

Consequently,

once established, that portion of the

schedule is generally frozen,

which implies that

all

but the most critical

changes cannot be made without permission

from the highest levels in

an

organization.

This helps in achieving high

degree of stability in the production

system.

In

the next stage, perhaps the

next two days or three periods,

changes are still

disruptive, but not

to

that

extent that they are in

first phase.

Management

views the schedule as firm and

only exceptional changes are

made which helps an

organization

gain some competitive

advantage.

In

the third stage, management

views the schedule as full,

meaning that all available

capacity has

been

allocated.

Although

changes do impact the schedule,

their effect is less dramatic and

they are usually made

if

there

is good reason for doing

so.

IN

the final phase, management

views the schedule as open,

meaning that not all

capacity has been

allocated.

This is where new orders are

usually in the Schedule.

.

144

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model