|

AGGREGATE PLANNING:Demand and Capacity Options |

| << ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK |

| AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling >> |

Production

and Operations Management

MGT613

VU

Lesson

29

AGGREGATE

PLANNING

Learning

Objectives

Explain

the working and usefulness of Aggregate

Planning.

Identify

the variable decision makers to

work with in aggregate

planning and some of the possible

strategies

they can use.

Describe

some of the graphical and

quantitative techniques planners

use.

Prepare

aggregate plans and compare

their costs.

Planning

Horizon

Aggregate

planning:

Intermediate-range capacity planning,

usually covering 2 to 12 months.

Long

Range

Intermediate

Range

Short

Range

Now

2

months

1

Year

As

Operations Manager we should be able to

understand and identify the various

Planning Levels which

are

Short Range Plans,

Intermediate Plans and Long

Range Plans.

Short-range

plans (Detailed plans)

1.

Machine loading

2.

Job assignments

Intermediate

plans (General levels)

1.

Employment

2.

Finished Good

inventories

3.

Subcontracting, Backorders

4.

Output

Long-range

plans

1.

Long term capacity

2.

Location / layout

135

Production

and Operations Management

MGT613

VU

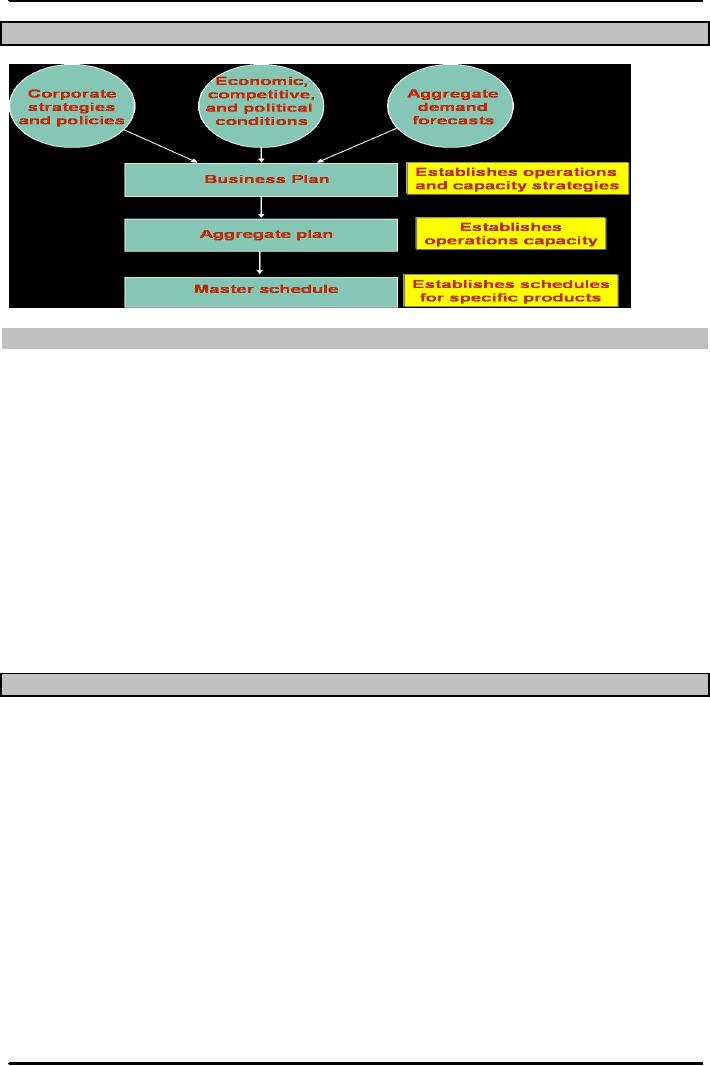

Planning

Sequence

Aggregate

Planning Inputs

Resources

1.

Workforce

2.

Facilities

Demand

forecast

Policies

1.

Subcontracting

2.

Overtime

3.

Inventory levels

4.

Back orders

Costs

1.

Inventory carrying

2.

Back orders

3.

Hiring/firing

4.

Overtime

5.

Inventory changes

6.

subcontracting

Aggregate

Planning Outputs

1.

Total cost of a plan

2.

Projected levels of inventory

3.

Inventory

4.

Output

5.

Employment

6.

Subcontracting

7.

Backordering

136

Production

and Operations Management

MGT613

VU

Aggregate

Planning Strategies

Proactive

Strategy: Strategies that

alter demand to match

capacity are known as

Proactive Strategy.

Reactive

Strategy: Strategies that

alter capacity to match

demand are known as Reactive

Strategy.

Mixed.

Strategies that make use of

qualities from both

Proactive and Reactive Strategy

are known

as

Mixed Strategies.

Demand

and Capacity Options

Demand

Options: The four common

demand options primarily focus on

market aspects apart

from

backorders

which is strictly operational

management in nature. The operations

manager should know

all

four

demand options but should be

more interested in back order

option.

1.

Pricing

2.

Promotion

3.

Back

orders

4.

New

demand

Capacity

Options: The common capacity

options primarily focus

on.

1.

Hire and layoff

workers

2.

Overtime/slack time

3.

Part-time workers

4.

Inventories

5.

Subcontracting

6.

Maintain a level

workforce

7.

Maintain a steady output

rate

8.

Match demand period by

period

9.

Use a combination of decision

variables

An

important point to be noted is

that Demand options are short range in

nature while Capacity

options

are

long duration (term or

range).

Which

Strategy to Use

The

organization needs to consider two

factors before choosing a strategy

1.

Costs

2.

Company/Corporate Policy

Policy

can

set

constraints

on

available

options.

E.g.

Layoffs,

subcontracting/Outsourcing

( PIA subcontracting its databases) to

protect secrecy.

As

a rule of thumb, aggregate planners

seek to match supply and

demand within in

constraints

by policies and minimum

costs.

137

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model