|

QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart |

| << TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT |

| ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK >> |

Production

and Operations Management

MGT613

VU

Lesson

27

QUALITY

CONTROL & QUALITY

ASSURANCE

Quality

Control or QC as it is popularly referred

as "is concerned with

quality of conformance of a

process".

The prime purpose of QC is to

assure that the processes

are performing in an

acceptable

manner.

Organizations accomplish QC by monitoring

process outputs using statistical

techniques. The

practical

and pragmatic QC based Operations

Strategy for a service or manufacturing

organization

would

focus on the principle of quality in

design.

Learning

Objectives

1.

Introduction

to Quality Control and

Assurance

2.

Phases

of Quality Control

3.

Elements

of Control Process

4.

How

control charts are used to

monitor a process and the

concepts that underlie their

use.

5.

Use

and interpret control

charts.

6.

Use

of run tests to check for

non randomness in process

output.

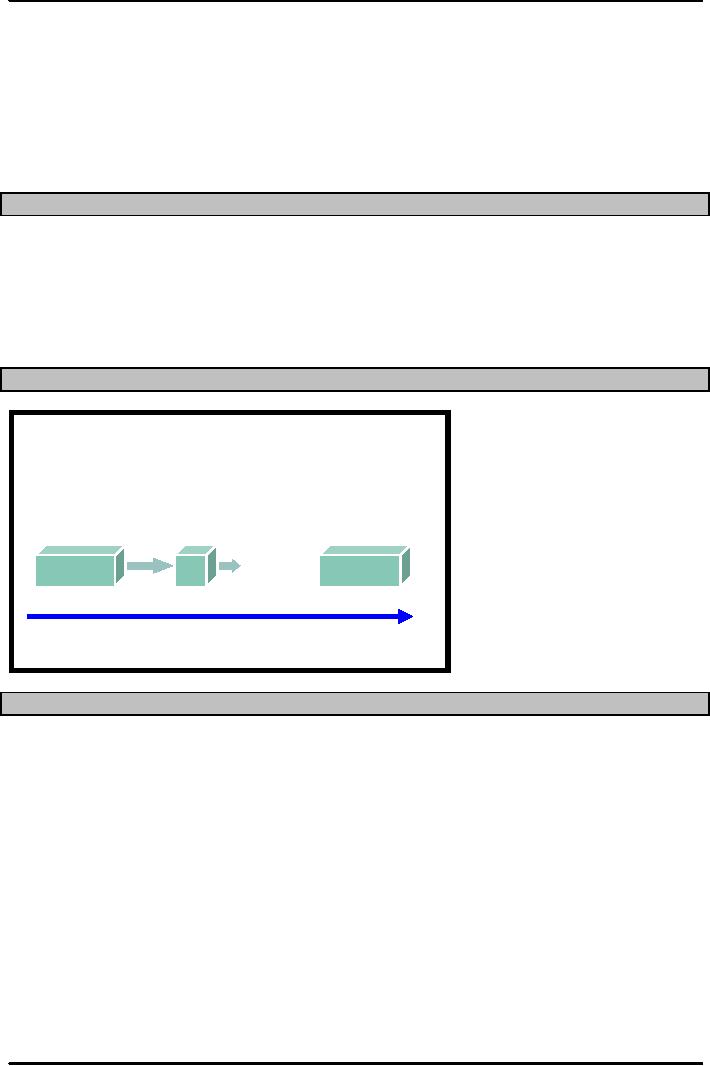

Phases

of Quality Assurance

Phases

of Quality Assurance

Inspection

Quality

built

Inspection

and

Before

/ after

into

the

Corrective

action

production

process

during

production

Pro

Continuous

Acceptance

ces

improvement

sampling

s

The

most

The

least

progressive

progressive

INSPECTION

Inspection

is an important strategy, in its simplest

form, is any method or device or

tactics used to

minimize

defects in products or services being

offered to the customers. As Operations

Manager we

should

be able to identify the following

four questions while considering

Inspection process.

1.

How Much/How Often

2.

Where/When

3.

Centralized vs. On-site

4.

Whether to inspect Variables or

Attributes.

An

important thing to remember is

that No inspection is necessary

for low value, high

volume products

like

common items like common pins, erasers or

pencils while automated inspection is

necessary for

high

value items. Automated inspection

may be necessary for even

high value, low volume items

as

well.

The word volume here refers

to quantity.

120

Production

and Operations Management

MGT613

VU

Input

Transformatio

Output

Acceptance

Acceptance

Process

sampling

sampling

control

INSPECTION

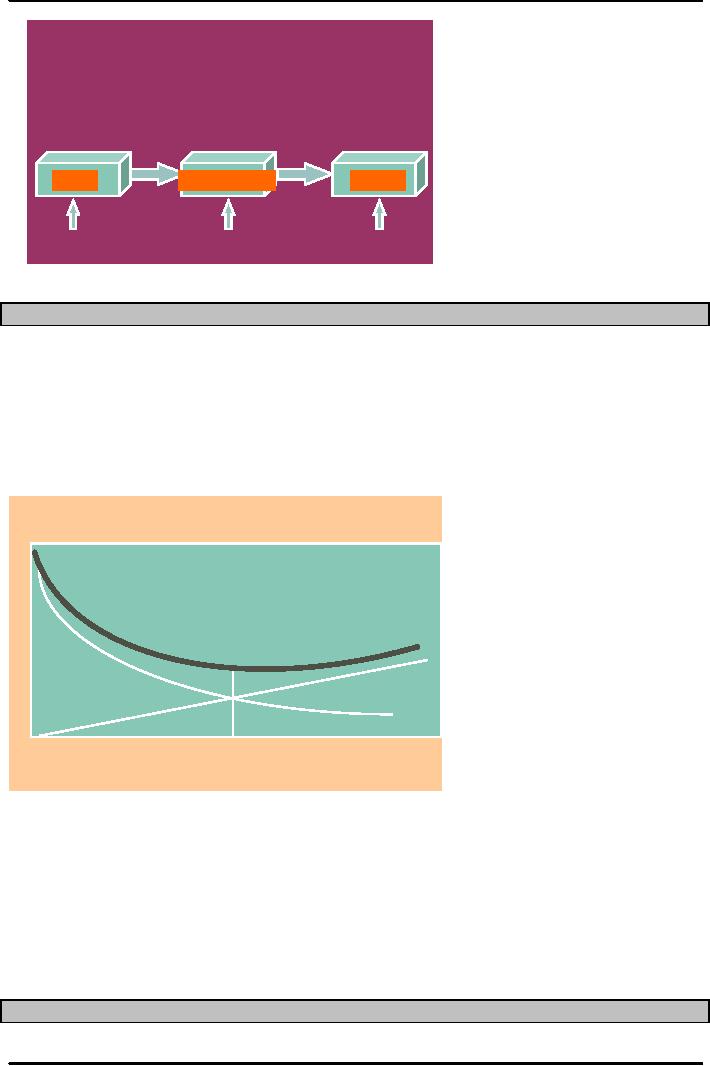

COSTS FOR HOW MUCH/HOW

OFTEN

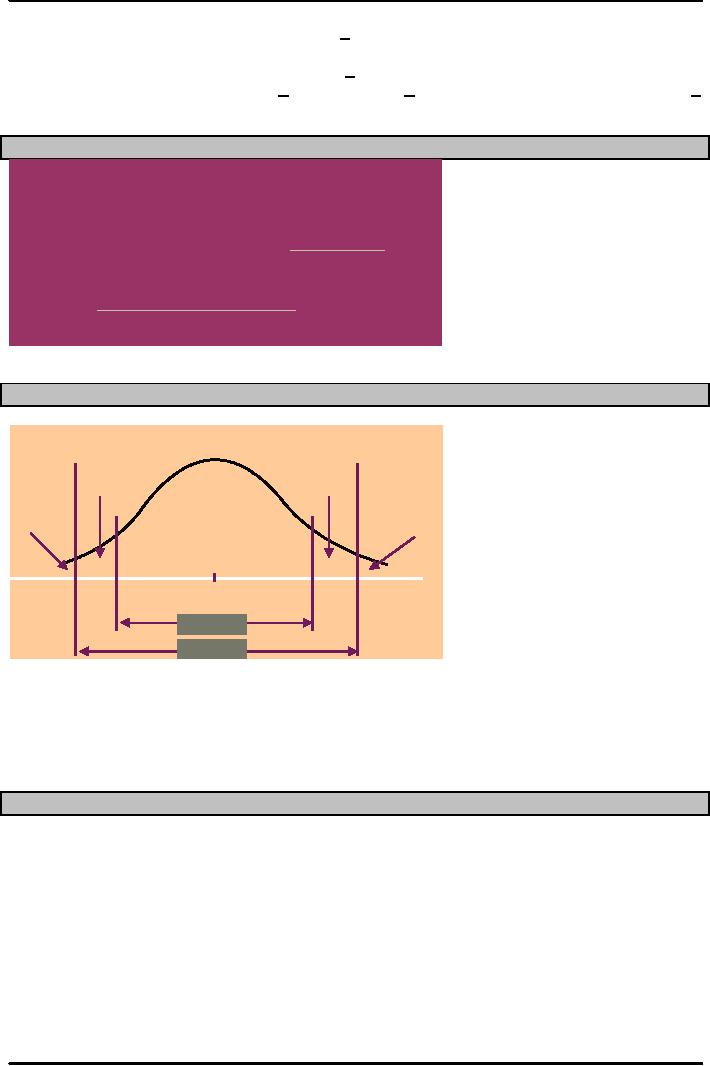

The

graph on the next page

shows the relationship between

amount of inspection required

and

costs

incurred in carrying out such

inspection.

1.

With increase in Inspection

activities the cost of undetected

defectives decreases.

2.

With increase in inspection

activities the cost of inspection

increases.

We

need to observe for Total

cost function curve which

shows high costs at no

inspection and gradually

comes

down and reaches a minimum

value at the optimal amount of inspection

and then start

increases.

C

O

S

T

Optimal

Amount

of Inspection

Inspection

Costs for How Much/How

Often

1.

Where to Inspect

in the Process

2.

Raw materials and purchased

parts ( DO not purchase poor

quality products)

3.

Finished products ( Poor products returned by

customers can also lead to

additional shipping

costs)

4.

Before a costly operation ( Do

not waste Resources of Man,

Material and Machine)

5.

Before an irreversible process (

Pottery, Ceramics, Tiles, PC chips,

glass filaments)

6.

Before a covering process (

Before painting, plating and

assembly)

EXAMPLES

OF INSPECTION POINTS IN SERVICE

INDUSTRY

121

Production

and Operations Management

MGT613

VU

We

cannot have same inspection points

for the service industry, infact we

need to pay attention to

the

type

of industry or business in which a

service organization competes. Please

refer to the table on the

next

page and note the difference

in characteristics and location of

inspection points.

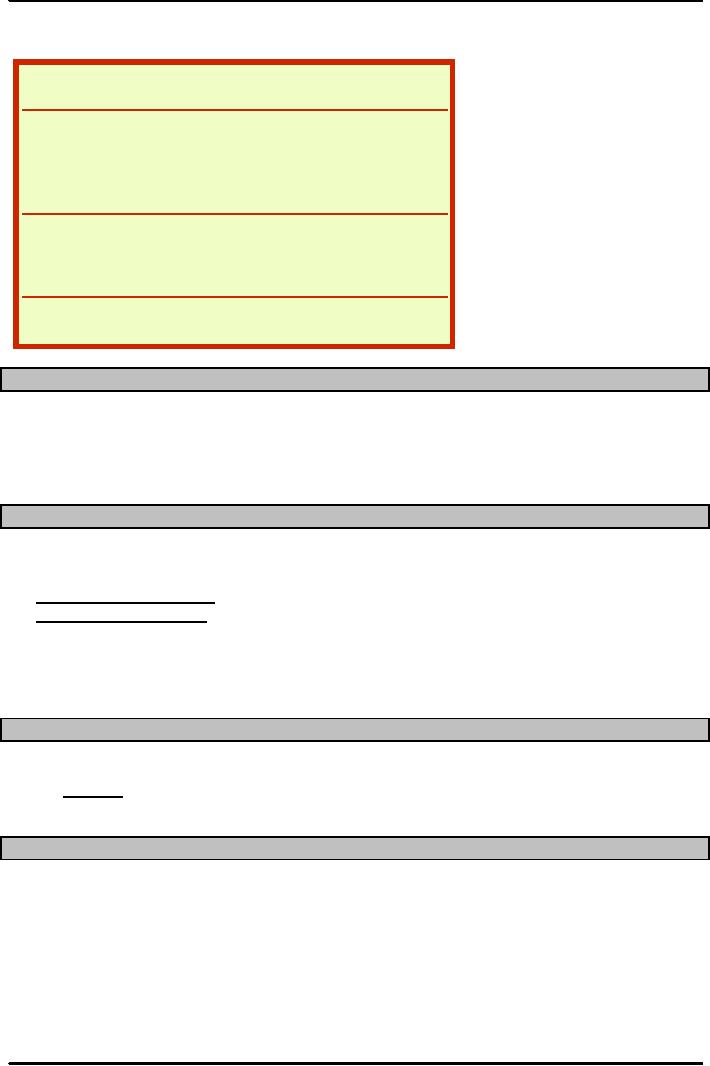

Type

of

Inspection

Characteristics

business

points

Fast

Food

Cashier

Accuracy

Counter

area Appearance,

productivity

Eating

area

Cleanliness

Building

Appearance

Kitchen

Health

regulations

Safe,

well lighted

Hotel/motel

Parking lot

Accuracy,

timeliness

Accounting

Appearance,

safety

Building

Waiting

times

Main

desk

Supermarket

Cashiers

Accuracy,

courtesy

Deliveries

Quality,

quantity

CENTRALIZED

VS ONSITE INSPECTION

1.

Inspection of Ships, Nuclear Plants,

Petroleum Refinery, Chemical

Plant equipments for

cracks,

brittle

fracture etc both external

and internal inspection.

2.

Lab tests include blood

tests, material

testing

QUALITY

CONTROL IN TERMS OF STATISTICAL

PROCESS CONTROL:

We

now focus on the idea of Quality

Control in terms of Statistical

Process Control, for this we

need to

define

Statistical

Process Control:

Statistical evaluation of the output of a

process during

production

Quality

of Conformance: A

product or service conforms to

specifications

Which

Characteristics can be controlled: Only

those characteristics which

can be counted or

measured.

Main

Task of QC: is to distinguish random

from non random variability,

because non random

variability

indicates that the process is out of

control

Control

Chart

Control

Chart: A time ordered plot representative

sample statistics obtained

from an on going

process

(e.g. sample means)

Purpose: to

monitor process output to

see if it is random

Upper

and lower control limits

define the range of acceptable

variation

CONTROL

CHART & STATISTICAL PROCESS

CONTROL

122

Production

and Operations Management

MGT613

VU

Out

of

Abnormal

variation

contro

due

to assignable

UC

Mea

Normal

variation

LC

Abnormal

variation

due

to assignable

0

1

2

3

4

5

6

7

8

9

10

11 12 13 14 15

Sample

Statistical

Process Control

The

essence of statistical process

control is to assure that the

output of a process is random so

that

future

output will

be random.

Statistical

Process Control

The

Control Process consists of the

following important

stages.

1.

Define

2.

Measure

3.

Compare

4.

Evaluate

5.

Correct

6.

Monitor results

Variations

and Control

�Random

variation:

Natural variations in the output of a

process, created by countless

minor factors

Also

called COMMON/ CHANCE.

INHERENT and part of the process.

E.g. Difference between

old

and

new machines.

�Assignable

variation: A

variation whose source can

be identified

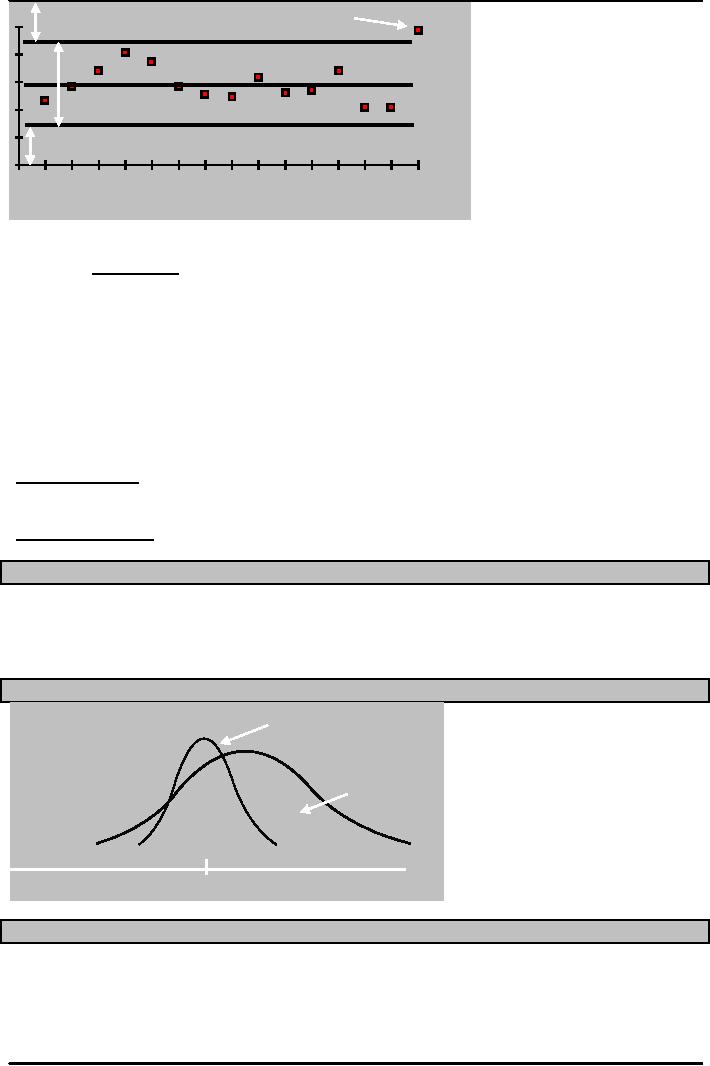

SAMPLING

DISTRIBUTION

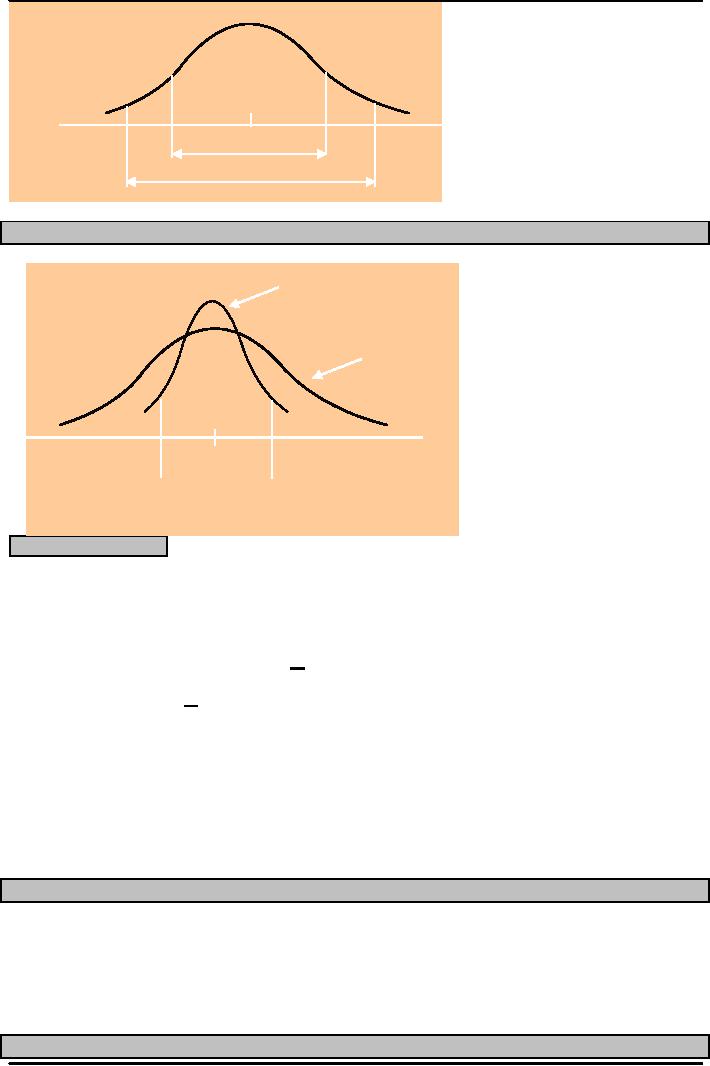

The

variability of a sample statistic can be

described by its SAMPLING

DISTRIBUTION. The goal

of

sampling

is to determine whether non random

/assignable/ correctable sources of variation

are present in

the

output of the process. E.g.

Soft drinks bottle are

never 250 ML. slight

differences among the mean.

SAMPLING

DISTRIBUTION

Sampling

distribution

Process

distribution

Mean

NORMAL

DISTRIBUTION

123

Production

and Operations Management

MGT613

VU

σ

= Standard

deviation

-3σ

-2σ

+2σ

+3σ

Mean

95.44%

99.74%

CONTROL

LIMITS

Sampling

distribution

Process

distribution

Mean

Lower

Upper

contro

contro

l

l

CONTROL

CHARTS

A

control chart is a time ordered plot of

sample statistics.

It

is used to distinguish between random

variability and non random

variability.

The

basis of control chart is sample

distribution which essentially

describes random variability.

Theoretically

any value is possible as the distribution

extends to infinity.

99.7%

of all values will be within

+

3 standard

deviations

Control

Charts

We

draw a line at + 3 and call it

control chart limits and observe

any value beyond this to be

out

of

limits.

Control

Chart limits are the

dividing lines between random deviations

and mean of the

distribution

and non random deviations and mean of the

distribution.

The

limits that separate random

variations from non random

variations is known as UCL

and

LCL.

A

sample statistic that falls between

UCL and LCL suggests ( does

not proves) randomness and a

value

outside

suggests ( does not proves) no

randomness.

SPC

Errors

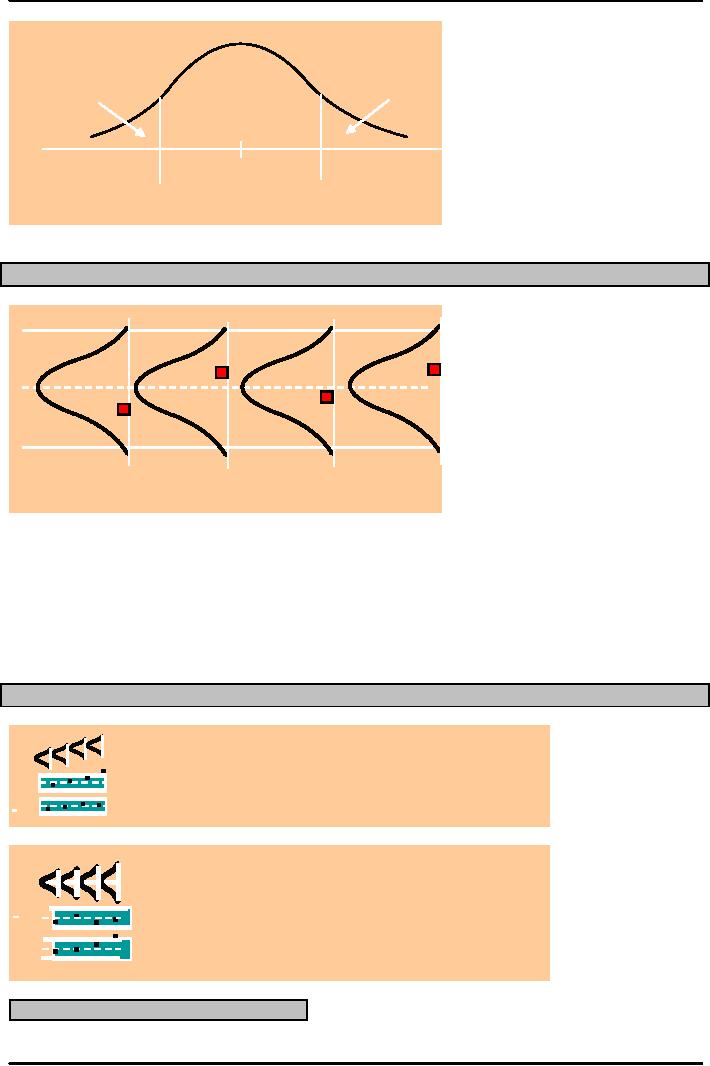

Type

I error: Concluding a process is

not in control when it

actually is or concluding that

no

randomness

is present when it is only

randomness that is

present.

Type

II error: Concluding a process is in

control when it is not that

no randomness is not

present

when

it is present.

Type

I Error

124

Production

and Operations Management

MGT613

VU

α/

α/

Mean

LC

UC

α

= Probabilit

y

OBSERVATIONS

FROM SAMPLE

DISTRIBUTION

UCL

LCL

1

2

3

4

Sample

number

Control

Charts for Variables

Mean

control charts

Used

to monitor the central tendency of a

process.

X

bar charts

Range

control charts

Used

to monitor the process dispersion

R

charts

MEAN

AND RANGE CHARTS

(process

mean is

shiftingupward)

Sampling

Distribution

UCL

Detects

shift

L

C

L

UCL

R-chart

Does

not detect shift

x-Chart

L

C

L

Sampling

Distribution

(process

variability is increasing)

UCL

Does

not

x-Chart

LC

reveal

increase

L

UCL

R-chart

Reveals

increase

L

C

L

CONTROL

CHART FOR

ATTRIBUTES

p-Chart

- Control chart used to monitor the

proportion of defectives in a

process

125

Production

and Operations Management

MGT613

VU

c-Chart

- Control chart used to monitor the

number of defects per unit

Use

of p-Charts

When

observations can be placed into two

categories.

Good

or bad

Pass

or fail

Operate

or don't operate

When

the data consists of multiple

samples of several observations

each

Use

of c-Charts

Use

only when the number of occurrences per

unit of measure can be

counted; non-occurrences

cannot

be counted.

Scratches,

chips, dents, or errors per

item

Cracks

or faults per unit of

distance

Breaks

or Tears per unit of

area

Bacteria

or pollutants per unit of

volume

Calls,

complaints, failures per unit of

time

Use

of Control Charts

At

what point in the process to

use control charts

What

size samples to take

What

type of control chart to

use

1.

Variables

2.

Attributes

RUN

TESTS

Run

test a

test for randomness

Any

sort of pattern in the data would

suggest a non-random

process

All

points are within the

control limits - the process

may not be random

Nonrandom

Patterns in Control

charts

Trend

Cycles

Bias

Mean

shift

Too

much dispersion

Counting

Runs

126

Production

and Operations Management

MGT613

VU

Counting

Above/Below Median

Runs

(7

B A

A

B

A

B

B

B A

A

Counting

Up/Down Runs

(8

U

U

D

U

D

U D U U

Underlining

each runs helps in counting

IN

case of Ups and Down the

first value does not

receives either a U or D because

nothing precedes it.

PROCESS

CAPABILITY

Tolerances

or specifications is the range of acceptable values

established by engineering design

or

customer requirements

Process

variability: is the natural variability

in a process

Process

capability: is the process variability

relative to specification

Process

Capability is thus more importantly

related to our discussion of

Quality Control and

Quality

Assurance

and we will take up three cases in

detail to understand this important

concept.

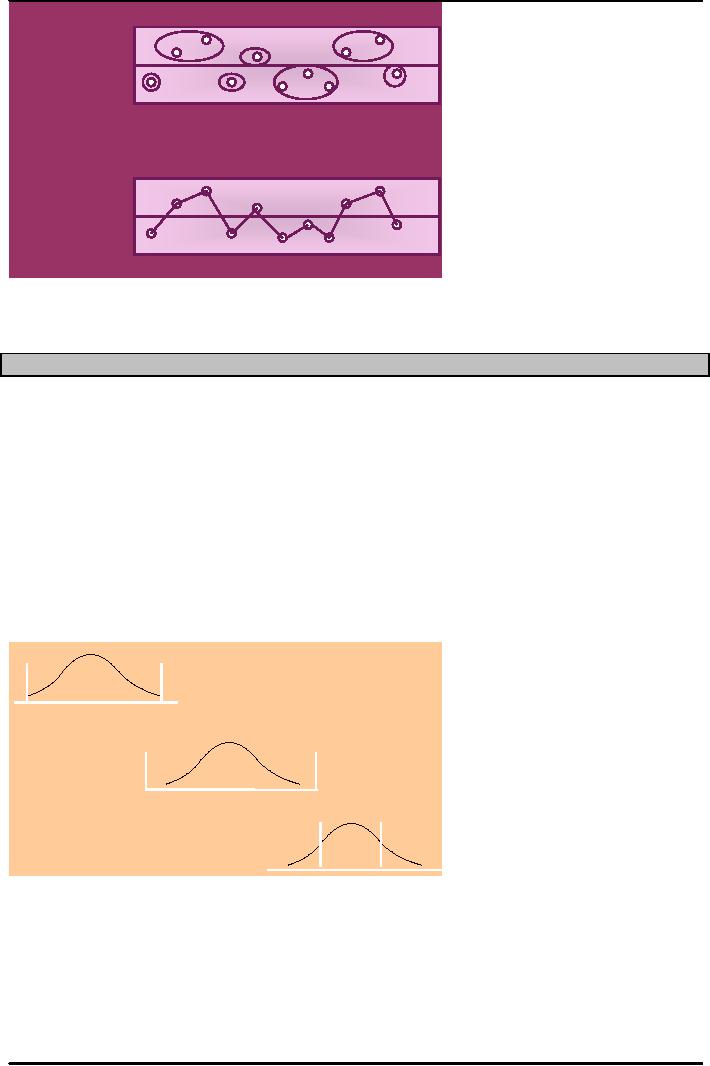

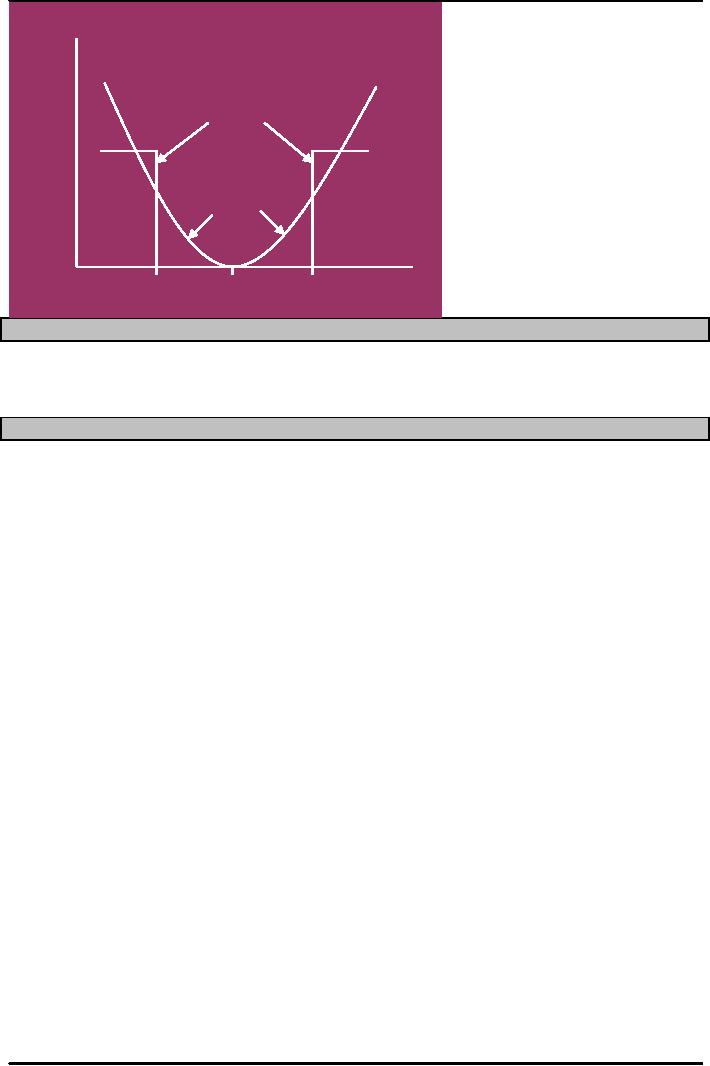

1.

In Case A we observe that

process specifications and

output are matched.

2.

In Case B process variability is

well within the process

specification and output.

3.

In Case C, we need to check

whether a process is capable of meeting

specifications and not

just

use

a control chart.

Lower

Upper

Specificatio

Specificatio

A.

Process variability

matches

specifications

Lower

Upper

Specificatio

Specificatio

B.

Process variability

Lower

Upper

well

within specifications Specificatio

Specificatio

Process

Capability

Case

C, A manager in case C can

take the following

steps.

1.

Redesign the process to obtain the desired

output.

2.

Use an alternative process to

obtain the desired output.

3.

Retain the current process

but attempt to eliminate output

using 100 percent

inspection

4.

Examine the specifications to see if

they are necessary or can be

relaxed

127

Production

and Operations Management

MGT613

VU

Process

Variability is the key factor in

Process Capability. It is measured in

terms of process

standard

deviation.

Process capability is considered to be + 3 Standard

Deviations from the process

mean. E.g.

An

insurance company provides a service of

registering a new membership ( filling of

form) in 10 mins,

acceptable

range of variation around the time is + 1

minute, the process has a

standard deviation of

0.5min.It

would not be capable because + 3

SDs would be + 1.5 Mins,

exceeding the specification of +

1

minute.

Process

Capability Ratio

Specification

width

Process

capability ratio, Cp =

Process

width

Upper

specification lower specification

Cp=

6σ

3

SIGMA AND 6 SIGMA

QUALITY

Upper

Lower

specification

specification

1350

ppm

1350

ppm

1.7

ppm

1.7

ppm

Process

mean

+/-

3 Sigma

+/-

6 Sigma

Improving

Process Capability

1.

Simplify

2.

Standardize

3.

Mistake-proof ( Poka Yoke)

4.

Upgrade equipment

5.

Automate

Taguchi

Loss Function

128

Production

and Operations Management

MGT613

VU

Traditional

cost

Cost

Taguchi

cost

Lowe

Uppe

Target

r

r

Limitations

of Capability Indexes

1.

Process may not be

stable

2.

Process output may not be

normally distributed

3.

Process not centered but

Cp is used

OPERATIONS

STRATEGY WRT Q/C

It

is neither necessary nor desirable to

use Control charts for

every production

process.

Some

processes are highly stable

and do not require Control

Charts.

Managers

should use Control Charts on

processes that go out of

control.

Use

control Charts for new

processes till they obtain

stable results.

Judicious

use of SPC will ensure

detection of departures from

randomness in a process.

129

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model