|

TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT |

| << TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality |

| QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart >> |

Production

and Operations Management

MGT613

VU

Lesson

26

TQM

QUALITY

In

this lecture we will look

into detail TQM. We will

initially focus on Six Sigma concept. We

will try

to

understand six sigma concept in

terms of managerial and

technical perspective. We will also

try to

understand

the Deming Wheel of Quality and

seven common tools of quality.

And last but not the

least

we

will also try to understand the

concepts of statistical process

control and benchmarking with

respect

to

quality.

ISO

CERTIFICATIONS

Quality

Certification ensures that the

organization has been able

to achieve TQM philosophy. The

two

popular

certifications which are

pursued by the organizations include

ISO 14000 and ISO

9000.

1.

ISO 14000: Is a set of

international standards for

assessing a company's

environmental

performance.

2.

ISO 9000: Is a set of

international standards on quality

management and quality

assurance,

critical

to international business.

SIX

SIGMA

Statistically

speaking a process is said to be in Six

Sigma stage if it does not have more

than 3 or 4

defects

per million. Most of the organizations,

measure their quality

program in terms of Six

Sigma.

Conceptually

the Six Sigma Program is designed to reduce

defects and requires the use of

certain tools

and

techniques.

Six

Sigma Programs are always

directed towards quality improvement,

cost cutting and time

saving. Six

Sigma

Programs are employed

in:

Design

Production

Service

Operation

management

Inventory

management

Delivery

Six

Sigma Management concepts find greater

appreciation and application in recent

times. The Six

Sigma

Management characteristics

include:

1.

Providing strong leadership.

2.

Defining performance merits.

3.

Selecting projects likely to

succeed.

4.

Selecting and training appropriate

people.

Six

Sigma Technical aspects form a

part and parcel of managerial strategy and

aids in cost cutting

and

defect

minimization. The Technical

aspects of Six Sigma

include

1.

Improving

process performance

2.

Reducing

variation

3.

Utilizing

statistical models

4.

Designing

a structured improvement strategy

116

Production

and Operations Management

MGT613

VU

Six

Sigma Team

Six

Sigma Teams are formed for

implement of Six Sigma in true

spirit keeping in mind both

managerial

as

well as technical

aspects.

1.

Top

management

2.

Program

champions

3.

Master

"black belts"

4.

"Black

belts"

5.

"Green

belts"

Six

Sigma Process

Six

Sigma Process has various

stages often organizations

combine one or two stages

for better

monitoring

and control purposes. Quality Experts

normally identify the following 5

stages.

1.

Define

2.

Measure

3.

Analyze

4.

Improve

5.

Control

Obstacles

to Implementing Six Sigma ( TQM)

includes the lack of:

1.

Company-wide definition of

quality.

2.

Strategic plan for

change.

3.

Customer focus.

4.

Real employee empowerment.

5.

Strong motivation.

6.

Time to devote to quality

initiatives.

7.

Leadership.

8.

Poor inter-organizational

communication.

9.

View of quality as a "quick

fix".

10.

Emphasis on short-term financial

results.

11.

Internal political and "turf"

wars.

Criticisms

of TQM

Blind

pursuit of TQM programs.

Programs

may not be linked to

strategies.

Quality-related

decisions may not be tied to

market performance.

Failure

to carefully plan a

program.

BASIC

STEPS IN PROBLEM

SOLVING

The

problem solving method is more or less

the same what we covered in the initial

part of our

semester,

we always try to follow the

same procedure or method which is to analyze the

problem and

then

generate pragmatic solutions

and implement the best

solution.

1.

Define the problem and establish an

improvement goal.

2.

Collect data

3.

Analyze the problem

4.

Generate potential solutions

5.

Choose a solution

6.

Implement the solution

7.

Monitor the solution to see if it

accomplishes the goal.

117

Production

and Operations Management

MGT613

VU

PROCESS

IMPROVEMENT

A

systematic approach to improving a

process would always result

in process improvement.

Following

are

the common approaches for improving the

process.

1.

Process mapping

2.

Analyze the process

3.

Redesign the process

Process

mapping consists mainly of

collecting information about the

process, identifying

the

process for each step and

determining the inputs and

outputs.

Analyze

the process: Ask questions about the

process including process

flow being logical,

any

activities or steps being missing or

identification of duplication

activities.

Questions

about each step which

includes is a particular step

necessary, does the step

adds

value,

does it generates waste,

could the time to perform the

step be reduced, could two

or

more

steps be combined.

Redesign

the process: takes a fresh approach to

solve an issue on hand.

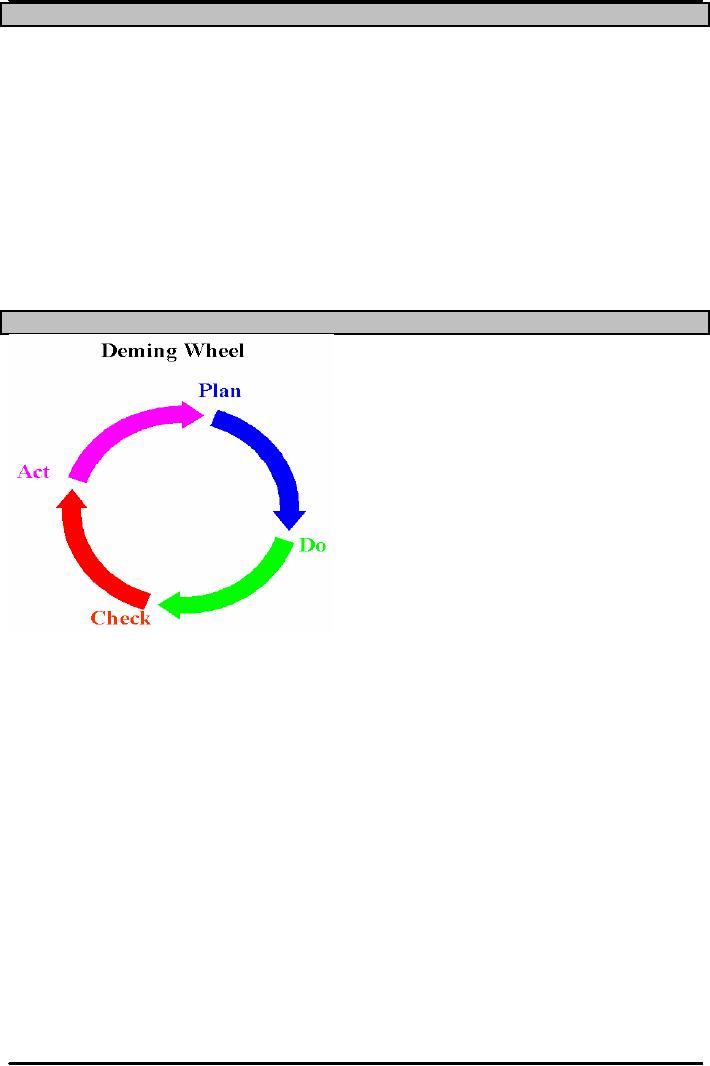

THE

PDSA CYCLE (SHEWHART

CYCLE/DEMING WHEEL)

The

concept of the PDCA Cycle

was first introduced by

Walter Shewhart, the leading

statistician, who

also

developed statistical process

control in the Bell Laboratories in the

US during the 1930's. It is often

referred

to as `the Shewhart Cycle'. It was

taken up and promoted very

effectively from the 1950s on

by

the

famous Quality Management

authority, W. Edwards Deming, and is consequently

known by many

as

`the Deming Wheel'. It is a

continuous process and enables the

operations manager to check the

work

at

various stages.

The

PDCA Cycle is a checklist of the

four stages which you

must go through to get from

`problem-

faced'

to `problem solved'.

The

four stages of PDCA/Shewhart

Cycle or Deming Wheel

are:

1.

PLAN

Study

& Document the existing

process.

Collect

data to identify problems.

Survey

data and develop a plan for

improvement.

Specify

measures for evaluating the

plan.

2.

DO

Implement

the plan on a small

scale.

Document

any changes made during

this phase.

Collect

data systematically for

evaluation.

118

Production

and Operations Management

MGT613

VU

3.

CHECK

Evaluate

the data collection during

this phase.

Check

how closely the results

match the original goals of the plan

phase.

4.

ACT

If

the results are successful, standardize

the new method and communicate the

new

method

to all people associate with

the process.

Implement

training for the new

method.

If

results are unsuccessful, revise the

plan and repeat the process or

cease this project.

SEVEN

BASIC TOOLS

1.

Check Sheet

2.

Flow Chart

3.

Histogram

4.

Pareto Chart

5.

Scatter Diagram

6.

Cause & Effect

Diagram

7.

Statistical Process

Control

Quality

Circles

Team

approach

List

reduction

Balance

sheet

Paired

comparisons

Benchmarking

Process

Identify

a critical process that

needs improving.

Identify

an organization that excels in

this process.

Contact

that organization.

Analyze

the data.

Improve

the critical process.

119

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model