|

Production

and Operations Management

MGT613

VU

Lesson

24

SERVICE

QUALITY

Learning

Objectives

After

completing this lecture the

students should be able to

describe the five dimensions of

service

quality

in detail. This would enable them to

use the service quality gap

model to diagnose quality

problems

also understand the quality service by design

concepts. This lecture would

provide the

students

with an opportunity to learn and

illustrate how Taguchi

methods and poka-yoke methods

are

applied

to quality design. The students

should be able to at least

gain awareness how

organizations

perform

service quality function deployment in

order to improve their operations side.

The students

should

also be able to construct a statistical

process control chart.

Moments

of Truth

Each

customer contact (between the service provider and

customer) is called a moment of

truth.

An

organization has the ability to

either satisfy or dissatisfy them

when you contact them.

A

service

recovery is

satisfying a previously dissatisfied

customer and making them a

loyal

customer.

Dimensions

of Service Quality

Dimensions

for Service Quality are more or

less the same which we

associate with the concept

of

Quality

in General. Also, we as service demanders

(customers) are well aware

of the fact that we

always

seek

reliability, agility (prompt

responsiveness), assurance, tangibility

and empathy while

being

provided

with a service. More or less

these dimensions help the customer to

rate and distinguish one

service

provider from another. A

good service from a bad service. Often

organizations use a

performance

measure matrix using the

same service dimensions and they

often call it RATE based

on

the

5 dimensions described below.

1.

Reliability:

Perform promised service dependably and

accurately.

2.

Responsiveness:

Willingness to help customers

promptly.

3.

Assurance:

Ability to convey trust and

confidence.

4.

Tangibles:

Physical facilities and facilitating

goods.

5.

Empathy:

Ability to be approachable.

Normally

in such situations, R represents

Reliability and Responsiveness, A

represent Assurance, T

represents

Tangibles and E represents Empathy

respectively.

106

Production

and Operations Management

MGT613

VU

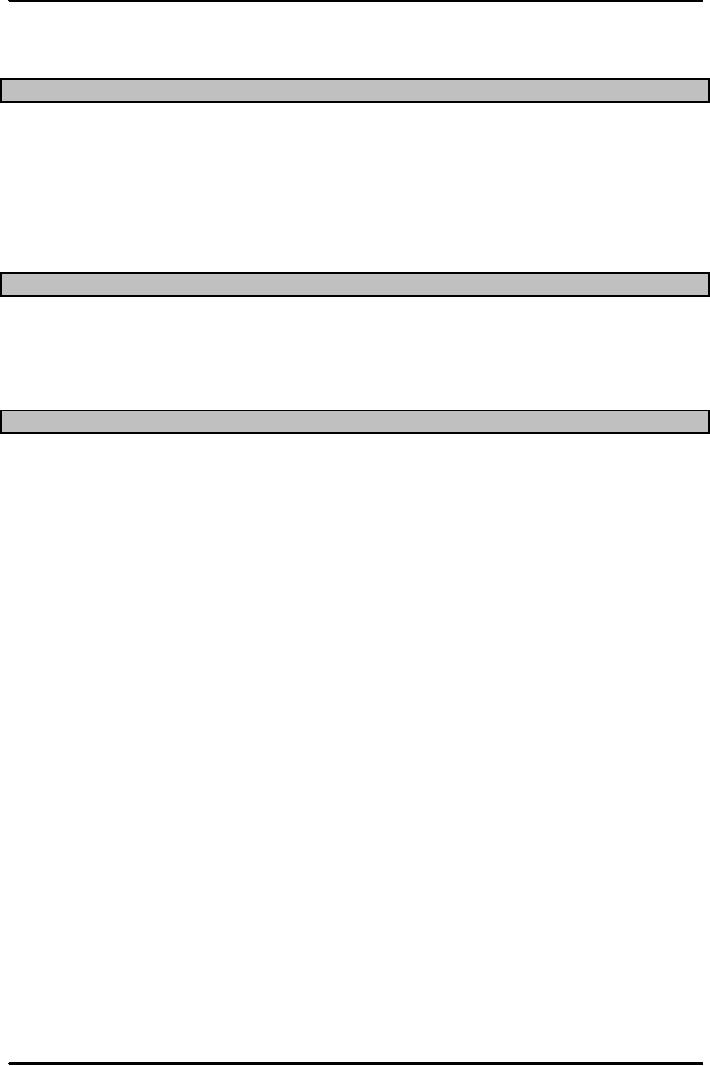

Perceived

Service Quality

It

is often seen that a

customers required service is not

provided by the service provider

primarily

because

of a gap between Service Quality Dimensions

and Service Quality Assessment by the

customer.

Word

of

Personal

Past

mouth

needs

experience

Service

Quality

Service

Quality Assessment

Expected

Dimensions

1.

Expectations exceeded

service

Reliability

ES<PS

(Quality surprise)

Responsiveness

2.

Expectations met

Assurance

ES~PS

(Satisfactory quality)

Perceived

Empathy

3.

Expectations not met

service

Tangibles

ES>PS

(Unacceptable

quality)

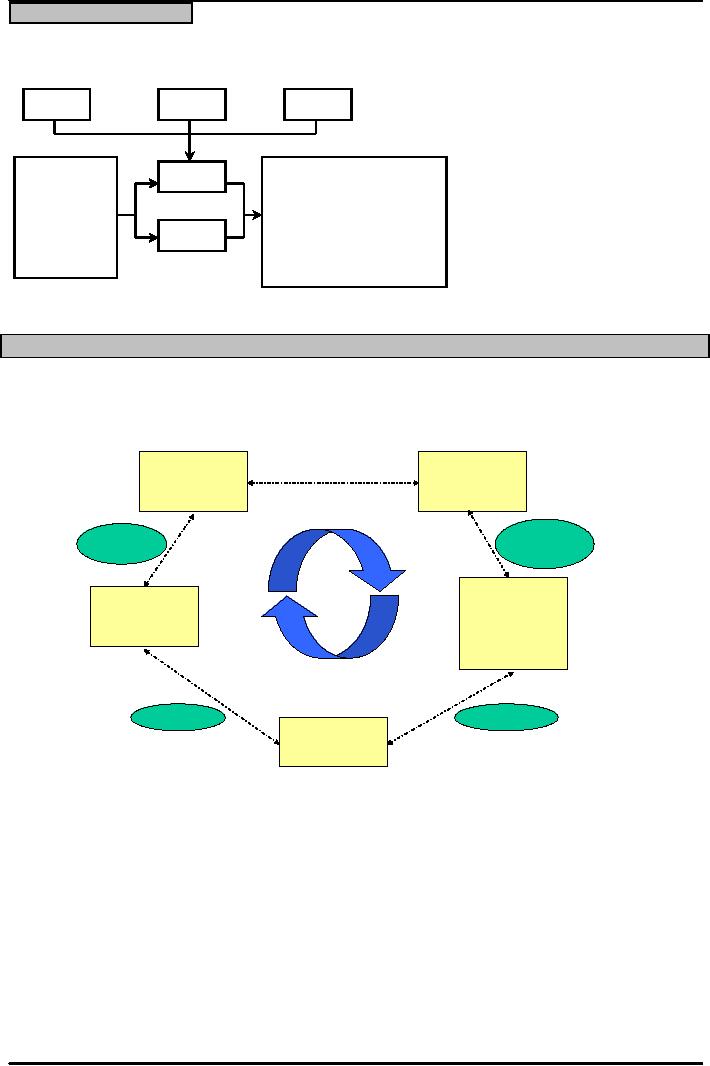

Service

Quality Gap Model

We

can pictorially capture the gaps

that exist between service provided and

the service demanded

Customer

Customer

Customer

Satisfaction

GAP

5

Perceptions

Expectations

Understanding

Managing

the

Customer

/

the

Customer

Evidence

Marketing

Research

Communication

GAP

1

GAP

4

Management

Service

Perceptions

Delivery

of

Customer

Expectations

Conformance

Design

GAP 2

GAP

3

Conformance

Service

Design

Service

Standards

107

Production

and Operations Management

MGT613

VU

Service

Gap Analysis

A

good example where gap analysis is

used for improvements in

business is in the services

field

The

most popular assessment tool

used in service quality is called

SERVQUAL, which

involves

a set of the 5 most important dimensions

of quality according to rankings

of

customers

Also

involves a set of 5 gaps

which represent the difference between

customers'

expectations

and perceptions or in other words the difference

between expected level of

service

vs. Actual level of service

provided

SERVQUAL

(Stands for

SERVICEQUALITY).

SERVQUAL

Model Gaps

Let's

try to capture all 5 gaps; one by

one this would help us to

understand in detail the 5 dimensions of

service

quality.

Gap

1

The

difference between actual

customer expectations and management's

idea or perception of

customer

expectations.

Managers

and employees have a very internal process-oriented

view of their business, it is

tough to

break

this view and to see things

the way the customer

does

This

gap of the SERVQUAL Model can

help management with

customer service

Gap

2

Mismatch

between manager's expectations of service

quality and service quality

specifications

To

implement a system to improve

this gap, management must

first understand exactly what

the

customer

wants

If

this understanding is not

present, it will be impossible

for management to know

whether their

expectations

are aligned with customer

specifications.

Gap

3

Poor

delivery of service

quality

Once

the specifications from gap 2 are

aligned the next step is to

deliver these services in a

perfect

manner

Quality

of delivery must be perfected during the

interaction with the

customer

The

employees that are responsible for

these actions are referred to as contact

personnel

Some

reasons for a lack of

quality include poor

training, communication, and

preparation.

Gap

4

Differences

between service delivery and

external communication with

customer

Customers

are influenced by what they

hear and see about a

company's service

Word-of-mouth

publicity and advertising are

main outlets which customers

open their

opinions

to

The

difference between what a customer

hears about a company's service and

what is

actually

delivered is represented by gap 4

This

gap can lead to dangerously

negative customer perceptions

108

Production

and Operations Management

MGT613

VU

Gap

5

Differences

between Expected and

Perceived Quality

This

gap is directly related to everyone's

perception of service quality

Customers

expect certain things from

certain companies

When

someone goes into a

McDonalds to order their

favorite meal a Big Mac,

they are

expecting

exactly what they are

accustomed to getting (a quick, no

hassle, tasty big

burger

with

all the works). If it takes 15 minutes to

get a Big Mac that doesn't

even have the

famous

special sauce on it the customer's perceived service

of McDonalds is going to

plummet.

If

gaps 1 through 4 are closed

to a minimum then gap 5 should

follow, if there are any

gaps

left

in steps 1 through 4 the perceived

customer service quality will be

negatively affected

The

way to make sure these

gaps are closed is through

thorough systems design,

precise

communication

with customers, and a

well-trained workforce.

Quality

Service by Design

We

had discussed earlier, that design of a

product or service half ensures a

good productive system

and

we

did mention about Quality

indirectly. We now take a

direct approach and identify the ways in

which

we

can incorporate and identify

Quality in the Design of

Services.

1.

Quality in the Service Package :Quality

based service should be offered at

same price, club

class

passengers

in an airline though being

provided additional luxury

are not able to bring

enough

revenue.

An airline that does not add

quality would loose out to

its competitors.

2.

Taguchi Methods (Robustness): Relate to

the quality based methods

being able to deliver under

all

possible

environments. If a company is unable to

offer an after sales service to a

customer at any

particular

place in the same country, it would

simply lose out to its

competitors.

3.

Poka-Yoke: Poka Yoke (pronounced

POH-kah YOH-kay) is the Japanese

word for mistake

proof.

In

services, a simple mistake can have

dire consequences, think of a

hair dresser or stylist

giving

you

a wrong haircut. His mistake cannot be

rectified because service again is an

entity which is

based

on transaction between the service

provider and service

receiver. These

devices/strategies/mechanisms/methods

are used either to prevent

the special causes that result

in

defects,

or to inexpensively inspect each item

that is produced to determine whether it

is acceptable

or

defective.

4.

Quality Function Deployment: is

also known as QFD or House of

Quality. It is an important tool

of

Quality

Management and allows a company

not only to benchmark itself

with industry leader

but

also

to review its internal operations

critically.

The

thing to remember here is

that Quality in design ensures the

safe as well as reliable operations

of

the

service. Consider for example the simple

case of an oil change or a

hair cut. If the service provider

is

unable

to include Quality in service, or fails

to provide a consistent service under

all conditions or

fails

to

do justice to idea of mistake proof

service or is unable to deploy Quality

Function in his service, he or

she

would lose customers and

competitive advantage along with

loss in revenues and increase in

costs.

Classification

of Service Failures with Poka-Yoke

Opportunities

Server

Errors

Customer

Errors

Task:

Doing work

incorrectly

Preparation:

Failure to bring

necessary

materials

Treatment:

Failure to listen to

customer

Encounter:

Failure to follow system

flow

Tangible:

Failure to wear clean uniform

Resolution:

Failure to signal service

failure

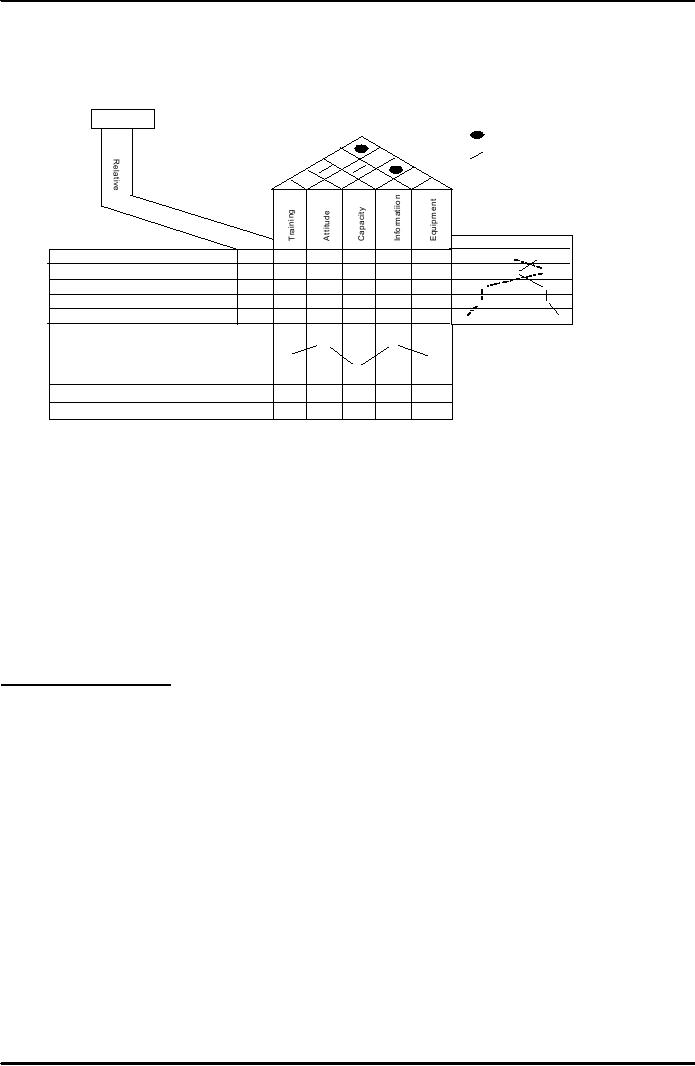

House

of Quality

109

Production

and Operations Management

MGT613

VU

QFD

can strongly help an

organization focus on the critical

characteristics of a new or existing

product

or

service from the separate viewpoints of

the customer market segments,

company, or technology-

development

needs.

R

e l a t io n s h i p s

*

S

t ro n g

M

e d iu m

O

W

eak

O

O

*

*

C

u s t o m e r P e rc e p t io n s

S

e r vic e E le m e n t s

o

V

illa g e V o l v o

Im

po

+

rt

a

V

o l vo

D

e a le r

nc

e

C

u s t o m e r E x p e c t a t io n s

1

2

3

4

5

+

R

e lia b ilit y

o

9

8

5

5

+

o

9

R

es p o ns iven e s s

3

3

2

7

+

A

s s u ra n c e

o

9

6

5

6

+

o

7

4

E

m p a th y

+

o

2

2

3

T

a n g i b le s

+

o

o

C

o m p a ris o n

w

it h V o l v o D e a le r

o

o

o

_

W

e ig h t e d s c o re

82

63

102

65

127

Im

p r o v e m e n t d i ffi c u l t y r a n k

1

3

2

4

5

Achieving

Service Quality: Service Quality can be

achieved by making use of the following

strategies

Cost

of Quality

Service

Process Control

Statistical

Process Control

Unconditional

Service Guarantee

We

will discuss all four in

detail during our

discussions in lectures that

follow this lecture for the

time

being

we can reiterate the fact

that quality is offered free

of cost. Also, as prevention is

better than cure,

it

makes a lot more sense to

incur cost in prevention of

defects instead of allowing the defects

to occur

and

then rectifying them. Statistical

Process Control is one important

tool to ensure that Service

Quality

is

achieved before a defect is introduced in the service

being offered or product

being manufactured.

Costs

of Service Quality (Bank

Example)

This

example shows how a weak

design service can incur loss in

customer service, which leads to

loss

in

revenues. With this example

we also try to focus our

attention on the concept of cost in

quality

dimension.

We try to capture the importance of

prevention costs and how

they are more beneficial to

the

organization

as compared to detection and failure

costs. As a rule of thumb it is

said that prevention

costs

are half the detection costs

and about 12 to 16% of failure

costs, but these percentages

often fail to

represent,

the cost expenditures in all types of

services.

110

Production

and Operations Management

MGT613

VU

Failure

costs

Detection

costs

Prevention

costs

External

failure:

Loss

of future

Process

control

Quality

planning

business

Negative

Peer

review

Training

program

word-of-mouth

Liability

Supervision

Quality

audits

insurance

Legal

Customer

Data

acquisition

judgments

comment

card

and

analysis

Interest

Inspection

Recruitment

and

penalties

selection

Supplier

evaluation

Internal

failure:

Scrapped

forms

Rework

Recovery:

Expedite

disruption

Labor

and

Control

Chart of Departure Delays

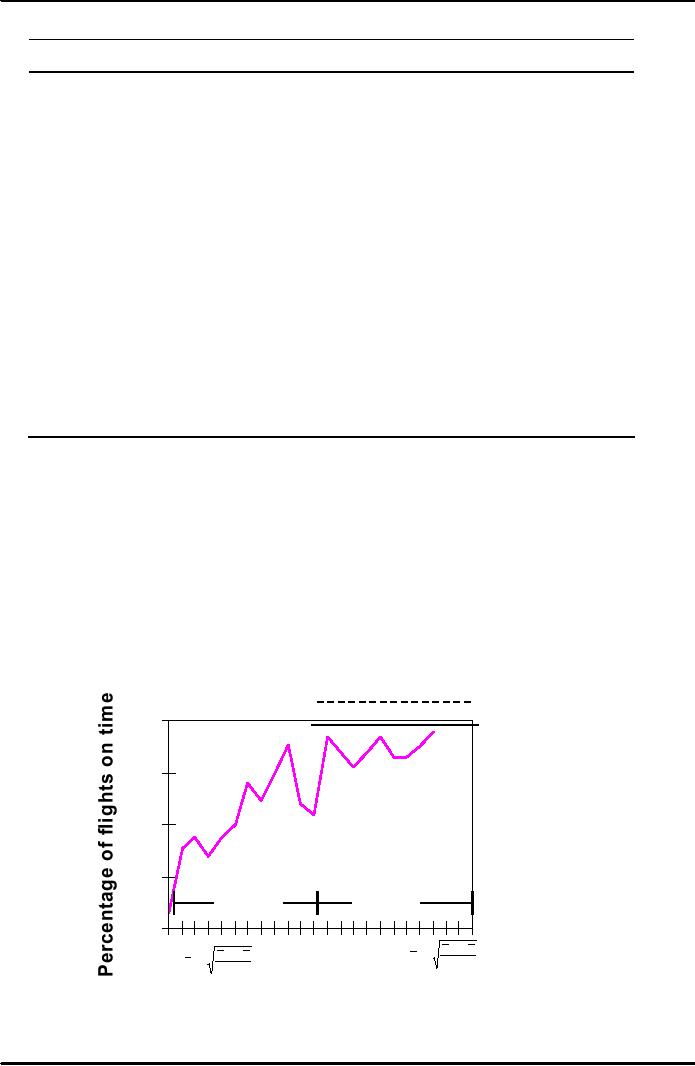

We

talked about the concept of Service

quality and one of its dimensions

was Tangibility. We can

apply

this

dimension to the service provided by

airlines operating in Pakistan. If we happen to

visit any airport

in

the northern part of Pakistan during

winters especially during the

months of December and

January,

we

face a situation where often there is a

delay in the flight arrival and

departure. We can make good

use

of statistics to improve our service

quality. In the graph below

we have been able to identify

a

Lower

Control Limit and an Upper

Control Limit.

expecte

100

Lower

Control

90

80

70

199

60

p(1

-

p

p(1

-

p

LCL

=

p

-

3

UCL

=

p

+

3

n

n

111

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model