|

Production

and Operations Management

MGT613

VU

Lesson

23

MANAGEMENT OF

QUALITY

After

completing the lecture on Management of

Quality, the POMA students

should be able to

understand

the term quality and the importance of

Quality. The student should be

able to learn the

Determinants

of Quality, when they

discuss Total Quality

management also they should

be able to

identify

the various costs associated

with Quality. The students

should also be able to

appreciate the

famous

ISO 9000 and ISO

14000 quality systems, which

are also actively seen in

Pakistan. And last

but

not

the least out of curiosity than

academic interest the students

should be aware of philosophies

of

Quality

Gurus.

Introduction

Quality

Management can be understood only if we

are able to understand the term quality,

which is

defined

as

Quality

is

the ability of a product or service to

consistently meet or exceed

customer expectations.

Quality

as determinant of Revenue has been

often neglected, people tend to

associate quality with

high

price

of the product or item they

want to purchase, historically speaking

this is an incorrect

statement.

The

debate between American and Japanese

philosophy proves that quality is

offered free of cost and

is

the

prime source of revenue or

profit.

When

the American industry in 70s

and 80s talked about

cost cutting and productivity

improvement

they

did not paid heed to

Quality Management, which

was the "Holy Grail"

for the Japanese

Industry.

When

Japanese manufacturers entered and occupied the

American Markets the only

thing that made

their

products and services better

than the Americans was the

concept of Quality, which

led to

increase

in the revenues and productivity of

Japanese manufacturers.

Evolution

of Quality Management

1.

Prior to Industrial Revolution, the

skilled craftsman performed

all stages of production.

Pride in

workmanship

and reputation often formed the

basis of producing a quality

well. One or small

group

of

workers was responsible for the

entire product. After

industrial revolution and

specialization and

division

of labour each worker was

then responsible for small

portion of work. This led to

loss in

pride

of workmanship and failure to produce

quality products.

2.

Frederick

Winslow Taylor the father of

scientific management brought back the

concept of quality

by

incorporating product inspection as

well as focusing on the importance of

manufacturing

management.

3.

G.S.

Radford introduced the concept of

quality in the product design stage and

linked high quality

with

increased productivity and lower

costs.

4.

1924

W. Shewhart of Bell Technologies

introduced the Statistical process

control charts.

5.

1930

H.F.Dodge and H.G.Romig also of

Bell Technologies introduced

Tables for acceptance

sampling.

6.

1940's

- Universities, Bell Technologies and US

Army were using Statistical

sampling techniques

for

training engineers. American Society

for Quality Control aka ASQC

( now ASQ) was

formed

during

the same era

7.

1950's

- Quality assurance/TQC (The

era of Deming, Juran and Feigenbaum)

which changed the

concepts

of quality for ever.

102

Production

and Operations Management

MGT613

VU

8.

1960's - Zero defects championed by

Quality Guru Phillip Crosby.

It produced the perfect missile

for

US army

9.

1970's - Quality assurance in

services like health care,

banking and travel

industry.

10.

Late 1970s the quality

assurance concept changed to Strategic

quality approach, Harvard

Professor

David

Garvin advocated preventing mistakes

from occurring all

together.

Quality

Assurance vs. Strategic

Approach

Strategic

Approach is the SUPERLATIVE form of

Quality Assurance

Quality

Assurance places emphasis on

finding and correcting

defects before

reaching

market

Strategic

Approach is Proactive, focusing on

preventing mistakes from

occurring and places

greater

emphasis on customer

satisfaction

Quality

Guru

The

Quality Gurus are given more

respect and recognized as

Key Contributors to Quality

Management.

Presented

below is their contributions in a

nut shell, students should

learn to recognize

these

1.

Walter Shewhart is also known as

"Father of statistical quality

control"

2.

W. Edwards Deming presented 14 points

for quality management which

focused primarily on

common

cause of variation.

3.

Joseph M. Juran is famous for

his concept of "Quality is the fitness

for use".

4.

Armand Feigenbaum said, "Quality is a

total field or total

function".

5.

Philip B. Crosby is famous

for his philosophy that

"Quality is free".

6.

Kaoru Ishikawa- presented the

"fish bone diagram" or "cause

effect diagram".

7.

Genichi Taguchi robust design

for designing products insensitive to

change in environment.

Taguchi's

contribution was, "Taguchi

loss function".

Dimensions

of Quality

The

concepts of dimensions of quality

represent the fact that

customers value a product

keeping in

mind

different dimensions. Quality and Operations

Managers come across

customer perceptions

relating

to demand for durable,

reliable, performance to a standard and

that too in away that

is

aesthetically

correct.

1.

Performance

-

main characteristics of the

product/service

2.

Aesthetics

-

appearance, feel, smell,

taste

3.

Special

Features -

extra characteristics

4.

Conformance

-

how well product/service conforms to

customer's expectations

5.

Reliability

-

consistency of performance

6.

Durability

-

useful life of the

product/service

7.

Perceived

Quality - indirect

evaluation of quality (e.g.

reputation)

8.

Serviceability

- service after

sale

103

Production

and Operations Management

MGT613

VU

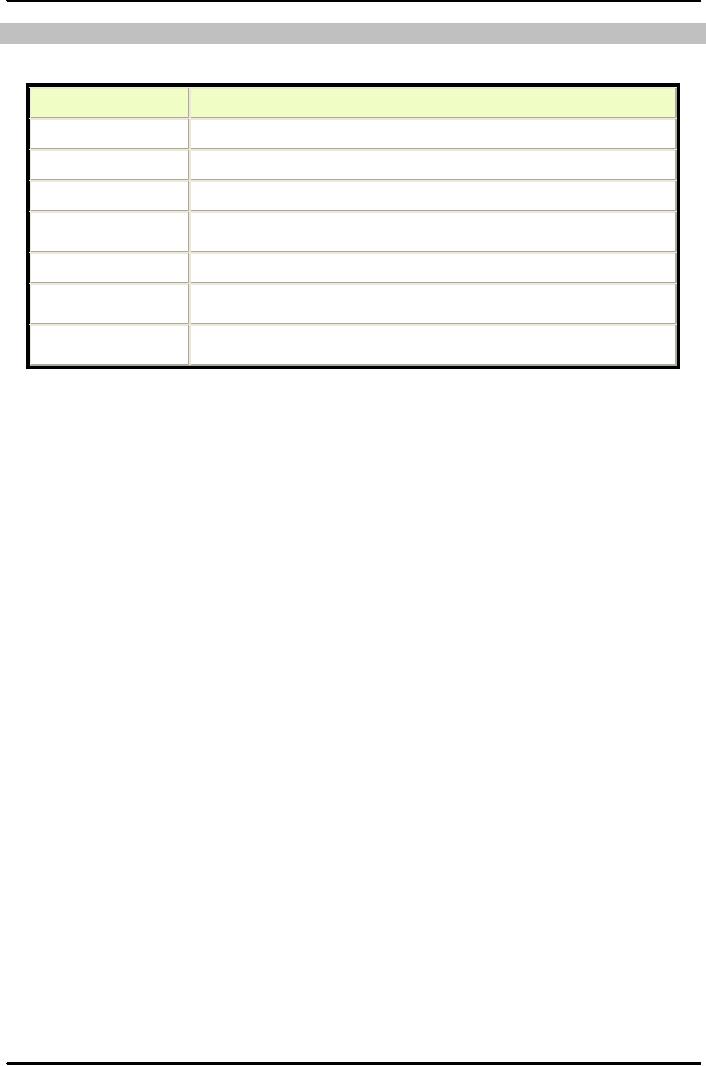

Examples

of Quality Dimensions

Dimension

(Product)

(Service)

Automobile

Auto

Repair

1.

Performance

Everything

works, fit &

All

work done, at agreed

finish

price

Ride,

handling, grade of

Friendliness,

courtesy,

materials

used

Competency,

quickness

2.

Aesthetics

Interior

design, soft touch

Clean

work/waiting area

3.

Special features Gauge/control

placement Location, call

when ready

Cellular

phone, CD

Computer

diagnostics

player

Examples

of Quality Dimensions (Cont'd)

Dimension

(Product)

(Service)

Automobile

Auto

Repair

5.

Reliability

Infrequency

of breakdowns

Work

done correctly,

ready

when promised

6.

Durability

Useful

life in miles, resistance

Work

holds up over

to

rust & corrosion

time

7.

Perceived

Top-rated

car

Award-winning

service

quality

department

8.

Handling

of complaints and/or Handling of

complaints

Serviceability

requests

for information

Service

Quality

Tangibles

Convenience

Reliability

Responsiveness

Time

Assurance

Courtesy

104

Production

and Operations Management

MGT613

VU

Examples

of Service Quality

Dimension

Examples

1.

Tangibles

Were

the facilities clean, personnel

neat?

2.

Convenience

Was

the service center conveniently

located?

3.

Reliability

Was

the problem fixed?

4.

Responsiveness

Were

customer service personnel willing and

able to answer

questions?

5.

Time

How

long did the customer

wait?

6.

Assurance

Did

the customer service personnel seem

knowledgeable about the

repair?

7.

Courtesy

Were

customer service personnel and the cashier

friendly and courteous?

105

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model