|

Production

and Operations Management

MGT613

VU

Lesson

22

LOCATION

PLANNING AND ANALYSIS

Lecture

Objectives

By

studying location planning and analysis,

an operations management student should be

able to

understand

the

Importance

of Location Planning and

Analysis

Criteria

for Manufacturing and Service Location

selection considerations

Transportation

Model

IMPORTANCE

OF LOCATION

Location

decisions are not limited to one

time strategic planning decisions for

building a new

manufacturing

or service facility rather most of the

organizations face the challenge of

increasing their

capacity

through selection of new locations or

extension of existing

locations.

As

an operations management student, we can focus on the

importance of location for

any organization

through

various departments of the

organization.

Accounting

which prepares cost

estimates for changing

locations as well as operating at

new

locations.

Distribution

which seeks warehouse

layouts that make material

handling easier and

customer

response

shorter.

Importance

of Location

Engineering

which considers the impact of

product /service location

choices.

Finance

which performs the financial analysis

for investments in new

locations.

Human

Resources, which hires and

trains employees to support new locations

or relocations of

operations.

Management

Information Systems which

provide information technologies

that link operations

at

different locations.

Importance

of Location

Marketing

which assesses new locations

and revised locations that are

popular with the

customers.

Operations

Management which seeks and

finalizes locations that

create, sustains, protect

and

project

the best performance criteria for

the whole

organization.

Location

plays an important role for

every business whether new

or existing. We can refer to the

same

airport

example we discussed in our

earlier lectures before. The

airport is not only crowded

but fails to

separate

the different services it provides to

different categories of individuals

present at the airport.

The

airport

may need to explain its

existing facility. In Pakistan too, we

have seen new airports set

up at

Karachi,

Lahore and Islamabad which

cater to greater traffic of the aero

planes and more

passengers.

Location

decisions play an integral part of the

strategic planning process of every

organization. It is

important

to learn about the need and nature of

location decisions. As a part of his

routine

responsibilities

a senior Operations Manager often carries

out the evaluation of different

available

locations.

GLOBALIZATION

AND GEOGRAPHIC DISPERSION OF

OPERATIONS

Globalization

has affected Pakistan tremendously. A

number of Multi National

Corporations are

operating

and functioning in Pakistan. It is

important to spend some time

in understanding how

globalization

makes it necessary and pertinent

for a MNC to disperse and

spread its scope and

function

of

Operation. It would be more correct if

try to understand the philosophy of MNC's

not operating in

certain

regions or certain particular countries.

The western worlds call

these the disadvantages of

Globalization,

if an organization decides to pack up its

business and leave a host

company.

95

Production

and Operations Management

MGT613

VU

DISADVANTAGES

TO GLOBALIZATION

The

common disadvantages which lead to a MNC

forgoing globalization

includes.

Handing

over proprietary Technology to

host countries.

Political

risks.

Poor

Employee ( Managers and worker )

skills.

Slow

customer response

time.

Effective

communication between interfaces

difficult

MANAGING

GLOBAL OPERATIONS

When

organizations become global

they often end up paying a

heavy price in terms of

managing

complex

managerial issues and

challenges.

Host

country languages

Host

Country Norms and

Customs.

Workforce

management

Unfamiliar

laws and regulations.

Unexpected

Cost mix.

Need

for Location

Decisions

Quite

often MNC's move to a host

country with a lot of hype

and propaganda of bringing jobs to

the

local

labour but the reality is

its own need to increase

its revenue and profits.

Most of the time the

need

for

location decision focuses

on

Marketing

Strategy

Cost

of Doing Business

Growth

Depletion

of Resources

Nature

of Location Decisions

Location

Decisions are primarily strategic in nature and have

certain objectives and options

attached

Strategic

Importance

1.

Long term commitment/costs

2.

Impact on investments, revenues, and

operations

3.

Supply chains

Objectives

1.

Profit potential

2.

No single location may be

better than others

3.

Identify several locations from

which to choose

Options

1.

Expand existing

facilities

2.

Add new facilities

3.

Move

Making

Location Decisions

1.

Decide

on the criteria

2.

Identify

the important factors

3.

Develop

location alternatives

4.

Evaluate

the alternatives

96

Production

and Operations Management

MGT613

VU

5.

Make selection

Location

Decision Factors

Regional

Factors

Location

of raw materials

Location

of markets

Labor

factors

Climate

and taxes

Community

Considerations

Quality

of life

Services

Attitudes

Taxes

Environmental

regulations

Utilities

Developer

support

Site

Related Factors

�Land

�Transportation

�Environmental

�Legal

Multiple

Plant Strategies

1.

Product plant strategy

2.

Market area plant

strategy

3.

Process plant strategy

Mostly

mix of all three

Factors

Affecting Location

Decisions

The

process of determining a geographic site

for firms operations takes

into account both

manufacturing

and

marketing aspects. We just focus on the

manufacturing aspects as its more

closely related to

Operations

Management

Manufacturing

Favorable

Labor Climate

Proximity

to markets.

Quality

of Life

Proximity

of Suppliers and

Resources.

Proximity

to the Parent Company's

facilities.

Utilities,

Taxes and Real estate

costs.

Other

factors ( expansion, construction costs,

and location near the

highway or main

railways)

Dominant

Factors in Services

Look

for concept check

information provided by our

expert. We also present the

following

dominant

factors in selection of locations for

services.

Proximity

to Customers.

Transportation

costs and proximity to

markets.

Location

of competitors.

Site

specific factors.

Trends

in Locations

97

Production

and Operations Management

MGT613

VU

�Foreign

producers locating in different

host countries even Pakistan

Currency

fluctuations

Just-in-time

manufacturing techniques

Micro-factories

Information

Technology

Evaluating

Locations

�Cost-Profit-Volume

Analysis

Determine

fixed and variable

costs

Plot

total costs

Determine

lowest total costs

Location

Cost-Volume Analysis

�Assumptions

Fixed

costs are constant

Variable

costs are linear

Output

can be closely

estimated

Only

one product involved

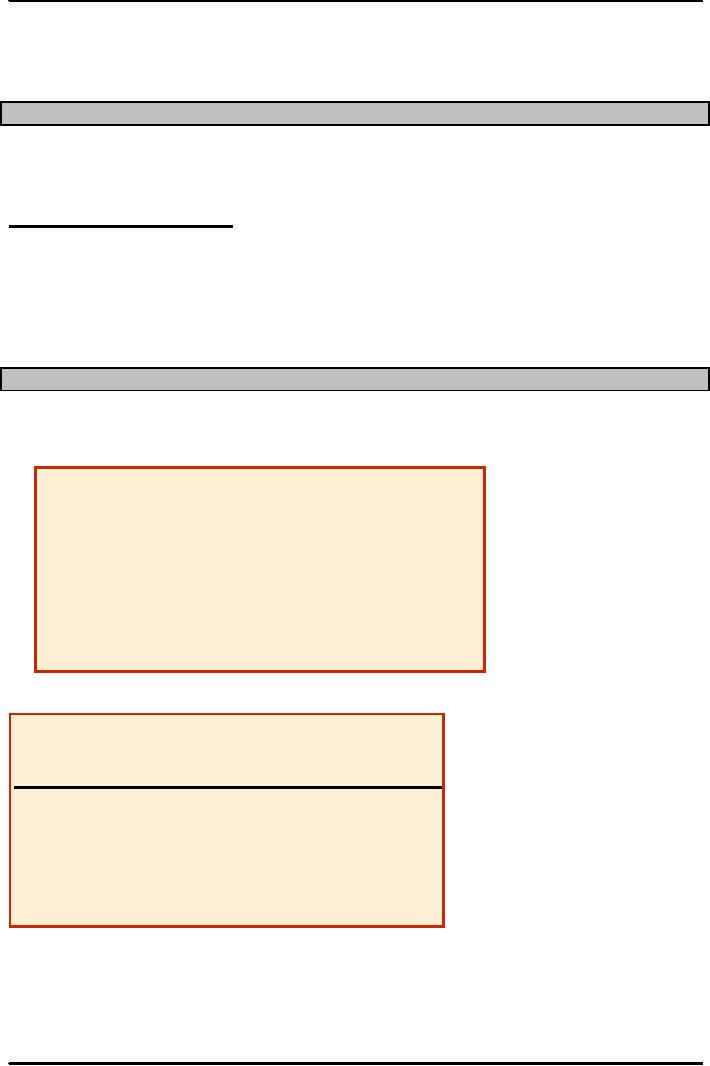

Example

1: Cost-Volume Analysis

The

quantity is 10,000 and the Fixed

and variable costs for

four potential

locations

Location

Fixed

Variable

Cost

Cost

Rs

11

Rs

250,000

A

30

100,000

B

20

150,000

C

35

200,000

D

Example

1: Solution

Fixed

Variable

Total

Costs

Costs

Costs

A

Rs250,000 Rs11(10,000)

Rs360,000

B

100,000

30(10,000)

400,000

C

150,000

20(10,000)

350,000

D

200,000

35(10,000)

550,000

Example

1: Solution

We

calculate the variable costs by

multiplying the unit cost

with the given quantity

and

calculate

total costs for all

four locations

98

Production

and Operations Management

MGT613

VU

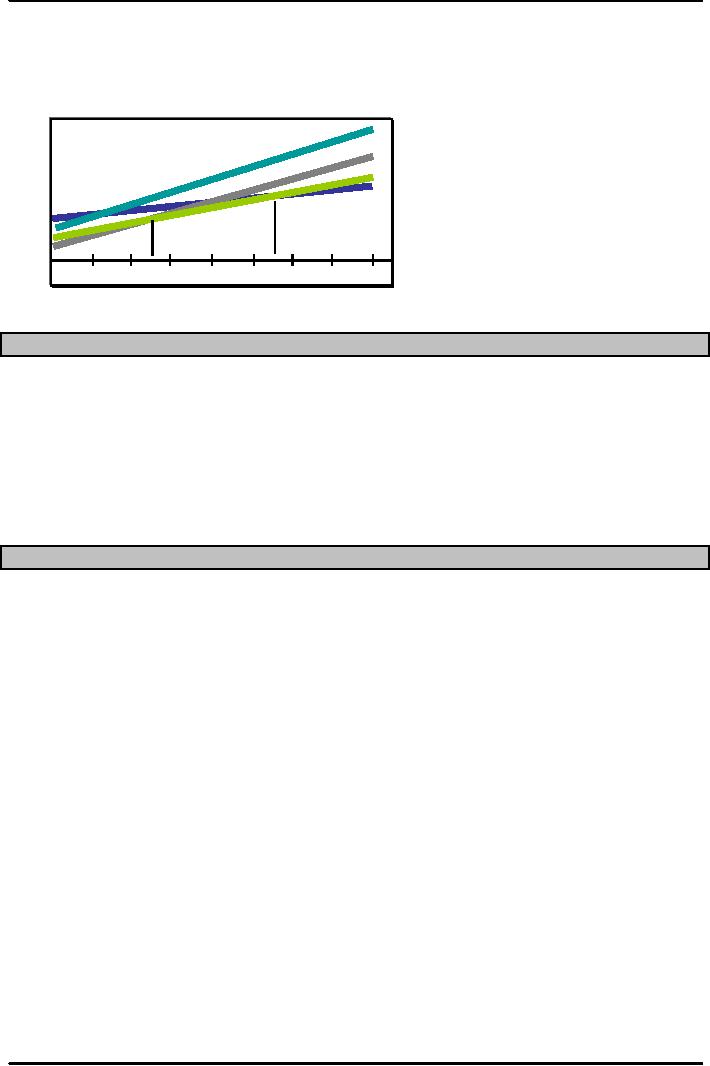

We

also graph them to decide effectively,

the total costs are graphed

and we see that for

10,000

units

clearly location c has an advantage,

beyond 10,000 units,

diseconomies of scales set in

and

makes

Location C look less

lucrative.

We

select the Location for

which the total cost is the

lowest.

Our

Location C, shows the lowest

total cost for an equal

quantity of 10,000

units.

Rs(000)

800

D

700

B

600

500

C

400

A

300

A

200

C

100

B

0

0

2

4

6

8

10

12

14

16

Annual

Output (000)

Evaluating

Locations

Operations

Manager can evaluate

business site locations by making

use of the following three

techniques

1.

Transportation Model

Decision

based on movement costs of raw materials

or finished goods

2.

Factor Rating

Decision

based on quantitative and qualitative

inputs

3.

Center of Gravity Method

Decision

based on minimum distribution

costs

Transportation

Method

Transportation

Method is a quantitative approach that

can help solve multiple

facility location problems.

It

is used to determine the allocation

pattern that can be used to

minimize the cost of shipping

products

from

two or more plants or sources of supply

to two or more warehouses or

destinations.

Based

on Linear Programming.

It

does not solve all the

problems of the multiple facility

location.

It

only finds the best shipping

pattern between plants and warehouses

for a particular set

of

plant

locations with a given

capacity.

The

Operations manager or logistics analyst

must try a variety of

location-capacity

combinations

and use this to find the

optimal distribution for

each alternative.

Distribution

costs( variable shipping and possible

variable production costs)

are important

inputs

in evaluating a particular location

allocation combination.

Investments

costs and other fixed

costs are also

considered.

Qualitative

factors ( like land and construction

cost against annual profits)

are also included in

the

analysis for each location

capacity combination.

Transportation

Method

�Step

I

Set

up the initial matrix/tableau. The

basic steps include

Create

a row for each plant (

existing or new) being considered and a

column for each

warehouse.

Add

a column for plant capacities and a

row for warehouse demands

and then insert

specific

numerical

values.

Transportation

Method

�Step

II

Each

cell not in the requirement

row or capacity column

represents a shipping route

from a plant to

warehouse.

Insert the unit costs in the

upper right hand corner of each of

these cells.

99

Production

and Operations Management

MGT613

VU

Example

Pakistan

Cellular Mobile Company plans to

build a 5000 unit production

plant at Islamabad

because

demand

for mobile phones in Pakistan

has gone up. The tableau on

the next slide shows the

unit cost of

shipping

one truck/loader of mobiles from the

existing plant at Lahore and the possible

location at

Islamabad.

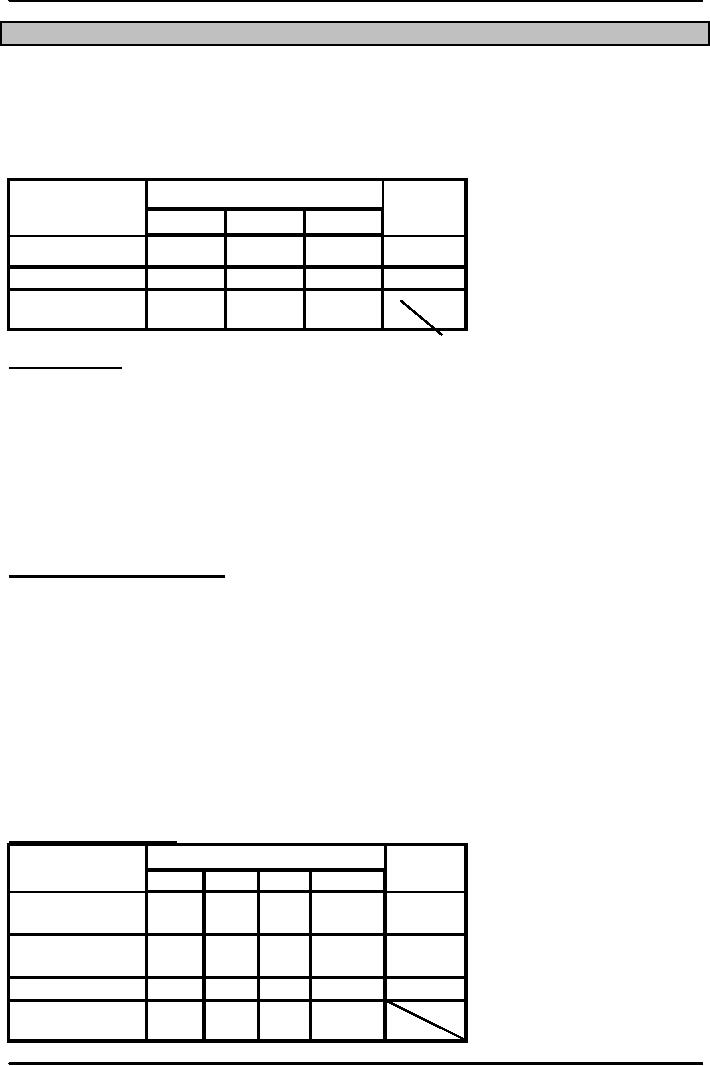

Transportation

Method Ma

Plant

Capacity

WAREHOUSE

1

2

3

Lahore

500.0

600.0

5500

5000

Islamabad

700.0

4500

6000

5000

REQUIREMENTS

2500

4500

3000

10000

10000

Matrix/Tableau

In

transportation method, the sum of the

shipments in a row must

equal the corresponding plants

capacity.

Similarly

the sum of the shipments to a column

must add to corresponding warehouses

demand

requirements.

Thus shipments to Warehouse 1 from Lahore

and Islamabad must equal

2500

mobiles.

Dummy

Plants or Warehouses

The

prime requirement of transportation

model is that the sum of

capacities must equal the

sum

of

demands, which happens to be

10,000 units of mobile

phones.

IN

reality the total capacity

may exceed total requirements or

vice verca.

Dummy

Plants or Warehouses

If

capacity exceeds requirements by say M

units, we add extra column (

a dummy warehouse)

with

a demand of M units and make the

shipping costs in the new

created cell equal to Rs.

0.

Since

no shipments are made to the

dummy warehouse so it represents an

unused plant

capacity.

Dummy

Plants or Warehouses

If

requirements exceed capacity by say M

units, we add extra row ( a

dummy plant) with a

supply

of M units and make the shipping

costs ( stock out costs) in the

new created cell equal

to

Rs.

0.

Since

no shipments are made to the

dummy warehouse or plants so this

step is automatically

taken

care of in Softwares used for

such issues.

Optimal

Solution

We

try to find the least

allocation cost

process.

And

we keep on repeating with various

options till a new solution

with least costs is

obtained

and

we call it the optimal

solution.

Transportation

Method

Plant

Capacity

WAREHOUSE

1

2

3

Dummy

Lahore

1.0

6.0

1.0

0

5000

2500

2500

Islamabad

7.0

2.00

6.00

0

5000

4500

500

0

0

0

0

Dummy

REQUIREMENTS

2500

4500

3000

0

10000

10000

100

Production

and Operations Management

MGT613

VU

The

total transportation cost

would be Sum of all Units

time X the Unit Cost

=

2500(1.0)+4500(2.0)+2500(1.0)+500(6.0)

=2500+9000+2500+3000=Rs

17,000.

The

operations manager needs to be judicious

in his approach and may decide to expand

the plant at

Lahore

and build a small plant in

Islamabad.

Summary

The

lecture focused primarily on the

importance of location. Various

aspects relating to

Location

Planning

and Analysis were focused. MNC's

reasons for not selecting

various countries under the garb

of

disadvantages in Global Operations were

also examined. Site

locations for both

manufacturing and

services

were considered. Last but not the

least a detailed study of the

Transportation Model was

also

carried

out. Students should also

know how to make use of cost

volume analysis and transportation

model

to carry out practical

investigation of real life

time Operations Management

problems.

101

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model