|

Production

and Operations Management

MGT613

VU

Lesson

20

In

our last lecture, we identified

Facilities layout as the configuration of

departments, sections,

work

centers,

equipment with focus being on movement of

goods or services or works. So

whether it's a

traveler

making use of the railway

platform, or bus station or

airport, or an automobile or a

product

during

its production stage or a

patient needing medical

attention, they all would

qualify as good

examples

of work being moved through

a facility. Often poor design of

productive system can result

in

poor

design of the facilities layout. We

discussed product, process and

hybrid layouts, we now focus

our

attention

on cellular production. In cellular

manufacturing, production work stations

and equipment are

arranged

in a sequence that supports a

smooth flow of materials and components

through the production

process

with minimal transport or delay.

Implementation of this lean method

often represents the

first

major

shift in production activity,

and it is the key enabler of increased

production velocity and

flexibility,

as well as the reduction of capital

requirements. The concept of lean

production and Just in

Time

Production Systems would be

studied in detail when we

will discuss improvement of

Productive

Systems.

Cellular

Layouts

Cellular

production techniques reflect a

relatively new concept in

manufacturing and have yet

found

immediate

acceptance in Pakistani manufacturing

industry as well. Organizations

which opt for

cellular

manufacturing

follow the lean production

strategy. There are two

important concepts to understand

at

the

moment, what cellular production is and

what group technology is? We

will discuss lean

production

systems

in detail towards the end of our

semester later, for the time

being we can consider

lean

production

systems as systems which focus on

high quality process with

elimination of waste and

effective

use of available

resources.

Cellular

Production

Layout in which machines

are grouped into a cell

that can process items that

have

similar

processing requirements.

Group

Technology

The grouping into part

families of items with similar design or

manufacturing

characteristics.

Cellular

production always would

represent the layout of machines

while group technology

would

reflect

the collection of items or products which

need the same manufacturing requirements.

Both these

terms

greatly influence the improvements of

process and operations for any

organization.

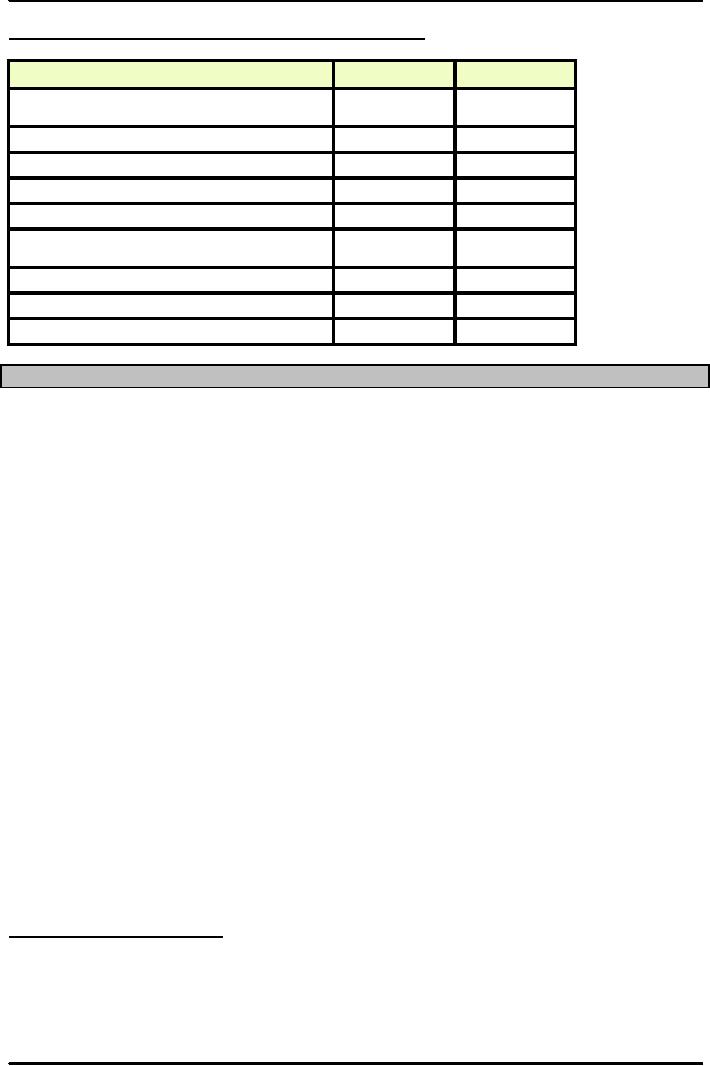

It

is pertinent to understand the advantage of cellular

layouts over the functional

layouts. We already

know

that functional layouts are

not only conventional in nature

but also require more space

as well as

somewhat

rigid layout plans, with

increased special workforce and

continuous supervision. The

table

below

represents the same concept.

84

Production

and Operations Management

MGT613

VU

Primary

Differences between Functional and

Cellular Layouts

Dimension

Functional

Cellular

Number

of moves between departments

many

few

Travel

distances

longer

shorter

Travel

paths

variable

fixed

Job

waiting times

greater

shorter

Throughput

time

higher

lower

Amount

of work in process

higher

lower

Supervision

difficulty

higher

lower

Scheduling

complexity

higher

lower

Equipment

utilization

lower

Higher

Facilities

Layouts

We

have so far discussed what

product and process based

layouts are, in between we also

focused our

attention

on hybrid configuration as well as

cellular production layouts. We

can thus safely

define

facilities

layout as the

configuration of departments, work

centers and equipment, with

particular

emphasis

on movement of work (customers or

materials) through the

system.

We

come across different

layouts in our daily lives

especially with respect to the

services side. Some

important

Service Layouts, which we should

know include

Warehouse

and storage layouts

Retail

layouts

Office

layouts

People

often confuse retail stores

with warehouse stores, an

effective way to understand the

importance

of

these important business

channels is to identify the layouts

associated with it. Retail

configurations

are

human friendly and allow the movement of

goods through small trolleys

for the customers and if

placement

of goods in the aisle is to be carried

out then simple forklifts or

small vehicles are

used,

sometimes

over head cranes or hoists

are also used.

Another

important point of difference

being the way the goods are

displayed and shelved. The

layouts

are

properly illuminated and ventilated and

mostly maintained at a human comfort

temperature through

effective

heating and air-conditioning. The

floors too are mostly

vinyled and designed to make

the

customer

movement less stressful. The movement of

goods involves light loads and

easy transportation,

as

against this the warehouse and

storage layouts, which

require heavy loads and

transportation. These

goods

require heavy vehicles and loaders

for movement. The stores have

different illumination

arrangement

then retail outlets. The

security measures are

different for both types of

layouts, ranging

from

close circuit television

cameras to electric barbed

wires.

Importance

of Layout Decisions

Operations

Managers are often questioned

about the importance of a new or

existing facilities layout.

In

addition

to the fact that operations manager

work for improvement towards design and

effect use of

operation

systems, they should also

know the importance of layout

decision in terms of money.

Some of

these

are:-

85

Production

and Operations Management

MGT613

VU

1.

Layout decisions require substantial investments of

money and effort.

2.

Layout decisions involve long-term

commitments.

3.

Layout decisions have significant impact

on cost and efficiency of short-term

operations.

The

Need for Layout

Decisions

An

operations manager should be aware of the

fact that the need for a

proper and effective

layout

facility

is always there, it is often said

that if there is no facilities layout

problem being faced by an

organization

then it is probably unaware of its

true potential. The need

for layout planning arises

both in

the

process of designing new

facilities and in

Redesigning

existing facilities. Some of the common

reasons faced by the organization

include:-

1.

In-efficient Operations (High

Cost/Bottlenecks that hamper

true potential).

2.

Accidents or Safety

Hazards.

3.

Changes in design of products or

services.

4.

Introduction of new products or

services.

5.

Changes in volume of output or

mix of outputs.

6.

Changes in Methods or

equipment.

7.

Changes in Environmental and Legal

requirements.

8.

Morale Problems ( e.g. lack of

face to face contact between supervisor

and worker or even

senior

management and junior

management).

Design

Product Layouts: Line

Balancing

Line

Balancing is the process of assigning

tasks to workstations in such a

way that the

workstations

have

approximately equal time

requirements.

The

objective of line balancing is to

obtain equal time requirements at

majority of the workstations.

This

shortens

the time of manufacturing as well as

reduces the idle time. Often

industry uses the term

cycle

time

to represent the time in which the

organizations resources are

engaged to complete a process

and

idle

time to represent the time in

which the resources are left

unused.

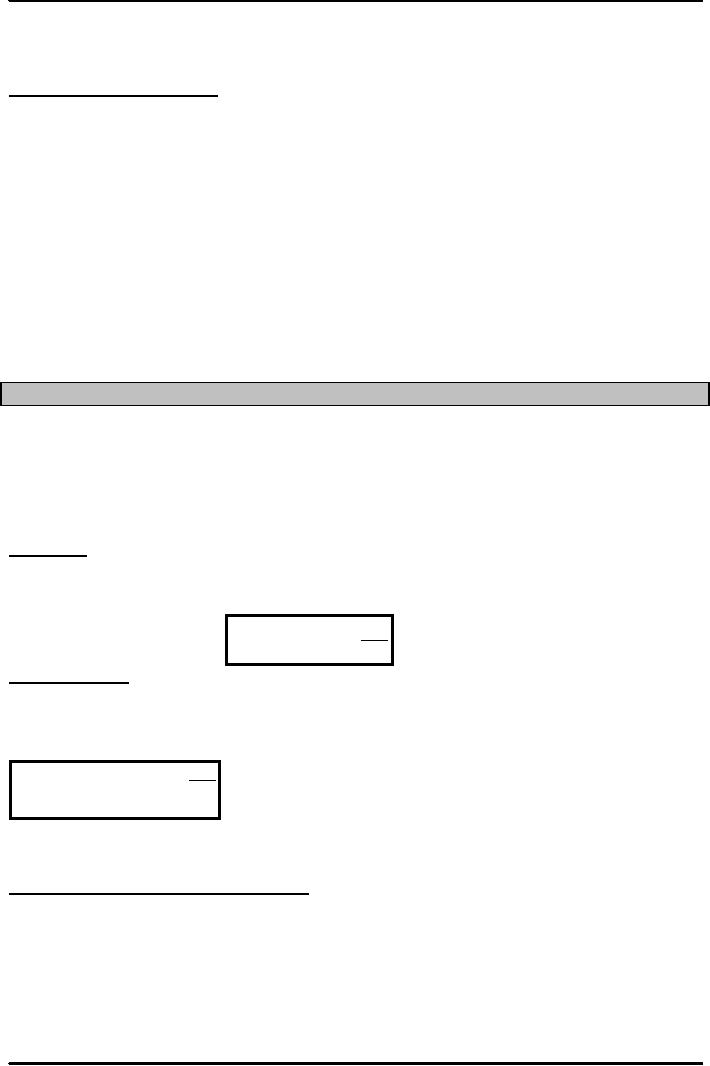

Cycle

Time

Cycle

time is the

maximum time allowed at each

workstation to complete its set of

tasks on a unit. If CT

represents

cycle time and D represents

the desired output then we

can calculate cycle time

as

OT

CT

= cycle time =

D

Maximum

Output

If

we know what is the cycle

time required for the

manufacturing of a product or offering of

a service

we

can calculate the maximum output. If OC

is the Output capacity, OT is the

operating Time and CT is

the

Cycle time then

OT

OC

=

Output

capacity

=

CT

If

an automobile manufacturer works for 8

hours and requires 4 hours to complete its cycle

then the out

put

capacity would be 8/4= 2

automobiles.

Minimum

Number of Workstations

Required

Organizations

working especially service organizations

side often design their work

facilities in a way

that

they can increase their

capacity output by increasing the number of

work stations. If D is the desired

output,

t is the time required for a

specific time and OT is the Operating

Time then the number of

workstations

N can be calculated as .

86

Production

and Operations Management

MGT613

VU

(D)(∑

t)

N=

OT

∑

t

= sum of task times

Precedence

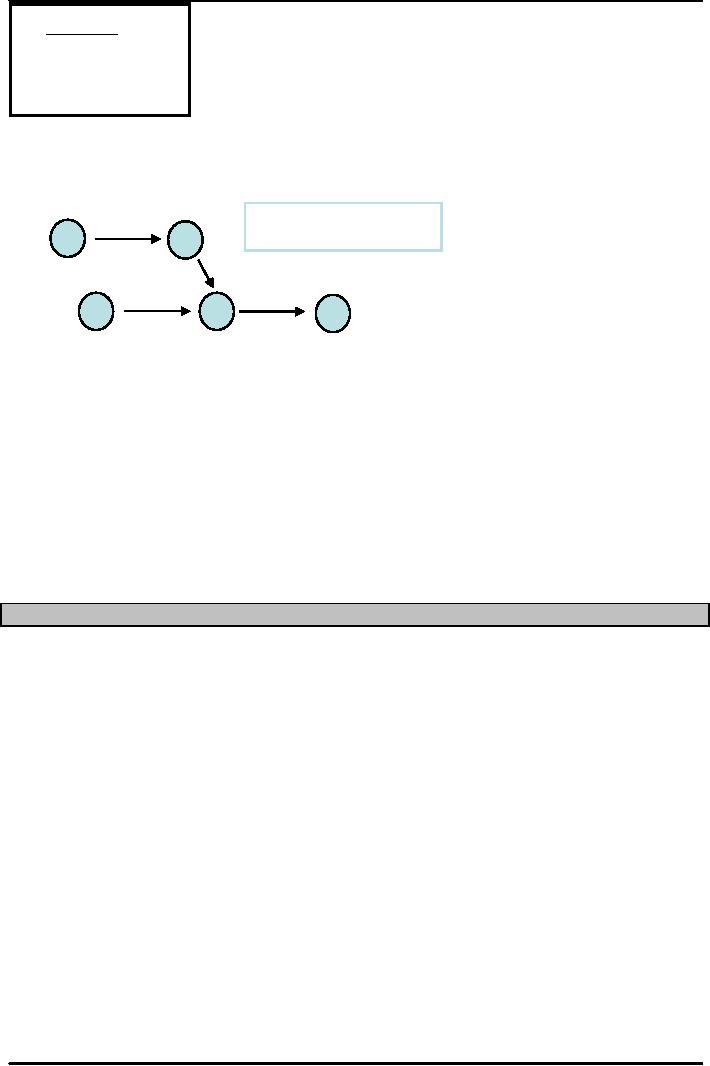

Diagram

Precedence

diagram:

Tool used in line balancing

to display elemental tasks

and sequence requirements

0.1

1.0

A

Simple Precedence

a

Diagram

b

c

d

e

0.7

0.5

min.

0.2

Line

Balancing Rules

·

Assign

tasks in order of most

following tasks.

Count the number of tasks that

follow.

·

Assign tasks in order of

greatest positional

weight.

Positional weight is the sum of

each task's time and the

times of all following

tasks.

Designing

Process Layouts require

certain information, which

includes the following:

1.

List of departments

2.

Projection of work

flows

3.

Distance between locations

4.

Amount of money to be

invested

5.

List of special considerations

6.

Location of key

utilities

Summary

Facilities

layout plays an important

part in an organization achieving

its maximum potential. This

also

indicates

that facilities layout allow

an organization to enjoy a competitive

advantage over its

competitors.

Facilities layout require more

than just cost benefit

analysis infact the decision

requires

how

much space is required by the

facility and how to

configure or optimize the use of

this space for the

product

or process. Of the different types of

product, process, fixed and

hybrid types of configurations,

the

current trend is towards cellular

manufacturing and group

technology.

Capital

investments, materials handling costs and

flexibility are

important

criteria

in judging most facilities

layout. Low volumes of

production do allow the use of

Group

Technology

or cellular manufacturing. Designing a

process layout requires collecting

information about

acceptable

block plan, and translating the

block plan into a detailed

layout. In product

layout,

workstations

are arranged in a naturally occurring,

heuristic (commonsense) for

high volume of

production.

In line balancing the tasks

are assigned to workstations so as to

satisfy all precedence

and

cycle

time constraints while minimizing the

number of work stations.

87

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model