|

Production

and Operations Management

MGT613

VU

Lesson

16

It is

important to realize that

managers make capacity decisions at the

organizational level and not

at

the

operational level. Often,

debottlenecking a process can

increase departmental efficiency

without

increasing

or improving the organizational performance.

This does not mean

that capacity decisions

are

not taken at the operational

level rather managers end up making

capacity decisions at the

individual

process level in accounting,

finance, human resources, information

technologies,

marketing

and operations departments.

Operations

Mangers must understand capacity

measures, economies and

diseconomies of scale,

capacity

cushions and trade off between

customer service and capacity

utilization.

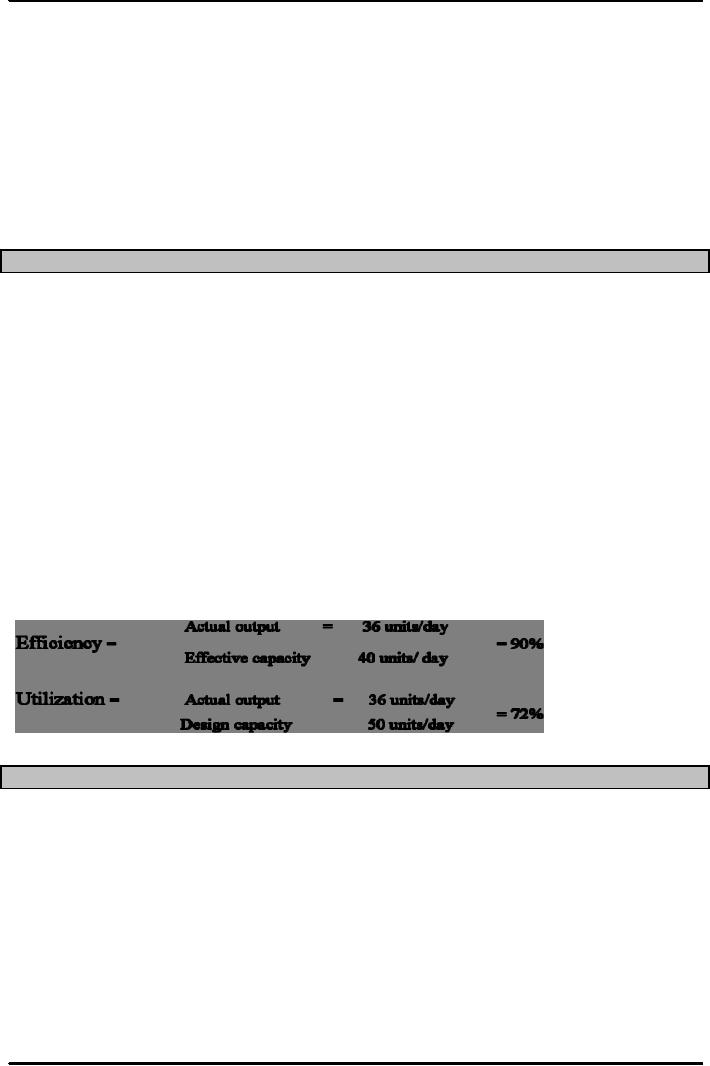

Efficiency

and Utilization

Operations

Manager should know what is

Capacity? They should be

able to identify the terms

Design

Capacity

and Effective capacity

before they can understand another

important concept of

Utilization.

Design

capacity is the maximum output rate or

service capacity an operation, process,

or

facility.

Organizations

facility or operation is designed for

Effective capacity which refers to

Design

capacity

minus allowances such as personal time, maintenance,

and scrap

Actual

output is the rate of output actually

achieved--cannot exceed effective

capacity.

Efficiency/Utilization

Example

Use

the following data to determine the

Efficiency and

Utilization

Design

capacity = 50 trucks/day

Effective

capacity = 40 trucks/day

Actual

output = 36 units/day

Determinants

of Effective Capacity

Operations

Manager often focus on determinants of

effective capacity by taking

into account both

macro

and micro levels. At the macro

levels the managers look for

Supply chain and External

factors,

while

at the micro level they look

for operational factors including

facilities and man and machine

resources.

There are 7 determinants of effective

capacity namely:-

1.

Facilities. The design of facilities

includes the size as well as the

provision of expansion.

Other

important

factors that are necessary

include transportation costs,

distance to market,

labor

supply,

energy supply sources and the

ease and smoothness with

which work can be

performed.

We

should also include

environmental factors such as heating,

lighting and ventilation

which

not

only increase the performance of the

workforce but also act as

source of motivation

and

worker

loyalty. A failure to comply

with this would indicate

poor design which in

reality

translates

to lack of managerial

acumen.

68

Production

and Operations Management

MGT613

VU

2.

Product and service factors can have a tremendous

influence on capacity. E.g.

when items are

similar,

the ability of the system to produce

those items is generally much greater

than when

successive

items are different and unique.

The idea is more uniformity in the

final product

service

output the greater capacity. I am making

a reference to a PC manufacturer in USA

which

decided that it would standardize its

products and split its

assembly lines only at the

point

where

the a small differential product

feature was required.

3.

Process factors refer to the quantity and

quality requirements of a process.

Quantity always

refers

to capacity. Another added

feature is quality of output. If

quality of output does not

match

the

standard requirements it would generate

inspection and possible reworks.

4.

Human factors include skill,

craftsmanship, training and qualification to

handle any job it

also

includes

the motivational factors.

5.

Operational factors with respect to

effective capacity always

refer to scheduling, late

deliveries,

acceptability

of purchased materials, parts, quality

inspection, control procedures and

inventory

problems.

Scheduling issues arise when

an organization has a difference in

equipment

capabilities

for development of alternative

capacities. Inventory problems have a

negative

impact

on capacity

6.

Supply chain factors relate to

any short coming to suppliers, warehouse

processing, operational

hick

up or distribution issues.

7.

External factors include product

standards, safety regulations, unions and

pollution control

standards.

At times organizations have experienced shutting

down of their facility if

they could

not

provide support to government regulations

of pollution control.

Strategy

Formulation With respect to

Capacity Planning

1.

Capacity strategy for long-term

demand which focus on demand

patterns and takes into

account

growth

rate and variability

2.

Facilities that focus on cost of

building and operating

3.

Technological changes relate to rate and

direction of technology

changes

4.

Behavior of competitors

5.

Availability of capital and

other inputs

Key

Decisions of Capacity Planning

It

is important to identify the key

decisions in order to carryout a correct

capacity planning

decision.

Some

of the common key decisions are

1.

Amount of capacity

needed

2.

Timing of changes

3.

Need to maintain

balance

4.

Extent of flexibility of

facilities

Steps

for Capacity Planning

Strategy

It

is important to understand how to

formulate a capacity planning

strategy

1.

Estimate future capacity

requirements

2.

Evaluate existing

capacity

3.

Identify alternatives

4.

Conduct financial analysis

5.

Assess key qualitative

issues

6.

Select one

alternative

7.

Implement alternative

chosen

8.

Monitor results

Developing

Capacity Alternatives

69

Production

and Operations Management

MGT613

VU

1.

Design flexibility into

systems refers to long term nature of

expansion, if at the time of

original

design,

flexibility alternative is provided, and

it would save cost in

remodeling and

modifications

when expansion is carried

out later.

2.

Take stage of life cycle

into account. It is important that

operations manager observe and

check

whether

the capacity increase alternative is

for a new product/service or mature

product or

service.

The predictability for a new

service is riskier as compared to an established

mature

product

or service.

3.

Take a "big picture" approach to

capacity changes while

developing the capacity of the

system,

it

is necessary to understand the interrelationship of

the components of the system. The

big

picture

approach relates to setting up of parking

space, house keeping and landscaping if

an

expansion

is to be accommodated in a multi purpose

shopping plus apartment

complex.

4.

By developing capacity alternatives,

organizations prepare to deal with

capacity "chunks"

Capacity

increases are normally

obtained in big chunks instead of

incremental increase. A

steel

mills

furnace may not be able to

provide exact required increase in

capacity and thus

would

provide

excessive capacity which may

lead to increase in inventory.

E.g. the demand for

steel

say

is 2000 tone per annum in the city of

sukkhur, from a local steel

mill the capacity is

1800

tones

per annum. The steel mill

can increase its production

from 1800 tones to 2200

tones per

annum

and not to exactly 2000

tones per annum.

Organizations

attempt to smooth out capacity

requirements. This topic is discussed in

more detail when

we

will cover the topic of

aggregate planning for the

time being we can see

that simply adding

capacity

by

increasing the size of workforce,

machines, facility does not

help. Operations manager should be

able

to

identify the optimal operating

level. All Production units have an

ideal or optimal level of

operation

in

terms of unit cost of

output. At the ideal level,

cost per unit is the lowest

for that production

unit.

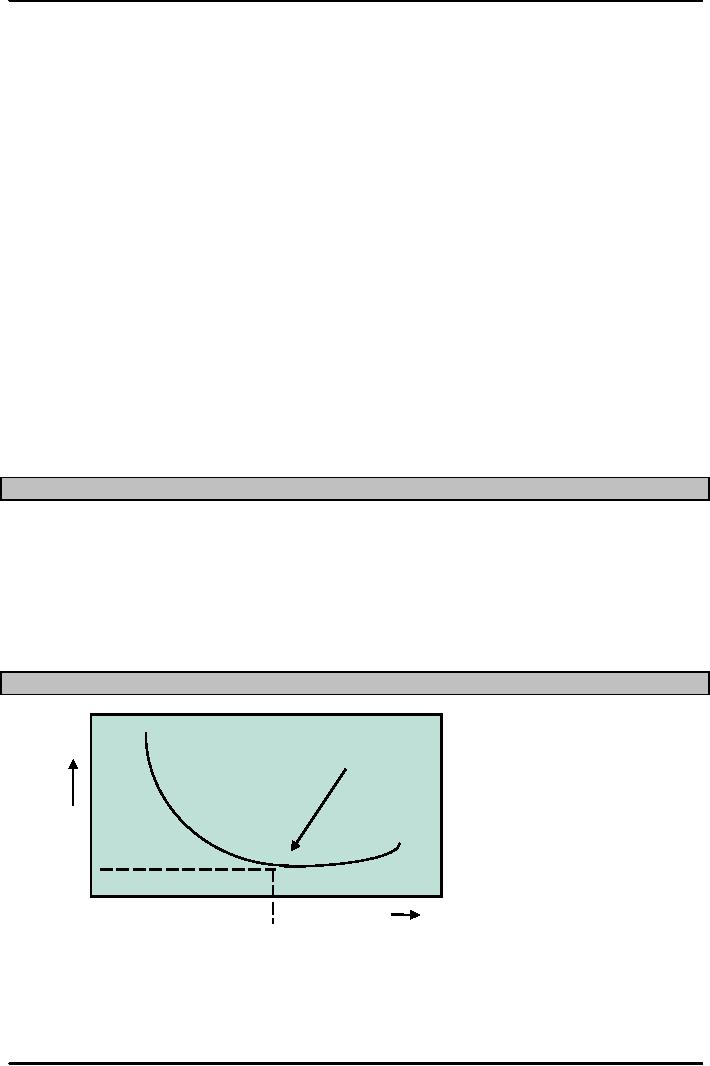

Economies

of Scale and Diseconomies of

scale

An

operations manager should know

what economies and diseconomies of

scale are

Economies

of scale reflects a concept that

states the average unit cost

of a good or service can be

reduced

by increasing its output rate while

diseconomies of scale reflects the case

when the average cost

per

unit increases as the facility's

size increases.

If

the output rate is less than the

optimal level, increasing output rate

results in decreasing average

unit

costs

then it reflects Economies of Scale. On the

other hand if the output rate is more

than the optimal

level,

increasing the output rate results in increasing

average unit costs

Evaluating

Alternatives

Minimum

Average Cost per Unit

Average

cost

per

unit

Minimum

Cost

0

Rate

of output

Explanation

of the Cost Curve

The

explanation for the shape of

the cost curve is that

low levels of output

(Production), the costs of

facilities

and equipment must be absorbed

(paid for) by few units.

Hence the cost per unit is very

high.

As

the output is increased, there are more

units to absorb the fixed

cost of utilities, facilities

and

equipment,

so unit cost is

decreased.

70

Production

and Operations Management

MGT613

VU

Minimum

Cost would be recorded at the

optimal rate, beyond that the

unit cost will

start

to increase. Other factors now

become more important which

include worker fatigue,

equipment

breakdown,

the loss of flexibility, which

leaves less margin for

error and increases

difficulty in

coordinating

activities.

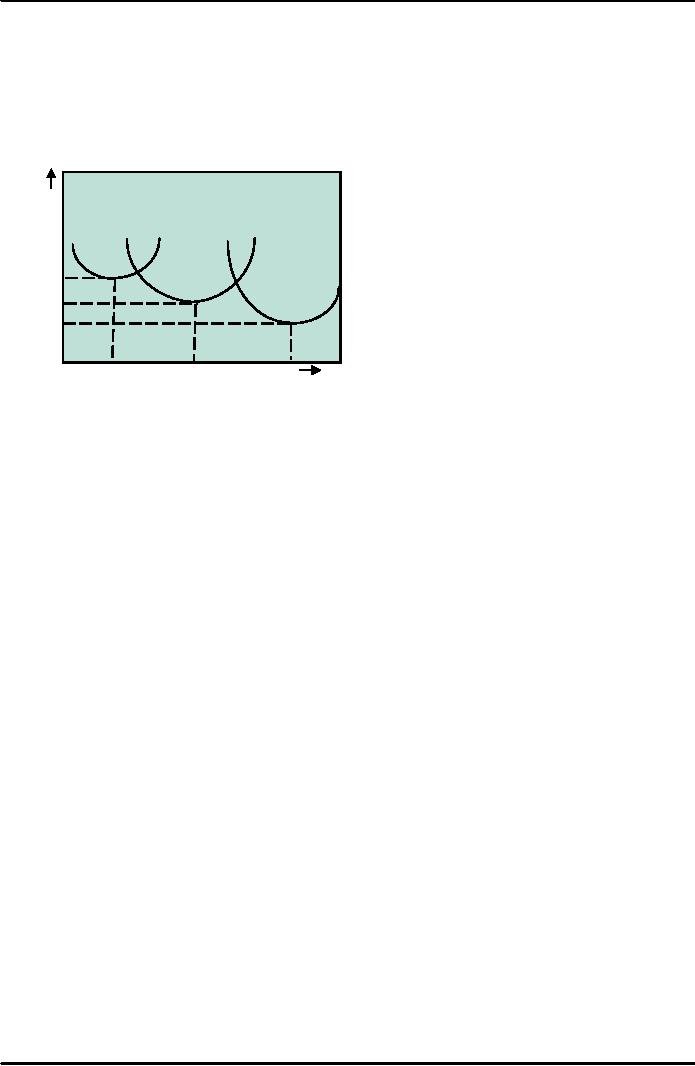

Evaluating

Alternatives

Minimum

cost & optimal operating rate are

functions of size of

production

unit.

Average

cost per unit

Small

Medium

plant

plant

Large

plant

0

Output

rate

Evaluating

Alternatives

As

the general capacity of the plant

increases, the optimal

output rate increases and

the

minimum

cost for the optimal rate

decreases.

This

is the prime reason why

larger plants tend to have higher

optimal output rates and

lower

minimum

costs than smaller plants.

The

senior management normally takes in to

account the same considerations in

addition to

availability

of financial, capital resources

and forecasted

demand.

The

important step is to determine

enough points for each

size facility to be able to

make a

comparison

among different sizes.

In

some industries or types of services,

facility sizes are given,

where as in other facility size

are

continuous

variable.

Occasionally

the management decides for a

size which does not have the

desired rate of output.

E.g.

Pharmaceutical Company, oil field,

gas fields.

An

organization needs to examine the

alternatives for future

capacity from a number of

different

perspectives.

Economic

Conditions set the external

conditions which influence the

following

1.

Will Alternative be feasible?

2.

How much will it

cost?

3.

How soon can we have

it?

4.

What will be the operating and

maintenance costs?

Possible

Negative Opinion due to the following

decisions.

1.

Decision to build a new

power plant, nuclear, coal,

geothermal

2.

Displacement of people if a new hydro

plant is to be built.

3.

Environmental issues related to

company's new

project.

71

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model