|

Production

and Operations Management

MGT613

VU

Lecture

12

In

our last discussion we focused on the

objectivity and importance of Product and Service

Design. We

also

went through the primary and

secondary reasons due to which

organizations opt for

designing a

new

product or offering of a new service. We

also talked about the strategy

for designing of new

products

and services. We investigated the

legal, ethical and environmental

regulations. We also

formulated

a design strategy and also discussed

guidelines, which the organizations

must fulfill in order

to

achieve competitive advantage through

designing of effective productive

systems.

Critical

Issues in Product and

Service Design

An

organization needs to decide about the

following critical issues in

developing its product and

service

design.

How

much standardization

Product/service

reliability

Range

of operating conditions

Product/service

life cycles

Standardization

Standardization

is the extent to which there is an

absence of variety in a product, service

or process.

Standardized

products are immediately available to

customers. You go to a market and request

for a

charger

for your cellular phone, the shopkeeper

would ask for the model,

make and deliver you as

special

product which is made by

your cell phone company or by an

independent manufacturer,

who

provides

a standardized compatible model.

Advantages

of Standardization

1.

Fewer parts to deal with in

inventory & manufacturing .The

trend is to use the same

components for

different

models of products or even in services side, the

data of a customer once

taken as input can

be

utilized for other

services.

2.

Design costs are generally

lower (the standardized product

has a proven track record, so there is

no

need

to check its safety and reliability

features from square 1, its

true, its tested and

verified on

prototype

models before being

marketed)

3.

Reduced training costs and

time. An important advantage and can

improve PRODUCTIVITY.

4.

More routine purchasing, handling,

and inspection procedures

(These indicate a decrease in

cost and

can

improve reliability as well as

over all design and manufacturing

processes)

5.

Orders fillable from

inventory, no need to carry

extra safety stock levels as

compatible

components/parts

can be used. Any product

registering lower sales can

be phased out but

its

components

may be reused in an other more

popular product even Softwares in

cellular phones,

hands

free arrangement etc)

6.

Opportunities for long

production runs and automation

.Uninterrupted stock of components

available,

so production can be controlled

and if possible a demand forecast

may be used.

7.

Need for fewer parts

justify increased expenditures on

perfecting designs and improving

quality

control

procedures. The company can

free up its inventory

carrying costs and use it on

increasing

its

long term tangible and intangible

quality standards

Disadvantages

of Standardization

1.

Designs may be frozen ( Standardized)

with too many imperfections

remaining ( An existing

shortcoming

may never be removed because of

this leading to product or component

failure,

catalytic

converter failure led to a number of

good cars in 1980s).

50

Production

and Operations Management

MGT613

VU

2.

High cost of design changes

increases resistance to improvements

(associated with its lack

of

confidence

on the design side as well as

outsourcers, who provide design

services).

3.

Reduction in Variety which

leads to decreased variety

results in less consumer appeal.

This also at

times

lead to the competitor producing a

better product or greater variety

which itself is a feature

of

lean

production.

Mass

Customization

Mass

customization is a strategy of producing standardized

goods or services, but

incorporating some

degree

of customization through delayed

differentiation and modular

design.

Delayed

Differentiation is the postponement tactic.

Producing but not quite

completing a product or

service

until customer preferences or

specifications are known, a pc

manufacturer employed this

technology

and improved its time of

delivery. This led to new

concepts of marketing and

manufacturing

to

register higher profits and

revenues.

Product/Service

Reliability

Reliability:

The ability of a product,

part, or system to perform

its intended function under

a prescribed

set

of conditions

Failure:

Situation in which a product,

part, or system does not

perform as intended

Normal

operating conditions: The

set of conditions under

which an item's reliability is

specified e.g. an

automobile

designed for operation Europe

may not fulfill its

intended service in Pakistan. SO IT

WOULD

FAIL AND BE LESS RELIABLE

Life

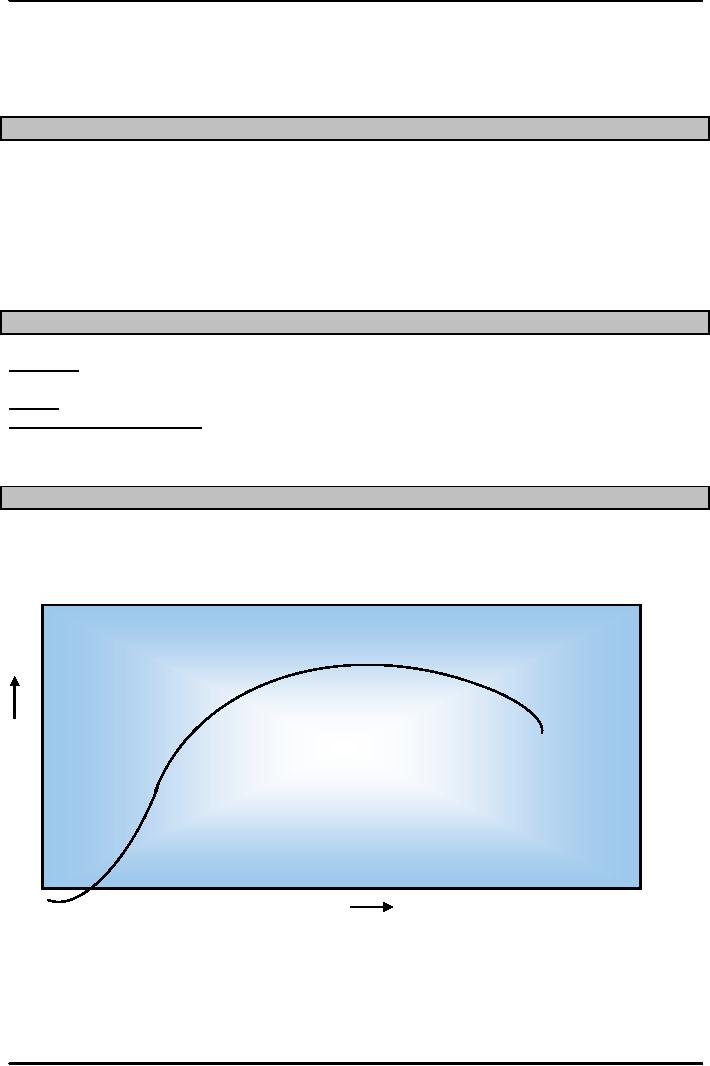

Cycles of Products or Services

We

often hear the term short and long

product lives which reflect

upon the idea how product

lives are

governed

by Technological rate of change. In other

words the need and utility of the Product

gets

severely

reduced. E.g. VCR no longer

enjoys the source of entertainment it

enjoyed in 1970s to

1990s.

Most

of the products exhibit Product Life

cycles except wooden pencils, paper

clips, nails, knives

etc.

Saturation

Demand

Maturity

Decline

Growth

Introduction

Time

Life

Cycles

of Products or Services normally

entail the following

phases.

1.

INTRODUCTION PHASE: When items

are first introduced, it is

received with

curiosity.

Demand

is low in the beginning then

when buyers begin familiar

with the product and see it as

a

reliable

and good buy, they start

buying it.

51

Production

and Operations Management

MGT613

VU

2.

GROWTH PHASE: With the

passage of time, production and design

improvements lead to

decrease

in cost and price becomes an

attractive feature with

increase in reliability.

3.

MATURITY PHASE: When the product

reaches maturity stage its

demand can only increase

if

design

is refined or changed and some

differentiation feature is added

this may increase the

demand

but when it goes

down

4.

SATURATION PHASE: In this

phase product demand declines

and the market is

saturated

with

either a compatible product or

substitutes.

5.

DECLINE: In this phase, most

of the organizations adopt a defensive

design R&D Strategy in

an

attempt to prolong the life of the

product by employing new

packaging, redesigning

it,

improving

its reliability

As

students of Operations Management, you

may be asked to suggest the Product

Life Cycle for

Telecom

Industry constituents or in other words where

would you place cell phones,

wireless

phones,

landline phones or satellite/cable

based telephones in view of the life

cycle you just

studied.

You

can make an attempt to answer this

for Pakistan as well as other

developed countries. Can

you

appreciate

the similarities and points of

differences?

52

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model