|

Production

and Operations Management

MGT613

VU

Lesson

10

The

formula for the moving

average is:

Ft = w

1A t -1

+ w 2 A

t - 2 + w 3 A

t -3 + ... + w n

A t -n

n

∑w

=1

wt =

weight given to time period

"t" occurrence (weights must

add to one)

i

i=1

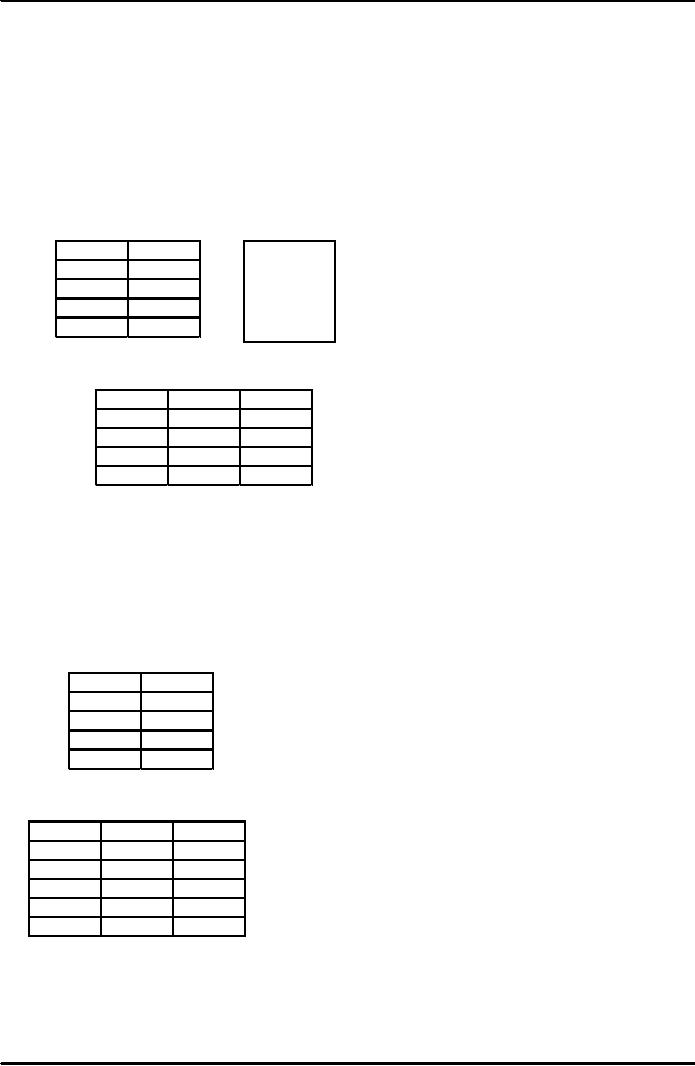

Weighted

Moving Average Problem (1)

Data

Question:

Given the weekly demand and

weights, what is the

forecast for the 4th

period or

Week

4?

Week

Demand

Weights:

1

650

t-1

.5

2

678

t-2

.3

3

720

t-3

.2

4

Weighted

Moving Average Problem (1)

Solution

Week

Demand

Forecast

1

650

2

678

3

720

4

693.4

F4

= 0.5(720)+0.3(678)+0.2(650)=693.4

Note:

More weight age would be given to recent

most values.

Weighted

Moving Average Problem (2)

Data

Question:

Given the weekly demand

information and weights, what is

the weighted moving

average

forecast of the 5th period

or week?

Week

Demand

Weights:

1

820

t-1

0.7

2

775

t-2

0.2

3

680

t-3

0.1

4

655

Weighted

Moving Average Problem (2)

Solution

Week

Demand

Forecast

1

820

2

775

3

680

4

655

5

672

40

Production

and Operations Management

MGT613

VU

F5

= (0.1)(755)+(0.2)(680)+(0.7)(655)= 672

Note:

More weight age would be given to recent

most values.

Exponential

Smoothing Model

Ft =

Ft-1 + a(At-1 -

Ft-1)

Where:

Ft =

Forcast vaue

for thecomingt

timeperiod

l

Ft - 1 =

Forecast

v luein 1 past

timeperiod

a

At - 1 =

Actualoccurancein

thepast t tim

period

e

α

= Alphasmoothingconstant

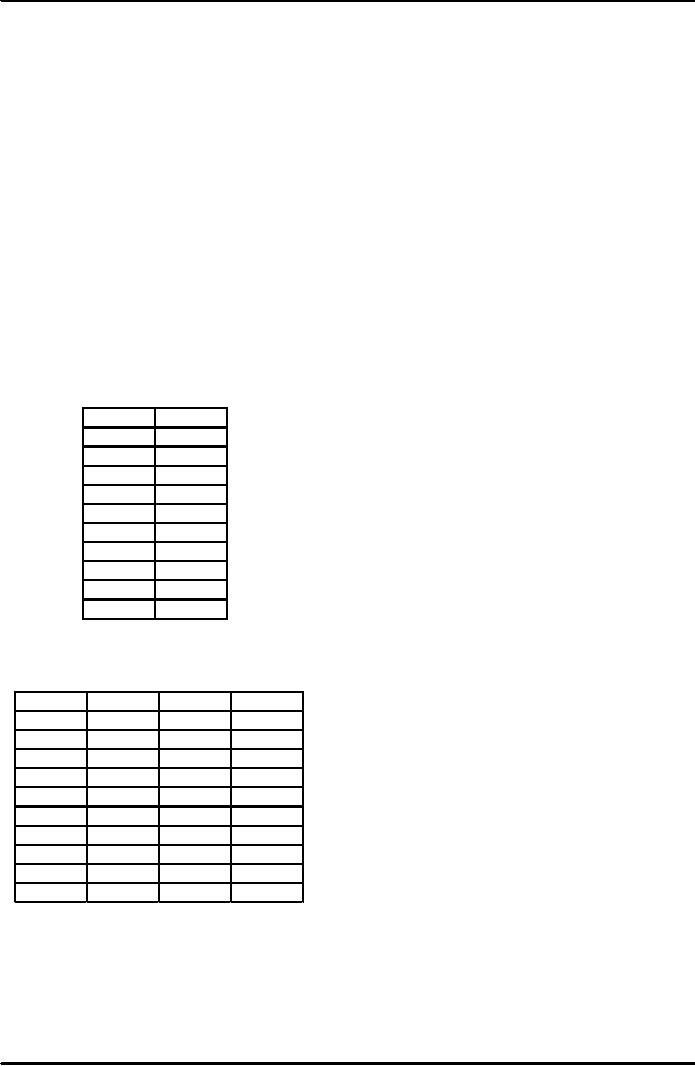

Exponential

Smoothing Problem (1)

Data

Question:

Given the weekly demand data, what

are the exponential smoothing

forecasts

for

periods 2-10 using a=0.10

and a=0.60?

Assume

F1=D1

Week

Demand

1

820

2

775

3

680

4

655

5

750

6

802

7

798

8

689

9

775

10

Exponential

Smoothing Solution

(1)

Week

Demand

0.1

0.6

1

820

820.00

820.00

2

775

820.00

820.00

3

680

815.50

820.00

4

655

801.95

817.30

5

750

787.26

808.09

6

802

783.53

795.59

7

798

785.38

788.35

8

689

786.64

786.57

9

775

776.88

786.61

10

776.69

780.77

41

Production

and Operations Management

MGT613

VU

Exponential

Smoothing Problem (2)

Data

Question:

What are the exponential smoothing

forecasts for periods 2-5

using Alpha

=0.5?

Assume F1=D1

Week

Demand

1

820

2

775

3

680

4

655

5

Exponential

Smoothing Problem (2)

Solution

Week

Demand

1

820

2

775

3

680

4

655

5

F1=820+(0.5)(820-820)=820

F3=820+(0.5)(775-820)=797.75

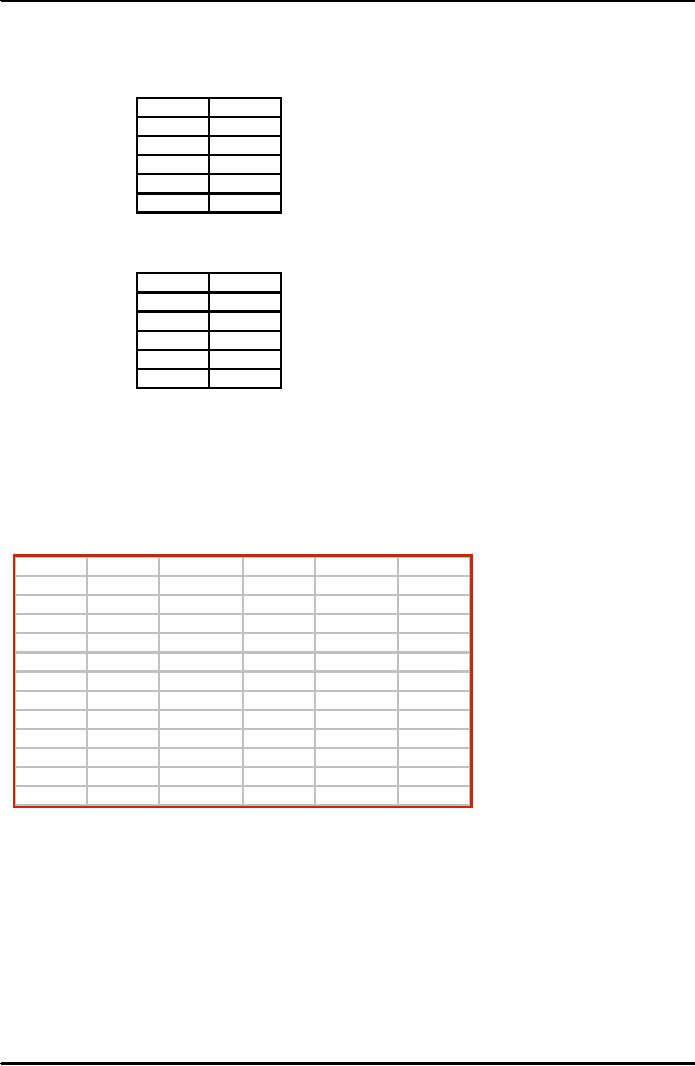

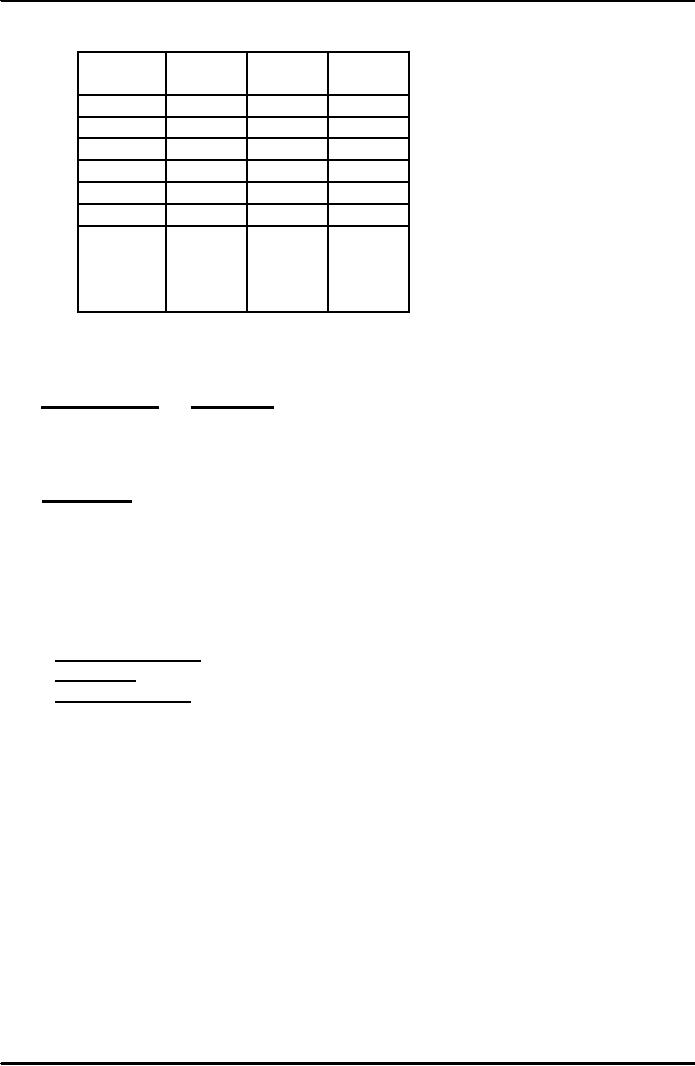

Example

3 - Exponential Smoothing

Period

Actual

Alpha

= 0.1 Error

Alpha

= 0.4 Error

1

42

2

40

42

-2.00

42

-2

3

43

41.8

1.20

41.2

1.8

4

40

41.92

-1.92

41.92

-1.92

5

41

41.73

-0.73

41.15

-0.15

6

39

41.66

-2.66

41.09

-2.09

7

46

41.39

4.61

40.25

5.75

8

44

41.85

2.15

42.55

1.45

9

45

42.07

2.93

43.13

1.87

10

38

42.36

-4.36

43.88

-5.88

11

40

41.92

-1.92

41.53

-1.53

12

41.73

40.92

42

Production

and Operations Management

MGT613

VU

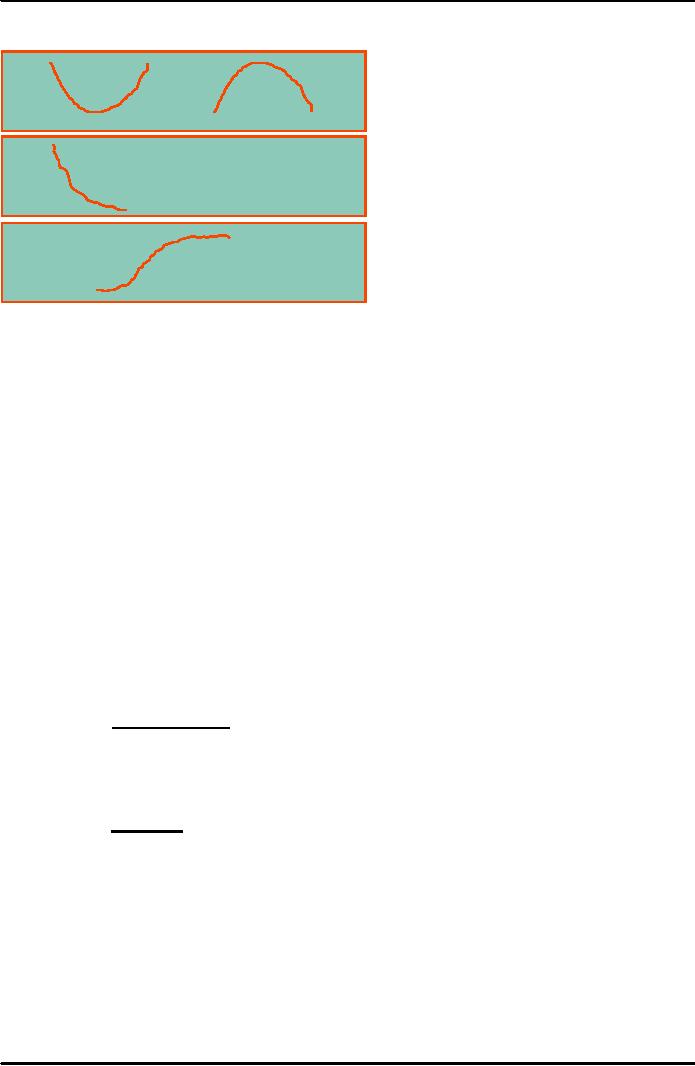

Common

Nonlinear Trends

Parabolic

Exponential

Growth

·

Parabolic Trends

·

Concaved

Upwards and Concaved

Downwards

The

left and right arms are

widening as the value

increases or the parabola is

·

opening

upwards.

It

represents the quadratic

function

·

Linear

Trend Equation

Ft = a +

bt

Where:

·

Ft =

Forecast for period t

·

t =

Specified number of time

periods

·

a =

Value of Ft at t = 0

·

b = Slope of

the line

n

∑

(ty)

-

∑

t∑

y

b=

n∑ t 2

- ∑

t 2

y

-

∑t

a= ∑

n

43

Production

and Operations Management

MGT613

VU

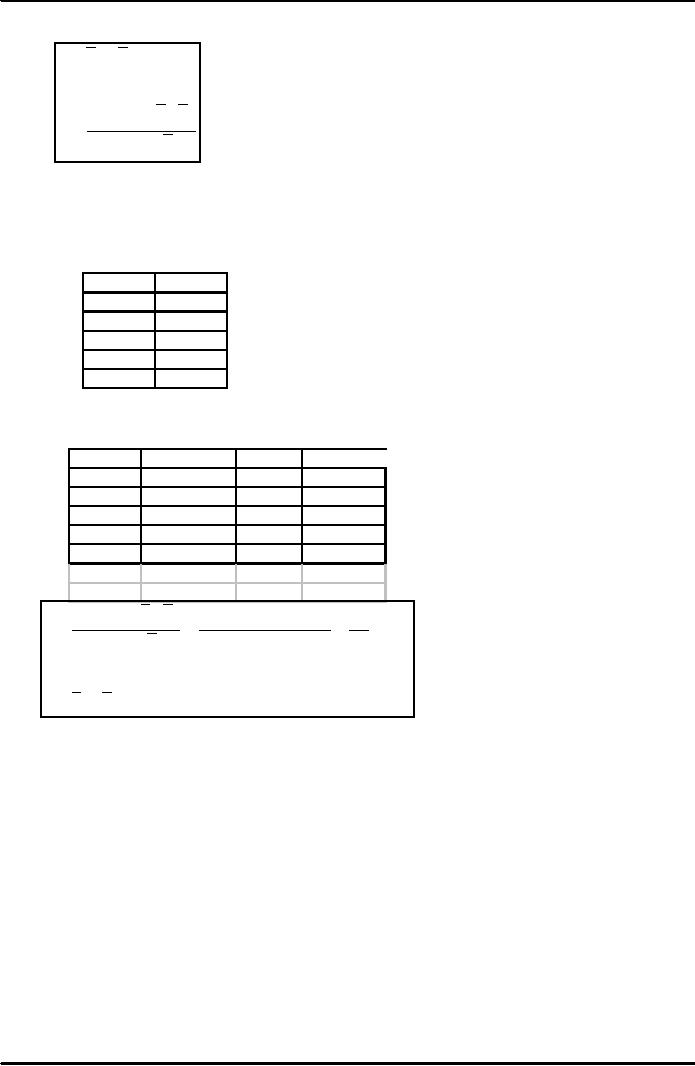

Linear

Trend Equation Example

y

2

Week

t

Sales

ty

1

1

150

150

2

4

157

314

3

9

162

486

4

16

166

664

5

25

177

885

Σ

t2

= 55 Σ y = 812 Σ ty

Σ

t =

15

=

2499

(Σ t)2

=

225

Linear

Trend Calculation

5

(2499) - 15(812)

12495

-12180

b=

=

=

6.3

5(55)

- 225

275

-225

812

- 6.3(15)

a=

=

143.

5

y

= 143.5 + 6.3t

Associative

Forecasting

1.

Predictor

variables -

used to predict values of

variable interest

2.

Regression

-

technique for fitting a line

to a set of points

3.

Least

squares line -

minimizes sum of squared

deviations around the

line

Forecast

Accuracy

·

Error

- difference between actual

value and predicted

value

·

Mean

Absolute Deviation

(MAD)

·

Average

absolute error

·

Mean

Squared Error (MSE)

·

Average

of squared error

·

Mean

Absolute Percent Error

(MAPE)

·

Average

absolute percent

error

44

Production

and Operations Management

MGT613

VU

Simple

Linear Regression Formulas

for Calculating "a" and

"b"

a

= y - bx

∑

xy

- n( y)(x)

b=

∑

x

- n(x)

2

2

Simple

Linear Regression Problem

Data

Question:

Given the data below,

what is the simple linear

regression model that can be used

to

predict

sales in future

weeks?

Week

Sales

1

150

2

157

3

162

4

166

5

177

Answer:

First,

using the linear regression

formulas, we can compute "a" and

"b"

Week

Week*Week

Sales

Week*Sales

1

1

150

150

2

4

157

314

3

9

162

486

4

16

166

664

5

25

177

885

3

55

162.4

2499

Average

Sum

Average

Sum

∑

xy

- n( y)(x) = 2499 - 5(162.4)(3) =

63 =

6.3

b=

∑

x

- n(x)

55

-

5(9)

2

2

10

a

= y - bx = 162.4 - (6.3)(3) = 143.5

The

resulting regression model

is:

Yt =

143.5 + 6.3x

45

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMER’S AND PRODUCER’S RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model