|

Principles

of Marketing MGT301

VU

Lesson

29

Lesson

overview and learning objectives:

In today's global

marketplace, selling a product is

sometimes easier than getting it to

customers.

Therefore,

physical distribution and logistics

management are receiving increased

attention from

strategic

planners. The task of physical

distribution systems is to minimize

the total cost of

providing

a desired level of customer

services while bringing those

services to the customer

with

the

maximum amount of speed.

Major logistics functions of

order processing, warehousing,

inventory

management, and transportation

are discussed and explored

in today's Lesson.

LOGISTIC

MANAGEMENT

A.

Push Versus Pull

Strategy:

A

promotion strategy that

calls for using the sales

force and trade promotion to

push the product

through

the channel is called push

strategy. The producer promotes

the product to wholesalers,

the

wholesalers

promote to retailers and the

retailers promote to consumers. While

the pull strategy is

the

promotional strategy

that

calls

for spending a lot on

advertising

and

consumer

Marketing

Demand

activities

promotion

to

build

up

Interme-

Producer

End

users

diaries

consumer

demand; if successful,

Demand

consumer

will ask their

retailers

Push

Strategy

for

the product, the retailer

will

ask

the wholesalers

and

Marketing

activities

wholesalers

will ask

the

producers.

So these are two

Demand

Demand

Interme-

Producer

End

users

strategies

through

which

diaries

availability

of products can be

Pull

St rategy

created

in the market for

final

consumers.

B.

Physical

Distribution and Logistics

Management

Companies

must decide on the best

way to store, handle, and

move their products and

services so

that

they are available to customers in

the right assortments, at

the right time, and in

the right

place.

Logistics effectiveness has a

major impact on both customer satisfaction

and company costs.

Here

we consider the nature

and importance of marketing logistics,

goals of the logistics system, major

logistics

functions,

and

the need for integrated

logistics management.

a.

Nature and Importance of

Physical Distribution and

Marketing Logistics

To

some managers, physical distribution

means only trucks and

warehouses. But modern

logistics

is

much more than this.

Physical distribution--or marketing

logistics--involves planning,

implementing,

and controlling the physical

flow of materials, final

goods, and related

information

from

points of origin to points of

consumption to meet customer requirements at a

profit. In

short,

it involves getting the right

product to the right customer in

the right place at the

right time.

Traditional

physical distribution typically started

with products at the plant

and then tried to

find

low-cost

solutions to get them to

customers. However, today's

marketers prefer market

logistics

thinking,

which starts with the

marketplace and works

backward to the factory.

Logistics addresses

not

only the problem of outbound

distribution (moving products

from the factory to

customers)

but

also the problem of inbound

distribution (moving products

and materials from suppliers

to the

factory).

141

Principles

of Marketing MGT301

VU

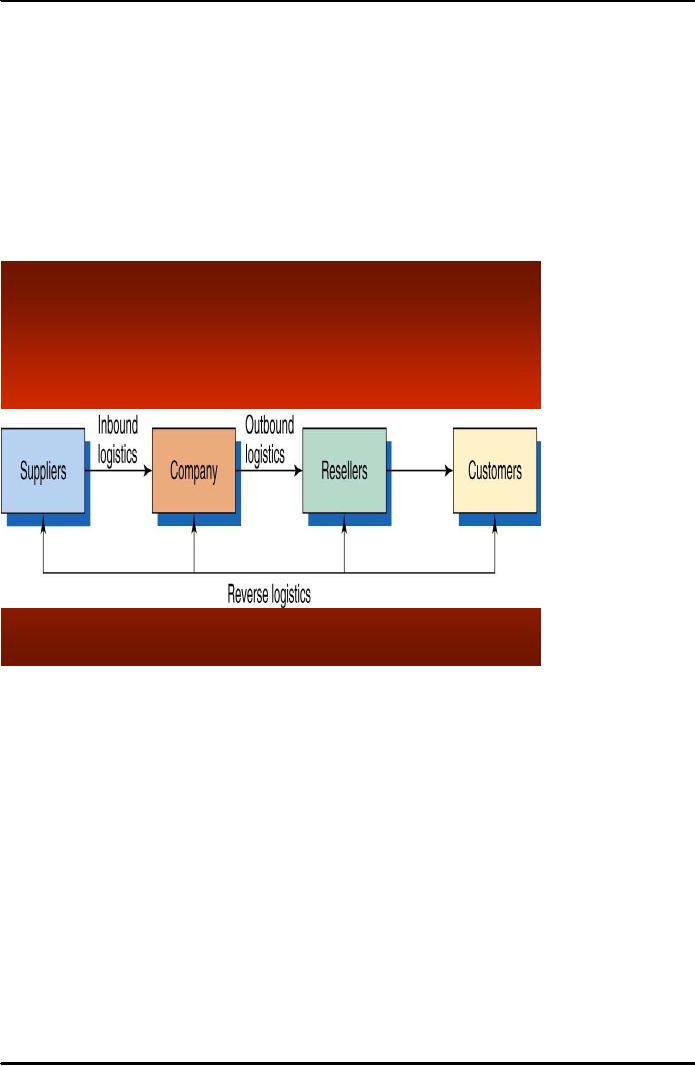

It

involves the management of

entire supply

chains, value-added

flows from suppliers to

final users,

as

shown in Figure . Thus, the

logistics manager's task is to coordinate

activities of suppliers,

purchasing

agents, marketers, channel

members, and customers. These activities

include

forecasting,

information systems, purchasing,

production planning, order

processing, inventory,

warehousing,

and transportation

planning.

Companies

today are placing greater emphasis on

logistics for several

reasons. First,

customer

service

and satisfaction have become

the cornerstones of marketing strategy, and

distribution is an

important

customer service element. More

and more, companies are

finding that they can

attract

and

keep customers by giving better

service or lower prices

through better physical

distribution.

Second,

logistics is a major cost element

for most companies.

According to one study, in a

recent

year

American companies "spent $670

billion--a gaping 10.5 percent of

gross domestic

product--

to

wrap, bundle, load, unload,

sort, reload, and transport

goods." About 15 percent of an

average

product's

price is

accounted

for by

shipping

and

transport

alone.

Su

ppl y Chai n M anageme nt

Poor

physical

distribution

decisions

result in

high

costs.

Improvements

in

physical

distribution

efficiency

can yield

tremendous

cost

savings

for both

the

company and

its

customers.

Third,

the

explosion

in

product

variety has

created

a need for

improved

logistics

management.

Finally, improvements in information

technology have created

opportunities for

major

gains in distribution efficiency.

The increased use of computers,

point-of-sale scanners,

uniform

product codes, satellite

tracking, electronic data interchange

(EDI), and electronic

funds

transfer

(EFT) has allowed companies to

create advanced systems for

order processing,

inventory

control

and handling, and

transportation routing and

scheduling.

b.

Goals of the Logistics System

Some

companies state their

logistics objective as providing maximum

customer service at the

least

cost.

Unfortunately, no logistics system

can both

maximize customer

service and

minimize

distribution

costs. Maximum customer

service implies rapid delivery, large

inventories, flexible

assortments,

liberal returns policies, and

other services--all of which

raise distribution costs.

In

contrast,

minimum distribution costs

imply slower delivery, smaller

inventories, and larger

shipping

lots--which

represent a lower level of

overall customer

service.

The

goal of the marketing

logistics system should be to

provide a targeted level of

customer

service

at the least cost. A company

must first research the

importance of various distribution

services

to its customers and then set

desired service levels for

each segment. The

company

normally

will want to offer at least

the same level of service as

its competitors do. But the

objective

is

to maximize profits,

not

sales. Therefore, the

company must weigh the benefits of

providing

higher

levels of service against

the costs. Some companies

offer less service than

their competitors

142

Principles

of Marketing MGT301

VU

and

charge a lower price. Other

companies offer more service

and charge higher prices to

cover

higher

costs.

c.

Major Logistics Functions

Given

a set of logistics objectives, the

company is ready to design a

logistics system that

will

minimize

the cost of attaining these objectives.

The major logistics

functions include order

processing,

warehousing,

inventory management, and

transportation.

i.

Order

Processing

Orders

can be submitted in many

ways--by mail or telephone, through

salespeople, or via

computer

and EDI. In some cases,

the suppliers might actually

generate orders for their

customers:

Once

received, orders must be

processed quickly and accurately.

Both the company and

its

customers

benefit when order

processing is carried out

efficiently. Most companies

now use

computerized

order-processing systems that

speed up the

ordershippingbilling cycle.

For

example,

General Electric operates a

computer-based system that, on

receipt of a customer's order,

checks

the customer's credit standing as well as

whether and where the items

are in stock. The

computer

then issues an order to ship,

bills the customer, updates

the inventory records, sends

a

production

order for new stock, and

relays the message back to

the salesperson that the

customer's

order

is on its way--all in less than 15

seconds.

ii.

Warehousing

Every

company must store its goods

while they wait to be sold. A

storage function is

needed

because

production and consumption

cycles rarely match. A company

must decide on how

many

and

what

types of

warehouses it needs and

where

they

will be located. The company

might use either

storage

warehouses or

distribution

centers. Storage

warehouses store goods for

moderate to long

periods.

Distribution

centers are designed to move

goods rather than just

store them. They are

large and

highly

automated warehouses designed to receive

goods from various plants

and suppliers, take

orders,

fill them efficiently, and

deliver goods to customers as quickly as

possible.

Warehousing

facilities and equipment technology

have improved greatly in recent years.

Older,

multistoried

warehouses with outdated materials-handling methods

are facing competition

from

newer,

single-storied automated

warehouses with

advanced materials-handling systems under

the

control

of a central computer. In these

warehouses, only a few

employees are

necessary.

Computers

read orders and direct lift

trucks, electric hoists, or robots to

gather goods, move

them

to

loading docks, and issue invoices.

These warehouses have

reduced worker injuries,

labor costs,

theft,

and breakage and have

improved inventory

control.

iii.

Inventory

Inventory

levels also affect customer

satisfaction. The major problem is to

maintain the delicate

balance

between carrying too much

inventory and carrying too

little. Carrying too much

inventory

results

in higher-than-necessary inventory-carrying costs

and stock obsolescence. Carrying

too little

may

result in stock outs, costly

emergency shipments or production, and

customer dissatisfaction.

In

making inventory decisions, management

must balance the costs of

carrying larger inventories

against

resulting sales and

profits.

During

the past decade, many

companies have greatly reduced

their inventories and

related costs

through

just-in-time

logistics

systems. Through such systems, producers

and retailers carry

only

small

inventories of parts or merchandise,

often only enough for a

few days of operations.

New

stock

arrives exactly when needed,

rather than being stored in

inventory until being used.

Just-in-

time

systems require accurate forecasting along

with fast, frequent, and

flexible delivery so

that

new

supplies will be available

when needed. However, these

systems result in substantial savings

in

inventory-carrying

and handling costs.

iv.

Transportation

Marketers

need to take an interest in their

company's transportation

decisions.

The choice of

transportation

carriers affects the pricing of

products, delivery performance, and

condition of the

goods

when they arrive--all of

which will affect customer satisfaction.

In shipping goods to its

143

Principles

of Marketing MGT301

VU

warehouses,

dealers, and customers, the

company can choose among

five transportation

modes:

rail,

truck, water, pipeline, and

air.

Railroads

are

the nation's largest carrier,

accounting for 26 percent of total

cargo ton-miles

moved.

They

are one of the most

cost-effective modes for shipping

large amounts of bulk

products--coal,

sand,

minerals, farm and forest

products--over long distances. In recent

years, railroads have

increased

their customer services by designing

new equipment to handle special

categories of

goods,

providing flatcars for carrying

truck trailers by rail (piggyback),

and providing

in-transit

services

such as the diversion of shipped

goods to other destinations en route

and the processing

of

goods en route. Thus, after

decades of losing out to truckers,

railroads appear ready for

a

comeback.

Trucks

have

increased their share of

transportation steadily and

now account for 24 percent of

total

cargo

ton-miles (over 52 percent of actual

tonnage). They account for

the largest portion

of

transportation

within

cities

as opposed to between

cities.

Trucks are highly flexible

in their routing

and

time schedules, and they

can usually offer faster

service than railroads. They

are efficient for

short

hauls of high-value merchandise. Trucking

firms have added many

services in recent years.

Pipelines

are a

specialized means of shipping petroleum,

natural gas, and chemicals

from sources to

markets.

Most pipelines are used by

their owners to ship their own

products.

Although

air

carriers

transport less than 1 percent of

the nation's goods, they

are becoming more

important

as a transportation mode. Air

freight rates are much

higher than rail or truck

rates, but

air

freight is ideal when speed

is needed or distant markets

have to be reached. Among

the most

frequently

air-freighted products are

perishables (fresh fish, cut

flowers) and high-value,

low-bulk

items

(technical instruments, jewelry).

Companies find that air

freight also reduces

inventory levels,

packaging

costs, and the number of

warehouses needed.

Shippers

increasingly are using intermodal

transportation--combining two or more

modes of

transportation.

Piggyback

describes

the use of rail and

trucks; fishyback,

water

and trucks; trainship,

water

and rail; and airtruck,

air

and trucks. Combining modes

provides advantages that no

single

mode

can deliver. Each combination

offers advantages to the shipper.

For example, not only

is

piggyback

cheaper than trucking alone

but it also provides flexibility

and convenience.

In

choosing a transportation mode for a

product, shippers must

balance many considerations:

speed,

dependability, availability, cost, and

others. Thus, if a shipper needs speed,

air and truck

are

the

prime choices. If the goal

is low cost, then water or pipeline

might be best. Shipping costs

are

often

a significant portion of the marketing

costs of a product. It is often

difficult for businesses

to

pass

on these higher costs to customers

when there are active

competitors. One option is to

reduce

dependence

on the unreliable transportation.

However, that may not be

possible for some

businesses.

As the case you just

read suggests, a company's physical

distribution and

transportation

flexibility

is an important part of its marketing

decisions, a factor that

could make or break

its

ability

to serve its customers.

d.

Integrated Logistics

Management

Today,

more and more companies

are adopting the concept of integrated

logistics management.

This

concept recognizes that providing

better customer service and

trimming distribution

costs

requires

teamwork,

both

inside the company and

among all the marketing

channel organizations.

Inside,

the company's various functional departments

must work closely together to

maximize the

company's

own logistics performance. Outside,

the company must integrate

its logistics system

with

those of its suppliers and customers to maximize

the performance of the entire

distribution

system.

Cross-Functional

Teamwork Inside the Company

In

most companies, responsibility

for various logistics activities is

assigned to many

different

functional

units--marketing, sales, finance,

manufacturing, purchasing. Too often,

each function

tries

to optimize its own logistics performance

without regard for the

activities of the other

functions.

However, transportation, inventory,

warehousing, and order-processing

activities

interact,

often in an inverse way. For

example, lower inventory

levels reduce

inventory-carrying

144

Principles

of Marketing MGT301

VU

costs.

But they may also

reduce customer service and

increase costs from stock

outs, back orders,

special

production runs, and costly

fast-freight shipments. Because

distribution activities involve

strong

trade-offs, decisions by different

functions must be coordinated to achieve

superior overall

logistics

performance.

The

goal of integrated logistics management

is to harmonize all of the company's

distribution

decisions.

Close working relationships among

functions can be achieved in

several ways. Some

companies

have created permanent

logistics committees made up of managers

responsible for

different

physical distribution activities. Companies

can also create management

positions that link

the

logistics activities of functional areas.

Many companies have a vice

president of logistics with

cross-functional

authority. The important

thing is that the company

coordinate its logistics and

marketing

activities to create high market satisfaction at a

reasonable cost.

e.

Building Channel Partnerships

The

members of a distribution channel

are linked closely in delivering customer

satisfaction and

value.

One company's distribution system is

another company's supply system.

The success of each

channel

member depends on the performance of

the entire supply chain.

Companies must do

more

than improve their own

logistics. They must also

work with other channel

members to

improve

whole-channel distribution. Today, smart

companies are coordinating

their logistics

strategies

and building strong partnerships

with suppliers and customers to

improve customer

service

and reduce channel

costs.

These

channel partnerships can take

many forms. Many companies

have created cross-functional,

cross-company

teams.

Other

companies partner through

shared

projects. For

example, many larger

retailers are working

closely

with suppliers on in-store

programs. Channel partnerships may

also take the form

of

information

sharing and

continuous

inventory replenishment systems.

Companies manage their

supply

chains

through information. Suppliers

link up with customers to share

information and coordinate

their

logistics decisions. Here

are just two

examples:

Today,

as a result of such partnerships, many

companies have switched from

anticipatory-based

distribution

systems to

response-based

distribution systems. In

anticipatory distribution, the

company

produces

the amount of goods called

for by a sales forecast. It

builds and holds stock at

various

supply

points, such as the plant,

distribution centers, and retail

outlets. A response-based

distribution

system, in contrast, is customer

triggered. The

producer continuously builds

and replaces

stock

as orders arrive. It produces what is

currently selling.

f.

Third-Party Logistics

Companies

may use third-party

logistics providers for

several reasons. First,

because getting the

product

to market is their main focus,

these providers can often do

it more efficiently and at

lower

cost

than clients whose strengths lie

elsewhere. According to one study,

outsourcing warehousing

alone

typically results in 10 percent to 15 percent cost

savings. Another expert

estimates that

companies

can save 15 percent to 25 percent in

their total logistics costs

by outsourcing. Second,

outsourcing

logistics frees a company to

focus more intensely on its

core business.

Finally,

integrated

logistics companies understand increasingly

complex logistics environments.

This can be

especially

helpful to companies attempting to

expand their global market

coverage.

KEY

TERMS (Lesson # 28-29)

distribution

channel

A

set of interdependent organizations

involved in the process of making a

product or service

available

for use or consumption by

the consumer or business user.

Channel

level

A

layer of intermediaries that

performs some work in

bringing the product and its

ownership

closer

to the final buyer.

145

Principles

of Marketing MGT301

VU

Direct

marketing channel

A

marketing channel that has no

intermediary levels.

Indirect

marketing channel

Channel

containing one or more intermediary

levels.

Channel

conflict

Disagreement

among marketing channel members on

goals and roles--who should

do what and

for

what rewards.

Conventional

distribution channel

A

channel consisting of one or more independent

producers, wholesalers, and retailers,

each a

separate

business seeking to maximize its

own profits even at the

expense of profits for the

system

as

a whole.

Vertical

Marketing System

(VMS)

A

distribution channel structure in

which producers, wholesales, and

retailers act as a

unified

system.

One channel member owns the

others, has contracts with them, or

has so much power

that

they all cooperate

Corporate

VMS

A

vertical marketing system that

combines successive stages of

production and distribution

under

single

ownership--channel leadership is

established through common

ownership.

Contractual

VMS

A

vertical marketing system in which

independent firms at different levels of

production and

distribution

join together through contracts to

obtain more economies or

sales impact than

they

could

achieve alone.

Franchise

organization

A

contractual vertical marketing system in

which a channel member,

called a franchiser,

links

several

stages in the production-distribution

process.

Administered

VMS

A

vertical marketing system that

coordinates successive stages of

production and distribution,

not

through

common ownership or contractual

ties but through the

size and power of one of

the

parties.

Horizontal

marketing system

A

channel arrangement in which two or

more companies at one level

join together to follow a

new

marketing

opportunity.

Hybrid

marketing channel

Multi

channel distribution system in

which a single firm sets up

two or more marketing channels to

reach

one or more customer

segments.

Intensive

distribution

Stocking

the product in as many

outlets as possible.

146

Principles

of Marketing MGT301

VU

Exclusive

distribution

Giving

a limited number of dealers

the exclusive right to distribute

the company's products in

their

territories.

Selective

distribution

The

use of more than one, but

fewer than all, of the

intermediaries who are

willing to carry the

company's

products.

Physical

distribution (or marketing

logistics)

The

tasks involved in planning,

implementing, and controlling

the physical flow of materials,

final

goods,

and related information from

points of origin to points of

consumption to meet customer

requirements

at a profit.

Distribution

center

A

large, highly automated warehouse

designed to receive goods

from various plants and

suppliers,

take

orders, fill them

efficiently, and deliver

goods to customers as quickly as

possible.

Integrated

logistics management

The

logistics concept that emphasizes

teamwork, both inside the

company and among all

the

marketing

channel organizations, to maximize the

performance of the entire

distribution system.

Third-party

logistics provider

An

independent logistics provider that

performs any or all of the

functions required to get

their

clients'

product to market.

147

Table of Contents:

- PRINCIPLES OF MARKETING:Introduction of Marketing, How is Marketing Done?

- ROAD MAP:UNDERSTANDING MARKETING AND MARKETING PROCESS

- MARKETING FUNCTIONS:CUSTOMER RELATIONSHIP MANAGEMENT

- MARKETING IN HISTORICAL PERSPECTIVE AND EVOLUTION OF MARKETING:End of the Mass Market

- MARKETING CHALLENGES IN THE 21st CENTURY:Connections with Customers

- STRATEGIC PLANNING AND MARKETING PROCESS:Setting Company Objectives and Goals

- PORTFOLIO ANALYSIS:MARKETING PROCESS,Marketing Strategy Planning Process

- MARKETING PROCESS:Analyzing marketing opportunities, Contents of Marketing Plan

- MARKETING ENVIRONMENT:The Company’s Microenvironment, Customers

- MARKETING MACRO ENVIRONMENT:Demographic Environment, Cultural Environment

- ANALYZING MARKETING OPPORTUNITIES AND DEVELOPING STRATEGIES:MIS, Marketing Research

- THE MARKETING RESEARCH PROCESS:Developing the Research Plan, Research Approaches

- THE MARKETING RESEARCH PROCESS (Continued):CONSUMER MARKET

- CONSUMER BUYING BEHAVIOR:Model of consumer behavior, Cultural Factors

- CONSUMER BUYING BEHAVIOR (CONTINUED):Personal Factors, Psychological Factors

- BUSINESS MARKETS AND BUYING BEHAVIOR:Market structure and demand

- MARKET SEGMENTATION:Steps in Target Marketing, Mass Marketing

- MARKET SEGMENTATION (CONTINUED):Market Targeting, How Many Differences to Promote

- Product:Marketing Mix, Levels of Product and Services, Consumer Products

- PRODUCT:Individual product decisions, Product Attributes, Branding

- PRODUCT:NEW PRODUCT DEVELOPMENT PROCESS, Idea generation, Test Marketing

- NEW PRODUCT DEVELOPMENT:PRODUCT LIFE- CYCLE STAGES AND STRATEGIES

- KEY TERMS:New-product development, Idea generation, Product development

- Price the 2nd P of Marketing Mix:Marketing Objectives, Costs, The Market and Demand

- PRICE THE 2ND P OF MARKETING MIX:General Pricing Approaches, Fixed Cost

- PRICE THE 2ND P OF MARKETING MIX:Discount and Allowance Pricing, Segmented Pricing

- PRICE THE 2ND P OF MARKETING MIX:Price Changes, Initiating Price Increases

- PLACE- THE 3RD P OF MARKETING MIX:Marketing Channel, Channel Behavior

- LOGISTIC MANAGEMENT:Push Versus Pull Strategy, Goals of the Logistics System

- RETAILING AND WHOLESALING:Customer Service, Product Line, Discount Stores

- KEY TERMS:Distribution channel, Franchise organization, Distribution center

- PROMOTION THE 4TH P OF MARKETING MIX:Integrated Marketing Communications

- ADVERTISING:The Five M’s of Advertising, Advertising decisions

- ADVERTISING:SALES PROMOTION, Evaluating Advertising, Sales Promotion

- PERSONAL SELLING:The Role of the Sales Force, Builds Relationships

- SALES FORCE MANAGEMENT:Managing the Sales Force, Compensating Salespeople

- SALES FORCE MANAGEMENT:DIRECT MARKETING, Forms of Direct Marketing

- DIRECT MARKETING:PUBLIC RELATIONS, Major Public Relations Decisions

- KEY TERMS:Public relations, Advertising, Catalog Marketing

- CREATING COMPETITIVE ADVANTAGE:Competitor Analysis, Competitive Strategies

- GLOBAL MARKETING:International Trade System, Economic Environment

- E-MARKETING:Internet Marketing, Electronic Commerce, Basic-Forms

- MARKETING AND SOCIETY:Social Criticisms of Marketing, Marketing Ethics

- MARKETING:BCG MATRIX, CONSUMER BEHAVIOR, PRODUCT AND SERVICES

- A NEW PRODUCT DEVELOPMENT:PRICING STRATEGIES, GLOBAL MARKET PLACE