|

7

Solar

Power

This

chapter provides an introduction to

the components of a standalone

photovoltaic

system. The

word standalone refers to

the fact that the

system

works

without any connection to an

established power grid. In

this chapter,

we

will present the basic

concepts of the generation

and storage of

photovol-

taic

solar energy. We will also

provide a method for

designing a functional

solar

system with limited access

to information and

resources.

This

chapter only discusses the

use of solar energy for

the direct production

of

electricity (photovoltaic

solar energy). Solar

energy can also be used

to

heat

fluids

(thermal

solar energy) which

can then be used as a heat

source

or

to turn a turbine to generate

electricity. Thermal solar

energy systems are

beyond

the scope of this

chapter.

Solar

energy

A

photovoltaic system is based on

the ability of certain

materials to convert

the

radiant energy of the sun

into electrical energy. The

total amount of solar

energy

that lights a given area is

known as irradiance

(G) and it is

measured

in

watts

per square meter (W/m2). The instantaneous values

are normally

averaged

over a period of time, so it is

common to talk about total

irradiance

per

hour, day or month.

Of

course, the precise amount

of radiation that arrives at

the surface of the

Earth

cannot be predicted with

high precision, due to

natural weather

varia-

tions.

Therefore it is necessary to work

with statistical data based

on the "so-

lar

history" of a particular place.

This data is gathered by a

weather station

over

a long period and is

available from a number of

sources, as tables or

211

212

Chapter

7: Solar Power

databases.

In most cases, it can be

difficult to

find detailed

information about

a

specific area,

and you will need to

work with approximate

values.

A

few organizations have

produced maps that include

average values of

daily

global

irradiation for different

regions. These values are

known as peak

sun

hours

or

PSHs. You

can use the PSH

value for your region to

simplify your

calculations.

One unit of "peak sun"

corresponds to a radiation of 1000

Watts

per

square meter. If we find that

certain area has 4 PSH in

the worst of the

months,

it means that in that month

we should not expect a daily

irradiation

bigger

than 4000 W/m2 (day).

The peak sun hours

are an easy way to

repre-

sent

the worst case average of

irradiation per day.

Low

resolution PSH maps are

available from a number of

online sources, such

as

http://www.solar4power.com/solar-power-global-maps.html. For

more de-

tailed

information, consult a local

solar energy vendor or

weather station.

What

about wind power?

It

is possible to use a wind

generator in place of solar

panels when an

autonomous

system is being designed for

installation on a hill or

mountain.

To

be effective, the average

wind speed over the

year should be at least 3

to

4

meter per second, and

the wind generator should be

6 meters higher than

other

objects within a distance of

100 meters. A location far

away from the

coast

usually lacks sufficient

wind energy to support a

wind powered system.

Generally

speaking, photovoltaic systems

are more reliable than

wind gen-

erators,

as sunlight is more available

than consistent wind in most

places. On

the

other hand, wind generators

are able to charge batteries

even at night, as

long

as there is sufficient

wind. It is of course possible to

use wind in con-

junction

with solar power to help

cover times when there is

extended cloud

cover,

or when there is insufficient

wind.

For

most locations, the cost of

a good wind generator is not

justified by

the

meager

amount of power it will add

to the overall system. This

chapter will

therefore

focus on the use of solar

panels for generating

electricity.

Photovoltaic

system components

A

basic photovoltaic system

consists of four main

components: the solar

panel, the

batteries, the

regulator, and

the load. The

panels are responsi-

ble

for collecting the energy of

the sun and generating

electricity. The

battery

stores

the electrical energy for

later use. The regulator

ensures that panel

and

battery are working together

in an optimal fashion. The

load refers to any

device

that requires electrical

power, and is the sum of

the consumption of

all

Chapter

7: Solar Power

213

electrical

equipment connected to the

system. It is important to

remember

that

solar panels and batteries

use direct

current (DC).

If

the range of operational

voltage of your equipment

does not fit the

voltage

supplied

by your battery, it will

also be necessary to include

some type of

converter. If the

equipment that you want to

power uses a different DC

volt-

age

than the one supplied by

the battery, you will

need to use a DC/DC

con-

verter. If some of

your equipment requires AC

power, you will need to

use a

DC/AC

converter, also

known as an inverter.

Every

electrical system should

also incorporate various

safety devices in the

event

that something goes wrong.

These devices include proper

wiring, cir-

cuit

breakers, surge protectors,

fuses, ground rods, lighting

arrestors, etc.

The

solar panel

The

solar

panel is composed of

solar cells that collect

solar radiation and

transform

it into electrical energy.

This part of the system is

sometimes referred

to

as a solar

module or

photovoltaic

generator.

Solar

panel arrays can

be

made

by connecting a set of panels in

series and/or parallel in

order to provide

the

necessary energy for a given

load. The electrical current

supplied by a so-

lar

panel varies proportionally to

the solar radiation. This

will vary according

to

climatological

conditions, the hour of the

day, and the time of

the year.

Figure

7.1: A solar

panel

Several

technologies are used in the

manufacturing of solar cells.

The most

common

is crystalline silicon, and

can be either monocrystalline or

polycrystal-

line.

Amorphous silicon can be

cheaper but is less

efficient at converting

solar

214

Chapter

7: Solar Power

energy

to electricity. With a reduced

life expectancy and a 6 to 8%

transforma-

tion

efficiency, amorphous silicon is

typically used for low

power equipment,

such

as portable calculators. New

solar technologies, such as

silicon ribbon

and

thin film photovoltaics, are

currently under development.

These technolo-

gies

promise higher efficiencies

but are not yet

widely available.

The

battery

The

battery

stores

the energy produced by the

panels that is not

immedi-

ately

consumed by the load. This

stored energy can then be

used during pe-

riods

of low solar irradiation.

The battery component is

also sometimes called

the

accumulator. Batteries

store electricity in the

form of chemical

energy.

The

most common type of

batteries used in solar

applications are

maintenance-free

lead-acid batteries, also

called recombinant

or

VRLA

(valve

regulated lead

acid)

batteries.

Figure

7.2: A 200 Ah lead-acid

battery. The negative

terminal was broken due

to

weight

on the terminals during

transportation.

Aside

from storing energy, sealed

lead-acid batteries also

serve two impor-

tant

functions:

�

They are able to provide an

instantaneous power superior to

what the array

of

panels can generate. This

instantaneous power is needed to

start some

appliances,

such as the motor of a

refrigerator or a pump.

�

They determine the operating

voltage of your

installation.

Chapter

7: Solar Power

215

For

a small power installation

and where space constraints

are important,

other

type of batteries (such as

NiCd, NiMh, or Li-ion) can

be used. These

types

of batteries need a specialized

charger/regulator and cannot

directly

replace

lead-acid batteries.

The

regulator

The

regulator

(or more

formally, the solar

power charge

regulator)

assures

that

the battery is working in

appropriate conditions. It avoids

overcharging

or

overdischarging

the

battery, both of which are

very detrimental to the life

of

the

battery. To ensure proper

charging and discharging of

the battery, the

regu-

lator

maintains knowledge of the

state

of charge (SoC) of the

battery. The

SoC

is estimated based on the

actual voltage of the

battery. By measuring

the

battery voltage and being

programmed with the type of

storage technol-

ogy

used by the battery, the

regulator can know the

precise points where

the

battery

would be overcharged or excessively

discharged.

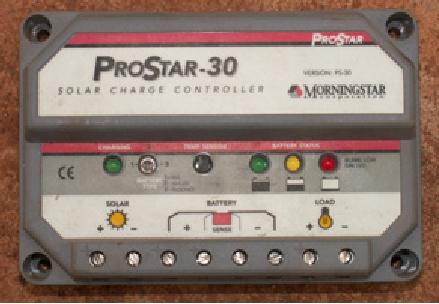

Figure

7.3: A 30 Amp solar charge

controller

The

regulator can include other

features that add valuable

information and

security

control to the equipment.

These features include

ammeters, voltme-

ters,

measurement of ampere-hour, timers,

alarms, etc. While

convenient,

none

of these features are

required for a working

photovoltaic system.

The

converter

The

electricity provided by the

panel array and battery is

DC at a fixed

volt-

age.

The voltage provided might

not match what is required

by your load. A

direct/alternating

(DC/AC) converter, also

known as inverter,

converts

216

Chapter

7: Solar Power

the

DC current from your

batteries into AC. This

comes at the price of

losing

some

energy during the

conversion. If necessary, you

can also use

convert-

ers

to obtain DC at voltage level

other than what is supplied

by the batteries.

DC/DC

converters also

lose some energy during

the conversion. For

opti-

mal

operation, you should design

your solar-powered system to

match the

generated

DC voltage to match the

load.

Figure

7.4: An 800 Watt DC/AC

converter (power

inverter)

The

load

The

load

is the

equipment that consumes the

power generated by your

energy

system.

The load may include

wireless communications equipment,

routers,

workstations,

lamps, TV sets, VSAT modems,

etc. Although it is not

possible to

precisely

calculate the exact total

consumption of your equipment, it is

vital to

be

able to make a good

estimate. In this type of

system it is absolutely

nec-

essary

to use efficient

and low power equipment to

avoid wasting energy.

Putting

it all together

The

complete photovoltaic system

incorporates all of these

components. The

solar

panels generate power when

solar energy is available.

The regulator

ensures

the most efficient

operation of the panels and

prevents damage to

the

batteries. The battery bank

stores collected energy for

later use. Con-

verters

and inverters adapt the

stored energy to match the

requirements of

your

load. Finally, the load

consumes the stored energy

to do work. When all

of

the components are in

balance and are properly

maintained, the

system

will

support itself for

years.

Chapter

7: Solar Power

217

+

+

Regulator

DC/DC

DC

load

+

Solar

panels

+

Inverter

AC

load

Battery

bank

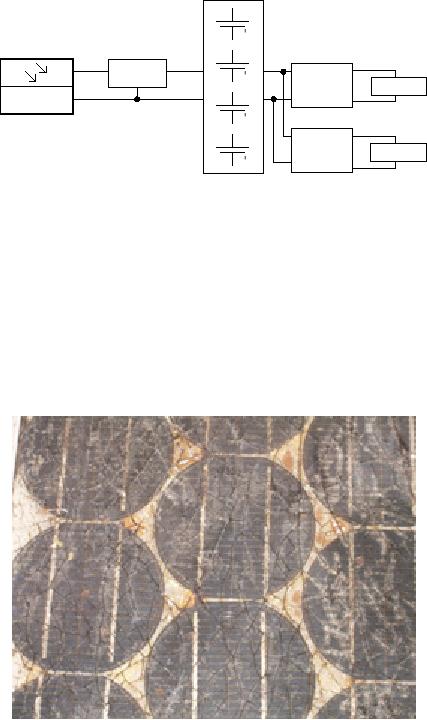

Figure

7.5: A solar installation

with DC and AC

loads

We

will now examine each of

the individual components of

the photovoltaic

system

in greater detail.

The

solar panel

An

individual solar panel is

made of many solar cells.

The cells are

electri-

cally

connected to provide a particular

value of current and

voltage. The indi-

vidual

cells are properly

encapsulated to provide isolation

and protection

from

humidity and

corrosion.

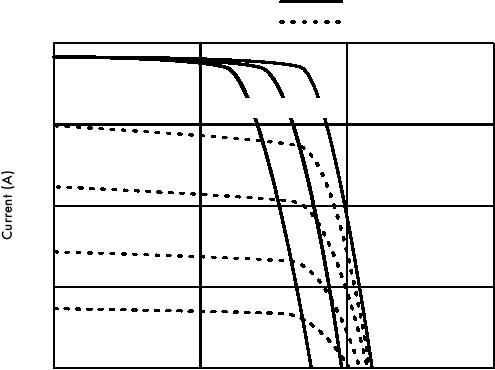

Figure

7.6: The effect of water

and corrosion in a solar

panel

There

are different types of

modules available on the

market, depending on

the

power demands of your

application. The most common

modules are

composed

of 32 or 36 solar cells of crystalline

silicon. These cells are

all of

equal

size, wired in series, and

encapsulated between glass

and plastic ma-

218

Chapter

7: Solar Power

terial,

using a polymer resin (EVA)

as a thermal insulator. The

surface area of

the

module is typically between

0.1 and 0.5 m2.

Solar panels usually

have

two

electrical contacts, one

positive and one

negative.

Some

panels also include extra

contacts to allow the

installation of bypass

diodes

across

individual cells. Bypass

diodes protect the panel

against a

phenomenon

known as "hot-spots". A hot-spot

occurs when some of the

cells

are

in shadow while the rest of

the panel is in full sun.

Rather than producing

energy,

shaded cells behave as a

load that dissipates energy.

In this situa-

tion,

shaded cells can see a

significant

increase in temperature (about 85

to

100�C.)

Bypass diodes will prevent

hot-spots on shaded cells,

but reduce the

maximum

voltage of the panel. They

should only be used when

shading is

unavoidable.

It is a much better solution to

expose the entire panel to

full sun

whenever

possible.

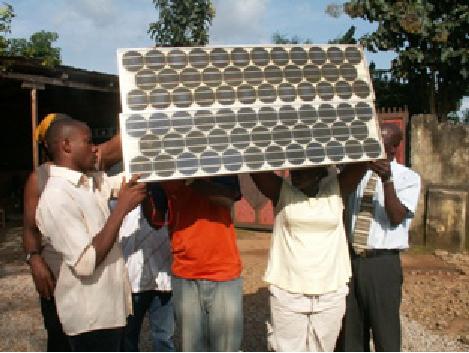

Irradiance:

1kW / m2

Cell

Temperature 25C

8

75C

50C 25C

800W

/ m2

6

600W

/ m2

4

400W

/ m2

2

200W

/ m2

0

10

20

30

Voltage

(V)

Figure

7.7: Different IV Curves.

The current (A) changes with

the irradiance, and

the

voltage

(V) changes with the

temperature.

The

electrical performance of a solar

module its represented by

the IV

char-

acteristic

curve, which

represents the current that

is provided based on

the

voltage

generated for a certain

solar radiation.

Chapter

7: Solar Power

219

The

curve represents all the

possible values of voltage-current.

The curves

depend

on two main factors: the

temperature and the solar

radiation received

by

the cells. For a given

solar cell area, the

current generated is directly

pro-

portional

to solar irradiance (G),

while the voltage reduces

slightly with an

increase

of temperature. A good regulator

will try to maximize the

amount of

energy

that a panel provides by

tracking the point that

provides maximum

power

(V x I). The maximum power

corresponds to the knee of

the IV curve.

Solar

Panel Parameters

The

main parameters that

characterize a photovoltaic panel

are:

1.

SHORT

CIRCUIT CURRENT (ISC):

the maximum current provided

by the

panel

when the connectors are

short circuited.

2.

OPEN

CIRCUIT VOLTAGE (VOC):

the maximum voltage that

the panel

provides

when the terminals are

not connected to any load

(an open cir-

cuit).

This value is normally 22 V

for panels that are

going to work in 12 V

systems,

and is directly proportional to

the number of cells

connected in

series.

3.

MAXIMUM

POWER POINT (Pmax): the point where

the power supplied

by

the panel is at maximum,

where Pmax = Imax x

Vmax. The

maximum

power

point of a panel is measured in

Watts (W) or peak Watts

(Wp).

It is

important

not to forget that in normal

conditions the panel will

not work at

peak

conditions, as the voltage of

operation is fixed by

the load or the

regulator.

Typical values of Vmax and Imax

should be a

bit smaller than

the

ISC and VOC

4.

FILL

FACTOR (FF):

the relation between the

maximum power that

the

panel

can actually provide and

the product ISC . VOC.

This gives you an

idea

of the quality of the panel

because it is an indication of the

type of IV

characteristic

curve. The closer FF is to 1,

the more power a panel

can

provide.

Common values usually are

between 0.7 and

0.8.

5.

EFFICIENCY

(h):

the ratio between the

maximum electrical power

that

the

panel can give to the

load and the power of

the solar radiation (PL)

incident

on the panel. This is

normally around 10-12%,

depending on the

type

of cells (monocrystalline,

polycrystalline, amorphous or thin

film).

Considering

the definitions of

point of maximum power and

the fill factor

we

see

that:

h

=

Pmax / PL

= FF . ISC .

VOC / PL

220

Chapter

7: Solar Power

The

values of ISC,

VOC, IPmax and

VPmax

are

provided by the manufacturer

and

refer

to standard conditions of measurement

with irradiance G = 1000

W/m2,

at

sea-level, for a temperature of

cells of Tc = 25�C.

The

panel parameters values

change for other conditions of irradiance

and tem-

perature.

Manufacturers will sometimes

include graphs or tables with

values for

conditions

different from the standard. You

should check the performance

values

at

the panel temperatures that are

likely to match your particular

installation.

Be

aware that two panels

can have the same

Wp but very different

behavior

in

different operating conditions.

When acquiring a panel, it is

important to

verify,

if possible, that their

parameters (at least,

ISC and VOC) match the

val-

ues

promised by the

manufacturer.

Panel

parameters for system

sizing

To

calculate the number of

panels required to cover a

given load, you

just

need

to know the current and

voltage at the point of

maximum power: IPmax

and

VPmax.

You

should always be aware that

the panel is not going to

perform under per-

fect

conditions as the load or

regulation system is not

always going to work

at

the

point of maximum power of

the panel. You should

assume a loss of effi-

ciency

of 5% in your calculations to compensate

for this.

Interconnection

of panels

A

solar

panel array is a

collection of solar panels

that are electrically

inter-

connected

and installed on some type

of support structure. Using a

solar

panel

array allows you to generate

greater voltage and current

than is possi-

ble

with a single solar panel.

The panels are

interconnected in such a

way

that

the voltage generated is

close to (but greater than)

the level of voltage

of

the

batteries, and that the

current generated is sufficient

to feed the equip-

ment

and to charge the

batteries.

Connecting

solar panels in series

increases the generated

voltage. Connect-

ing

panels in parallel increases

the current. The number of

panels used

should

be increased until the

amount of power generated

slightly exceeds

the

demands of your load.

It

is very important that all

of the panels in your array

are as identical as

possi-

ble.

In an array, you should use

panels of the same brand

and characteristics

because

any difference in their

operating conditions will

have a big impact on

the

health and performance of

your system. Even panels

that have identical

Chapter

7: Solar Power

221

performance

ratings will usually display

some variance in their

characteristics

due

to manufacturing processes. The

actual operating characteristics of

two

panels

from the same manufacturer

can vary by as much as

�10%.

Whenever

possible, it is a good idea to

test the real-world

performance of

individual

panels to verify their

operating characteristics before

assembling

them

into an array.

Figure

7.8: Interconnection of panels in

parallel. The voltage

remains constant

while

the

current duplicates. (Photo:

Fantsuam Foundation,

Nigeria)

How

to choose a good panel

One

obvious metric to use when

shopping for solar panels is

to compare the

ratio

of the nominal peak power

(Wp)

to the price. This will

give you a rough

idea

of the cost per Watt

for different panels. But

there are a number of

other

considerations

to keep in mind as

well.

If

you are going to install

solar panels in geographical

areas where soiling

(from

dust, sand, or grit) will

likely be a problem, consider

purchasing pan-

els

with a low affinity for

soil retention. These panels

are made of materials

that

increase the likelihood that

the panel will be

automatically cleaned by

wind

and rain.

Always

check the mechanical

construction of each panel.

Verify that the

glass

is hardened and the aluminum

frame is robust and well

built. The solar

222

Chapter

7: Solar Power

cells

inside the panel can

last for more than 20

years, but they are

very frag-

ile

and the panel must

protect them from mechanical

hazards. Look for

the

manufacturer's

quality guarantee in terms of

expected power output and

me-

chanical

construction.

Finally,

be sure that the

manufacturer provides not

only the nominal

peak

power

of the panel (Wp)

but also the variation of

the power with

irradiation

and

temperature. This is particularly

important when panels are

used in ar-

rays,

as variations in the operating

parameters can have a big

impact on the

quality

of power generated and the

useful lifetime of the

panels.

The

batter y

The

battery "hosts" a certain

reversible chemical reaction

that stores electri-

cal

energy that can later be

retrieved when needed.

Electrical energy is

transformed

into chemical energy when

the battery is being

charged, and the

reverse

happens when the battery is

discharged.

A

battery is formed by a set of

elements or cells

arranged in

series. Lead-

acid

batteries consist of two

submerged lead electrodes in an

electrolytic so-

lution

of water and sulfuric acid.

A potential difference of about 2

volts takes

place

between the electrodes,

depending on the instantaneous

value of the

charge

state of the battery. The

most common batteries in

photovoltaic solar

applications

have a nominal voltage of 12 or 24

volts. A 12 V battery

there-

fore

contains 6 cells in

series.

The

battery serves two important

purposes in a photovoltaic system: to

pro-

vide

electrical energy to the

system when energy is not

supplied by the array

of

solar panels, and to store

excess energy generated by

the panels when-

ever

that energy exceeds the

load. The battery

experiences a cyclical

proc-

ess

of charging and discharging,

depending on the presence or

absence of

sunlight.

During the hours that

there is sun, the array of

panels produces

electrical

energy. The energy that is

not consumed immediately it is

used to

charge

the battery. During the

hours of absence of sun, any

demand of elec-

trical

energy is supplied by the

battery, thereby discharging

it.

These

cycles of charge and

discharge occur whenever the

energy produced

by

the panels does not

match the energy required to

support the load.

When

there

is sufficient

sun and the load is

light, the batteries will

charge. Obvi-

ously,

the batteries will discharge

at night whenever any amount

of power is

required.

The batteries will also

discharge when the

irradiance is insufficient

to

cover the requirements of

the load (due to the

natural variation of

climato-

logical

conditions, clouds, dust,

etc.)

Chapter

7: Solar Power

223

If

the battery does not

store enough energy to meet

the demand during

peri-

ods

without sun, the system

will be exhausted and will

be unavailable for

consumption.

On the other hand, the

oversizing the system (by

adding far too

many

panels and batteries) is

expensive and inefficient.

When designing a

stand-alone

system we need to reach a

compromise between the cost

of

components

and the availability of

power from the system.

One way to do

this

is to estimate the required

number

of days of autonomy. In the

case of

a

telecommunications system, the

number of days of autonomy

depends on

its

critical function within

your network design. If the

equipment is going to

serve

as repeater and is part of

the backbone of your

network, you will

likely

want

to design your photovoltaic

system with an autonomy of up to

5-7 days.

On

the other hand, if the

solar system is responsible

for a providing energy

to

client

equipment you can probably

reduce number of days of

autonomy to

two

or three. In areas with low

irradiance, this value may

need to be in-

creased

even more. In any case,

you will always have to

find the

proper bal-

ance

between cost and

reliability.

Types

of batteries

Many

different battery technologies

exist, and are intended

for use in a vari-

ety

of different applications. The

most suitable type for

photovoltaic applica-

tions

is the stationary

battery, designed to

have a fixed

location and for

scenarios

where the power consumption

is more or less irregular.

"Station-

ary"

batteries can accommodate

deep discharge cycles, but

they are not

de-

signed

to produce high currents in

brief periods of

time.

Stationary

batteries can use an

electrolyte that is alkaline

(such as Nickel-

Cadmium)

or acidic (such as Lead-Acid).

Stationary batteries based

on

Nickel-Cadmium

are recommended for their

high reliability and

resistance

whenever

possible. Unfortunately, they

tend to be much more

expensive and

difficult

to obtain than sealed

lead-acid batteries.

In

many cases when it is

difficult to

find local,

good and cheap stationary

bat-

teries

(importing batteries is not

cheap), you will be forced

to use batteries

targeted

to the automobile

market.

Using

car batteries

Automobile

batteries are not well

suited for photovoltaic

applications as they

are

designed to provide a substantial

current for just few

seconds (when

starting

then engine) rather than

sustaining a low current for

long period of

time.

This design characteristic of

car batteries (also called

traction

batter-

ies) results in

an shortened effective life

when used in photovoltaic

systems.

Traction

batteries can be used in

small applications where low

cost is the

most

important consideration, or when

other batteries are not

available.

224

Chapter

7: Solar Power

Traction

batteries are designed for

vehicles and electric

wheelbarrows. They

are

cheaper than stationary

batteries and can serve in a

photovoltaic installa-

tion,

although they require very

frequent maintenance. These

batteries

should

never be deeply discharged,

because doing so will

greatly reduce

their

ability to hold a charge. A

truck battery should not

discharged by more

than

70% of its total capacity.

This means that you

can only use a

maximum

of

30% of a lead-acid battery's

nominal capacity before it

must be recharged.

You

can extend the life of a

lead-acid battery by using

distilled water. By

us-

ing

a densimeter or hydrometer, you

can measure the density of

the battery's

electrolyte.

A typical battery has

specific gravity of

1.28. Adding distilled

water

and

lowering the density to 1.2

can help reduce the

anode's corrosion, at a

cost

of reducing the overall

capacity of the battery. If

you adjust the density

of

battery

electrolyte, you must

use

distilled water, as tap

water or well water

will

permanently damage the

battery.

States

of charge

There

are two special state of

charge that can take

place during the

cyclic

charge

and discharge of the

battery. They should both be

avoided in order to

preserve

the useful life of the

battery.

Overcharge

Overcharge

takes

place when the battery

arrives at the limit of its

capacity. If

energy

is applied to a battery beyond

its point of maximum charge,

the electro-

lyte

begins to break down. This

produces bubbles of oxygen

and hydrogen, in

a

process is known as gasification. This

results in a loss of water,

oxidation on

the

positive electrode, and in

extreme cases, a danger of

explosion.

On

the other hand, the

presence of gas avoids the

stratification of the

acid.

After several continuous

cycles of charge and

discharge, the acid

tends

to concentrate itself at the

bottom of the battery

thereby reducing

the

effective capacity. The

process of gasification agitates

the electrolyte

and

avoids stratification.

Again,

it is necessary to find a

compromise between the

advantages (avoid-

ing

electrolyte stratification)

and the disadvantages

(losing water and

produc-

tion

of hydrogen). One solution is to

allow a slight overcharge

condition every

so

often. One typical method is

to allow a voltage of 2.35 to

2.4 Volts for

each

element

of the battery every few

days, at 25�C. The regulator

should ensure

a

periodical and controlled

overcharges.

Chapter

7: Solar Power

225

Overdischarge

In

the same way that

there is a upper limit,

there is also a lower limit

to a bat-

tery's

state of charge. Discharging

beyond that limit will

result in deterioration

of

the battery. When the

effective battery supply is

exhausted, the

regulator

prevents

any more energy from

being extracted from the

battery. When the

voltage

of the battery reaches the

minimum limit of 1.85 Volts

per cell at

25�C,

the regulator disconnects

the load from the

battery.

If

the discharge of the battery

is very deep and the

battery remains dis-

charged

for a long time, three

effects take place: the

formation of crystallized

sulfate

on the battery plates, the

loosening of the active

material on the bat-

tery

plate, and plate buckling.

The process of forming

stable sulfate

crystals

is

called hard sulfation. This

is particularly negative as it generates

big crys-

tals

that do not take part in

any chemical reaction and

can make your

battery

unusable.

Battery

Parameters

The

main parameters that

characterize a battery

are:

�

Nominal

Voltage, VNBat.

the most common value

being 12 V.

�

Nominal

Capacity, CNBat:

the maximum amount of energy

that can be ex-

tracted

from a fully charged

battery. It is expressed in Ampere-hours

(Ah)

or

Watt-hours (Wh). The amount

of energy that can be

obtained from a

battery

depends on the time in which

the extraction process takes

place.

Discharging

a battery over a long period

will yield more energy

compared

to

discharging the same battery

over a short period. The

capacity of a bat-

tery

is therefore specified at

different discharging times.

For photovoltaic

applications,

this time should be longer

than 100 hours

(C100).

�

Maximum

Depth of Discharge,

DoDmax: The depth of discharge is

the

amount

of energy extracted from a battery in a

single discharge cycle,

ex-

pressed

as a percentage. The life expectancy of a

battery depends on how

deeply

it is discharged in each cycle. The

manufacturer should provide graphs

that

relate the number of charge-discharge

cycles to the life of the

battery. As a

general

rule you should avoid

discharging a deep cycle

battery beyond

50%.

Traction batteries should

only be discharged by as little as

30%.

�

Useful

Capacity, CUBat:

It is the real (as in

usable) capacity of a battery.

It

is

equal to the product of the

nominal capacity and the

maximum DoD. For

example,

a stationary battery of nominal

capacity (C100) of 120 Ah

and

depth

of discharge of 70% has a

useful capacity of (120 x

0.7) 84 Ah.

226

Chapter

7: Solar Power

Measuring

the state of charge of the

battery

A

sealed lead-acid battery of 12 V

provides different voltages

depending on

its

state of charge. When the

battery is fully charged in an

open circuit, the

output

voltage is about 12.8 V. The

output voltage lowers

quickly to 12.6 V

when

loads are attached. As the

battery is providing constant

current during

operation,

the battery voltage reduces

linearly from 12.6 to 11.6 V

depending

on

the state of charge. A

sealed lead-acid batteries

provides 95% of its

en-

ergy

within this voltage range.

If we make the broad

assumption that a

fully

loaded

battery has a voltage of

12.6 V when "full" and

11.6 V when "empty",

we

can estimate that a battery

has discharged 70% when it

reaches a volt-

age

of 11.9 V. These values are

only a rough approximation

since they de-

pend

on the life and quality of

the battery, the

temperature, etc.

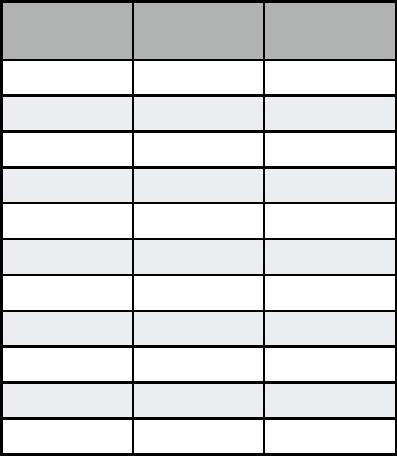

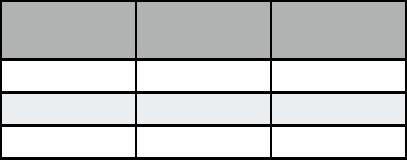

State

of Charge

12V

Battery

Volts

per Cell

Voltage

100%

12.7

2.12

90%

12.5

2.08

80%

12.42

2.07

70%

12.32

2.05

60%

12.2

2.03

50%

12.06

2.01

40%

11.9

1.98

30%

11.75

1.96

20%

11.58

1.93

10%

11.31

1.89

0%

10.5

1.75

According

to this table, and

considering that a truck

battery should not be

discharged

more than 20% to 30%, we

can determine that the

useful capac-

ity

of a truck 170 Ah truck

battery is 34 Ah (20%) to 51 Ah (30%).

Using the

same

table, we find that we

should program the regulator

to prevent the bat-

tery

from discharging below 12.3

V.

Chapter

7: Solar Power

227

Battery

and regulator protection

Thermomagnetic

circuit breakers or one time

fuses must be used to

protect

the

batteries and the

installation from short

circuit and malfunctions.

There

are

two types of fuses:

slow

blow, and

quick

blow. Slow

blow fuses should

be

used with inductive or

capacitive loads where a

high current can occur

at

power

up. Slow blow fuses

will allow a higher current

than their rating to

pass

for

a short time. Quick blow

fuses will immediately blow

if the current flowing

through

them is higher than their

rating.

The

regulator is connected to the

battery and the loads, so

two different kinds

of

protection needs to be considered.

One fuse should be placed

between

the

battery and the regulator,

to protect the battery from

short-circuit in case

of

regulator failure. A second

fuse is needed to protect

the regulator from

ex-

cessive

load current. This second

fuse is normally integrated

into the regula-

tor

itself.

Figure

7.9: A battery bank of 3600

Ah, currents reach levels of

45 A during charging

Every

fuse is rated with a maximum

current and a maximum usable

voltage.

The

maximum current of the fuse

should be 20% bigger than

the maximum

current

expected. Even if the

batteries carry a low

voltage, a short circuit

can

lead

to a very high current which

can easily reach several

hundred amperes.

Large

currents can cause fire,

damage the equipment and

batteries, and

possibly

cause electric shock to a

human body

If

a fuse breaks, never replace

a fuse with a wire or a

higher rated fuse.

First

determine

the cause of the problem,

then replace the fuse

with another one

which

has the same

characteristics.

228

Chapter

7: Solar Power

Temperature

effects

The

ambient temperature has

several important effects on

the characteristics

of

a battery:

�

The nominal capacity of a

battery (that the

manufacturer usually gives

for

25�C)

increases with temperature at

the rate of about 1%/�C.

But if the

temperature

is too high, the chemical

reaction that takes place in

the bat-

tery

accelerates, which can cause

the same type of oxidation

that takes

places

during overcharging. This

will obviously reduce the

life expectancy

of

battery. This problem can be

compensated partially in car

batteries by

using

a low density of dissolution (a

specific gravity of

1.25 when the

bat-

tery

is totally charged).

�

As the temperature is reduced,

the useful life of the

battery increases.

But

if the temperature is too

low, you run the

the risk of freezing the

elec-

trolyte.

The freezing temperature

depends on the density of

the solution,

which

is also related to the state

of charge of the battery.

The lower the

density,

the greater the risk of

freezing. In areas of low

temperatures, you

should

avoid deeply discharging the

batteries (that is,

DoDmax is effec-

tively

reduced.)

�

The temperature also changes

the relation between voltage

and charge. It

is

preferable to use a regulator

which adjusts the low

voltage disconnect

and

reconnect parameters according to

temperature. The

temperature

sensor

of the regulator should be fixed

to the battery using tape or

some

other

simple method.

�

In hot areas it is important to

keep the batteries as cool

as possible. The

batteries

must be stored in a shaded

area and never get

direct sunlight. It's

also

desirable to place the

batteries on a small support to

allow air to flow

under

them, thus increase the

cooling.

How

to choose a good battery

Choosing

a good battery can be very

challenging in developing regions.

High

capacity

batteries are heavy, bulky

and expensive to import. A

200 Ah battery

weights

around 50 kg (120 pounds)

and it can not be

transported as hand

luggage.

If you want long-life (as in

> 5 years) and maintenance

free batter-

ies

be ready to pay the

price.

A

good battery should always

come with its technical

specifications,

including

the

capacity at different discharge

rates (C20, C100), operating

temperature,

cut-off

voltage points, and

requirements for

chargers.

The

batteries must be free of

cracks, liquid spillage or

any sign of damage,

and

battery terminals should be

free of corrosion. As laboratory

tests are

Chapter

7: Solar Power

229

necessary

to obtain complete data

about real capacity and

aging, expect

lots

of low quality batteries

(including fakes) in the

local markets. A

typical

price

(not including transport and

import tax) is $3-4 USD

per Ah for 12 V

lead-acid

batteries.

Life

expectancy versus number of

cycles

Batteries

are the only component of a

solar system that should be

amortized

over

a short period and regularly

replaced. You can increase

the useful life-

time

of a battery by reducing the

depth of discharge per

cycle. Even deep

cycle

batteries will have an

increased battery life if

the the number of

deep

discharge

(>30%) cycles is

reduced.

If

you completely discharge the

battery every day, you

will typically need

to

change

it after less than one

year. If you use only

1/3 of the capacity the

bat-

tery,

it can last more than 3

years. It can be cheaper to

buy a battery with 3

times

the capacity than to change

the battery every

year.

The

power charge regulator

The

power charge regulator is

also known as charge

controller, voltage

regu-

lator,

charge-discharge controller or

charge-discharge and load

controller.

The

regulator sits between the

array of panels, the

batteries, and your

equipment

or loads.

Remember

that the voltage of a

battery, although always

close to 2 V per

cell,

varies according to its

state of charge. By monitoring

the voltage of the

battery,

the regulator prevents

overcharging or overdischarging.

Regulators

used in solar applications

should be connected in series:

they

disconnect

the array of panels from

the battery to avoid

overcharging, and

they

disconnect the battery from

the load to avoid

overdischarging. The

connection

and disconnection is done by

means of switches which can

be

of

two types: electromechanical

(relays) or solid state

(bipolar transistor,

MOSFET).

Regulators should never be

connected in parallel.

In

order to protect the battery

from gasification, the

switch opens the

charging

circuit when the voltage in

the battery reaches its

high voltage

disconnect

(HVD) or cut-off set point.

The low voltage disconnect

(LVD)

prevents

the battery from

overdischarging by disconnecting or

shedding

the

load. To prevent continuous

connections and disconnections

the regu-

lator

will not connect back

the loads until the

battery reaches a low

recon-

nect

voltage (LRV).

230

Chapter

7: Solar Power

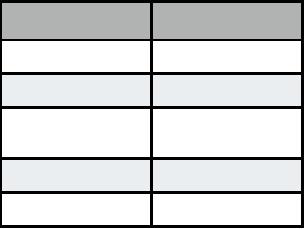

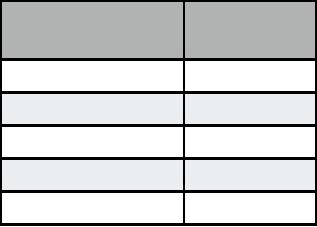

Typical

values for a 12 V lead-acid

battery are:

Voltage

Point

Voltage

LVD

11.5

LRV

12.6

Constant

Voltage

14.3

Regulated

Equalization

14.6

HVD

15.5

The

most modern regulators are also

able to automatically disconnect

the panels

during

the night to avoid discharging of the

battery. They can also

periodically

overcharge

the battery to improve their life, and

they may use a

mechanism

known

as pulse width modulation

(PWM) to prevent excessive

gassing.

As

the peak power operating

point of the array of panels

will vary with

tem-

perature

and solar illumination, new

regulators are capable of

constantly

tracking

the maximum point of power

of the solar array. This

feature is known

as

maximum power point tracking

(MPPT).

Regulator

Parameters

When

selecting a regulator for

your system, you should at

least know the

operating

voltage and

the maximum

current that

the regulator can

handle.

The

operating Voltage will be

12, 24, or 48 V. The maximum

current must be

20%

bigger than the current

provided by the array of

panels connected to

the

regulator.

Other

features and data of

interest include:

�

Specific values

for LVD, LRV and

HVD.

�

Support for temperature

compensation. The voltage

that indicates the

state

of

charge of the battery vary

with temperature. For that

reason some regu-

lators

are able to measure the

battery temperature and

correct the different

cut-off

and reconnection

values.

�

Instrumentation and gauges.

The most common instruments

measure the

voltage

of the panels and batteries,

the state of charge (SoC) or Depth of

Dis-

charge

(DoD). Some regulators include

special alarms to indicate that

the

panels

or loads have been disconnected,

LVD or HVD has been reached,

etc.

Chapter

7: Solar Power

231

Conver

ters

The

regulator provides DC power at a

specific voltage. Converters

and invert-

ers

are used to adjust the

voltage to match the

requirements of your

load.

DC/DC

Converters

DC/DC

converters transform a continuous

voltage to another

continuous

voltage

of a different value. There

are two conversion methods

which can be

used

to adapt the voltage from

the batteries: linear

conversion and

switch-

ing

conversion.

Linear

conversion lowers the

voltage from the batteries

by converting excess

energy

to heat. This method is very

simple but is obviously

inefficient.

Switching

conversion generally uses a

magnetic component to

temporarily

store

the energy and transform it

to another voltage. The

resulting voltage

can

be greater, less than, or

the inverse (negative) of

the input voltage.

The

efficiency

of a linear regulator decreases as

the difference between

the

input

voltage and the output

voltage increases. For

example, if we want to

convert

from 12 V to 6 V, the linear

regulator will have an efficiency

of only

50%.

A standard switching regulator

has an efficiency of at

least 80%.

DC/AC

Converter or Inverter

Inverters

are used when your

equipment requires AC power.

Inverters chop

and

invert the DC current to

generate a square wave that

is later filtered

to

approximate

a sine wave and eliminate

undesired harmonics. Very

few

inverters

actually supply a pure sine

wave as output. Most models

available

on

the market produce what is

known as "modified sine

wave", as their volt-

age

output is not a pure

sinusoid. When it comes to efficiency,

modified

sine

wave

inverters perform better

than pure sinusoidal

inverters.

Be

aware that not all

the equipment will accept a

modified sine

wave as volt-

age

input. Most commonly, some

laser printers will not

work with a modified

sine

wave inverter. Motors will

work, but they may

consume more power

than

if

they are fed with a

pure sine wave. In addition,

DC power supplies tend

to

warm

up more, and audio

amplifiers

can emit a buzzing

sound.

Aside

from the type of waveform,

some important features of

inverters include:

�

Reliability

in the presence of surges. Inverters

have two power

ratings:

one

for continuous power, and a

higher rating for peak

power. They are

capable

of providing the peak power

for a very short amount of

time, as

when

starting a motor. The

inverter should also be able

to safely interrupt

232

Chapter

7: Solar Power

itself

(with a circuit breaker or

fuse) in the event of a

short circuit, or if

the

requested

power is too high.

�

Conversion

efficiency.

Inverters

are most efficient

when providing 50% to

90%

of their continuous power

rating. You should select an

inverter that

most

closely matches your load

requirements. The manufacturer

usually

provides

the performance of the

inverter at 70% of its

nominal power.

�

Battery

charging. Many

inverters also incorporate

the inverse function:

the

possibility of charging batteries in

the presence of an alternative

source

of

current (grid, generator,

etc). This type of inverter

is known as a charger/

inverter.

�

Automatic

fall-over. Some

inverters can switch

automatically between

different

sources of power (grid,

generator, solar) depending on

what is

available.

When

using telecommunication equipment, it is

best to avoid the use of

DC/

AC

converters and feed them

directly from a DC source.

Most communica-

tions

equipment can accept a wide

range of input

voltage.

Equipment

or load

It

should be obvious that as

power requirements increase,

the expense of the

photovoltaic

system also increases. It is

therefore critical to match

the size of

the

system as closely as possible to

the expected load. When

designing the

system

you must first

make a realistic estimate of

the maximum consump-

tion.

Once the installation is in

place, the established

maximum consumption

must

be respected in order to avoid

frequent power

failures.

Home

Appliances

The

use of photovoltaic solar

energy is not recommended

for heat-exchange

applications

(electrical heating, refrigerators,

toasters, etc.) Whenever

possi-

ble,

energy should be used

sparingly using low power

appliances.

Here

are some points to keep in

mind when choosing

appropriate equipment

for

use with a solar

system:

�

The photovoltaic solar

energy is suitable for

illumination. In this case,

the

use

of halogen light bulbs or fluorescent

lamps is mandatory.

Although

these

lamps are more expensive,

they have much better

energy efficiency

than

incandescent light bulbs.

LED lamps are also a

good choice as they

are

very efficient

and are fed with

DC.

�

It is possible to use photovoltaic

power for appliances that

require low and

constant

consumption (as in a typical

case, the TV). Smaller

televisions

Chapter

7: Solar Power

233

use

less power than larger

televisions. Also consider

that a black-and-white

TV

consumes about half the

power of a color TV.

�

Photovoltaic solar energy is

not recommended for any

application that

transforms

energy into heat (thermal

energy). Use solar heating

or butane

as

alternative.

�

Conventional automatic washing

machines will work, but

you should avoid

the

use of any washing programs

that include centrifuged

water heating.

�

If you must use a

refrigerators, it should consume as

little power as

possi-

ble.

There are specialized

refrigerators that work in

DC, although their

con-

sumption

can be quite high (around

1000 Wh/day).

The

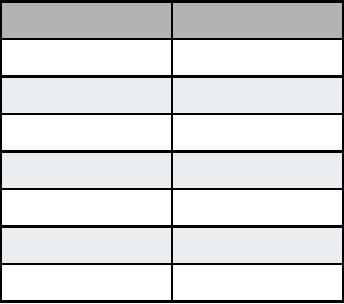

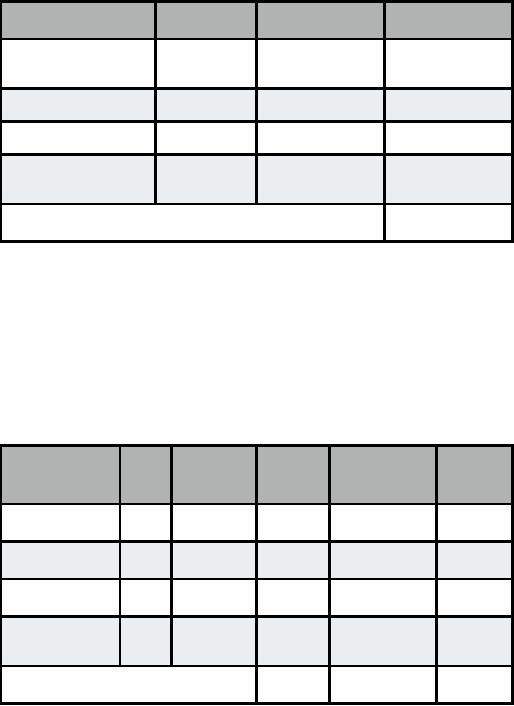

estimation of total consumption is a

fundamental step in sizing

your solar

system.

Here is a table that gives

you a general idea of the

power consump-

tion

that you can expect

from different

appliances.

Equipment

Consumption

(Watts)

Portable

computer

30-50

Low

power lamp

6-10

WRAP

router (one radio)

4-10

VSAT

modem

15-30

PC

(without LCD)

20-30

PC

(with LCD)

200-300

Network

Switch (16 port)

6-8

Wireless

telecommunications equipment

Saving

power by choosing the right

gear saves a lot of money

and trouble.

For

example , a long distance

link doesn't necessarily

need a strong amplifier

that

draws a lot of power. A

Wi-Fi card with good

receiver sensitivity and

a

fresnel

zone that is at least 60%

clear will work better

than an amplifier,

and

save

power consumption as well. A

well known saying of radio

amateurs ap-

plies

here, too: The best

amplifier is a good

antenna. Further measures

to

reduce

power consumption include

throttling the CPU speed,

reducing

transmit

power to the minimum value

that is necessary to provide a

stable

234

Chapter

7: Solar Power

link,

increasing the length of

beacon intervals, and

switching the system

off

during

times it is not

needed.

Most

autonomous solar systems

work at 12 or 24 volts. Preferably, a

wireless

device

that runs on DC voltage

should be used, operating at

the 12 Volts that

most

lead acid batteries provide.

Transforming the voltage

provided by the

battery

to AC or using a voltage at the

input of the access point

different from

the

voltage of the battery will

cause unnecessary energy

loss. A router or

access

point that accepts 8-20

Volts DC is perfect.

Most

cheap access points have a

switched mode voltage

regulator inside

and

will work through such a

voltage range without

modification or

becoming

hot

(even if the device was

shipped with a 5 or 12 Volt

power supply).

WARNING:

Operating your access point

with a power supply other

than the

one

provided by your manufacturer

will certainly void any

warranty, and may

cause

damage to your equipment.

While the following

technique will

typically

work

as described, remember that

should you attempt it,

you do so at your

own

risk.

Open

your access point and

look near the DC input

for two relatively big

ca-

pacitors

and an inductor (a ferrite

toroid with copper wire

wrapped around it).

If

they are present then

the device has a switched

mode input, and

the

maximum

input voltage should be

somewhat below the voltage

printed on the

capacitors.

Usually the rating of these

capacitors is 16 or 25 volts. Be

aware

that

an unregulated power supply

has a ripple and may

feed a much higher

voltage

into your access point

than the typical voltage

printed on it may

sug-

gest.

So, connecting an unregulated

power supply with 24 Volts

to a device

with

25 Volt-capacitors is not a good

idea. Of course, opening

your device

will

void any existing warranty.

Do not try to operate an

access point at

higher

voltage

if it doesn't have a switched

mode regulator. It will get

hot, malfunc-

tion,

or burn.

Equipment

based on traditional Intel

x86 CPUs are power

hungry in compari-

son

with RISC-based architectures as

ARM or MIPS. One of the

boards with

lowest

power consumptions is the

Soekris platform that uses

an AMD

ElanSC520

processor. Another alternative to

AMD (ElanSC or Geode

SC1100)

is the use of equipment with

MIPS processors. MIPS

processors

have

a better performance than an

AMD Geode at the price of

consuming

between

20-30% of more

energy.

The

popular Linksys WRT54G runs

at any voltage between 5 and

20 volts

DC

and draws about 6 Watts,

but it has an Ethernet

switch onboard.

Having

a

switch is of course nice and

handy - but it draws extra

power. Linksys also

offers

a Wi-Fi access point called

WAP54G that draws only 3

Watts and can

run

OpenWRT and Freifunk firmware.

The 4G Systems Accesscube

draws

Chapter

7: Solar Power

235

about

6 Watts when equipped with a

single WiFi interface. If

802.11b is suffi-

cient,

mini-PCI cards with the

Orinoco chipset perform very

well while draw-

ing

a minimum amount of

power.

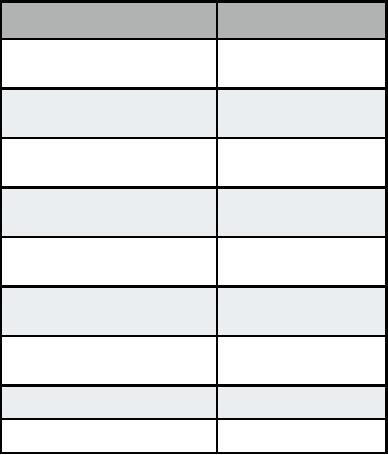

Equipment

Consumption

(Watts)

Linksys

WRT54G

6

(BCM2050

radio)

Linksys

WAP54G

3

(BCM2050

radio)

Orinoco

WavePoint II ROR

15

(30mW

radio)

Soekris

net4511

1.8

(no

radio)

PC

Engines WRAP.1E-1

2.04

(no

radio)

Mikrotik

Routerboard 532

2.3

(no

radio)

Inhand

ELF3

1.53

(no

radio)

Senao

250mW radio

3

Ubiquiti

400mW radio

6

The

amount of power required by

wireless equipment depends

not only on

the

architecture but on the

number of network interfaces,

radios, type of

memory/storage

and traffic. As a

general rule, a wireless

board of low con-

sumption

consumes 2 to 3 W, and a 200 mW

radio card consumes as

much

as

3 W. High power cards (such

as the 400 mW Ubiquity)

consume around 6

W.

A repeating station with two

radios can range between 8

and 10 W.

Although

the standard IEEE 802.11

incorporates a power saving

mode (PS)

mechanism,

its benefit is not as

good as you might hope.

The main mecha-

nism

for energy saving is to

allow stations to periodically

put their wireless

cards

to "sleep" by means of a timing

circuit. When the wireless

card wakes

up

it verifies if a beacon

exists, indicating pending

traffic. The

energy saving

therefore

only takes place in the

client side, as the access

point always

needs

to remain awake to send

beacons and store

traffic for

the clients.

Power

saving mode may be

incompatible between implementations

from

different

manufacturers, which can

cause unstable wireless

connections. It is

236

Chapter

7: Solar Power

nearly

always best to leave power

saving mode disabled on all

equipment, as

the

difficulties

created will likely outweigh

the meager amount of

saved

power.

Selecting

the voltage

Most

low power stand-alone

systems use 12 V battery

power as that is the

most

common operational voltage in

sealed lead-acid batteries.

When de-

signing

a wireless communication system

you need to take into

consideration

the

most efficient

voltage of operation of your

equipment. While the

input

voltage

can accept a wide range of

values, you need to ensure

that the over-

all

power consumption of the

system is minimal.

Wiring

An

important component of the

installation is the wiring, as

proper wiring

will

ensure efficient energy

transfer. Some good

practices that you

should

consider

include:

�

Use a screw to fasten the

cable to the battery

terminal. Loose

connections

will

waste power.

�

Spread Vaseline or mineral

jelly on the battery

terminals. Corroded

connec-

tion

have an increased resistance,

resulting in loss.

�

For low currents (<10 A)

consider the use of Faston

or Anderson power-

pole

connectors.

For

bigger currents, use

metallic ring lugs.

Wire

size is normally given in

American Wire Gauge (AWG).

During your cal-

culations

you will need to convert

between AWG and mm2 to

estimate cable

resistance.

For example, an AWG #6 cable

has a diameter of 4.11 mm

and

can

handle up to 55 A. A conversion chart,

including an estimate of

resis-

tance

and current carrying

capacity, is available in Appendix

D.

Keep in

mind

that the current carrying

capacity can also vary

depending on the type

of

insulation and application.

When in doubt, consult the

manufacturer for

more

information.

Orientation

of the panels

Most

of the energy coming from

the sun arrives in straight

line. The solar

module

will capture more energy if

it is "facing" the sun,

perpendicular to the

straight

line between the position of

the installation and the

sun. Of course,

the

sun's position is constantly

changing relative to the

earth, so we need to

find an optimal

position for our panels.

The orientation of the

panels is de-

termined

by two angles, the

azimuth

a and

the inclination

or

elevation

�.

The

azimuth is the angle that

measures the deviation with

respect to the

Chapter

7: Solar Power

237

south

in the northern hemisphere,

and with respect to the

north in the south-

ern

hemisphere. The inclination is

the angle formed by the

surface of the

module

and the horizontal

plane.

Azimuth

You

should have the module

turned towards the

terrestrial equator

(facing

south

in the northern hemisphere,

and north in the southern)

so that during

the

day the panel catches

the greatest possible amount

of radiation (a = 0).

It

is very important that no

part of the panels are

ever under shade!.

Study

the

elements that surround the

panel array (trees,

buildings, walls,

other

panels,

etc.) to be sure that they

will not cast a shadow on

the panels at any

time

of the day or year. It is

acceptable to turn the

panels �20� towards

the

east

or the west if needed (a =

�20�).

Inclination

Once

you have fixed

the azimuth, the parameter

that is key in our

calcula-

tions

is the inclination of the

panel, which we will express

as the angle beta

(�).

The maximum height that

the sun reaches every

day will vary, with

the

maximum

on the day of the summer

solstice and the minimum on

the winter

solstice.

Ideally, the panels should

track this variation, but

this is usually not

possible

for cost reasons.

In

installations with telecommunications

equipment it is normal to install

the

panels

at a fixed inclination. In most

telecommunications scenarios the

energy

demands

of the system are constant

throughout the year.

Providing for suffi-

cient

power during the "worst

month" will work well

for the rest of the

year.

The

value of � should maximize

the ratio between the

offer and the

demand

of

energy.

�

For installations with

consistent (or nearly consistent)

consumption through-

out

the year, it is preferable to

optimize the installation to

capture the maxi-

mum

radiation during "the

winter" months. You should

use the absolute

value

of

the latitude of the place

(angle F) increased by 10� (� = |

F |

+ 10

�).

�

For installations with less

consumptions during winter,

the value of the

lati-

tude

of the place can be used as

the solar panel inclination.

This way the

system

is optimized for the months

of spring and autumn (� = | F |).

�

For installations that are only used during summer,

you should use the absolute

value

of the latitude of the place

(angle F) decreased by 10� (� = | F

| -

10�).

The

inclination of the panel

should never be less than

15� to avoid the

accu-

mulation

of dust and/or humidity on

the panel. In areas where

snow and ice

238

Chapter

7: Solar Power

occur,

it is very important to protect

the panels and to incline

them an angle

of

65� or greater.

If

there is a considerable increase in consumption during

the summer, you

might

consider

arranging for two fixed inclinations, one

position for the months of

summer

and another for the months of

winter. This would require

special support

structures

and a regular schedule for

changing the position of the

panels.

How

to size your photovoltaic

system

When

choosing equipment to meet

your power needs, you

will need to de-

termine

the following, at a

minimum:

�

The number and type of

solar panels required to

capture enough solar

en-

ergy

to support your load.

�

The minimum capacity of the

battery. The battery will

need to store enough

energy

to provide power at night

and through days with

little sun, and

will

determine

your number of days of

autonomy.

�

The characteristics of all

other components (the

regulator, wiring,

etc.)

needed

to support the amount of

power generated and

stored.

System

sizing calculations are

important, because unless

the system com-

ponents

are balanced, energy (and

ultimately, money) is wasted.

For exam-

ple,

if we install more solar

panels to produce more

energy, the batteries

should

have enough capacity to

store the additional energy

produced. If the

bank

of batteries is too small

and the load is not

using the energy as it

is

generated,

then energy must be thrown

away. A regulator of a smaller

am-

perage

than needed, or one single

cable that is too small,

can be a cause of

failure

(or even fire)

and render the installation

unusable.

Never

forget that the ability of

the photovoltaic energy to

produce and store

electrical

energy is limited. Accidentally

leaving on a light bulb

during the

day

can easily drain your

reserves before nighttime, at

which point no addi-

tional

power will be available. The

availability of "fuel" for

photovoltaic sys-

tems

(i.e. solar radiation) can

be difficult to predict. In fact, it is

never possi-

ble

to be absolutely sure that a

standalone system is going to be

able to

provide

the necessary energy at any

particular moment. Solar

systems are

designed

for a certain consumption,

and if the user exceeds

the planned

limits

the provision of energy will

fail.

The

design method that we

propose consists of considering

the energy re-

quirements,

and based on them to

calculate a system that

works for the

maximum

amount of time so it is as reliable as

possible. Of course, if

more

Chapter

7: Solar Power

239

panels