|

Page

17 of 97

Chapter 6

-

Discussion centers on fiber optic

products that can be used to serve

serial data

communications.

Chapter 7

-

Standards that cover the

use of fiber optic data

links within premises

networks are

enumerated.

Organization from which they

can be ordered, in full, are

provided.

Chapter

8 -

A glossary that covers the

subject of fiber optic data

communications. It provides

terminology

specifically covered within

this book. However, it goes

further and provides

terminology

that

may not be used here but

may be encountered within a broader

view of the interest area or

within

communications

in general.

CHAPTER

2

THE

FIBER OPTIC DATA COMMUNICATIONS LINK FOR THE

PREMISES

ENVIRONMENT

2.1

The Fiber Optic Data

Communications Link,

End-to-End

In

this chapter we consider the

simple fiber optic data

link for the premises

environment. This is

the

basic

building block for a fiber

optic based network. A model

of this simple link is shown

in Figure 2-1.

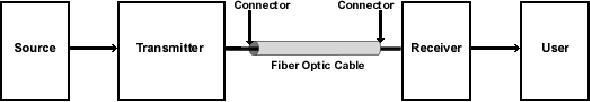

Figure

2-1: Model of "simple" fiber

optic data link

The

illustration indicates the

Source-User pair, Transmitter and

Receiver. It also clearly shows

the fiber

optic

cable constituting the Transmission

Medium as well as the

connectors that provide the

interface of

the

Transmitter to the Transmission

Medium and the Transmission

Medium to the

Receiver.

All

of these are components of

the simple fiber optic

data link. Each will be discussed.

Consideration

will

be in the following order:

fiber optic cable, Transmitter,

Receiver and connectors. We will

conclude

by

taking up the question of

how to analyze the

performance of the simple

fiber optic data

link.

2.2

Fiber Optic Cable

We

begin by asking Just what is a

fiber optic cable? A fiber

optic cable is a cylindrical pipe. It

may be

made

out of glass or plastic or a

combination of glass and plastic. It is

fabricated in such a way

that this

pipe

can guide light from one end of it to

the other.

The

idea of having light guided

through bent glass is not

new or high tech. The

author was once

Page

18 of 97

informed

that Leonardo DaVinci

actually mentioned such a

means for guiding light in

one of his

notebooks.

However, he has not been

able to verify this assertion. What is

known for certain is that

total

internal

reflection of light in a beam of

water - essentially guided

light - was demonstrated by the

physicist

John Tyndall [1820-1893] in

either 1854 or 1870 - depending upon

which reference you

consult.

Tyndall showed that light

could be bent around a

corner while it traveled

through a jet of

pouring

water.

Using

light for communications

came after this. Alexander

Graham Bell [1847-1922]

invented the

photo-phone

around 1880. Bell demonstrated

that a membrane in response to

sound could modulate

an

optical

signal, light. But, this was

a free space transmission

system. The light was not

guided.

Guided

optical communications had to wait

for the 20th century.

The first patent on guided

optical

communications

over glass was obtained by AT &T in

1934. However, at that time

there were really no

materials

to fabricate a glass (or

other type of transparent

material) fiber optic cable

with sufficiently

low

attenuation to make guided optical

communications practical. This had to

wait for about

thirty

years.

During

the 1960's researchers

working at a number of different

academic, industrial and

government

laboratories

obtained a much better

understanding of the loss mechanisms in

glass fiber optic

cable.

Between

1968 and 1970 the attenuation of glass

fiber optic cable dropped from

over 1000 dB/km to

less

than

20 dB/km. Corning patented its

fabrication process for the

cable. The continued decrease

in

attenuation

through the 1970's allowed

practical guided light

communications using glass

fiber optic

cable

to take off. In the late

1980's and 1990's this

momentum increased with the

even lower cost

plastic

fiber

optic cable and Plastic Clad

Silica (PCS).

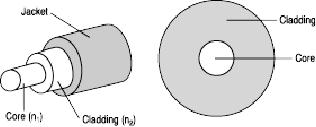

Basically,

a fiber optic cable is composed of

two concentric layers termed

the core and the

cladding.

These

are shown on the right

side of Figure 2-2. The core

and cladding have different

indices of

refraction

with the core having n1 and

the cladding n2.

Light is piped through the

core. A fiber optic

cable

has an additional coating

around the cladding called

the jacket. Core, cladding

and jacket are all

shown

in the three dimensional

view on the left side of

Figure 2-2. The jacket

usually consists of one or

more

layers of polymer. Its role

is to protect the core and cladding

from shocks that might

affect their

optical

or physical properties. It acts as a

shock absorber. The jacket also

provides protection

from

abrasions,

solvents and other contaminants.

The jacket does not

have any optical properties

that might

affect

the propagation of light

within the fiber optic

cable.

The

illustration on the left

side of Figure 2-2 is

somewhat simplistic. In actuality,

there may be a

strength

member added to the fiber

optic cable so that it can be pulled

during installation.

Figure

2-2: Fiber Optic Cable, 3

dimensional view and basic

cross section

Page

19 of 97

This

would be added just inside

the jacket. There may be a

buffer between the strength

member and the

cladding.

This protects the core and

cladding from damage and

allows the fiber optic cable

to be bundled

with

other fiber optic cables.

Neither of these is

shown.

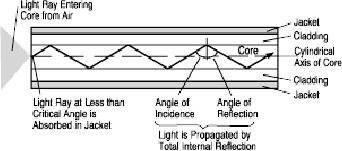

How

is light guided down the

fiber optic cable in the

core? This occurs because

the core and cladding

have

different indices of refraction

with the index of the

core, n1, always being greater than

the index of

the

cladding, n2. Figure 2-3 shows

how this is employed to

effect the propagation of

light down the

fiber

optic

cable and confine it to the

core.

As

illustrated a light ray is

injected into the fiber

optic cable on the right. If

the light ray is injected

and

strikes

the core-to-cladding interface at an

angle greater than an entity

called the critical angle

then it is

reflected

back into the core. Since

the angle of incidence is

always equal to the angle of

reflection the

reflected

light will again be reflected. The

light ray will then continue

this bouncing path down

the

length

of the fiber optic cable. If

the light ray strikes

the core-to-cladding interface at an

angle less than

the

critical angle then it

passes into the cladding

where it is attenuated very rapidly

with propagation

distance.

Light

can be guided down the fiber

optic cable if it enters at less than

the critical angle. This

angle is

fixed

by the indices of refraction of

the core and cladding and is given by

the formula:

Θc

= arc cosine (n2 /n1).

The

critical angle is measured

from the cylindrical axis of

the core. By way of example,

if n1 =

1.446

and

n2=

1.430 then a quick

computation will show that

the critical angle is 8.53

degrees, a fairly

small

angle.

Of

course, it must be noted that a

light ray enters the core

from the air outside, to

the left of Figure

2-3.

The

refractive index of the air

must be taken into account

in order to assure that a

light ray in the core

will

be at an angle less than the

critical angle. This can be done

fairly simply. The following

basic rule

then

applies. Suppose a light ray enters

the core from the air at an

angle less than an entity

called the

external

acceptance angle - Θext

It will be guided

down the core.

Here

Θext

= arc sin

[(n1/

n0) sin (Θc)]

with

n0 being the index of

refraction of air. This

angle is, likewise, measured

from the cylindrical axis

of

the

core. In the example above a

computation shows it to be 12.4

degrees - again a fairly small

angle.

Page

20 of 97

Figure

2-3: Propagation of a light

ray down a fiber optic

cable

Fiber

optic data link performance

is a subject that will be discussed in

full at the end of this

chapter.

However,

let's jump the gun

just a little. In considering

the performance of a fiber

optic data link

the

network

architect is interested in the

effect that the fiber

optic cable has on overall

link performance.

Consideration

of performance comes to answering

three questions:

1)

How much light can be

coupled into the core

through the external

acceptance angle?

2)

How much attenuation will a

light ray experience in propagating

down the core?

3)

How much time dispersion will

light rays representing the

same input pulse experience

in propagating

down

the core?

The

more light that can be

coupled into the core the

more light will reach the

Receiver and the lower

the

BER.

The lower the attenuation in

propagating down the core

the more light reaches

the Receiver and

the

lower the BER. The

less time dispersion

realized in propagating down

the core the faster

the

signaling

rate and the higher the

end-to-end data rate from

Source-to-User.

The

answers to these questions depend

upon many factors. The

major factors are the size

of the fiber, the

composition

of the fiber and the mode of

propagation.

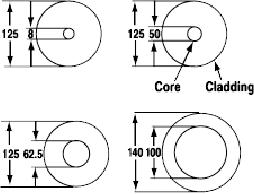

When

it comes to size, fiber

optic cables have

exceedingly small diameters. Figure

2-4 illustrates the

cross

sections of the core and cladding diameters of

four commonly used fiber

optic cables. The

diameter

sizes shown are in microns,

10-6 m. To get some feeling

for how small these

sizes actually are,

understand

that a human hair has a

diameter of 100 microns. Fiber

optic cable sizes are

usually

expressed

by first giving the core size

followed by the cladding size.

Consequently, 50/125 indicates

a

core

diameter of 50 microns and a cladding

diameter of 125 microns; 100/140

indicates a core diameter

of

100 microns and a cladding diameter of

140 microns. The larger the

core the more light can

be

coupled

into it from external

acceptance angle cone.

However, larger diameter

cores may actually

allow

too

much light in and too much

light may cause Receiver

saturation problems. The

left most cable

shown

in Figure 2-4, the 125/8

cable, is often found when a

fiber optic data link

operates with single-

mode

propagation. The cable that is

second from the right in

Figure 2-4, the 62.5/125

cable, is often

found

in a fiber optic data link

that operates with

multi-mode propagation.

Page

21 of 97

Figure

2-4: Typical core and

cladding diameters -Sizes

are in microns

When

it comes to composition or material

makeup fiber optic cables

are of three types: glass,

plastic and

Plastic

Clad Silica (PCS). These three candidate

types differ with respect to

attenuation and cost. We

will

describe these in detail.

Attenuation and cost will first be

mentioned only qualitatively.

Later,

toward

the end of this sub-chapter

the candidates will be compared

quantitatively.

By

the way, attenuation is

principally caused by two

physical effects, absorption and

scattering.

Absorption

removes signal energy in the

interaction between the

propagating light (photons)

and

molecules

in the core. Scattering

redirects light out of the

core to the cladding. When

attenuation for a

fiber

optic cable is dealt with

quantitatively it is referenced for

operation at a particular

optical

wavelength,

a window, where it is

minimized.

Glass

fiber optic cable has the

lowest attenuation and comes at

the highest cost. A pure

glass fiber optic

cable

has a glass core and a glass

cladding. This candidate has, by

far, the most wide

spread use. It has

been

the most popular with

link installers and it is the candidate

with which installers have

the most

experience.

The glass employed in a

fiber optic cable is ultra

pure, ultra transparent,

silicon dioxide or

fused

quartz. One reference put

this in perspective by noting that "if

seawater were as clear as

this type

of

fiber optic cable then you

would be able to see to the

bottom of the deepest trench

in the Pacific

Ocean."

During the glass fiber

optic cable fabrication process

impurities are purposely

added to the pure

glass

so as to obtain the desired

indices of refraction needed to

guide light. Germanium or

phosphorous

are

added to increase the index

of refraction. Boron or fluorine is

added to decrease the index

of

refraction.

Other impurities may somehow

remain in the glass cable

after fabrication. These

residual

impurities

may increase the attenuation

by either scattering or absorbing

light.

Plastic

fiber optic cable has the

highest attenuation, but

comes at the lowest cost.

Plastic fiber optic

cable

has

a plastic core and plastic cladding.

This fiber optic cable is

quite thick. Typical

dimensions are

480/500,

735/750 and 980/1000. The core

generally consists of PMMA

(polymethylmethacrylate)

coated

with a fluropolymer. Plastic

fiber optic cable was pioneered in Japan

principally for use in

the

automotive

industry. It is just beginning to

gain attention in the

premises data communications

market in

the

United States. The increased

interest is due to two reasons.

First, the higher

attenuation relative to

glass

may not be a serious obstacle with

the short cable runs often

required in premise networks.

Secondly,

the cost advantage sparks interest

when network architects are

faced with budget decisions.

Plastic

fiber optic cable does have

a problem with flammability.

Because of this, it may not

be

appropriate

for certain environments and

care has to be given when it

is run through a

plenum.

Otherwise,

plastic fiber is considered extremely

rugged with a tight bend

radius and the ability

to

Page

22 of 97

withstand

abuse.

Plastic

Clad Silica (PCS) fiber

optic cable has an attenuation

that lies between glass and

plastic and a

cost

that lies between their cost

as well. Plastic Clad Silica

(PCS) fiber optic cable has a

glass core

which

is often vitreous silica

while the cladding is

plastic - usually a silicone

elastomer with a

lower

refractive

index. In 1984 the IEC standardized

PCS fiber optic cable to

have the following

dimensions:

core

200 microns, silicone elastomer

cladding 380 microns, jacket 600

microns. PCS fabricated with

a

silicone

elastomer cladding suffers

from three major defects. It

has considerable plasticity. This

makes

connector

application difficult. Adhesive

bonding is not possible and it is

practically insoluble in

organic

solvents.

All of this makes this type

of fiber optic cable not

particularly popular with

link installers.

However,

there have been some

improvements in it in recent

years.

When

it comes to mode of propagation fiber

optic cable can be one of two types,

multi-mode or single-

mode.

These provide different performance

with respect to both

attenuation and time dispersion.

The

single-mode

fiber optic cable provides

the better performance at,

of course, a higher cost.

In

order to understand the

difference in these types an

explanation must be given of

what is meant by

mode

of propagation.

Light

has a dual nature and can be

viewed as either a wave

phenomenon or a particle

phenomenon

(photons).

For the present purposes

consider it as a wave. When

this wave is guided down a

fiber optic

cable

it exhibits certain modes. These

are variations in the

intensity of the light, both

over the cable cross

section

and down the cable length. These

modes are actually numbered

from lowest to highest. In a

very

simple

sense each of these modes

can be thought of as a ray of light.

Although, it should be noted

that

the

term ray of light is a hold

over from classical physics

and does not really describe

the true nature of

light.

In

any case, view the

modes as rays of light. For

a given fiber optic cable

the number of modes that

exist

depend

upon the dimensions of the

cable and the variation of the

indices of refraction of both core

and

cladding

across the cross section.

There are three principal

possibilities. These are illustrated in

Figure

2-5.

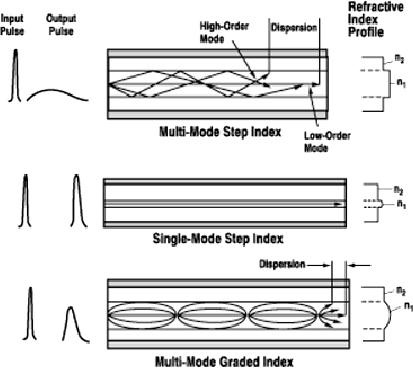

Consider

the top illustration in

Figure 2-5. This diagram

corresponds to multi-mode propagation

with a

refractive

index profile that is called

step index. As can be seen

the diameter of the core is

fairly large

relative

to the cladding. There is also a sharp

discontinuity in the index of

refraction as you go from

core

to

cladding. As a result, when

light enters the fiber optic

cable on the right it propagates

down toward

the

left in multiple rays or

multiple modes. This yields

the designation multi-mode. As

indicated the

lowest

order mode travels straight

down the center. It travels

along the cylindrical axis

of the core. The

higher

modes represented by rays,

bounce back and forth, going

down the cable to the left.

The higher

the

mode the more bounces per unit distance

down to the left.

Over

to the left of this top

illustration are shown a candidate

input pulse and the

resulting output

pulse.

Note

that the output pulse is

significantly attenuated relative to

the input pulse. It also

suffers significant

time

dispersion. The reasons for

this are as follows. The

higher order modes, the

bouncing rays, tend

to

leak

into the cladding as they

propagate down the fiber

optic cable. They lose some of

their energy into

heat.

This results in an attenuated

output signal. The input

pulse is split among the

different rays that

travel

down the fiber optic cable.

The bouncing rays and the

lowest order mode, traveling

down the

center

axis, are all traversing

paths of different lengths from

input to output. Consequently,

they do not

all

reach the right end of the

fiber optic cable at the

same time. When the

output pulse is

constructed

from

these separate ray

components the result is

time dispersion.

Page

23 of 97

Figure

2-5: Types of mode

propagation in fiber optic cable

(Courtesy of AMP

Incorporated)

Fiber

optic cable that exhibits

multi-mode propagation with a

step index profile is

thereby characterized

as

having higher attenuation and

more time dispersion than

the other propagation

candidates have.

However,

it is also the least costly and in the

premises environment the

most widely used. It is

especially

attractive

for link lengths up to 5 km.

Usually, it has a core diameter

that ranges from 100 microns

to

970

microns. It can be fabricated either

from glass, plastic or

PCS.

Consider

the middle illustration in

Figure 2-5. This diagram

corresponds to single-mode

propagation

with

a refractive index profile

that is called step index.

As can be seen the diameter of

the core is fairly

small

relative to the cladding.

Typically, the cladding is

ten times thicker than

the core. Because of

this

when

light enters the fiber optic

cable on the right it propagates

down toward the left in

just a single ray,

a

single-mode, and the lowest

order mode. In extremely

simple terms this lowest

order mode is confined

to

a thin cylinder around the

axis of the core. (In

actuality it is a little more

complex). The higher

order

modes

are absent. Consequently,

there is no energy lost to heat by

having these modes leak

into the

cladding.

They simply are not present.

All energy is confined to this

single, lowest order, mode.

Since

the

higher order mode energy is

not lost, attenuation is not

significant. Also, since the

input signal is

confined

to a single ray path, that

of the lowest order mode,

there is little time

dispersion, only that

due

to

propagation through the

non-zero diameter, single mode

cylinder.

Single

mode propagation exists only above a

certain specific wavelength

called the cutoff

wavelength.

To

the left of this middle

illustration is shown a candidate input

pulse and the resulting

output pulse.

Comparing

the output pulse and the

input pulse note that

there is little attenuation and

time dispersion.

Fiber

optic cable that exhibits

single-mode propagation is thereby

characterized as having

lower

Page

24 of 97

attenuation

and less time dispersion

than the other propagation

candidates have. Less time

dispersion of

course

means higher bandwidth and

this is in the 50 to 100 GHz/ km range.

However, single mode

fiber

optic

cable is also the most costly in

the premises environment.

For this reason, it has been

used more

with

Wide Area Networks than

with premises data

communications. It is attractive more

for link lengths

go

all the way up to 100 km.

Nonetheless, single-mode fiber

optic cable has been getting

increased

attention

as Local Area Networks have

been extended to greater distances

over corporate campuses.

The

core

diameter for this type of

fiber optic cable is exceedingly

small ranging from 5 microns

to 10

microns.

The standard cladding diameter is 125

microns.

Single-mode

fiber optic cable is fabricated

from glass. Because of the

thickness of the core,

plastic

cannot

be used to fabricate single-mode

fiber optic cable. The

author is unaware of PCS

being used to

fabricate

it.

It

should be noted that not

all single-mode fibers use a

step index profile. Some

use more complex

profiles

to optimize performance at a particular

wavelength.

Consider

the bottom illustration in

Figure 2-5. This corresponds to

multi-mode propagation with

a

refractive

index profile that is called

graded index. Here the

variation of the index of

refraction is

gradual

as it extends out from the

axis of the core through the

core to the cladding. There is no

sharp

discontinuity

in the indices of refraction

between core and cladding. The core here

is much larger than

in

the

single-mode step index case

discussed above. Multi-mode propagation

exists with a graded

index.

However,

as illustrated the paths of the

higher order modes are

somewhat confined. They

appear to

follow

a series of ellipses. Because

the higher mode paths are

confined the attenuation

through them due

to

leakage is more limited than

with a step index. The

time dispersion is more

limited than with a

step

index,

therefore, attenuation and time

dispersion are present, just

limited.

To

the left of this bottom

illustration is shown a candidate input

pulse and the resulting

output pulse.

When

comparing the output pulse

and the input pulse, note

that there is some

attenuation and time

dispersion,

but not nearly as great as

with multi-mode step index

fiber optic cable.

Fiber

optic cable that exhibits

multi-mode propagation with a

graded index profile is

thereby

characterized

as having attenuation and time

dispersion properties somewhere

between the other

two

candidates.

Likewise its cost is somewhere between

the other two candidates.

Popular graded index

fiber

optic

cables have core diameters of 50,

62.5 and 85 microns. They

have a cladding diameter of

125

microns

- the same as single-mode

fiber optic cables. This

type of fiber optic cable is

extremely popular

in

premise data communications applications.

In particular, the 62.5/125

fiber optic cable is the

most

popular

and most widely used in

these applications.

Glass

is generally used to fabricate

multi-mode graded index

fiber optic cable. However,

there has been

some

work at fabricating it with

plastic.

The

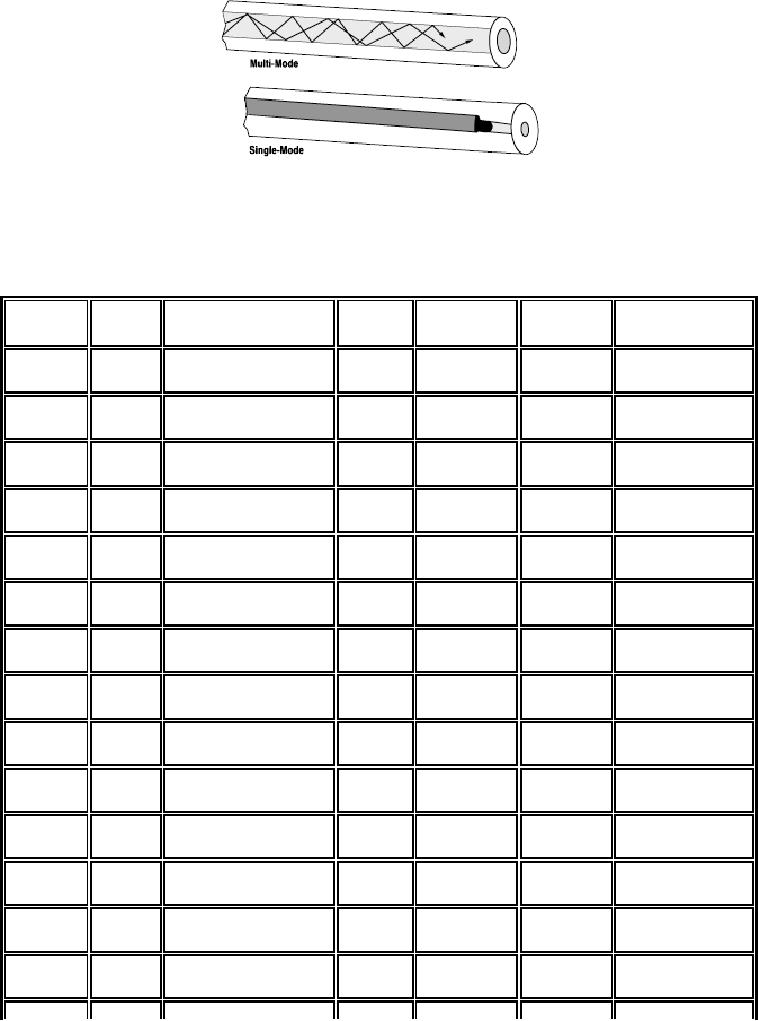

illustration Figure 2-6

provides a three dimensional

view of multi-mode and

single-mode

propagation

down a fiber optic cable.

Table 2-1 provides the

attenuation and bandwidth

characteristics

of

the different fiber optic

cable candidates. This table is far

from being all inclusive,

however, the

common

types are represented.

Page

25 of 97

Figure

2-6: Three dimensional view,

optical power in multi-mode

and single-mode

fibers

Index

of Refraction

Size

Atten.

Bandwidth

λ

Mode

Material

Profile

(microns)

dB/km

MHz/km

microns

Multi-

Glass

Step

800

62.5/125

5.0

6

mode

Multi-

Glass

Step

850

62.5/125

4.0

6

mode

Multi-

Glass

Graded

850

62.5/125

3.3

200

mode

Multi-

Glass

Graded

850

50/125

2.7

600

mode

Multi-

Glass

Graded

1300

62.5/125

0.9

800

mode

Multi-

Glass

Graded

1300

50/125

0.7

1500

mode

Multi-

Glass

Graded

850

85/125

2.8

200

mode

Multi-

Glass

Graded

1300

85/125

0.7

400

mode

Multi-

Glass

Graded

1550

85/125

0.4

500

mode

Multi-

Glass

Graded

850

100/140

3.5

300

mode

Multi-

Glass

Graded

1300

100/140

1.5

500

mode

Multi-

Glass

Graded

1550

100/140

0.9

500

mode

Multi-

Plastic

Step

650

485/500

240

5

@ 680

mode

Multi-

Plastic

Step

650

735/750

230

5

@ 680

mode

Page

26 of 97

Multi-

Plastic

Step

650

980/1000

220

5

@ 680

mode

Multi-

PCS

Step

790

200/350

10

20

mode

Single-

Glass

Step

650

3.7/80

or 125

10

600

mode

Single-

Glass

Step

850

5/80

or 125

2.3

1000

mode

Single-

Glass

Step

1300

9.3/125

0.5

*

mode

Single-

Glass

Step

1550

8.1/125

0.2

*

mode

*

Too high to measure accurately.

Effectively infinite.

Table

2-1: Attenuation and

Bandwidth characteristics of different

fiber optic cable

candidates

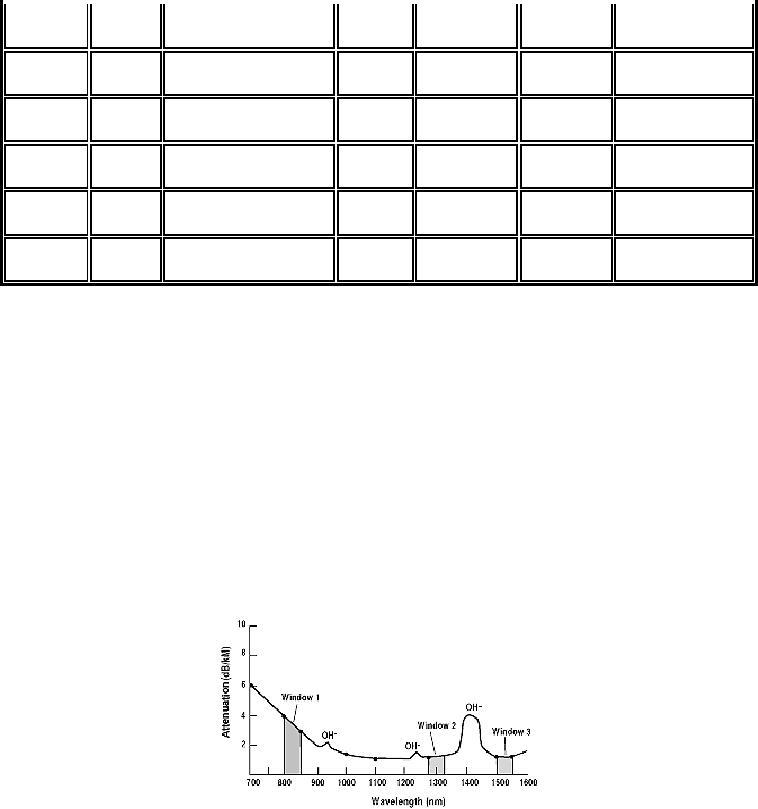

Figure

2-7 illustrates the

variation of attenuation with

wavelength taken over an ensemble of

fiber optic

cable

material types. The three

principal windows of operation,

propagation through a cable,

are

indicated.

These correspond to wavelength regions

where attenuation is low and

matched to the

ability

of

a Transmitter to generate light

efficiently and a Receiver to carry

out detection. The 'OH'

symbols

indicate

that at these particular

wavelengths the presence of

Hydroxyl radicals in the cable

material

cause

a bump up in attenuation. These radicals

result from the presence of

water. They enter the

fiber

optic

cable material through either a

chemical reaction in the

manufacturing process or as humidity

in

the

environment. The illustration

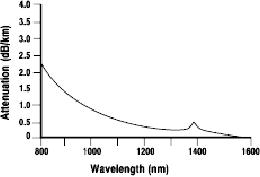

Figure 2-8 shows the

variation of attenuation with

wavelength for,

standard,

single-mode fiber optic

cable.

Figure

2-7: Attenuation vs.

Wavelength

Page

27 of 97

Figure

2-8: Attenuation spectrum of

standard single-mode

fiber

2.3

Transmitter

The

Transmitter component of Figure

2-1 serves two functions.

First, it must be a source of the

light

coupled

into the fiber optic cable.

Secondly, it must modulate

this light so as to represent the

binary data

that

it is receiving from the Source.

With the first of these

functions it is merely a light

emitter or a

source

of light. With the second of

these functions it is a valve,

generally operating by varying

the

intensity

of the light that it is

emitting and coupling into

the fiber.

Within

the context of interest in

this book the Source

provides the data to the

Transmitter as some

digital

electrical

signal. The Transmitter can

then be thought of as Electro-Optical

(EO) transducer.

First

some history. At the dawn of

fiber optic data

communications twenty-five years ago,

there was no

such

thing as a commercially available

Transmitter. The network

architect putting together a

fiber optic

data

link had to design the Transmitter

himself. Everything was

customized.

The

Transmitter was typically designed

using discrete electrical and

Electro-optical devices. This

very

quickly

gave way to designs based

upon hybrid modules

containing integrated circuits,

discrete

components

(resistors and capacitors) and optical source

diodes (light emitting

diodes-LED's or laser

diodes).

The modulation function was

generally performed using

separate integrated circuits

and

everything

was placed on the same printed

circuit board.

By

the 1980's higher and higher

data transmission speeds

were becoming of interest to

the data link

architect.

The design of the Transmitter

while still generally

customized became more

complex to

accommodate

these higher speeds. A greater

part of the Transmitter was

implemented using

VLSI

circuits

and attention was given to minimizing

the number of board interconnects.

Intense research

efforts

were undertaken to integrate

the optical source diode and the

transistor level circuits

needed for

modulation

on a common integrated circuit substrate,

without compromising performance. At

present,

the

Transmitter continues to be primarily

designed as a hybrid unit,

containing both discrete

components

and

integrated circuits in a single

package.

By

the late 1980's commercially

available Transmitter's became

available. As a result, the

link design

could

be kept separate from the

Transmitter design. The link

architect was relieved from

the need to do

high-speed

circuit design or to design proper bias

circuits for optical diodes.

The Transmitter could

generally

be looked at as a black box

selected to satisfy certain

requirements relative to

power,

wavelength,

data rate, bandwidth, etc.

This is where the situation

remains today.

Page

28 of 97

To

do a proper selection of a commercially

available Transmitter you

have to be able to know what

you

need

in order to match your other

link requirements. You have to be able to

understand the

differences

between

Transmitter candidates. There are

many. We can not begin to approach

this in total.

However,

we can look at this in a limited

way. Transmitter candidates can be

compared on the basis of

two

characteristics. Transmitter candidates

can be compared on the basis of the

optical source

component

employed and the method of

modulation.

Let

us deal with the optical source

component of the Transmitter

first. This has to meet a

number of

requirements.

These are delineated below:

First,

its physical dimensions must

be compatible with the size of

the fiber optic cable being

used. This

means

it must emit light in a cone

with cross sectional

diameter 8-100 microns, or it can

not be coupled

into

the fiber optic

cable.

Secondly,

the optical source must be able to

generate enough optical

power so that the desired

BER can

be

met.

Thirdly,

there should be high

efficiency in coupling the

light generated by the

optical source into

the

fiber

optic cable.

Fourthly,

the optical source should

have sufficient linearity to

prevent the generation of

harmonics and

intermodulation

distortion. If such interference is

generated it is extremely difficult to

remove. This

would

cancel the interference

resistance benefits of the

fiber optic cable.

Fifthly,

the optical source must be

easily modulated with an

electrical signal and must be

capable of

high-speed

modulation-or else the

bandwidth benefits of the

fiber optic cable are

lost.

Finally,

there are the usual

requirements of small size, low

weight, low cost and high

reliability. The

light

emitting junction diode stands

out as matching these

requirements. It can be modulated at

the

needed

speeds. The proper selection

of semiconductor materials and processing

techniques results in

high

optical power and efficient

coupling of it to the fiber

optic cable. These optical sources

are easily

manufactured

using standard integrated circuit

processing. This leads to low cost and

high reliability.

There

are two types of light

emitting junction diodes

that can be used as the

optical source of the

Transmitter.

These are the light emitting

diode (LED) and the laser diode (LD).

This is not the place

to

discuss

the physics of their

operation. LED's are simpler

and generate incoherent, lower

power, light.

LD's

are more complex and

generate coherent, higher

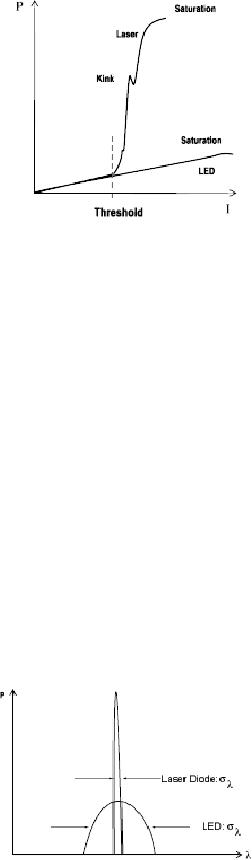

power light. Figure 2-9

illustrates the

optical

power

output, P, from each of

these devices as a function of the

electrical current input, I,

from the

modulation

circuitry. As the figure

indicates the LED has a

relatively linear P-I

characteristic while

the

LD

has a strong non-linearity or

threshold effect. The LD may

also be prone to kinks where

the power

actually

decreases with increasing

bandwidth.

With

minor exceptions, LDs have

advantages over LED's in the

following ways.

hey

can be modulated at very high

speeds.

T

They

produce greater optical

power.

They

have higher coupling

efficiency to the fiber

optic cable.

Page

29 of 97

LED's

have advantages over LD's

because they have

igher

reliability

h

better

linearity

lower

cost

Figure

2-9: LED and laser

diodes: P-I

characteristics

Both

the LED and LD generate an

optical beam with such

dimensions that it can be coupled

into a fiber

optic

cable. However, the LD produces an output

beam with much less

spatial width than an LED.

This

gives

it greater coupling efficiency. Each can be

modulated with a digital

electrical signal. For

very

high-speed

data rates the link

architect is generally driven to a

Transmitter having a LD.

When cost is a

major

issue the link architect is

generally driven to a Transmitter

having an LED.

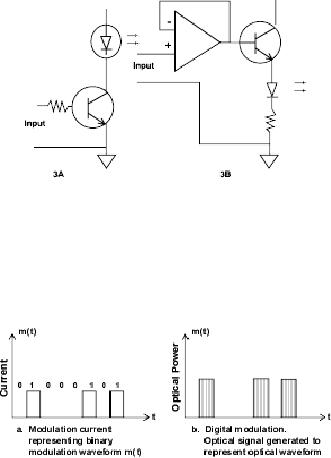

A

key difference in the

optical output of an LED and a LD is

the wavelength spread over

which the

optical

power is distributed. The

spectral width, σλ,

is the 3 dB optical power

width (measured in nm or

microns).

The spectral width impacts

the effective transmitted

signal bandwidth. A larger

spectral width

takes

up a larger portion of the

fiber optic cable link

bandwidth. Figure 2-10

illustrates the spectral

width

of

the two devices. The optical

power generated by each

device is the area under

the curve. The

spectral

width

is the half-power spread. A LD will

always have a smaller

spectral width than a LED.

The specific

value

of the spectral width

depends on the details of

the diode structure and the

semiconductor material.

However,

typical values for a LED

are around 40 nm for

operation at 850 nm and 80 nm at 1310

nm.

Typical

values for a LD are 1 nm for

operation at 850 nm and 3 nm at 1310

nm.

Page

30 of 97

Figure

2-10: LED and laser

spectral widths

Once

a Transmitter is selected on the

basis of being either an LED

or a LD additional concerns

should

be

considered in reviewing the

specifications of the candidates. These

concerns include

packaging,

environmental

sensitivity of device characteristics,

heat sinking and reliability.

With

either an LED or LD the

Transmitter package must

have a transparent window to

transmit light

into

the fiber optic cable. It

may be packaged with either

a fiber optic cable pigtail or

with a transparent

plastic

or glass window. Some

vendors supply the

Transmitter with a package

having a small

hemispherical

lens to help focus the

light into the fiber

optic cable.

Packaging

must also address the

thermal coupling for the

LED or LD. A complete

Transmitter module

may

consume over 1 W- significant

power consumption in a small

package. Attention has to be paid

to

the

heat sinking capabilities. Plastic

packages can be used for

lower speed and lower

reliability

applications.

However, for high speed and

high reliability look for

the Transmitter to be in a

metal

package

with built-in fins for heat

sinking.

Let

us now deal with the

modulator component of the

Transmitter.

There

are several different

schemes for carrying out

the modulation function. These

are respectively:

Intensity

Modulation, Frequency Shift

Keying, Phase Shift Keying

and Polarization Modulation.

Within

the

context of a premise fiber optic

data link the only one

really employed is Intensity

Modulation. This

is

the only one that will be

described.

Intensity

Modulation also is referred to as

Amplitude Shift Keying (ASK)

and On-Off Keying

(OOK).

This

is the simplest method for

modulating the carrier

generated by the optical source.

The resulting

modulated

optical carrier is given

by:

Es(t) = Eo

m(t)

cos ( 2�fst

)

Within

the context of a premises

fiber optic data link

the modulating signal m (t),

the Information,

assumes

only the values of '0' and

'1.' The parameter 'fs' is the optical carrier

frequency. This is an

incoherent

modulation scheme. This means

that the carrier does

not have to exhibit

stability. The

demodulation

function in the Receiver will

just be looking for the

presence or absence of energy

during

a

bit time interval.

Intensity

Modulation is employed universally

for premises fiber optic

data links because it is

well

matched

to the operation of both

LED's and LD's. The carrier

that each of these sources

produce is easy

to

modulate with this

technique. Passing current

through them operates both

of these devices. The

amount

of power that they radiate

(sometimes referred to as the

radiance) is proportional to this

current.

In

this way the optical

power takes the shape of

the input current. If the

input current is the

waveform m

(t)

representing the binary

information stream then the

resulting optical signal will

look like bursts of

optical

signal when m (t) represents

a '1' and the absence of

optical signal when m(t)

represents a '0.' The

situation

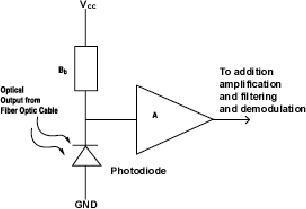

is illustrated in Figure 2-11 and

Figure 2-12. The first of

these figures shows the

essential

Page

31 of 97

Transmitter

circuitry for modulating

either an LED or LD with

Intensity Modulation. The

second of

these

figures illustrates the

input current representing

the Information and the

resulting optical

signal

generated

and provided to the fiber

optic cable.

Figure

2-11: Two methods for

modulating LEDs or

LDs

Figure

2-12: a. Input current

representing modulation waveform,

m(t); b. Output optical

signal representing m(t).

Vertical

cross

hatches indicate optical

carrier

It

must be noted that one

reason for the popularity of

Intensity Modulation is its

suitability for

operation

with

LED's. An LED can only

produce incoherent optical

power. Since Intensity Modulation

does not

require

coherence it can be used with an

LED.

2.4

Receiver

The

Receiver component of Figure

2-1 serves two functions.

First, it must sense or detect

the light

coupled

out of the fiber optic cable

then convert the light

into an electrical signal.

Secondly, it must

demodulate

this light to determine the

identity of the binary data

that it represents. In total, it must

detect

light

and then measure the

relevant Information bearing

light wave parameters in the

premises fiber

optic

data link context intensity

in order to retrieve the

Source's binary data.

Within

the realm of interest in

this book the fiber

optic cable provides the

data to the Receiver as

an

optical

signal. The Receiver then

translates it to its best estimates of

the binary data. It then

provides this

data

to the User in the form of

an electrical signal. The

Receiver can then be thought of as an

Electro-

Optical

(EO) transducer.

Page

32 of 97

A

Receiver is generally designed

with a Transmitter. Both are

modules within the same

package. The

very

heart of the Receiver is the

means for sensing the light

output of the fiber optic

cable. Light is

detected

and then converted to an electrical

signal. The demodulation

decision process is carried

out on

the

resulting electrical signal.

The light detection is

carried out by a photodiode.

This senses light and

converts

it into an electrical current.

However, the optical signal

from the fiber optic cable

and the

resulting

electrical current will have

small amplitudes. Consequently,

the photodiode circuitry

must be

followed

by one or more amplification stages.

There may even be filters

and equalizers to shape and

improve

the Information bearing

electrical signal.

All

of this active circuitry in

the Receiver presents a source of noise.

This is a source of noise whose

origin

is not the clean fiber

optic cable. Yet, this noise can

affect the demodulation

process.

The

very heart of the Receiver

is illustrated in Figure 2-13.

This shows a photodiode,

bias resistor and a

low

noise pre-amp. The output of

the pre-amp is an electrical

waveform version of the

original

Information

out the source. To the right

of this pre-amp would be

additional amplification, filters

and

equalizers.

All of these components may be on a

single integrated circuit,

hybrid or even a

printed

circuit

board.

Figure

2-13: Example of Receiver

block diagram - first

stage

The

complete Receiver may

incorporate a number of other

functions. If the data link

is supporting

synchronous

communications this will include

clock recovery. Other

functions may included

decoding

(e.g.

4B/5B encoded information),

error detection and

recovery.

The

complete Receiver must have

high detectability, high

bandwidth and low noise. It must

have high

detectability

so that it can detect low level

optical signals coming out

of the fiber optic cable.

The higher

the

sensitivity, the more attenuated

signals it can detect. It must have

high bandwidth or fast rise

time so

that

it can respond fast enough and

demodulate, high speed,

digital data. It must have

low noise so that it

does

not significantly impact the

BER of the link and counter

the interference resistance of

the fiber

optic

cable Transmission Medium.

There

are two types of photodiode

structures; Positive Intrinsic

Negative (PIN) and the

Avalanche Photo

Diode

(APD). In most premises

applications the PIN is the

preferred element in the

Receiver. This is

mainly

due to fact that it can be operated

from a standard power supply,

typically between 5 and 15 V.

Page

33 of 97

APD

devices have much better

sensitivity. In fact it has 5 to 10 dB

more sensitivity. They also

have

twice

the bandwidth. However, they

cannot be used on a 5V printed

circuit board. They also require

a

stable

power supply. This makes

cost higher. APD devices are

usually found in long

haul

communications

links.

The

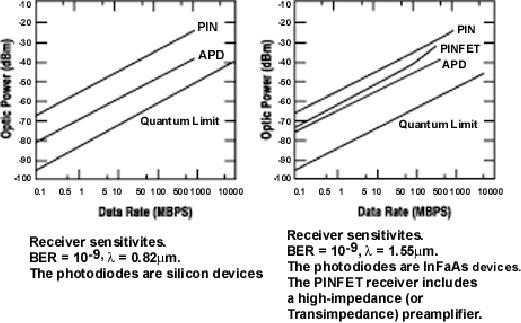

demodulation performance of the

Receiver is characterized by the

BER that it delivers to the

User.

This

is determined by the modulation

scheme - in premise applications -

Intensity modulation,

the

received

optical signal power, the

noise in the Receiver and the processing

bandwidth.

Considering

the Receiver performance is

generally characterized by a parameter

called the

sensitivity,

this

is usually a curve indicating

the minimum optical power

that the Receiver can detect

versus the data

rate,

in order to achieve a particular

BER. The sensitivity curve

varies from Receiver to

Receiver. It

subsumes

within it the signal-to-noise

ratio parameter that generally

drives all communications

link

performance.

The sensitivity depends upon

the type of photodiode

employed and the wavelength

of

operation.

Typical examples of sensitivity

curves are illustrated in

Figure 2-14.

In

examining the specification of

any Receiver you need to

look at the sensitivity

parameter. The curve

designated

Quantum Limit in Figure 2-14

is a reference. In a sense it represent

optimum performance on

the

part of the photodiode in

the Receiver. That is,

performance where there is

100% efficiency in

converting

light from the fiber

optic cable into an electric

current for

demodulation.

Figure

2-14: Receiver sensitivities

for BER = 10-9, with different

devices.

2.5

Connectors

The

Connector is a mechanical device

mounted on the end of a fiber

optic cable, light source,

Receiver

or

housing. It allows it to be mated to a

similar device. The

Transmitter provides the

Information bearing

light

to the fiber optic cable

through a connector. The

Receiver gets the

Information bearing light

from

the

fiber optic cable through a

connector. The connector

must direct light and

collect light. It must

also

Page

34 of 97

be

easily attached and detached from

equipment. This is a key

point. The connector is

disconnectable.

With

this feature it is different

than a splice which will be

discussed in the next

sub-chapter.

A

connector marks a place in the

premises fiber optic data

link where signal power can

be lost and the

BER

can be affected. It marks a place in the

premises fiber optic data

link where reliability can

be

affected

by a mechanical connection.

There

are many different connector

types. The ones for

glass fiber optic cable are

briefly described

below

and put in perspective. This is

followed by discussion of connectors

for plastic fiber optic

cable.

However,

it must be noted that the ST

connector is the most widely

used connector for premise

data

communications

Connectors

to be used with glass fiber

optic cable are listed below

in alphabetical order.

Biconic

- One of the earliest

connector types used in

fiber optic data links. It

has a tapered sleeve that

is

fixed

to the fiber optic cable.

When this plug is inserted

into its receptacle the

tapered end is a means

for

locating

the fiber optic cable in the

proper position. With this

connector, caps fit over

the ferrules, rest

against

guided rings and screw onto

the threaded sleeve to secure the

connection. This connector is

in

little

use today.

D4

- It is very similar to the FC

connector with its threaded

coupling, keying and PC end finish.

The

main

difference is its 2.0mm

diameter ferrule. Designed originally by

the Nippon Electric

Corp.

FC/PC

- Used for single-mode fiber

optic cable. It offers extremely

precise positioning of the

single-

mode

fiber optic cable with

respect to the Transmitter's

optical source emitter and the

Receiver's optical

detector.

It features a position locatable

notch and a threaded receptacle. Once

installed the position

is

maintained

with absolute

accuracy.

SC

- Used primarily with single-mode

fiber optic cables. It

offers low cost, simplicity

and durability. It

provides

for accurate alignment via

its ceramic ferrule. It is a

push on-pull off connector

with a locking

tab.

SMA

- The predecessor of the ST

connector. It features a threaded cap and

housing. The use of

this

connector

has decreased markedly in

recent years being replaced by ST and SC

connectors.

ST

- A keyed bayonet type

similar to a BNC connector. It is

used for both multi-mode and

single-mode

fiber

optic cables. Its use is

wide spread. It has the

ability both to be inserted

into and removed from

a

fiber

optic cable both quickly and

easily. Method of location is also easy.

There are two versions ST

and

ST-II.

These are keyed and spring loaded.

They are push-in and twist

types.

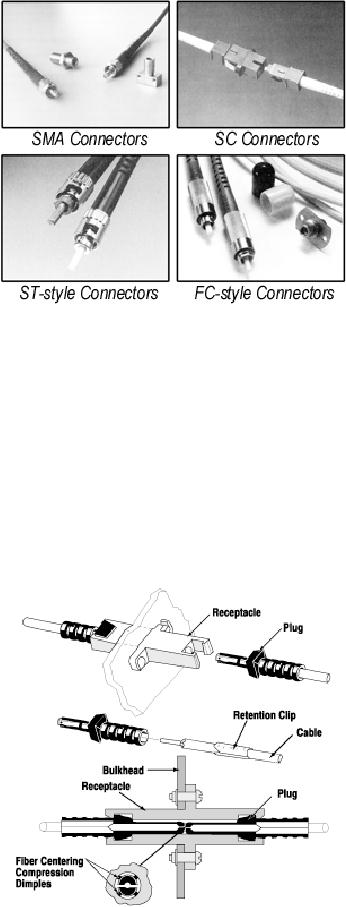

Photographs

of several of these connectors

are provided in Figure

2-15.

Page

35 of 97

Figure

2-15: Common connectors for

glass fiber optic cable

(Courtesy of AMP

Incorporated)

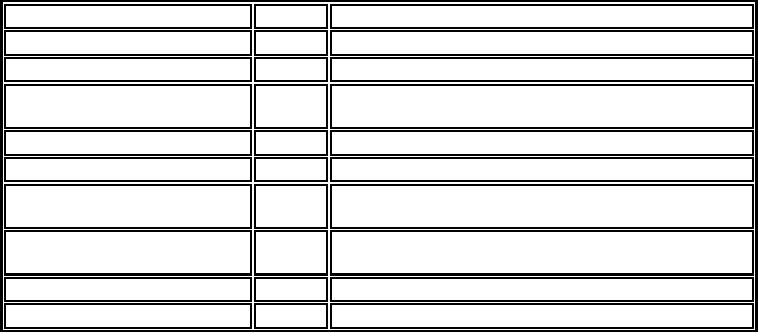

Plastic

Fiber Optic Cable Connectors -

Connectors that are

exclusively used for plastic

fiber optic cable

stress

very low cost and easy

application. Often used in

applications with no polishing or

epoxy. Figure

2-16

illustrates such a connector.

Connectors for plastic fiber

optic cable include both

proprietary

designs

and standard designs. Connectors used for

glass fiber optic cable,

such as ST or SMA are

also

available

for use with plastic

fiber optic cable. As plastic

fiber optic cable gains in popularity in

the data

communications

world there will be undoubtedly greater

standardization.

Figure

2-16: Plastic fiber optic

cable connector (Illustration courtesy of

AMP Incorporated)

Page

36 of 97

2.6

Splicing

A

splice is a device to connect one

fiber optic cable to another

permanently. It is the attribute

of

permanence

that distinguishes a splice

from connectors. Nonetheless,

some vendors offer splices

that

can

be disconnected that are not

permanent so that they can be

disconnected for repairs or

rearrangements.

The terminology can get

confusing.

Fiber

optic cables may have to be

spliced together for any of

a number of reasons.

One

reason is to realize a link of a

particular length. The

network installer may have

in his inventory

several

fiber optic cables but,

none long enough to satisfy

the required link length.

This may easily

arise

since

cable manufacturers offer cables in

limited lengths - usually 1 to 6

km. If a link of 10 km has to

be

installed

this can be done by splicing several

together. The installer may

then satisfy the

distance

requirement

and not have to buy a new

fiber optic cable.

Splices

may be required at building entrances,

wiring closets, couplers and literally

any intermediary

point

between Transmitter and

Receiver.

At

first glance you may

think that splicing two

fiber optic cables together

is like connecting two

wires.

To

the contrary, the

requirements for a fiber-optic

connection and a wire connection

are very different.

Two

copper connectors can be joined by solder

or by connectors that have

been crimped or soldered to

the

wires. The purpose is to create an

intimate contact between the

mated halves in order to have a

low

resistance

path across a junction. On

the other hand, connecting

two fiber optic cables

requires precise

alignment

of the mated fiber cores or

spots in a single-mode fiber

optic cable. This is demanded so

that

nearly

all of the light is coupled

from one fiber optic cable

across a junction to the

other fiber optic

cable.

Actual contact between the

fiber optic cables is not

even mandatory. The need

for precise

alignment

creates a challenge to a designer of a

splice.

There

are two principal types of

splices: fusion and

mechanical.

Fusion

splices - uses an electric arc to weld

two fiber optic cables

together. The splices

offer

sophisticated,

computer controlled alignment of

fiber optic cables to

achieve losses as low as

0.05 dB.

This

comes at a high cost.

Mechanical-splices

all share common elements.

They are easily applied in

the field, require little or

no

tooling

and offer losses of about

0.2 dB.

2.7

Analyzing Performance of a

Link

You

have a tentative design for a

fiber optic data link of

the type that is being

dealt with in this

chapter,

the

type illustrated in Figure

2-1. You want to know

whether this tentative design will

satisfy your

performance

requirements.

You

characterize your performance

requirements by BER. This

generally depends upon the

specific

Source-User

application. This could be as

high as 10-3 for applications like

digitized voice or as low

as

10-10 for

scientific data. The

tendency though has been to

require lower and lower

BERs.

The

question then is will the

tentative fiber optic link

design provide the required

BER? The answer to

Page

37 of 97

this

question hinges on the

sensitivity of the Receiver

that you have chosen for

your fiber optic data

link

design.

This indicates how much

received optical power must

appear at the Receiver in

order to deliver

the

required BER.

To

determine whether your

tentative fiber optic link

design can meet the sensitivity you

must analyze it.

You

must determine how much

power does reach the

Receiver. This is done with a

fiber optic data

link

power

budget.

A

power budget for a

particular example is presented in

Table 2-2 below and is then

discussed. This

example

corresponds to the design of a fiber

optic data link with

the following

attributes:

1.

Data

Rate of 50 MBPS.

2.

BER

of 10-9.

3.

Link

length of 5 km (premises distances).

4.

Multi-mode,

step index, glass fiber

optic cable having dimensions

62.5/125.Transmitter uses

LED

at

850 nm.

5.

Receiver uses PIN and has

sensitivity of -40 dBm at 50

MBPS.

6.

Fiber optic cable has 1

splice.

LINK

ELEMENT

VALUE

COMMENTS

Transmitter

LED output power 3

dBm

Specified

value by vendor

Source

coupling loss

-5

dB

Accounts

for reflections, area

mismatch etc.

Transmitter

to fiber optic cable

Transmitter

to fiber optic cable with ST

connector. Loss

-1

dB

connector

loss

accounts

for misalignment

Splice

loss

-0.25

dB

Mechanical

splice

Fiber

Optic Cable Attenuation

-20

dB

Line

2 of Table 2-1 applied to 5

km

Fiber

optic cable to receiver

Fiber

optic cable to Receiver with ST

connector. Loss

-1

dB

connector

loss

Accounts

for misalignment

Optical

Power Delivered at

-24.25

Receiver

dB

Receiver

Sensitivity

-40

dBm

Specified

in link design. Consistent with

Figure 2-14

LOSS

MARGIN

15.75

dB

Table

2-2: Example Power Budget

for a fiber optic data

link

The

entries in Table 2-2 are

more or less self-explanatory.

Clearly, the optical power

at the Receiver is

greater

than that required by the

sensitivity of the PIN to

give the required BER.

What is important to

note

is the entry termed Loss

Margin? This specifies the

amount by which the received

optical power

exceeds

the required sensitivity. In

this example it is 15.75 dB.

Good design practice requires it to be

at

least

10 dB. Why? Because no

matter how careful the

power budget is put

together, entries are

always

forgotten,

are too optimistic or vendor

specifications are not

accurate.

CHAPTER

3

EXPLOITING

THE BANDWIDTH OF FIBER OPTIC CABLE-

Table of Contents:

- Introduction:The Fundamental Problem of Communication, Program

- The Fiber Optic Data Communications Link For the Premises Environment:Fiber Optic Cable

- Exploiting The Bandwidth Of Fiber Optic Cable-Employment by Multiple Users:Sharing the Transmission Medium

- Exploiting The Delay Properties Of Fiber Optic Cable For LAN Extension:Brief History of Local Area Networks

- Exploiting The Advantages Of Fiber Optic Cable In the Industrial Environment:The Problem of Interference

- Serial Data Communications Over Fiber Optic Cable

- Standards

- Glossary