|

VU

Information

System (CS507)

LESSON

42

Supply

Chain Management

Introduction

The

business in the globalization

age is more about enhanced

efficiencies, increased

productivity

resulting

in lower costs of production,

quick and effective decision

making increased outreach

and

customer/client satisfaction and sharing knowledge

across institutions. This

enables a

business

to become a more effective player in

the free and extremely

competitive global market.

Globalization

encompasses the concept of moving

beyond the geographical

boundaries of a

country

and using technological advances to

maximum advantage for the

business. The

internet

and

Web technologies have brought

new dimensions to doing and

managing business. E-

Commerce

we have talked about. Obviously every

business has some inherent

risks. So does E-

Commerce.

For example, privacy, legality,

taxation are issues that

pose a challenge for a good

E-

business

environment although measures

both legislative and operational

have been taken and

continue

to be devised. As far as Management

Information Systems for

businesses are

concerned

these too have undergone a

major change particularly

with the availability of

Internet.

Gone are the days of

the stand alone systems

which looked at each aspect of

the

business

separately. Today we are

talking of end to end

solutions for businesses. In

other words

business

imperatives have driven us to re-define

the scope of the coverage/

extant of

management

information systems. The

Buzzword for some time

now is " ENTERPRISE

RESOURCE

PLANNING." (ERP).

The

stand alone systems scope

required a singular approach to each

aspect of the

business.

Why?

Perhaps at that time the

security issues could not be handled in

any other way. Perhaps it

was

much cheaper to employ

people to consolidate and produce

MIS for all aspects,

time taken

being

of little or no consequence. Perhaps

this is what technology allowed

us. Packaged or

customized software

was now available. We move

on and find ourselves with

an enhanced

scope

which requires all aspects

of the business to be integrated. This

meant that

issues/transactions

of each department which had

always impacted other departments

had to be

integrated in such

fashion that the resulting

MIS was complete in all

respects. Thus was laid

the

foundation

of the Customized Integrated software

development and packages.

The use of the

web

and internet expanded the

scope further requiring on

line transfer of data and

real time

functionalities.

This

lead to a further increase in

the scope where we started demanding an

analysis of the data

as an integral

part of the software used by a

business regardless of its size. It

also created a new

demand

for bringing the entire

supply chain into the

perspective as well as the Consumer.

The

result

of the enhancement of scope lead to

the Customized integrated software

approach

becoming an

Enterprise Resource Management Software of

which MIS was an integral

part.

Since

then we have re-defined the

scope to include Planning, Supply Chain

and Customers

resulting

in what is today referred to as the ERP. Certain

software developers around the

world

then

decided to produce generic versions of ERP

for various industries which could be

installed

straight

off without having to spend

time on the development

process of a customized

integrated

software. Obviously the generic versions

required that your business

systems and

processes

must be aligned exactly in accordance

with its design. This gave

rise to the concept of

BPR.

The versions were too

expensive to be modified and it

was deemed that it would

be

cheaper

to re-align the business

processes.

181

VU

Information

System (CS507)

BPR

was not simply of

redesigning certain input forms

but involved changed

practices of

working.

It involved change in human

thought and approaches to

their routine, mundane

tasks.

This

raised issues of Change Management.

Since the ERP generic models

need to be

implemented

this work is also required to be

undertaken and involves

training of the staff

and

transfer/conversion

of data in the legacy

system. Thus it is not a

simple straight

forward

proposition

but involves detailed and

phased approach towards successful

implementation at

considerable

cost. The ERP approach,

essentially meant for a highly

computerized Society,

assumes

that for it to be used from

one end of the business to

the other everyone is connected

and

uses computers. Therein lies a

major challenge to make such a

system a success in a

developing

country, like Pakistan, and

raises questions in terms of financial

viability and

suitability.

Perhaps it is time to go back

and look at the integrated

approach.

42.1

Integrating systems

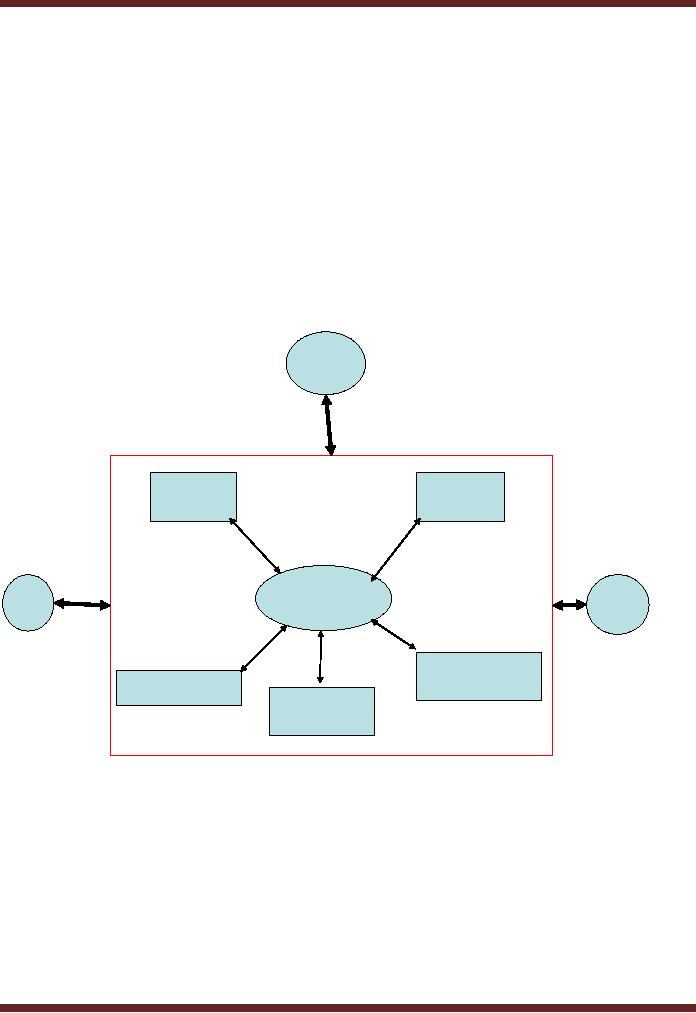

Let's

take a look what an

integrated information system

looks like.

Users

Financial

Marketing

Information

Information

System

System

Integrated

Information

Suppliers

Customers

system

Information

Resource

Human

Resource

Information

System

Information

System

Manufacturing

Information

System

As

seen in the above picture

all systems are interfaced

with one another, the input

in one system

automatically

updating the data in the

other relevant system. We

thus observe simultaneous

Data sharing

between various systems and simultaneous

execution of different

business

processes.

For Example, a confirmed

sales order received by the

sales department from

the

customer

will once entered into

the sales system

automatically provide data

input to

stores/packing/

shipping and possibly the production

systems. Thus ensuring that

all relevant

departments

are notified of ready for

necessary action

simultaneously.

42.2

Methods of integration

Information

systems can be integrated in the

following ways.

� Connect

Existing modules/system

182

VU

Information

System (CS507)

�

Use

Supply Chain Management (SCM) Software

�

Use

ERP Software

Connect

Existing Modules/system

The

basic concept is to maximize the use of

existing systems and minimize

the changes in them.

Good

integration allows the addition of

new applications to existing ones and

the connection of

systems

to intranets and the

internet. This approach

extends the life of applications

and saves

tremendous

amounts of money. However,

connecting existing system may be

difficult and

expensive

in many cases. Old systems

were built and developed

over a number of

years

encompassing

technologies and platforms of various

specifications.

42.3

Using

SCM Software

Supply chain

management (SCM) is the

process of planning, implementing,

and controlling the

operations of

the supply chain with the

purpose to satisfy customer requirements as

efficiently

as

possible. Supply chain management spans

all movement and storage of

raw materials, work-

in-process

inventory, and finished

goods from point-of-origin to

point-of-consumption. In

literal

terms, supply chain refers to the

flow of materials from their

sources (suppliers) to the

company

and then inside the

company for processing.

Today the concept is much

broader,

including

flow of materials, information, payments,

and services from suppliers

to factories and

warehouses

to end customers. This reduces

uncertainty and risks in the

supply chain thereby

positively

affecting inventory levels,

cycle time, business

processes.

42.4

Components

of Supply Chain

The

concept of supply chain can be divided

into three major

parts.

�

Upstream

supply chain segment includes the

organization's first-tier

suppliers

(manufacturers

and assemblers). The major

activities are purchasing and

shipping.

�

Internal

supply chain segment includes all

the processes to transform

inputs to outputs.

�

Downstream

supply chain segment includes

distributing, delivering to customer and

final

consumption

of the product.

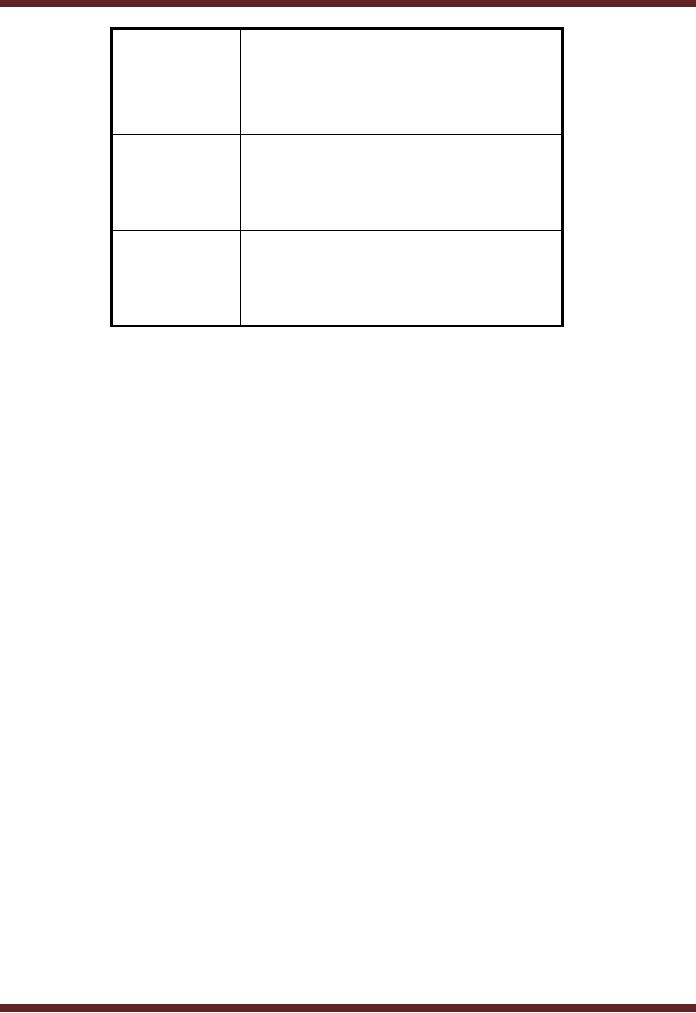

Example

For a

car manufacturer industry

the above three segments

can be shown as

follows.

183

VU

Information

System (CS507)

Upstream

Vendors to

the manufacturers.

Segment

Sub-

Vendors or Suppliers to

the

Vendors or

Suppliers to the

manufacturer.

Internal

Manufacturing

plants, Assembly

Segment

plants,

Packaging, warehouses,

dealers.

Downstream

Banks, transportation

companies,

Segment

distributors,

wholesalers, retailers.

42.5

Types of

Supply Chains

Supply chain

may exist in various forms depending on

the need of the

business:

1.

Made to Store Focuses on

tracking customer demand in real

time, so that the

production

process

can restock the finished

goods inventory.

2.

Continuous Replenishment focuses on

constant replacement of inventory by

working

closely

with suppliers. Applicable to

environments with stable

demand patterns.

3.

Built to order Focuses on

careful management of component

inventories and delivery

of

needed

supplies along the supply chain. A

solution to this potential

inventory problem is to

utilize

many common components

across several production

lines and in several

locations.

Challenges

to supply chains

There

are usually two major

sources of challenges to supply

chains.

1. The

uncertainties faced

a.

Demand forecast

b.

Competition

c. Weather

conditions

d.

Technological development

2. The

need to coordinate several

activities

a.

Business partners are

misunderstood

b.

Departments are not well

connected

184

Table of Contents:

- Need for information, Sources of Information: Primary, Secondary, Tertiary Sources

- Data vs. Information, Information Quality Checklist

- Size of the Organization and Information Requirements

- Hierarchical organization, Organizational Structure, Culture of the Organization

- Elements of Environment: Legal, Economic, Social, Technological, Corporate social responsibility, Ethics

- Manual Vs Computerised Information Systems, Emerging Digital Firms

- Open-Loop System, Closed Loop System, Open Systems, Closed Systems, Level of Planning

- Components of a system, Types of Systems, Attributes of an IS/CBIS

- Infrastructure: Transaction Processing System, Management Information System

- Support Systems: Office Automation Systems, Decision Support Systems, Types of DSS

- Data Mart: Online Analytical Processing (OLAP), Types of Models Used in DSS

- Organizational Information Systems, Marketing Information Systems, Key CRM Tasks

- Manufacturing Information System, Inventory Sub System, Production Sub System, Quality Sub system

- Accounting & Financial Information Systems, Human Resource Information Systems

- Decision Making: Types of Problems, Type of Decisions

- Phases of decision-making: Intelligence Phase, Design Phase, Choice Phase, Implementation Phase

- Planning for System Development: Models Used for and Types of System Development Life-Cycle

- Project lifecycle vs. SDLC, Costs of Proposed System, Classic lifecycle Model

- Entity Relationship Diagram (ERD), Design of the information flow, data base, User Interface

- Incremental Model: Evaluation, Incremental vs. Iterative

- Spiral Model: Determine Objectives, Alternatives and Constraints, Prototyping

- System Analysis: Systems Analyst, System Design, Designing user interface

- System Analysis & Design Methods, Structured Analysis and Design, Flow Chart

- Symbols used for flow charts: Good Practices, Data Flow Diagram

- Rules for DFD’s: Entity Relationship Diagram

- Symbols: Object-Orientation, Object Oriented Analysis

- Object Oriented Analysis and Design: Object, Classes, Inheritance, Encapsulation, Polymorphism

- Critical Success Factors (CSF): CSF vs. Key Performance Indicator, Centralized vs. Distributed Processing

- Security of Information System: Security Issues, Objective, Scope, Policy, Program

- Threat Identification: Types of Threats, Control Analysis, Impact analysis, Occurrence of threat

- Control Adjustment: cost effective Security, Roles & Responsibility, Report Preparation

- Physical vs. Logical access, Viruses, Sources of Transmissions, Technical controls

- Antivirus software: Scanners, Active monitors, Behavior blockers, Logical intrusion, Best Password practices, Firewall

- Types of Controls: Access Controls, Cryptography, Biometrics

- Audit trails and logs: Audit trails and types of errors, IS audit, Parameters of IS audit

- Risk Management: Phases, focal Point, System Characterization, Vulnerability Assessment

- Control Analysis: Likelihood Determination, Impact Analysis, Risk Determination, Results Documentation

- Risk Management: Business Continuity Planning, Components, Phases of BCP, Business Impact Analysis (BIA)

- Web Security: Passive attacks, Active Attacks, Methods to avoid internet attacks

- Internet Security Controls, Firewall Security SystemsIntrusion Detection Systems, Components of IDS, Digital Certificates

- Commerce vs. E-Business, Business to Consumer (B2C), Electronic Data Interchange (EDI), E-Government

- Supply Chain Management: Integrating systems, Methods, Using SCM Software

- Using ERP Software, Evolution of ERP, Business Objectives and IT

- ERP & E-commerce, ERP & CRM, ERP– Ownership and sponsor ship

- Ethics in IS: Threats to Privacy, Electronic Surveillance, Data Profiling, TRIPS, Workplace Monitoring