|

VU

Information

System (CS507)

LESSON

13

Organizational

Structure

Departments

are structured based on the

set of related responsibilities.

The set of responsibilities being

discharged

set the tone and structure

of that department. The complexity

and diversity of these

responsibilities

also affect how departments

are set in an organization.

Existence

of Functional departments in every

organization vary with the nature of industry

and the nature

of

products/services being offered

Certain

departments may not exist in

an organization, for instance financial

sector (banking, leasing

companies)

and travel agencies do not incorporate

the concept of manufacturing as they belong to

the

services

sector.

Let's

take a look at different

departments in different industry

segments in order to better understand

the

concept.

13.1

Financial Sector

The

departmental structures are

different in banking and financial

sector. This in turn becomes the

basis of

design

and development of functional information

systems. Banks commonly have

following departments

o Treasury

o Advances

o Trade

Finance

o Corporate

Finance

o Consumer

Banking

o Deposits

o Customer

Services

o Lease

o Credit

Card

o Debit

card

o Operations

Requirements

of Information Systems and

procedures of financial analysts,

investment houses, brokerage

houses,

leasing companies will

depend on their differing

functions and needs.

13.2

Air Line Industry

Various

departments may be

�

Flight

Operations department

o Flight

scheduling department

o Cockpit

crew department

o Cabin

Crew department

�

Engineering

department engine

maintenance

�

Ground

Support air craft handling department

�

Catering

�

Internal

audit

47

VU

Information

System (CS507)

�

Accounts &

Finance

�

Sales

ticketing, E-ticketing,

agents

�

Marketing

�

Store

engines, maintenance and repair

accessories

These

departments and their needs

determine the design of information

systems they require.

As

shown in the above two

examples, the constitution of departments

in both banking institutions

and air

travel industry

vary to a large extent.

13.3

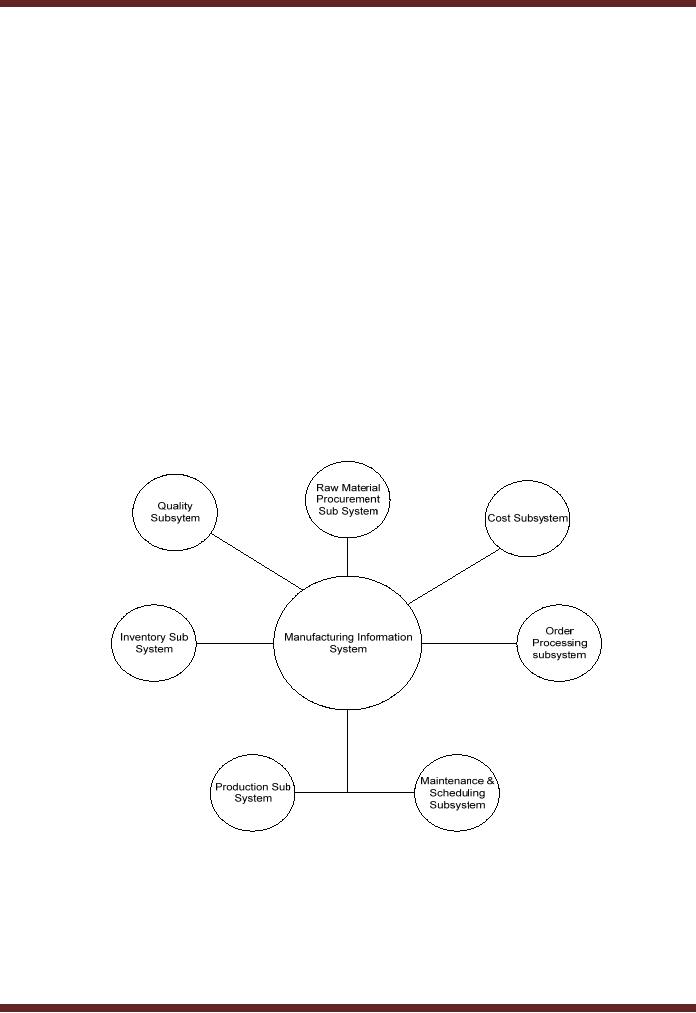

Manufacturing Information

System

The

information needs were and

are always there.

Information systems used to

exist when computerised

environments

were not available.

Automation has enhanced the

availability of information.

Every

industry has its own

departmental structure which

gives rise to a different

set of sub-systems as

part

of the

information system. Here we

would consider the sub-systems of a

manufacturing system only.

Following

are the sub-systems of an information

system.

Raw

Material Procurement

Sub-System

This is the

commencement of the manufacturing process.

Some might think of procurement as a

simple

purchasing

process like any other

commodity but the spirit of having an

all-embracing raw

material

procurement

sub-system is simply more

than that.

48

VU

Information

System (CS507)

Parameters

of Raw-material Procurement

Like

with every system, there

has to be a list of minimum

specifications which every

system or subsystem

has to

cover. Purchasing logistics of an

entity critically affect time to market

and other quality

related

issues.

Issues like selection of

suppliers, choice between

local purchase or import and

delivery time taken

by the supplier.

All these concerns are

met and dealt with in the

purchase subsystem. The

complexity of

the

purchase subsystem should depend on

types of raw materials required, number

of suppliers to deal

with

and complexity of the terms of

purchase agreements for long

term.

With

higher customer expectations, every

organization wants to efficiently manage

its suppliers and

other

internal

processes. Supply chain

management spans all movement

and storage of raw

materials, work-in-

process

inventory, and finished

goods from point-of-origin to

point-of-consumption. A procurement

system

should help in improving the supply chain

of the organization.

13.4

Inventory Sub System

Inventory

subsystem focuses on maintaining records

and movements on inventory

levels and usage.

This

control

of inventory is critical to the organization since

money lock-in of raw

materials purchase

represents

substantial

investment. Timely production of finished

goods require availability of right

quantity of material,

maintenance

of right stock levels,

determination of lead times

and flex times and

exchange of information

with

supplier at the right time. An inventory

subsystem helps us to address

these issues.

Inventory

subsystems

are critical where the organization is

following Just in Time

approach a philosophy

which

encourages

zero tolerance for stock

levels and placing orders

exactly when they are needed

for

manufacturing.

Proper logistic

management is important for the

timely and quality

production. Various factors which

can

play critical

role are

� Who

to purchase from supplier

selection

�

When

to purchase time of delivery or raw

materials

�

How

much to purchase Ideal

stock levels

�

An

efficient inventory subsystem

helps us to deal with these

issues in a time saving

manner.

13.5

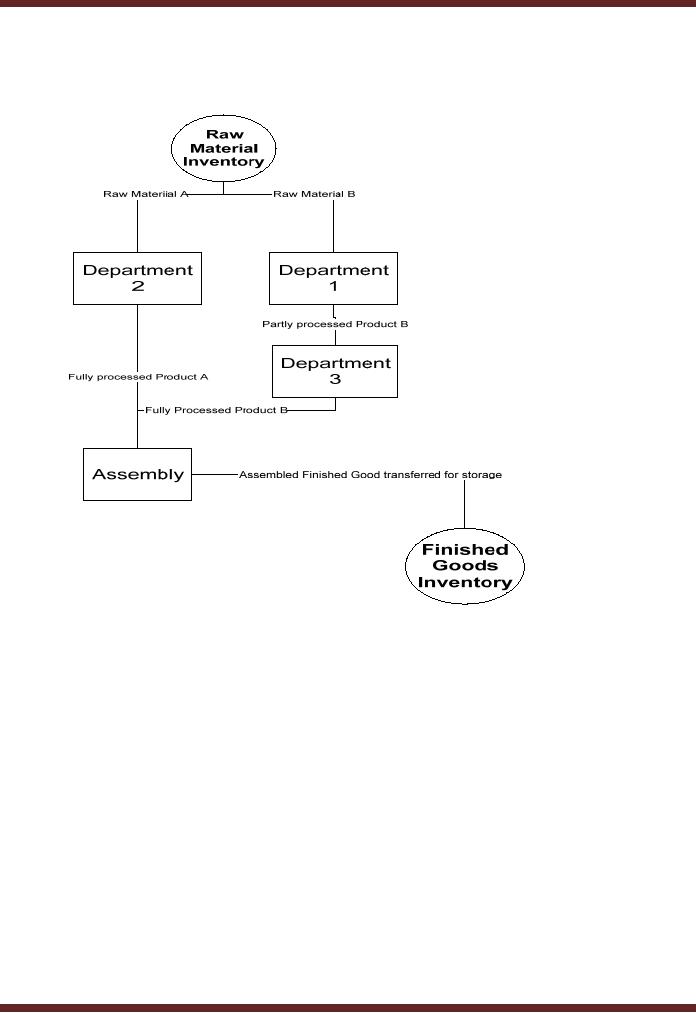

Production Sub System

It can

be seen as the most critical part of the

entire manufacturing sub system.

Basically it tracks the flow

of

the

job through the entire production

process. It also records

change in form of goods or

transfer of goods

from

one place to the

other.

Example

Consider

a manufacturing entity working with

three processing departments

and one assembly

department.

As raw

materials pass through the

processes, the sub system

records the relevant information at

specific

points

or locations until the finished goods

are transferred to stock

room.

49

VU

Information

System (CS507)

13.6

Maintenance & Scheduling Sub

System

For

efficient production, the machines should

be timely available. Many a

times, the machine is under repair

and is

not available to be used for

production. Without this subsystem,

there is a possibility of

customer's

orders

not being met on time. Certain issues

that can be very important

are

�

Deciding

delivery time in accordance with

availability of machines.

�

Any

foreseen machine-down-time.

�

Any

major overhauling / tuning / replacement

expected may result in

unavailability of machine. An

overhauling

schedule should be kept so that the

production of finished goods is

not halted.

�

Avoiding

duplication of jobs for the

same machine.

13.7

Quality Sub

system

This

subsystem ensures the production

made and end product being

delivered to the customer are

conforming

the quality standards set by the

company. Quality covers

aspects for the organization like

better

quality

raw materials and what is being

purchased is according to organization's

standards and

improved

finished

goods in accordance with the

customer specification.

50

VU

Information

System (CS507)

The

question now arises is why do we

need a quality sub-system? It is

defined and demanded by

customer,

it has

to be achieved by management, it is a

firm wide responsibility and these

subsystem provide the

firm's

managers

with information that

reveals the extent to which the firms products

are achieving the

quality

goals.

13.8

Total Quality Management

(TQM)

TQM is a

set of management and

control activities which focus on

quality assurance. The

quality of the

products

and services is enhanced and

then offered to consumers. An

organizational undertaking to

improve

the quality of manufacturing and service,

it focuses on obtaining continuous

feedback for making

improvements

and refining existing processes

over the long term. There

are certain Graphical tools

used to

implement

and promote TQM. For

instance

o Histogram

o Pareto

Analysis

o Cause

& Effect Diagram

Costing

Sub System

Costs

are incurred more frequently in a

manufacturing entity. Monitoring these

costs on regular

basis

requires

instituting a formal cost

subsystem. Cost sub systems

are responsible for generation of

cost reports

which

represent cost break ups on

various bases, for

instance

o Machine

usage basis

o Product

basis

o Department

wise

Order

Processing Sub

System

This

subsystem deals with

following issues.

�

Status

of orders placed with

suppliers

�

Status

of departmental requisitions

�

Quality

of materials received

�

Any

other issues related to

suppliers

Order

processing subsystem gives a

snapshot of statuses of various

orders placed, at any given

time.

Management

Levels in Manufacturing Information

Systems

Manufacturing

Information System should cater

for information requirements at

each level, for

instance

Strategic

level

3.

Locating new plant which

can save cost

4.

Investment in new manufacturing

technology

Knowledge

Level

3.

Distribute knowledge to drive the

production process

4.

Innovating new forms of manufacturing

processes

Management

level

2.

Monitoring production costs

and resources

51

VU

Information

System (CS507)

Operational

Level

2.

Status of production

tasks

13.9

Planning

Productions/Operations

This

function in many firms is supported by

IT. The major areas of

planning and their

computerised

support

are as follows.

o Materials

Requirement Planning (MRP)

o Manufacturing

Resource Planning (MRP II)

o Automated

Software

Computer

Aided Design (CAD)

Computer

Aided Manufacturing

(CAM)

Computer

Integrated Manufacturing

(CIM)

13.10

Materials Requirement Planning

(MRP)

Material

procurement needs to be planned in compliance

with the production Schedule.

Initially companies

used

to do plan it manually through a document

termed as "Material Requirement

Plan". Material

Requirements

Planning (MRP) is software based

production planning and

inventory control system

for

material

procurement and scheduling.

It

helps meeting three

objectives:

o Ensure

materials and products are

available for production and

delivery to customers.

o Maintain

the lowest possible level of

inventory.

o Plan

manufacturing activities, delivery schedules

and purchasing

activities.

MRP

helps in getting the right material

and physical resources together at the

right place and at the

right

time to

meet the customer's requirements.

This helps in achieving on time delivery,

High Quality, at the

best

price.

13.11

Manufacturing Resource Planning

(MRP II)

An

expanded version of MRP that

integrates finance, accounting,

accounts payable, and other

business

processes

into the MRP system. It also

includes production scheduling

function, and inventory

control

functions. It is an

integrated computer system that connects

the regular MRP to other

functional area,

especially

finance and human resources. It is

made up of a variety of functions, each

linked together:

o Business

planning

o Sales

and operations planning

o Production

planning

o Master

scheduling

o Material

requirements planning

o Capacity

requirements planning

Benefits

of MRP II

MRP II

involves the entire company

o Management

business rules for strategic

planning can be set, and

enforced by MRP II.

o Sales

and Marketing can incorporate

sales goals that fit

material and capacity

constraints.

o Relationships

can be developed with vendors to

improve purchasing just in

time.

o Inventory

shortages can be seen before they

happen, with communications to

customers to

get

approval of substitutions that will get a

part that does the same

thing, on schedule.

52

VU

Information

System (CS507)

Accounting

and finance departments get

accurate costs, and predict

cash flow.

o

Automated

Tools

IT has

been used successfully in

cutting the time required for the design

of products, services or

processes.

Some

of these applications are

�

Computer

Aided Design (CAD)

�

Computer

Aided Manufacturing

(CAM)

�

Computer

Integrated Manufacturing

(CIM)

13.12

Computer Aided Design (CAD)

"It is a

system that enables drawings

to be constructed on a computer screen

and subsequently

stored,

manipulated

and updated

electronically."

The

ability to rotate or create movement in the

design allows testing for

clearances and frequently

reduces

the

cost of prototyping the products.

The technology is used for a wide variety

of products in such fields as

architecture,

electronics, and aerospace,

naval, and automotive

engineering. Although CAD

systems

originally

merely automated drafting, they

now usually include three-dimensional modeling

and computer-

simulated

operation of the model. Rather than

having to build prototypes and change

components to

determine

the effects of tolerance ranges,

engineers can use computers

to simulate operation to

determine

loads

and stresses. For example,

an automobile manufacturer might

use CAD to calculate the

wind drag on

several

new car-body designs without

having to build physical models of

each one. In microelectronics,

as

devices

have become smaller and

more complex, CAD has

become an especially important

technology.

Among

the benefits of such systems are

lower product-development costs and a

greatly shortened

design

cycle.

While less expensive CAD

systems running on personal

computers have become

available for do-it-

yourself

home remodeling and simple

drafting, state-of-the-art CAD systems

running on workstations and

mainframe

computers are increasingly integrated

with computer-aided manufacturing

systems.

13.13

Computer Aided Manufacturing

(CAM)

Computer-aided

manufacturing (CAM) is a form of automation

where computers communicate

work

instructions

directly to the manufacturing machinery.

The technology evolved from the

numerically

controlled

machines of the 1950s, which were

directed by a set of coded instructions

contained in a

punched

paper tape. Today a single

computer can control banks of

robotic milling machines,

lathes,

welding

machines, and other tools,

moving the product from

machine to machine as each

step in the

manufacturing

process is completed. Such

systems allow easy, fast

reprogramming from the computer,

permitting

quick implementation of design

changes. The most advanced

systems, which are

often

integrated

with computer-aided design systems,

can also manage such

tasks as parts ordering,

scheduling,

and

tool replacement.

It is a

system that uses computer

aided techniques to control

production facility. Some of

these techniques

are

o Computer-aided

process planning Use of computer to

control activities and functions to

prepare

a

detailed set of plans and

instructions to produce a machine or part. --

Machines

o Computerised

Numerical control (CNC)

refers specifically to the computer

control of machine

tools

for the purpose of (repeatedly)

manufacturing complex parts in metal as

well as other

materials.

e.g. drills, wood routers

use this technology.

o Robotics

programming The science or study of

the technology associated with the

design,

fabrication,

theory, and application of robots.

Automobile industry.

53

VU

Information

System (CS507)

13.14

Computer Integrated Manufacturing

(CIM)

Integrated

computerized manufacturing system

combining all the elements of computer

aided design (cad)

and

computer-aided manufacturing (cam). This is an

interactive computer system usually installed on

a

local

area network linking several

related departmental functions

such as design, engineering,

production,

and

marketing. The concept of CIM insures

rapid high-quality product development

and manufacturing

through

real-time coordination of all related

functions. See also computer aided design

(cad).

Computer-integrated

manufacturing (CIM): It is the total

integration of Computer Aided Design

/

Manufacturing

and also other business

operations and databases. It is

concept/philosophy about the

implementation

of various integrated computer systems in factory

automation.

13.15

Computer Integrated Manufacturing (CIM)

Goals

CIM

has three basic

goals

�

Simplification

of all manufacturing technologies and

techniques

�

Automation

of as many of the manufacturing processes as

possible by integration of

many

information

technologies like

o Flexible

Manufacturing Systems a form of

flexible automation in which several

machine tools are

linked

together by a material-handling system controlled by a

central computer. It is

distinguished

from

an automated production line by

its ability to process more

than one product

style

simultaneously.

o Computer

aided Engineering (CAE) -- the

application of computer software in

engineering to

analyze

the robustness and performance of

components, assemblies, products and

manufacturing

tools.

o Just

in time (JIT) A Japanese idea

that inventory is manufactured

(or acquired) only as the

need

for it

arises or in time to be sold (or

used). A major goal is to cut

down on inventory

investment.

�

Integration

and coordination of all the manufacturing

aspects through computer hardware

and

software.

54

Table of Contents:

- Need for information, Sources of Information: Primary, Secondary, Tertiary Sources

- Data vs. Information, Information Quality Checklist

- Size of the Organization and Information Requirements

- Hierarchical organization, Organizational Structure, Culture of the Organization

- Elements of Environment: Legal, Economic, Social, Technological, Corporate social responsibility, Ethics

- Manual Vs Computerised Information Systems, Emerging Digital Firms

- Open-Loop System, Closed Loop System, Open Systems, Closed Systems, Level of Planning

- Components of a system, Types of Systems, Attributes of an IS/CBIS

- Infrastructure: Transaction Processing System, Management Information System

- Support Systems: Office Automation Systems, Decision Support Systems, Types of DSS

- Data Mart: Online Analytical Processing (OLAP), Types of Models Used in DSS

- Organizational Information Systems, Marketing Information Systems, Key CRM Tasks

- Manufacturing Information System, Inventory Sub System, Production Sub System, Quality Sub system

- Accounting & Financial Information Systems, Human Resource Information Systems

- Decision Making: Types of Problems, Type of Decisions

- Phases of decision-making: Intelligence Phase, Design Phase, Choice Phase, Implementation Phase

- Planning for System Development: Models Used for and Types of System Development Life-Cycle

- Project lifecycle vs. SDLC, Costs of Proposed System, Classic lifecycle Model

- Entity Relationship Diagram (ERD), Design of the information flow, data base, User Interface

- Incremental Model: Evaluation, Incremental vs. Iterative

- Spiral Model: Determine Objectives, Alternatives and Constraints, Prototyping

- System Analysis: Systems Analyst, System Design, Designing user interface

- System Analysis & Design Methods, Structured Analysis and Design, Flow Chart

- Symbols used for flow charts: Good Practices, Data Flow Diagram

- Rules for DFD’s: Entity Relationship Diagram

- Symbols: Object-Orientation, Object Oriented Analysis

- Object Oriented Analysis and Design: Object, Classes, Inheritance, Encapsulation, Polymorphism

- Critical Success Factors (CSF): CSF vs. Key Performance Indicator, Centralized vs. Distributed Processing

- Security of Information System: Security Issues, Objective, Scope, Policy, Program

- Threat Identification: Types of Threats, Control Analysis, Impact analysis, Occurrence of threat

- Control Adjustment: cost effective Security, Roles & Responsibility, Report Preparation

- Physical vs. Logical access, Viruses, Sources of Transmissions, Technical controls

- Antivirus software: Scanners, Active monitors, Behavior blockers, Logical intrusion, Best Password practices, Firewall

- Types of Controls: Access Controls, Cryptography, Biometrics

- Audit trails and logs: Audit trails and types of errors, IS audit, Parameters of IS audit

- Risk Management: Phases, focal Point, System Characterization, Vulnerability Assessment

- Control Analysis: Likelihood Determination, Impact Analysis, Risk Determination, Results Documentation

- Risk Management: Business Continuity Planning, Components, Phases of BCP, Business Impact Analysis (BIA)

- Web Security: Passive attacks, Active Attacks, Methods to avoid internet attacks

- Internet Security Controls, Firewall Security SystemsIntrusion Detection Systems, Components of IDS, Digital Certificates

- Commerce vs. E-Business, Business to Consumer (B2C), Electronic Data Interchange (EDI), E-Government

- Supply Chain Management: Integrating systems, Methods, Using SCM Software

- Using ERP Software, Evolution of ERP, Business Objectives and IT

- ERP & E-commerce, ERP & CRM, ERP– Ownership and sponsor ship

- Ethics in IS: Threats to Privacy, Electronic Surveillance, Data Profiling, TRIPS, Workplace Monitoring