|

MICROEMULSION TECHNIQUES:Significance of Packing Parameter |

| << TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway |

| SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS >> |

7.10

Microemulsion

Techniques

(ii)

Isooctane,

being bulkier with a larger

molecular volume, cannot penetrate

the

surfactant

tails so efficiently, thereby

leading to a more fluid

interface and thus

faster

growth

rates.

Although

these ideas provide

plausible explanations of the

phenomena they remain

controversial.

Measurement

of the surfactant film

rigidities in microemulsions show

that the solvent

type

has only a minor effect.

Solvent molecular volume may

also explain the observed

change

in final particle size. It was

proposed that a more stable

micelle system arises

from

greater

interactions between the

solvent and surfactant tails

which in turn leads to

an

enhanced

ability to stabilize larger

particles. Any increase in rate of

intermicellar exchange

will

result in a higher rate of growth

comparable to nucleation, hence is likely

to generate

systems

with lower polydispersity.

Effect of solvent on the size of

the Ag nanoparticles is

given

in Table 7.4.

Table

7.4. Effect of solvent on

the absorption spectra of

silver nanoparticles synthesized

in

reverse

micelles of AOT (data taken from

ref. 22)

System

Particle

size (nm)

6.0

AOT/decane

22.0

AOT/heptane

5.4

AOT/cyclohexane

Surfactants

and co-surfactants

Various

studies showed that the

choice of surfactant is critical to

the size, shape and

stability of

the

particles. The most commonly

used surfactant is the

anionic AOT, although a variety

of

common

cationic surfactants are also

frequently employed, such as

CTAB or DDAB (di-n-

didodecyldimethylammoniumbromide)

and non-ionics Triton X-100,

polyoxyethylene (5)

nonylphenyl

ether (NP-5) or polyoxyethylene

(9) nonylphenyl ether

(NP-9). For some

systems

co-surfactants

(intermediate chain length

alcohols, such as n-butanol or

n-hexanol) are also

employed.

The

Evolving Synthetic Strategies in

Chemistry

7.11

Among

the anionic surfactants that

form reverse micelles, the

best known are the

systems

derived

from AOT (sodium

1,4-bis-2-ethylhexylsulfosuccinate) in different

non-polar media.

The

reasons are as

follows:

(i)

AOT

has a well-known V-shaped

molecular geometry, giving rise to stable

reverse

micelles

without co-surfactant.

(ii)

AOT

has the remarkable ability

to solubilize water with

values of W (W =

[H2O]/[AOT]) as large as 40-60

depending on the surrounding

non-polar medium, the

solute

and the temperature; however

the droplet size depends

only on the water

amount,

W. The bulk properties of water

(polarity, viscosity, hydrogen

bond ability,

etc.)

either inside the pool

(free) or at the interface

(bound) change with W.

It

is also known that addition of

co-surfactant can reduce the surfactant

concentration in

microemulsion

preparation. Normally, low

molecular weight alcohols,

such as n-butanol can be

used

for this purpose. Their

short hydrophobic chain and

terminal hydroxyl group is

known to

enhance

the interaction with

surfactant monolayers at the

interface, which can influence

the

curvature

of the interface and internal

energy. The amphiphilic

nature of co-surfactants

could

also

enable them to distribute between

the aqueous and oil

phase.

In

general, it was concluded that

the addition of a co-surfactant

leads to a higher fluidity

of

the

interfacial film, thus

increasing the rate of intermicellar

exchange (but also leading to

a

higher

curvature of the droplets), so

smaller particles.

Surfactant

Concentration

When

the amount of water and oil

is kept at fixed values, an

increase of the amount of

surfactant

will

increase the number of

droplets. It means that the

number of metal ions per

droplet will

decrease

and consequently the size of the

particles. The morphology of reverse

micelles is

different

with the surfactant

concentration. At different

concentrations, the surfactant

molecules

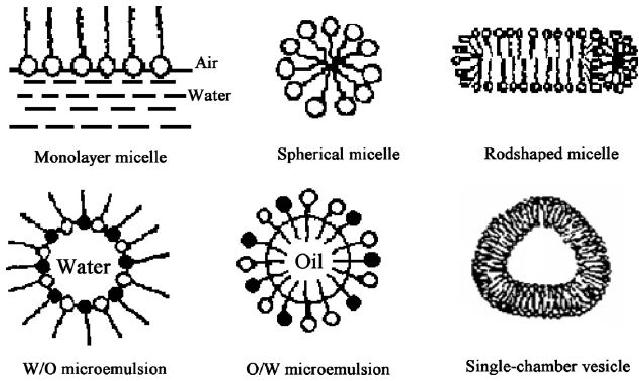

can

form various molecule aggregations

(Fig. 7.2).

7.12

Microemulsion

Techniques

Fig.

7.2. Structures of different

micelles (reproduced from

ref. 26)

It

was found that the change of

micelle structures had an energetic

barrier. The main points

are

given

as follows:

(i)

At

a low surfactant concentration,

only spherical micelles

appear in solution.

(ii)

When

the surfactant concentration in

the solution reaches a

well-defined saturation

value,

i.e., second critical

micelle concentration (second CMC),

the energetic barrier

will

be overcome and the micelle

structure will change from a spherical

micelle to

other

special structure, and then the

micelle will be steady again at a

new

concentration

range. For example, if the

concentration of surfactant attains to

40

50%,

the spherical micelle turns

into rod-shaped or column-shaped

micelle.

Furthermore,

the micelle is also able to self-assemble

into layer or liquid

crystal

structure.

The

special micelles formed at different

concentrations of surfactants can be

usually used as

effective

structure-directing agents to prepare

nanoparticles with desired

morphologies. Thus,

the

micelle

formed by the surfactant

with a proper concentration can

offer an appropriate growth

condition

for nanoparticles.

The

Evolving Synthetic Strategies in

Chemistry

7.13

Nature

of the Precipitating Agent

(reducing agent)

The

main point that should be

followed in the selection of

suitable reducing agent in

the

preparation

of nanoparticles is it must be stable in an

aqueous environment and does

not react

with

the other components of the

reverse micelle system. As a general

rule, a fast

nucleation

process

will result in the production of

small particles.

In

most of the cases, water

soluble sodium borohydride and

hydrazine (usually N2H4.2HCl

or

N2H4.H2O)

are used as effective

reducing agents. Eventhough bubbled

H2 gas results in

the

reduction

of metal particles, the

kinetics is not desirable, particularly

at room temperature. As it

was

mentioned earlier, faster

exchange between the reactants and

fast nucleation process

will

give

smaller particles. So both

sodium borohydride

(NaBH4)

and hydrazine are efficient

reducing

agents

for most of the transition

metal salts. The reduction

process is in this case

completed

instantly

and is very fast in comparison to

pure hydrogen.

When

increasing the concentration of

hydrazine while the

concentration of metal salt is

kept

constant,

a decrease in the particle size is

observed. This was shown when Ni

particles were

prepared

in a microemulsion containing

cetyltriammonium bromide (CTAB) as

surfactant, n-

hexanol

as oil phase, water as

aqueous phase and hydrazine as

reducing agent at a temperature of

350

K (Capek, 2004). The diameter of

the nickel particles

decreases when the ratio of

the

hydrazine

to nickel chloride concentrations

increases. The diameter of

the particles reaches

a

constant

value when this ratio is

above 10.

Effect

of the Micellar

Template

It

was claimed that particle

shape can be controlled by using

micellar templates. A

simple

surfactant/water/oil

system can produce many

different self-assembly structures: by

changing

composition,

one can obtain spheres (reverse

micelles or micelles), cylinders,

interconnected

cylinders

and planes, termed lamellar phases,

which also can re-organise into

onion-type

structures.

Hence in theory many possible

nanoparticle structures could be

grown inside these

different

shaped templates. Despite plenty of

work, there is still much

controversial debate on

these

aspects.

Influence

of ion/molecular adsorption

Anion

species added as electrolyte is

important for generating

different shapes of

metal

nanocrystals.

The initial micellar shape

is shown to be largely unaffected by

these additives. For

example,

in the case of copper nanoparticle

systems, a large excess of hydrazine

favours disk

7.14

Microemulsion

Techniques

over

spherical particles. In both

cases, Pileni et

al.

(2003) postulate that

selective adsorption of

molecules

or ions on to facets of the nanocrystal

affects growth in certain

directions, explaining

the

apparent preference for certain

shapes.

It

was also known that pH affects

the shape of nanocrystals,

for example,

nanostructured

NiZn

ferrites (Uskokovic et

al.,

2005). When the pH is lower,

needle-like nanocrystals

are

formed,

whereas other spheres are observed at

higher pH. One possible

reason for this is due

to

an

increased number of hydroxyl

ions at higher pH which

eliminate the sulphate and

bromide

ions,

hampering their ability to

promote uniaxial

growth.

SUMMARY

The

most remarkable features of

the microemulsion technique are:

(i) particle size and

composition

can be controlled to a great extent and a

narrow particle size distribution can

be

obtained

and (ii) Bimetallic particles can be

obtained at room

temperature.

A

large number of different

nano-materials can be synthesised in water-in-oil

microemulsions

and

reverse micelles. Particle growth

has shown to be strongly dependent on

intermicellar

exchange

rates. The resultant

particle size appears to be dependent on

dominant parameters,

namely

solvent type, surfactant/co-surfactant

type, concentration of the

reagents and composition

via

[water]:[surfactant] ratio, W.

However,

the generality of the

factors that affects the

shape of particle remains to be

established.

REFERENCES

1.

K. Tapas and A. Maitra, Adv.

Colloid Interface Sci.,

59 (1995) 95.

2.

J.J. Silber, U.A. Biasuttia,

E. Abuinb and E. Lissi, Adv.

Colloid Interface Sci.,

82 (1999)

189.

3.

T. Tadros, P. Izquierdo, J. Esquena and

C. Solans, Adv.

Colloid Interface Sci.,

108-109

(2004)

303.

4.

S. Eriksson, Ulf Nyl�n, S. Rojas and M.

Boutonnet,

Applied

Catalysis A: General 265

(2004)

207.

5.

T.P. Hoar and J.H. Schulman,

Nature

152

(1943) 102.

6.

M.-P. Pileni, Nature

2

(2003)145.

7.

T. Tago, T. Hatsuta, K. Miyajima, M.

Kishida, S. Tashiro and K. Wakabayashi,

J.

Am.

Ceram.

Soc. 85

(2002) 2188.

The

Evolving Synthetic Strategies in

Chemistry

7.15

8.

S. Rojas, F.J. Garcia-Garcia, S.

Jaras, M.V. Martinez-Huerta, J.L.

Garcia Fierro and M.

Boutonnet,

Applied

Catalysis A: General 285

(2005) 24.

9.

M. Boutonnet, J. Kitzling and P. Stenius,

Colloids.

Surf. 5

(1982) 209.

10.

A.P. Herrera, O. Resto, J.G.

Briano and C. Rinaldi, Nanotechnology

16

(2005) S618.

11.

L. Xiong and A. Manthiram, Solid

State Ionics 176

(2005) 385.

12.

V. Raghuveer, P.J. Ferreira, A.

Manthiram, Electrochem.

Commun. 8

(2006) 807.

13.

P.S. Khiew, S. Radiman, N.M.

Huang, Md Soot Ahmad and K. Nadarajah,

Mater.

Lett.

59

(2005) 989.

14.

J. Eastoe and A.R. Cox, Colloids

Surf A Physicochem. Eng.

Asp. 101

(1995) 63.

15.

Ch. Venkateswara Rao and B.

Viswanathan,

J.

Phys. Chem. C 111

(2007) 16538.

16.

V. Raghuveer, Keshav, Kumar and

B.Viswanathan, Indian

J. Eng. Mater. Sci. 9

(2002)

137.

17.

A. Bumajdad, M.I. Zaki, J. Eastoe and L.

Pasupulety, Langmuir

20

(2004)11223.

18.

S. Xing, Y. Chu, X. Sui and Z.

Wu, J.

Mater. Sci. 40

(2005) 215.

19.

E. Carpenter, J.A. Sims,

J.A. Wienmann, W.L. Zhou and

C.J. O'Connor, J.

Appl. Phys.

87

(2000) 5615.

20.

R. Schom�cker, M.-J. Schwuger and K.

Stickdorn, Chem.

Rev. 95

(1995) 849.

21.

V. Uskokovic and M. Drofenik, Colloids

Surf. A Physicochem. Eng.

Asp. 266

(2005)168.

22.

R.P. Bagwe and K.C. Khilar,

Langmuir

16

(2000) 905.

23.

C. Petit, P. Lixon and M.P.

Pileni, J.

Phys. Chem. 97

(1993) 12974.

24.

I. Capek, Adv.

Colloid Interface Sci.,

110 (2004) 49.

25.

Taleb, C. Petit and M.P.

Pileni, Chem.

Mater. 9

(1997) 950.

26.

J.H. Fendler, Chem.

Rev. 87

(1987) 877.

27.

W.L. Zhou, E.E. Carpenter,

J. Sims, A. Kumbhar and C.J. O'Connor,

Mater.

Res. Soc.

Symp.

Proc. 581

(2000) 107.

28.

C.-H. Lu and H.-C. Wang, J. Mater.

Chem. 13

(2003) 428.

29.

C. Liu, A.J. Rondinone and

Z.J. Zhang, Pure

Appl. Chem. 72

(2000) 37.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES