|

TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway |

| << SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE |

| MICROEMULSION TECHNIQUES:Significance of Packing Parameter >> |

Chapter

- 6

TEMPLATE

BASED SYNTHESIS

B.Kuppan

INTRODUCTION

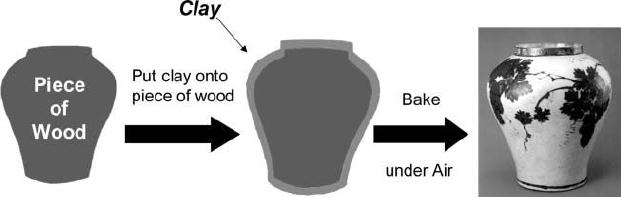

To

make a jar, a piece of wood of

the desired shape is first

fabricated, and layer of

clay

is applied to the wood. Heat

treatment of the clay/wood

composite at high

temperature

generates a ceramic jar.

During the heat treatment,

clay is transformed to

a

ceramic material and the

wood is burned off leaving

the empty space in

the

resulting

jar. When this process is

scale down to nanometer

regime, it is basically

the

template

synthesis process

[1].

Fig.

6.1. Schematic representation of

template synthesis (reproduced

from ref. 1)

One

class of templates are

surfactants that are used to

produce mesoporous materials.

It

is true to say one of the

most exciting discoveries in the

field of material

synthesis

over

the last 15 years is the

formation of mesoporous silicate and

alumino silicate

molecular

sieves with liquid crystal

templates. This family

materials generally

called

as

M41S family (MCM-41, MCM-48

and MCM-50) [2].

These

M41S family

materials

can be prepared by using cationic

surfactants as the templates, and

other

kind

of mesoporous materials also can be prepared by

using non-ionic surfactants

as

the

templates. These family materials

are called as SBA-n family

[3].

The

above mentioned mesoporous molecular

sieves also can be used as

templates

to

prepare ordered mesoporous carbon by

using sucrose as the carbon

precursors.

These

mesoporous silicates, aluminosilicates and mesoporous

carbon materials are

6.2

Template

Based Synthesis

more

important in the field of

catalysis because of its

high surface area, narrow

pore

size

distribution and large number of

surface functional groups.

The surfaces of these

materials

can also be tuned depending on the

applications.

Another

kind of template based

synthesis is to prepare freestanding,

non-oriented

and

oriented nanowires, nanorods or

nanotubes. The fabrication of

metal nanowires

had

potential applications in the

microelectronic industry and in

particular, for

interconnection

in electronic circuits. The

procedure is based on metal

displacement

reaction

leading to the growth of

metal nanowires into the

pores. The galvanic

displacement

reaction for the synthesis

of core /sheet nanostructured materials

has

been

investigated in the literature

[4].

Nanostructured

materials have attracted

much interest because of

their unique

properties.

In fact, due to their structure

features and size effects, they

show physical

properties

that are different from

bulk materials. Many methods

have been developed

for

the fabrication of nanowires.

Among these methods template

synthesis is

considered

as quite useful, because it can be

used for the preparation of

different

types

of nanostructures. The high

order degree of porous

structure of anodic

alumina

membrane

(AAM) (consisting in a close packed array

of columnar hexagonal

cells,

each

containing a central cylindrical pore

normal to the surface),

makes it an ideal

template

for the fabrication of

nanostructured materials, suitable

for applications in

optoelectronics,

sensors, magnetic memories and

electronic circuits

[5].

Synthesis,

Mechanism and Pathway

A

large number of studies have

been carried out to

investigate the formation

and

assembly

of mesostructures on the basis of

surfactant self-assembly. The

initial liquid

crystal

template mechanism first

proposed by Mobil's scientists is

essentially always

"true"

because the pathways

basically include almost all

possibilities. Two main

pathways

that is cooperative self

assembly and "true" liquid

crystal templating

process,

seems to be effective in the

synthesis of ordered

mesostructures.

Surfactants

for the formation of

templates

The

term surfactant is a blend of

"surface acting agent"

surfactants are

usually

organic

compounds that are

amphophilic in nature. Amphophilic

means they contain

Synthetic

Strategies in Chemistry

6.3

both

hydrophobic groups (tails) and

hydrophilic groups (heads). Therefore

they are

soluble

in both organic solvents and

water.

Generally

a clear homogeneous solution of

surfactants in water is required to

get

ordered

mesostructures. Frequently used

surfactants can be classified into

cationic,

anionic

and non-ionic surfactants.

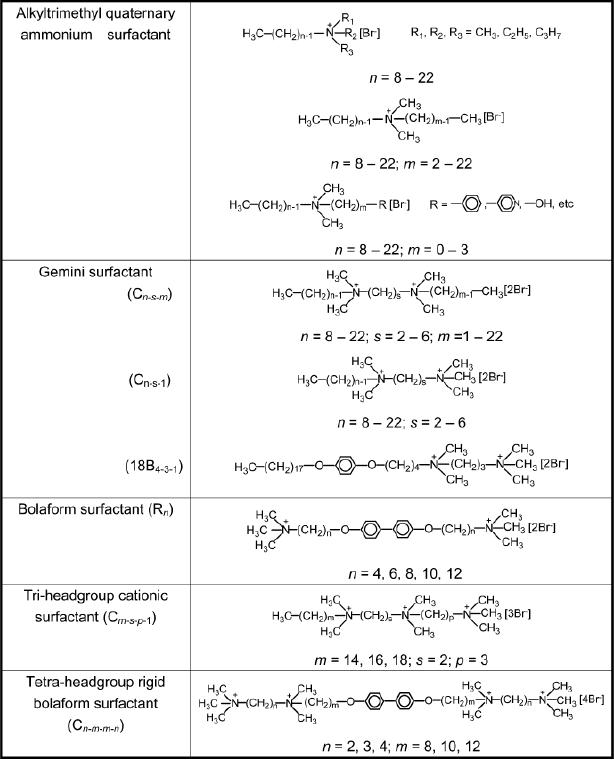

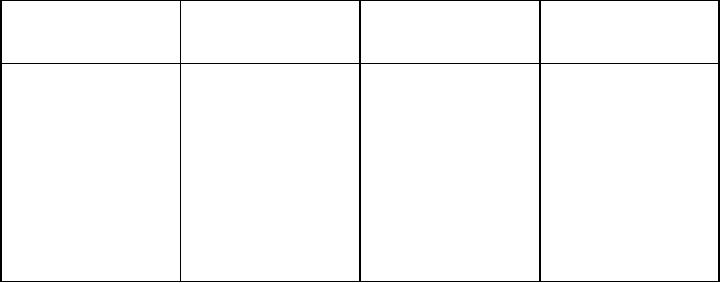

Table

6.1. Cationic

surfactants

(Reproduced

from ref.7)

6.4

Template

Based Synthesis

Quaternary

cationic surfactants, CnH2n+1N (CH3)3Br

(n = 8-22), are generally

efficient

for

the synthesis of ordered mesoporous

silicate materials. Commercially

available

CTAB

(cetyltrimethylammonium bromide) is often

used. Gemini

surfactants,

multiheadgroup

surfactants, and recently reported

cationic fluorinated surfactants

can

also

be used as templates to prepare

various mesostructures. Frequently

used cationic

quaternary

ammonium surfactants are

shown in the table

below

First

reports of mesoporous silica from

Mobil's company, cationic

surfactants

were

used as structure directing

agents (SDAs). Cationic

surfactants have

excellent

solubility,

have high critical micelle

temperature (CMT) values and can be

widely

used

in acidic and basic media. But

they are toxic and

expensive.

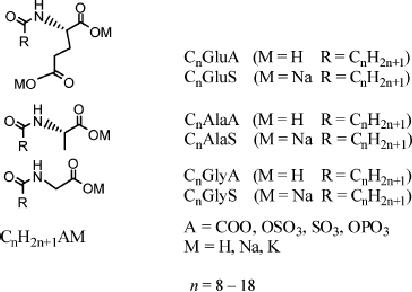

Anionic

surfactants include carboxilates,

sulphates, sulfonates, and

phosphates;

recently

a kind of lab-made anionic

surfactant terminal carboxylic

acids is used to

template

the synthesis of mesoporous silicas

with the assistance of

aminosilanes or

quaternary

aminosilanes

such

as

3-aminoprpoyltrimethoxysilane

(APS)

N-

trimethoxylsilylpropyl-N,

N, N-trimethylammonium chloride (TMAPS)

as co-

structure

directing agents

(CSDAs).

Anionic

surfactants

Fig.

6.2. Representation of anionic

surfactants (reproduced from

ref. 7)

Synthetic

Strategies in Chemistry

6.5

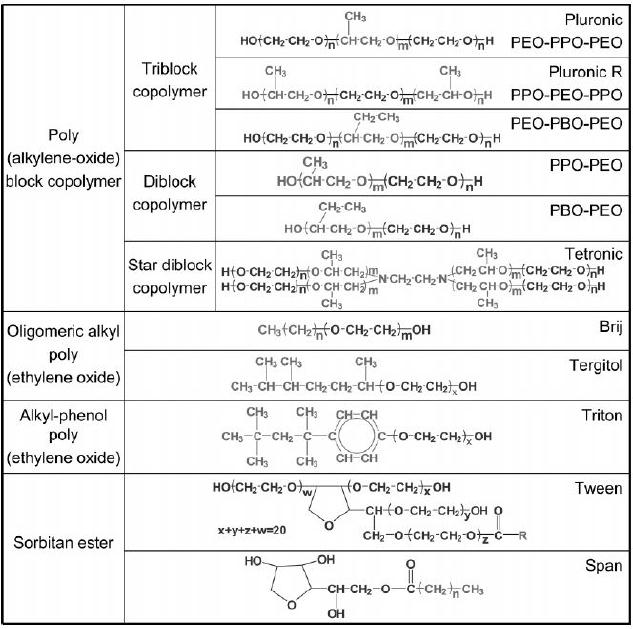

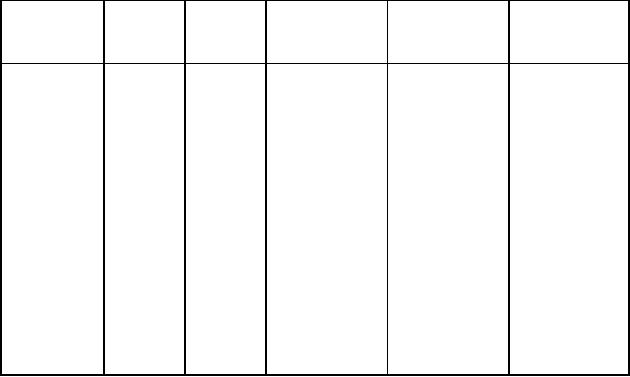

Table

6.2. Non-ionic surfactants

(reproduced from ref.

7)

Non-ionic

surfactants are available in a

wide variety of different

chemical structures.

They

are widely used in industry

because of attractive characteristics

like low price,

nontoxicity,

and biodegradability. In addition the

self assembling of

non-ionic

surfactants

products mesophase with

different geometries and arrangements.

They

become

more and more popular and

powerful in the syntheses of mesoporous

solids.

The

syntheses that largely promote

the development of mesoporous materials

are

simple

and reproducible. A family of mesoporous

silica materials has been

prepared

with

various mesoporous packing symmetries and

well defined pore

connectivity.

6.6

Template

Based Synthesis

Cooperative

Self-Assembly of Surfactant and

Silica Source to Form

Mesostructure

This

pathway is established on the basis of

the interaction between the

silicates

surfactants

to from inorganic-organic mesostructure

composites.

Cooperative

Self-Assembly Mechanism

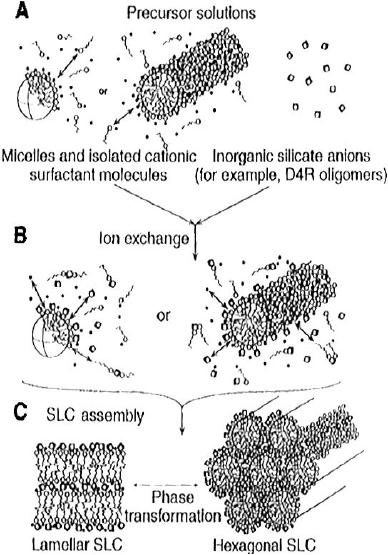

Fig.

6.3. schematic diagram of

the co-operative self

assembly of silicate-surfactant

mesophase.

(reproduced from ref.

6)

A

layer to hexagonal mechanism

(folded sheet mechanism) was

postulated by Kuroda

and

co-workers, according to which

the mesostructure is created

from a layer

kanemite

precursors. Silicate polyanions

such as silicate oligomers

interact with

positively

charged groups in cationic surfactants

driven by Coulomb forces.

The

silicate

species at the interface

polymerized and cross-link and further

change the

Synthetic

Strategies in Chemistry

6.7

charge

density of the inorganic

layers. With the proceeding of

the reaction, the

arrangement

of the surfactants and the charge

density between inorganic and

organic

species

influence each other. Hence

the compositions of the

inorganic-organic

hybrids

differ to some degree. It is

the matching of charge density at

the

surfactants/inorganic

species interfaces that

govern the assembly process.

The final

mesosphere

is the ordered 3D arrangement with

the lowest interface energy.

The

transformation

of the isotropic micellar

solutions of CTAB into

hexagonal or lamellar

phase

when mixed with anionic

silicate oligomers in highly

alkaline solutions

were

indeed

detected through a combination of

correlated solution state

2H,

13

29

C,

and

Si

nuclear

magnetic resonance (NMR)

spectroscopy, small angle

x-ray scattering

(SAXS),

and polarized optical microscopic

measurements. The mechanism in

different

surfactant systems has been

studied using NMR

technique.

This

cooperative formation mechanism in

non-ionic surfactant system

was

investigated

by in-situ

techniques.

Goldfarb and co-workers investigated

the

formation

mechanism of mesoporous silica SBA-15,

which are templated by

triblock

copolymer

P123 (EO20PO20EO20)

by

using direct imaging and

freeze-fracture

replication

cryo-TEM techniques, in

situ electron

paramagnetic resonance (EPR)

spectroscopy,

and electron spin-echo envelope

modulation (ESEEM)

experiments.

They

found a continuous transformation

from speriodial micelles

into threadlike

micelles.

Bundles were then formed

with dimension that are

similar to those found in

the

final materials. The

elongation of micelles in a consequence of

the reduction of

polarity

and water contact within the

micelles due to the adsorption

and

polymerization

of silicate species. Before

the hydrothermal treatment,

the majority of

PEO

chains insert into silicate

frameworks, which generates

micropores after

removal

of

templates. Moreover they

found that the extent of

the PEO chains located

within

the

silica micropores depended on

the hydrothermal aging

temperature and Si/P123

molar

ratio. The formation

dynamics of SBA-15 studied by

Flodstrom et al. on

the

basis

of time-resolved in

situ 1H NMR and TEM

investigations. They observed

four

stages

during the cooperative

assembly, which are the

adsorption of silicates on

globular

micelles, the association of globular

micelles into floes, the

precipitation of

floes,

and the micelle-micelle coalescence.

Khodakov et al. proposed a

structure with

6.8

Template

Based Synthesis

a

hydrophobic PPO core and a PEO water

silicate corona in the

first stage. The

cylindrical

micelles pack into the

domains. At the same time,

solvents are replaced by

condensed

silicate species.

These

mechanisms consider the

interactions on the surfactants/inorganic

species

interfaces.

Monnier and Huo et al. gave a

formula of the free energy

in the whole

process.

G=

Ginter

+

Gwall

+

Gintra

+

Gsol

In

which

Ginter

associated

with interaction between the

inorganic walls and

Gwall

is the

structural free energy for

the inorganic

frameworks,

surfactant

micelles,

Gintra

is the

van der Waals force and

conformational energy of the

surfactant, and

Gsol

is the

chemical potential associated

with the species in solution

phase.

Gsol

can be

For

surfactant-templating assembly

mesostructured silicates,

regarded

as a constant in a given solution

system. Therefore, the key

factor is the

interaction

between surfactant and inorganic

species, such as the

matching of charge

density.

The more negative

Ginter

is, the

more easily the assembly

process can be

proceeded.

Elaborate

investigations on mesoporous materials

have been focused on

understanding

and utilizing the inorganic-organic

interactions. Table 6.3

lists the

main

synthesis routes and the

corresponding surfactants and classical

products.

Stucky

and co-workers proposed four

general synthetic routes,

which are S+I-,

S-

I+,

S+X-I+, and S-X+I- (S+ = surfactant cations, S- = surfactant anions, I+ = inorganic

precursors

cations, I- = inorganic precursors anions,

X+ = cationic counter ions,

and

X- =

anionic counterions). To yield mesoporous

materials, it is important to adjust

the

chemistry

of the surfactants headgroups, which can

fit the requirement of

the

inorganic

components. Under basic

conditions, silicate anions

(I-)

match with the

surfactant

cations (S+)

through Coulomb forces (S+I-).

The assembly of the

polyacid

anions

and surfactant cations to "salt"-like

mesostructures also belongs to S+I-

interaction.

In contrast to this, one of the

examples of S+I- interaction occurs

between

cationic

keggin ion (Al137+) and anionic surfactants

like dodecyl

benzenesulfonate

salt.

Synthetic

Strategies in Chemistry

6.9

The

organic-inorganic assembly of surfactants

and inorganic precursors with

the same

charge

is also possible. However, counter ion is

necessary. For example, in

the

syntheses

of mesoporous silicates by the S+X-I+ interaction,

S+ and I-

are

cationic

surfactants

and inorganic anionic precursors, and

X- can be

halogen ions (Cl-,

Br-, and

I-),

SO42-, NO3-,

etc. In strongly acidic

medium, the initial S+X-I+ interaction

through

Coulomb

forces or more exactly,

double-layer hydrogen bonding

interaction,

gradually

transforms to the (IX)-S+ one.

It was the first time that

the mesoporous

silica

was synthesized under a strongly

acidic condition. Here

anions affect the

structures,

regularity, morphologies, thermal

stability, and properties of

mesoporous

silicas.

The Hofmeister series of the

anions are one of the possible

reasons that

change

the hydrolysis rates of the

silicate precursors and the

micellar structures.

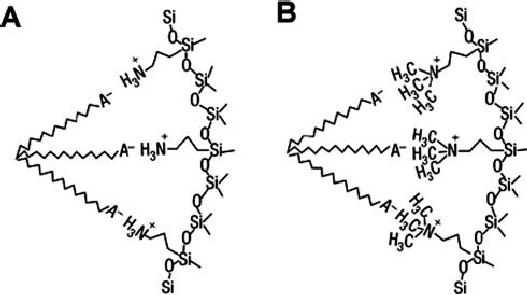

Schematic

illustration of the two

types of interactions between APS

(A) or TMAPS

(B)

and anionic surfactant headgroups.

Fig.

6.4. interactions between APS

(A) or TMAPS (B) and anionic

surfactant

headgroups

(reproduced from ref.

7)

Compared

with those cationic surfactants,

the repulsive interaction

between anionic

surfactants

and silicate species fails to

organize ordered mesostructures.

Concerning

the

charge matching effect, Che et al.

demonstrated a synthetic route to create

a

family

of mesoporous silica structures under

basic conditions by employing

anionic

6.10

Template

Based Synthesis

surfactants

as SDAs APS or TMAPS as CSDAs.

This route can be described as an

"S-

N+I-"

pathway, where N+ are cationic amino

groups of organoalkoxysilanes. Fig.

6.4

gives

the schematic illustration of

interactions between amino

groups and anionic

surfactant

head groups. The negatively

charged headgroups of the anionic

surfactants

interact

with the positively charged

ammonium sites of APS or TMAPS

electrostatic

ally

through neutralization. The

most efficient surfactant is

possibly terminal

carboxylic

acid. The co-condensation of

tetraethylorthosillane (TEOS) with APS

or

TMAPS

and assembly with surfactants

occur to form the silica

framework.

Table

6.3. Synthesis Routes to

Mesoporous Materials with

the Emphasis on Silicates

(reproduced

from ref.7)

route

interactions

symbols

conditions

classical

products

S+I-

S+,

cationic surfactants

electrostatic

basic

MCM-41,

MCM-48

I-,

anionic silicate

species

Coulomb

MCM-50,

SBA-6

force

SBA-2,

SBA-8

FDU-2,

FDU-11

FDU-

13

S-I+

S-,

anionic surfactants

electrostatic

aqueous

mesoporous

alumina

I+,

Transition metal ions

Coulomb

Force

S+X-I+

electrostatic

S+,

cationic surfactants

acidic

SBA-1,

SBA-2

I+,

cationic silicate

species

SBA-3

Coulomb

force,

double X-, Cl-,

Br-, I-,

SO4-, NO3-

layer

H bond

S-N+I-

electrostatic

S-,

anionic surfactants

basic

ASM-n

N+,

cationic amino groups

Coulomb

Synthetic

Strategies in Chemistry

6.11

I-,

anionic silicate

species

Force

S-X+I- electrostatic S-,

anionic phosphate

basic

W,

Mo oxides

Coulomb

surfactants

force,

double I-,

transition metal

ions,

layer

H bond X+,

Na+, K+,

Cr3+, Ni2+

SoIo

H

bond

So,

nonionic surfactants

neutral

HMS,

MSU,

disordered

(NoIo)

No,

organic amines

Worm-like

Io,

Silicate species,

aluminate

mesoporous

species

silicates

SoH+X-I+

electrostatic

So, nonionic

surfactants

acidic

SBA-n

(n=11,

Coulomb

12,

15, 16)

I+,

silicate species

FDU-n

(n=1, 5)

Force,

X-,

Cl-, Br-,

I-, SO42-,

NO3-1

KIT-5

and KIT-6

double,

layer

H

bond

No...I+

No,

organic amines

coordination

acidic

Nb,

Ta oxides

I+,

transition metal

bond

S+-I-

S+,

cationic surfactants

covalent

basic

mesoporous

I-,

silicate species

silica

bond

Liquid

Crystal Template

Pathway

In

this pathway true or

semi-liquid crystal mesophases

are involved in the

surfactant

assembly

to synthesize ordered mesoporous solids.

Attard and co-workers

synthesized

mesoporous silicas using high

concentrations of non-ionic surfactants

as

6.12

Template

Based Synthesis

templates.

The condensation of inorganic

precursors is improved owing to

the

confined

growth around the

surfactants and thus ceramic-like

frameworks are

formed.

After

the condensation, the

organic templates can be removed by

calciation,

extraction,

etc. The inorganic materials

"cast" the mesostuructures, pore sizes,

and

symmetries

from the liquid crystal

scaffolds. Direct templating of

microemulsion

liquid-crystal

mesophases were used to

synthesis mesoporous silicas from

butanol-

water-copolymer

silica ternary system

[6, 7].

Silica/surfactant

= 1/0.27

calcination

As-synthesized

As-synthesized

MCM-41

(hexagonal

structure)

MCM-41

Silica/surfactant

=

1/0.60

calcination

MCM-48

As-synthesized

MCM-48

(cubic

structure)

Fig.

6.4. possible mechanism pathways

for the formation of M41S

family by liquid

crystal

template method (reproduced

from ref. 2).

Evaporation

Induced Self Assembling

Techniques (EISA)

Evaporation

induced self-assembly

mechanism

The

evaporation induced self

assembling technique is one of the

best techniques to

prepare

the nanomaterials. The

successful synthesis of mesoporous silica

films, the

EISA

method is engaged to prepare ordered

mesoporous polymer and carbon

materials.

The EISA method is strategy

that avoids the cooperative

assembling

Synthetic

Strategies in Chemistry

6.13

process

between the precursors and the

surfactant template. Therefore,

the cross-

linking

and thermopolymerization process of the

resols separate from the

assembly.

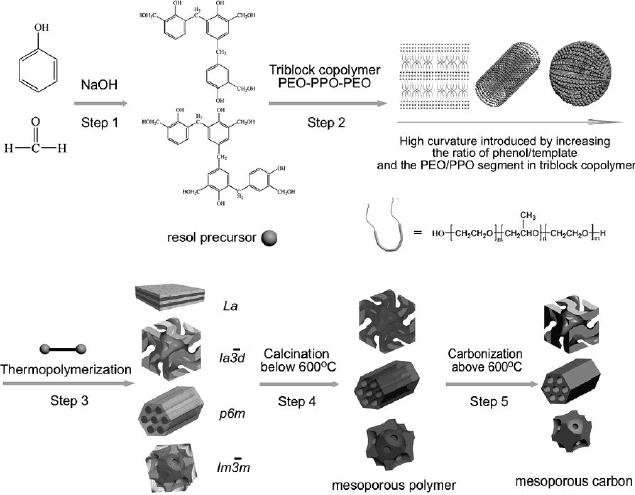

Fig.

6.5. Scheme for the

preparation of ordered mesoporous polymer resins

and

carbon

frameworks from the

surfactant templating process of

EISA. (reproduced

from

ref.

8)

Compare

to hydrothermal synthesis the

EISA method is easier and can

produce the

mesoporous

resins and carbon in a wider synthetic

range, including pH values,

surfactant

and phenol/template ratio.

The

choice of organic precursors is essential

for the EISA of the

organic organic

templating

process. The polymerization of

inorganic precursors should be low

enough

to

form a moldable inorganic-organic

framework at the initial

assembly stage of

inorganic

species with organic

surfactants. Highly ordered

mesostructures can be

formed.

The inorganic framework is

rigid. Therefore, the

mesophase can be

6.14

Template

Based Synthesis

solidified,

and the surfactant can be easily

removed by calcinations or extracted

with

ethanol.

The

synthesis procedure includes

five major steps (Fig.

6.5), which are

the

preparation

of resol precursors, the

formation of ordered hybrid mesophases

by

organic-organic

self assembly during the

solvent evaporation,

thermopolymerization

of

the resols around the

templates to solidify the ordered

mesophases, the removal

of

the

templates, and carbonization of the

resin polymer frameworks to

the homologous

carbons

[8].

Template

Synthesis of Metal

Nanostructures

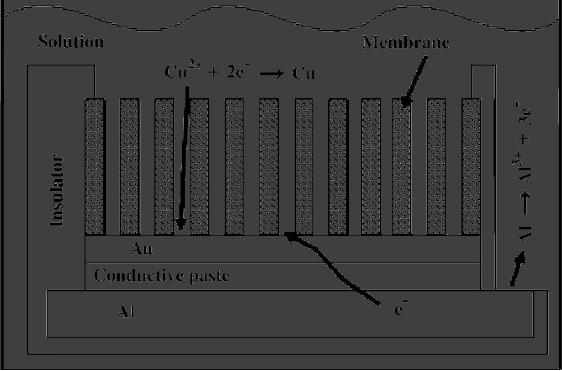

Fig.

6.6. Scheme of the

arrangement used for the

fabrication of copper nanowires

into

the AAM template (reproduced

from ref. 5)

Copper

nanowires are prepared by

using aluminium foil as

active metal having a

thickness

of 1.5 mm. In order to deposit copper

inside the channels of

anodic alumina

membrane

(AAM), prior to cementation a

thin conductive layer of Au

was sputtered

on

one side of the AAM using a

conventional sputter coater to make this

surface

electrically

conductive. A portion of AAM was mounted

onto the aluminum

support

by

means of a conductive paste and

delimited by an insulating film. Since

the

displacement

deposition process needs an

electrolytic contact of the

active metal

Synthetic

Strategies in Chemistry

6.15

surface,

a small area of the aluminum

support was exposed to the

deposition solution.

A

scheme of the arrangement

used for the fabrication of

copper nanowires is reported

in

Fig. 6.5. This arrangement

was placed horizontally in a beaker and

covered with

25

ml of a 0.2 M copper sulphate and 0.1 M

boric acid solution having pH 3.

The

experiments

were conducted at room

temperature. The surface

area of the AAM

exposed

to the deposition solution was of

the order of 1 cm2.

A fresh solution was

used

for each experiment.

Experiments were carried out

for different times

of

deposition

(from 7 h to 7 days)

[5].

Preparation

of Carbon Nanotubes

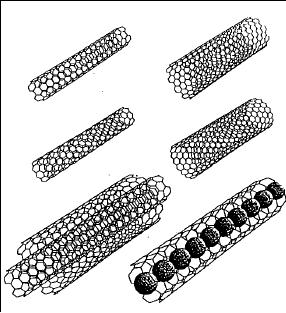

Fig.

6.7. Schematic representation of

carbon nanotubes (reproduced

from ref. 9)

Alumina

membrane is used as template

for the preparation of

carbon nanotubes; here

polyphenyl

acetylene is used as a carbon source

for the preparation of

carbon

nanotubes.

It

contains

only

carbon-hydrogen

bonds.

The

polyphenyl

acetylene/alumina

composite was prepared by adding 10 ml of

5% w/w polyphenyl

acetylene

in dichloromethane to the alumina

membrane applying vacuum from

the

bottom.

The entire polymer solution

penetrates inside the pores

of the membrane was

dried

in vacuum at 373 K for 10 min.

the composite was then

polished with fine

neutral

alumina powder to remove the

surface layers and ultrasonicated

for 20 min to

6.16

Template

Based Synthesis

remove

the residual alumina powder

used for polishing. The

composite was

carbonized

by heating in Ar atmosphere at 1173 K for

6 h at heating rate of 10 K/min.

This

resulted in the deposition of

carbon on the channel walls

of the membrane. The

carbon/alumina

composite was then placed in 48 % HF to

free the nanotubes.

The

nanotubes

were washed with distilled

water to remove HF

[9].

Preparation

of Porous Solids by Template

Method

Ordered

mesoporous carbon has been

prepared by using mesoporous silica as

the

template,

and this mesoporous silica can be

prepared by using CTAB,

P123,

surfactants

as the templates.

Mesoporous

silica SBA-15 is prepared by

the following method, P123

non-ionic

surfactant

was dissolved in 2 M HCl solution,

and it was stirred for 1 h

then TEOS

was

added as the silica source,

this mixture was stirred

until TEOS were

completely

dissolved.

The mixture was placed in oven at 373 K

for 48 h. The product was

filtered

and

washed with distilled water and

dried at 333 K for 6 h and then

SBA-15 was

calcined

at 823 K for 6 h in air

atmosphere.

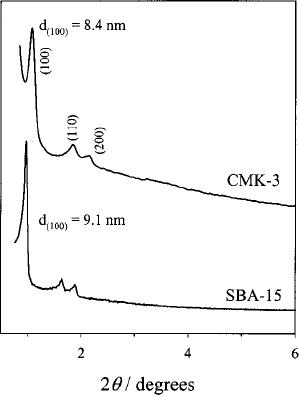

Fig.

6.8. XRD patterns of SBA-15

and CMK-3 (reproduced from

ref. 10)

Synthetic

Strategies in Chemistry

6.17

The

calcined SBA-15 was impregnated

with aqueous solution

sucrose containing

sulfuric

acid, this mixture was

heated to 373 k to 433 K for 24 h. then

the

carbonization

was completed by pyrolysis with

heating to typically 1173 K

under N2

atmosphere

for 6 h at the rate of 5 K/min.

the carbon-silica composite

obtained was

washed

with 1 M NaOH solution or 5 Wt %

hydrofluoric acid at room temperature,

to

remove

the silica template. The

template free carbon product

thus obtained was

filtered,

washed with ethanol and dried at 393

K.

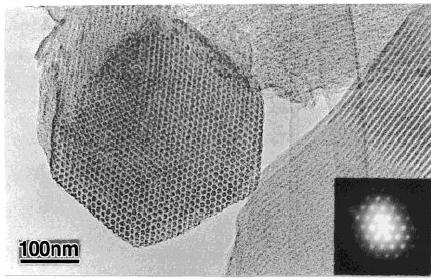

In

Fig. 6.9 the low

angle XRD conforms the

mesoporous structure and to support

this

mesoporous

structure the transition

electron microscopy images

shows the presence

of

ordered mesoporous structure [10].

Fig.

6.9 TEM and selected area

electron diffraction (SAED)

images of CMK-3

(reproduced

from ref.10)

SUMMARY

Strategy

aimed at the controllable synthesis

has been focused on the

control of micro,

meso

and macroscale, including synthetic

methods, architecture concepts,

and

fundamental

principles that govern the

rational design and synthesis. In this

chapter,

synthesis

mechanisms and the corresponding

pathways are first

demonstrated for the

synthesis

of mesoporous silicates from the

surfactant-templating approach.

Virtually

all

mesoporous silicates begin with an

understanding of the interaction

between

organic

surfactants and inorganic species, as

well as among

themselves.

6.18

Template

Based Synthesis

Soft

templating approach is one of the most

general strategies now

available for

crating

nanostructures. The assembly of

surfactants and silicates species is

normally

carried

in solutions or the interface to

allow the required driving

force for the

formation

of nanostructures. Relying on sol-gel,

solution and surface chemistry,

there

is

great potential to explore novel

strategies for mesostructures,

especially a strategy

that

can utilize interfacial tension.

Items that attract attention

also include the

control

of

weak interaction such as the

hydrophobic interaction between

the assembling

components.

In view of the fact that

surfactant self-assembly can occur

with

components

larger than 1 nm continuous to be

challenge and an interest in

condensed

matter

science.

REFERENCES

1.

J. Lee, J. Kim, T. Hyeon, Adv.

Mater.,

18 (2006) 2073.

2.

C. T. Kresge, M. E. Leonowicz, W. J. Roth, J. C.

Vartuli, J. S. Beck,

Nature,

359 (1992)

710.

3.

D. Zhao, J. Feng, Q. Huo, N. Elosh, G. H.

Fredirckson, B. F. Chemlka,

G.

D. Stucky, Science, 279

(1998)

548.

4.

G. Cao, D. Liu, Adv.

Colloid. Interface. Sci. 136

(2008) 45

5.

R. Inguanta, S. Piazza, C. Sunseri, Eleectrochem.

Commun., 10

(2008) 506

6.

A. Corma, Chem.

Rev. 97 (1997)

2373.

7.

Y. Wan, D. Zhao, Chem.

Rev. 107

(2007) 2821.

8.

Y. Meng, D. Gu, F. Zhang, Y.

Shi, L. Cheng, D. Feng, Z. Wu, Z.

Chen,

Y.

Wan, A. Stein, D. Zhao, Chem.

Mater.,

18 (2006) 4447.

9.

M. Sankaran, Ph.D Thesis,

Indian Institute of Technoloyg

Madras, 2007.

10.

S. Jun, S. Joo, R. Ryoo, M.

Kruk, M. Jaroniec, Z. Liu, T.

Ohsuna,

O.

Terasaki, J.

Am.Chem. Soc.,

122

(2000) 712.

Chapter

- 7

MICROEMULSION

TECHNIQUES

Ch.

Venkateswara Rao

The

main focus of this chapter

is to give brief introduction to

the microemulsion systems,

formation

of microemulsions, how those

microemulsions can be used for

the preparation of

various

types of nanoparticles and the

dominant factors that

influence the

nanoparticles

preparation

in the microemulsion.

INTRODUCTION

In

1943, Hoar and Schulman

first reported that oil can

be dissolved in bulk water or

water in

bulk

oil with the aid of

surfactant to produce a clear homogeneous

solution. The oil phases

are

simple

long-chain hydrocarbons and the

surfactants are long-chain

organic molecules with

a

hydrophilic

head (usually an ionic

sulfate or quarternary amine) and

lipophilic tail. The

generally

used

oil phases are cyclohexane,

decane, heptane and surfactants are

cetyltrimethylammonium

bromide

(CTAB), sodium bis(2-ethylhexyl)

sulfosuccinate (AOT).

The

clear homogeneous

solution

is called as microemulsion. According to

the nature of the bulk

solvent used in the

microemulsion,

they are designated as

water-in-oil or oil-in-water

microemulsions. The

microemulsion

is primarily distinguished from

the emulsion not by being

composed of smaller

droplets

but by being subjected to a

restrictive condition that it is

thermodynamically stable.

MICROEMULSION

FORMATION AND NANOPARTICLES PREPARATION

In

general, water and oil are

not miscible. But the

amphiphilic nature of the

surfactants such as

CTAB

makes them miscible. The

surfactant molecules form a

monolayer at the

interface

between

the oil and water, with

the hydrophobic tails of the

surfactant molecules dissolved in

the

oil

phase and the hydrophilic

head groups in the aqueous

phase. It leads to the

formation of

microemulsion.

So the microemulsion is defined as a

system of water, oil and

surfactant. This

system

is an optically isotropic and

thermodynamically stable. At macroscopic

scale, a

microemulsion

looks like a homogeneous

solution but at molecular

scale, it appears to be

heterogeneous.

Even though it is optically

isotropic; it cannot be properly

described as a solution.

The

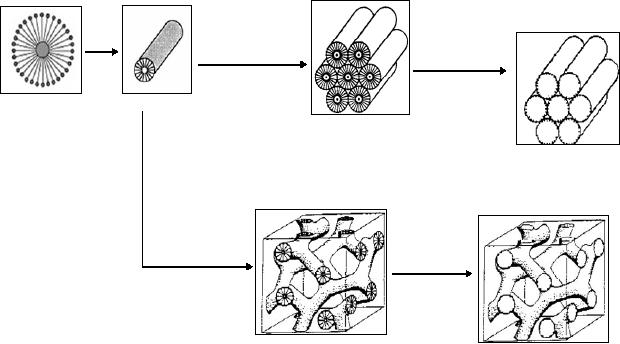

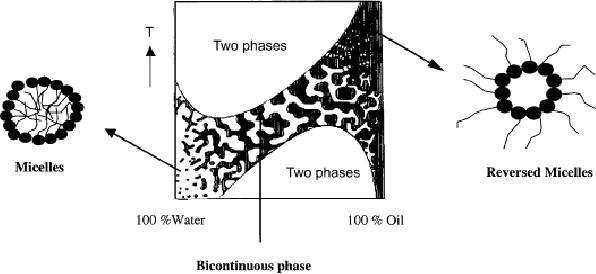

internal structure of the

microemulsion at a given temperature is

determined by the ratio

of

its

constituents. The structure consists

either of nanospherical monosized

droplets or a

7.2

Microemulsion

Techniques

bicontinuous

phase. The different

structures of a microemulsion at a given

concentration of

surfactant

are shown in Fig 1. It

indicates that

(i)

At

high concentration of water,

the internal structure of

the microemulsion consists of

small

oil droplets in a continuous

water phase (micelles),

known as o/w

microemulsion.

(ii)

With

increased oil concentration, a

bicontinuous phase without

any defined shape is

formed.

(iii)

At

high oil concentration, the

bicontinuous phase is transformed

into a structure of

small

water droplets in a continuous

oil phase (reverse

micelles), known as a

w/o

microemulsion.

Depending

on the type of surfactant

used to form microemulsion, size of

the different

droplets

will be varied from 5-100

nm. It is also evident that

the microemulsion system

is

sensitive

to temperature. It can be seen in Fig.

7.1 that the increase in

temperature will

destroy

the oil droplets while

the decrease in temperature will

destroy the water

droplets.

Fig.

7.1 The microscopic

structure of a microemulsion at a given

concentration of surfactant as

function

of temperature and water concentration

(reproduced from ref.

20).

Significance

of Packing Parameter

The

shape of micellar aggregates and

the formation of microemulsion can be

understood from

the

packing parameter of surfactant molecule

used for the microemulsion

formation. Packing

The

Evolving Synthetic Strategies in

Chemistry

7.3

parameter

is defined as v/a.l, where

v

is

the volume of hydrocarbon of

the surfactant, a

is

the

polar

head area and l

is

the fully extended chain

length of the surfactant.

The packing parameter

value

can be 1, <1 and >1. When the

packing parameter value (or

ratio v/a.l) is greater

than 1, the

aggregate

curvature will be toward the

water. This corresponds to a situation

where the oil is

penetrating

the surfactant tails and/or

the electrostatic repulsion

between the charged head

group

is

low. When the packing

parameter value (or ratio v/a.l)

is less than 1, it corresponds to

a

situation

where the electrostatic

repulsion is larger and/or

the oil is not penetrating

the surfactant

tails.

It implies that (i) when

oil is solubilized in hydrophilic

micelles, one can observe the

formation

of o/w microemulsions for v/a.l<1; (ii)

when water is solubilized in

hydrophobic

micelles,

one can observe the formation of w/o

microemulsions for v/a.l>1.; and

(iii) When

v/a.l≈1,

lamellar phases or bicontinuous

microemulsions are observed.

Based

on the experimental results, it is

observed that the micelles will be in

spherical shape

when

the packing parameter is less

than 1/3. The packing

parameters for cylinders and

planar

bilayers

are 0.5 and 1, respectively. In

the case of reverse micellar

structures, the

packing

parameter

is greater than 2 for cylinders as

well as spherical micelles. It was

observed that

reverse

micelles will be in cylinder shape up to

v/a.l≤2

and spherical shape when v/a.l>3.

Oil-in-water

(o/w) microemulsions are monodisperse.

Water-in-oil (w/o)

microemulsion

solutions

are mostly transparent,

isotropic liquid media with

nanosized water droplets

that are

dispersed

in the continuous oil phase

and stabilized by surfactant molecules at

the water/oil

interface.

These surfactant-covered water pools

offer a unique microenvironment

for the

formation

of nanoparticles. They not

only act as micro-/nano-reactors for

processing reactions

but

also exhibit the process aggregation of

particles because the

surfactants could adsorb on

the

particle

surface when the particle

size approaches to that of the

water pool. As a result,

the

particles

obtained in such a medium

are generally uniform in size and

shape (i.e.,

monodisperse).

APPLICATIONS

OF MICROEMULSIONS

1.

Synthesis of Metal

Nanoparticles

Precipitation

of metal particles in the

Water-in-oil (w/o) microemulsion

solutions (reverse

micellar

system) has been found to be

the simple methodology for

the preparation of

nanoparticles.

7.4

Microemulsion

Techniques

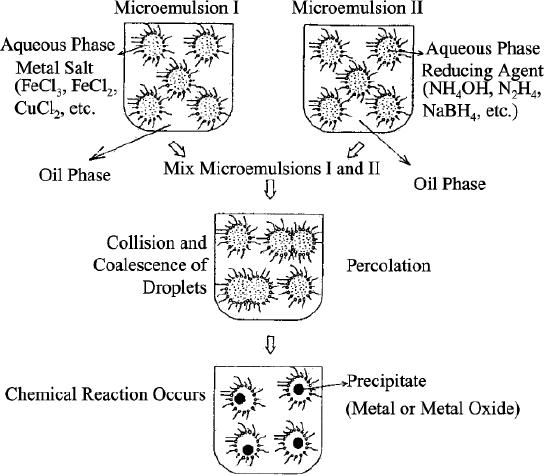

The

method of nanoparticle preparation

consists in mixing of two microemulsions

carrying the

appropriate

reactants (generally metal precursor and

reducing agent) in order to

obtain the

desired

particles. It is represented in Scheme

7.1.

Scheme

7.1. Proposed mechanism for

the formation of metal

particles by the

microemulsion

approach

(reproduced from ref.

24)

At

the beginning of reaction,

the attractive van der Waals

force and the repulsive

osmotic force

between

reverse micelles lead to collisions of

micelles. It results in the

interchange of the

reactants

(in general, metal ions and

reducing species) solubilized in

two different reverse

micelles

respectively. As a result, the

initial monomeric metal

nuclei begin to form and

grow.

When

the exchange of reactants is fast in

the water droplets, metal

ions reduce and the

metal

nuclei

grow quickly. It remains

unchanged when the particle

size reaches a certain size.

It

corresponds

to the thermodynamically stabilized

species in the presence of

microemulsion. Due

The

Evolving Synthetic Strategies in

Chemistry

7.5

to

the possible aggregation, the

final size of silver particles is

generally larger than that

of the

water

cores. Once the particles

attain the final size,

the surfactant molecules are

attached to the

surface

of particles and stabilize and protect

them against further growth.

The dynamic exchange

of

reactants such as metallic salts and

reducing agents between

droplets via the continuous

oil

phase

is strongly depressed due to the

restricted solubility of metal salts in

the oil phase. This is

a

reason

why the attractive interactions

(percolation) between droplets

play a dominant role in

the

particle

nucleation and growth in the

water-in-oil (w/o) microemulsion

reaction medium.

2.

Synthesis of Metal

Alloys

Various

metal alloys can be prepared in

the similar way as described

in scheme 1. It consists of

mixing

the reverse micelle containing

two or three metal precursors and

another reverse micelle

contain

reducing species. Example:

formation of Pt-Ru (1:1)

alloy. In order to prepare

the alloy

nanoparticles,

both Pt4+ and Ru3+

will be taken

in 1:1 atomic ratio to form

reverse microemulsion

I.

Reverse microemulsion II will be prepared by

using NaBH4 reducing agent. When both

the

reverse

microemulsions are mixed

together, reduction of Pt4+ and Ru3+

takes place by

BH4- ions

and

results in the formation of

Pt-Ru (1:1) nanoparticles

(Xiong and Manthiram, 2005). In

the

similar

way, Pt-Fe nanoparticles in different

ratios (1:1, 1:2 and 1:3)

can be prepared (Carpenter

et

al.,

2000). In the same manner,

various metal chalcogenides also can be

prepared by taking

two

micelle solutions containing

the desired ions prepared

separately and then rapidly

mixed.

In

conventional methods of preparation,

the reaction temperature

should be high to

promote

alloy

formation. As a result, the

formed particles will be large in

size. Moreover, the shape of

the

particle

cannot be controlled. Since the

reaction takes place inside

the micellar cores,

(i)

the enormous amount of heat

that is generated within the

micellar cores during the

reduction

process

is enough to form alloy of

desired composition.

and

(ii) both size, shape and

composition can be controlled.

3.

Synthesis of Metal

Oxides

The

synthesis of oxides from reverse

microemulsion relies on the

co-precipitation of one or more

metal

ions. It is almost similar in

many respects to the

precipitation of oxides from

aqueous

solutions.

But the precipitation occurs

within the micellar cores so

that particle size as well

as

shape

can be controlled. In a typical process,

precipitation of hydroxides is induced by

addition

of

a reverse micelle solution containing

dilute NH4OH

to a reverse micelle solution

containing

aqueous

metal ions at the micellar

cores. Alternatively, dilute

NH4OH can

simply be added

7.6

Microemulsion

Techniques

directly

to a micelle solution of the

metal ions. The

precipitation of the metal

hydroxides is

typically

followed by centrifugation and heating in

the presence of oxygen to

remove water

and/or

improve crystallinity. In general, it is

represented as follows:

A2+ +

2B2+ + OH-

(excess) → AB2O4 + xH2O↑

Where

A and B are metals.

In

this way, simple metal

oxides and multicomponent metal

oxides can be prepared. Some of

the

examples

of nanomaterials synthesized in w/o

microemulsions are given in

Table 7.1.

Table

7.1. Nanomaterials formed in

w/o microemulsions

Nanoparticle

system

Example

Reference

Pt

Metals/Metal

alloys

Rojas

et

al.,

2005

Pd

Boutonnet

et

al.,

1982

Ag

Taleb

et

al.,

1997

Au

Herrera

et

al.,

2005

Pt-Ru

Xiong

and Manthiram, 2005

Fe-Pt

Carpenter

et

al.,

2002

Pd-Co-Au

Raghuveer

et

al.,

2006

ZnS

Metal

chalcogenides

Khiew

et

al.,

2005

PbS

Eastoe

et

al.,

1995

RuSe

Venkateswara

Rao and Viswanathan, 2007

Pb2Ru2O7

Metal

oxides

Raghuveer

et

al.,

2002

CeO2

Bumajdad

et

al.,

2004

CoFe2O4

Liu

et

al.,

2003

LiNi0.8Co0.2O2

Lu

et

al.,

2000

Core-shell

nanoparticles

Fe3O4/SiO2

Tago

et

al.,

2002

Fe/Au

Zhou

et

al.,

2000

The

Evolving Synthetic Strategies in

Chemistry

7.7

4.

Synthesis of Core-Shell

Nanoparticles

Some

of the metallic nanoparticles

like Fe, Co, Ni are

susceptible to rapid oxidation.

This

problem

can be largely circumvented by coating

the nanoparticles with gold

or other inert

metals.

The technique for applying

gold coatings on metal

nanoparticles is reasonably

straightforward

and simply adds an additional

step to the reverse micelle

synthesis. In this

process,

a water-soluble gold salt

(HAuCl4)

is dissolved and dispersed in a separate

reverse

micelle

solution that is then added

to the metal-containing reverse micelle

solution that has

already

been reduced with an excess of

BH4-.

The aqueous AuCl4- ions encapsulate the

metal

particles

and are subsequently reduced by forming a

metallic gold shell around

the metal

particles.

8AuCl4- + 3

BH4- + 9H2O →

8Au + 3B(OH)3

+

21H+

+

32Cl-

The

preparation of core-shell type

structures is not limited to

metals as the core or

shell

materials.

Combinations of precipitation, reduction

and hydrolysis reactions can be

performed

sequentially

to produce oxides coated

with metals, oxides coated

with oxides, and so

forth.

EFFECTS

OF THE PARAMETERS ON THE FORMATION OF NANOPARTICLES

IN

MICROEMULSION

The

main parameters that

influence the size of

nanoparticle are molar

ratio, W =

[water]/[surfactant],

type of solvent employed,

surfactant or co-surfactants used

and

concentration

of reagents. Recent investigations

suggest that the particle

shape also can be

affected

by the influence of micellar

template, added anions and

molecular adsorption. But

a

general

method for controlling

nanocrystal shapes through

soft chemistry has not

yet been found.

The

major factors that influence

the formation of nanoparticles

are explained with

examples

below.

Water-to-Surfactant

Ratio, W

The

size of the metallic particle will

depend on the size of the

droplets in the microemulsion.

The

droplet

size will be influenced by the

water-to-surfactant ratio, W.

In

general, the volume of water

in microemulsions is proportional to the

cubic radius of the

water

core. And also the amount of

surfactant which is present as a film

around the water cores

is

proportional

to the surface area of the

micro/nanodroplets. So the molar

ratio of water to

surfactant

(W) has a linear

relationship with the radii

of the water cores (Rw). It

has been

observed

in AOT microemulsion system that

the water-pool radius

increases with the

water

7.8

Microemulsion

Techniques

content.

An increase of molar ratio, W at

constant concentration of surfactant will

increase the

average

diameter of the droplets.

Consequently, the obtained

nanoparticles will be large in

size.

Table

7.2. Characteristic of silver

particles obtained in w/o

microemulsion (data taken from

ref.

23)

W

Reducing

agent

Conc.

of reducing

Particle

size (nm)

agent

(M)

2.5

x 10-4

-

NaBH4

2

2.5

x 10-4

2.7

NaBH4

5

1.0

x 10-5

-

NaBH4

7.5

1.0

x 10-4

4.5

7.5

NaBH4

2.5

x 10-4

5.5

NaBH4

7.5

1.0

x 10-4

6.0

NaBH4

15

2.5

x 10-4

7.0

NaBH4

15

For

example, by dynamic light

scattering technique, it has

been confirmed that the

water core

radius,

Rw, is

coincident with the equation

Rw(nm) = 0.18W + 1.5 in a

wide range of alkanes. For

example

in the AOT-water-isooctane microemulsion

system, it was found that

the linear

relationship

between Rw and W was Rw

(Å) =

1.5W. Thus the linear

relationship may be

different

in

various systems. Generally, low

water content is favorable to

form smaller

microemulsion

droplets

(reverse micelles) which

yield fine nanoparticles

with a narrow size distribution. On

the

contrary,

high water content is

favorable to form bigger

microemulsion droplets which

are easy

to

fabricate larger particles.

The reason for the

behaviour is explained as follows:

Actually, at

low

water content, the water

solubilized in the polar core is

bound by the surfactant

molecules,

which

increases the boundary

strength and decreases the

intermicellar exchange rate. As a

result,

a

decrease in water content

induces formation of monodisperse

nanoparticles with small

particle

size.

However, the bound water

would turn into bulk

water with an increase in

water content,

which

is benefit for the water

pools to exchange their

contents by collisions and makes

the

chemical

reaction or co-precipitation between

compounds solubilized in two

different reverse

micelles

complete more quickly. Since

the nature of bulk water is

drastically different from

that

of

bound water, reactants would be

rapidly transferred from one

water core to another, and

thus

The

Evolving Synthetic Strategies in

Chemistry

7.9

the

resultant particle size is relatively

big and the size distribution

becomes relatively wide.

The

variation

of silver and Fe nanoparticles size with

W is given in Tables 7.2 and

7.3 respectively.

Table

7.3. Characteristic of iron

particles obtained in w/o

microemulsion (Data taken

from ref.

24)

[FeCl2]x104

[NaBH4]x103

Particle

size

S.

No

[AOT]

W

(mol/dm3)

(mol/dm3)

(nm)

3.9

3.5

7.5

22

0.1

1

4.1

0.68

1.6

22

0.1

2

2.5

0.35

0.93

10

0.05

3

1.9

24

48

5

0.025

4

2.5

24

48

9

0.025

5

3.3

24

48

13

0.025

6

4.3

24

48

18

0.025

7

4.7

24

48

22

0.025

8

5.4

24

48

26

0.025

9

5.8

24

48

31

0.025

10

Solvent

Effect

Particle

size is affected by solvent type.

This was shown initially by

Pileni (2003) in a study

on

silver

nanoparticles, in which larger

particles were seen (by

TEM) to be formed in isooctane

than

in

cyclohexane. This is probably due to

the significant difference in

intermicellar exchange rate

constant

between the two solvents - a

factor of 10.

The

change in growth rate has been

explained in the following

way:

(i)

Smaller

and less bulky solvent

molecules with lower

molecular volumes such

as

cyclohexane,

can penetrate between surfactant tails

and increase the

surfactant

curvature

and rigidity. The increased

rigidity at the interface

may lead to a slower

growth

rate.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES