|

Chapter

- 3

METHODS

BASED ON ACTIVATING THE REACTING

SUBSTANCE

R.

Mahalakshmy

1.

INTRODUCTION

The

art of carrying out

efficient chemical transformations is a

major concern in modern

organic

synthesis. Two aspects are of utmost

importance when considering

the outcome of a

reaction,

viz., selectivity and

efficiency (optimization of

yields).

The

new procedures

developed

should also be compatible with

our environment and thus

facilitate preserving

our

resources.

The right activation mode

is, therefore, development of methods

that promote an

efficient

chemical transformation. In this

article, activation should be

understood in a rather

wide

sense. In one-way it is described as a

sort of catalysis facilitating

the course of the

reaction

by lowering the activation

energy. Another way it is

explained in relation to

non-

catalytic

path.

Activation

mode

Physical

Chemical

(i)

Microwave

(ii)

Ultrasound

Catalytic

Non-catalytic

Aqueous

(iii)

High Pressure

Ionic

liquid

(i)

Solvophobic

(i)

Homogeneous

(ii)

Heterogeneous

Supercritical

(ii)

Solvent free

(iii)

Biocatalysis

Micelles

(iii)

Physicochemical

(iv)

Photocatalysis

Micro

emulsion

Electrochemical

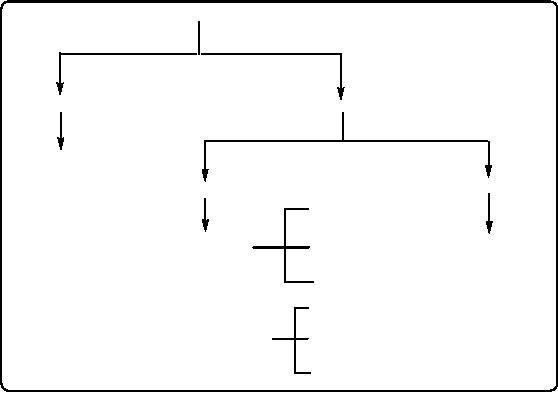

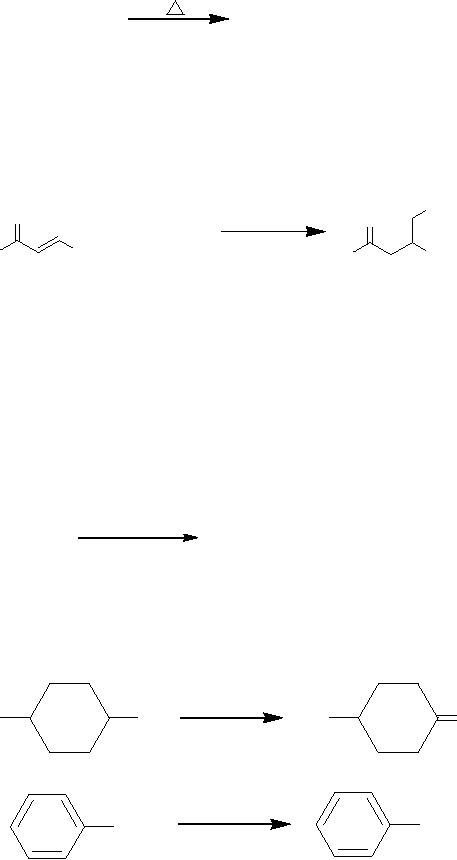

Scheme

3.1. Types of activation

mode

Activation

is achieved in different ways,

which may be classified into

physical, chemical or

biochemical,

physicochemical modes. Although

exhaustivity is not the aim,

this article tries

to

give a survey on the most recent

advances in either traditional

modes (pressure,

light,

3.2

Methods

Based on Activating the Reacting

Substance

chemical

catalysis) or in novel techniques

(microwaves, sonication,

biocatalysis).

The

various

activation modes discussed in

this article are shown in

scheme 3.1.

2.

PHYSICAL METHODS FOR THE ACTIVATION OF

REACTING

SUBSTANCE

2.1.

Activation by Microwave

Microwaves

are a form of electromagnetic waves

(wavelength between 1cm and

1m). When

molecules

with a permanent dipole are

placed in an electric field,

they become aligned

with

that

field. If the electric field

oscillates, then the

orientations of the molecules will

also

change

in response to each

oscillation.

Most

microwave ovens operate at 2.45

GHz,

wavelength

at which oscillations occur

4.9 x109 times

per second. Molecules

subjected to

this

microwave radiation are

extremely agitated as they

align and realign themselves

with the

oscillating

field, creating an intense

internal heat that can

escalate as quickly as 10�

C

per

second.

This technique proves to be

excellent in cases where

traditional heating has a

low

efficiency

because of poor heat transmission

and, hence, local overheating is a

major

inconvenience.

Microwave

energy is fast becoming the

method of choice for both

industrial and

academic

chemists for driving

reactions to completion, as it offers

the safest, most

effective

way

to increase reaction rates and

improve product yields,

while promoting green

chemistry.

Reactions

that previously took hours,

or even days, to complete can

now be performed in

minutes.

Decreasing reaction times

offers teaching opportunities: students

have more time

for

design, optimization, characterization

and analysis of reaction

processes and

products.

Additionally,

microwave-assisted reactions are

often performed in aqueous solutions or

neat,

minimizing

the need for organic

solvents, simplifying the

work-up process, and

providing

"green"

reaction conditions.

Is

microwave assisted organic

synthesis green and

safe?

It's

time to think of the

environment and our impact

on it. Microwave energy is an

inherently

efficient

way to transfer energy to a

reaction, as it transfers kinetically

rather than

thermally.

Because

of this quality, it is the

ideal energy source for

driving reactions and it

also has the

following

advantages.

Use

water, ethanol or other

environmentally benign

solvents

�

Neat

reactions/high conversions help

eliminate waste

�

Non-hazardous

reagents help students design safer

syntheses

�

Use

catalysts, not stoichiometric

reagents

�

Synthetic

Strategies in Chemistry

3.3

Not

only is microwave-assisted chemistry is

good for the environment, it

is also safer for

chemists.

Microwave synthesis systems designed

for the laboratory offer

an

Unmatched

level of safety.

�

Eliminate

hot plate burns

�

Reactions

return to room temperature

before removing from

microwave

�

A

few representative examples of

microwave assisted chemical

conversions are

considered.

(i)

Oxidation of Primary and Secondary

Alcohol

A

fast and facile microwave

accelerated oxidation of primary alcohols

to carboxylic acids

and

secondary alcohols to ketones were

carried out under

organic/aqueous biphasic

conditions

using 30% aqueous H2O2 in

the presence of sodium

tungstate and

tetrabutylammonium

hydrogen sulfate (TBAHS) as a

phase-transfer catalyst[1]. The

experimental

procedure involves a simple

mixing of an alcohol, Na2WO4, 2H2O and

TBAHS

followed

by the addition of 30% aqueous

H2O2 in

25:1:1:125 molar ratios for

primary and

25:1:1:40

molar ratio for secondary

alcohols in an open vessel. Then

the reaction mixtures

were

placed inside a monomode

microwave reactor and

irradiated under a reflux

condenser

for

specific time. The best

results were obtained when

the temperatures of reaction

mixtures

were

set to 90� C and 100� C

for primary and secondary

alcohols, respectively.

O

OH

OH

H2O2,

MW, 20 min

Na2WO4,

TBAHS

(Yield=

84%)

O

OH

H2O2,

MW, 10 min

Na2WO4,

TBAHS

(Yield=

92%)

(ii)

Nucleaphilic Substitution

Reaction

The

synthesis of arylamines through direct

nucleophilic substitution of aryl

halides typically

requires

highly polar solvents such

as DMF and DMSO at high temperatures

even with

highly

activated aryl halides. A

novel and efficient synthesis of

N-arylamines by the

reaction

of

activated p-bromonitrobenzene with

secondary amines (morpholine and

N-phenylpi-

3.4

Methods

Based on Activating the Reacting

Substance

perazine)

in the presence of basic Al2O3 under

microwave irradiation was

carried out under

solvent-free

conditions in a simple domestic

oven [2].

O2N

N

O

Al2O3,

3 min

Br

+ HN

O2N

O

MW

(350W)

Yield=

80%)

Both

alumina and amines are polar

so they absorb microwaves

effectively and

consequently

the

reaction is completed in a short

time.

Thus,

the microwave irradiation

has been successfully applied in

organic chemistry.

Spectacular

accelerations, higher yield

under milder reaction

conditions and higher

product

purities

have all been achieved so

far. More over, by using

this technique, a number

of

reactions

has been carried out

successfully that do not

occur by conventional heating

and

even

modifications of selectivity (chemo,

regio and stereoselectivity)

are obtained.

2.2.

Activation by Ultrasound

Ultrasounds

are acoustic waves with frequencies

ranging from 20 to 100 MHz.

They are

mechanical

waves that are not absorbed by

solid and, therefore, they

do not induce

heating.

They

are transmitted through any

substances solid, liquid or

gas, which possesses

elastic

properties.

How

does ultrasound accelerate a chemical

reaction?

The

energy of ultrasound is insufficient to

cause chemical reactions,

but when it travels

through

media a series of compressions and

rarefactions are created, the

rarefaction of liquids

leading

to cavities. During rarefaction,

the negative pressure

developed by the power

of

ultrasound

is enough to overcome the

intermolecular forces binding the

fluid and tear it,

producing

cavitation bubbles. The succeeding

compression cycle can cause

the micro bubbles

to

collapse almost instantaneously

with the release of large

amounts of energy.

The

enormous

rise in local temperatures and

pressures produces a dramatic beneficial

effect of

reaction

acceleration, with relatively

short times being required

for completing the

reaction

such

that the decomposition of

thermally labile products is

minimised.

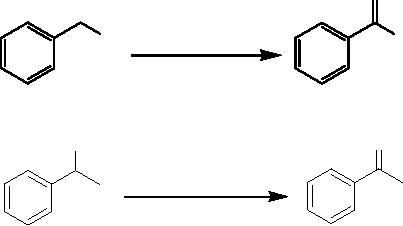

A

schematic

representation

of cavitaional erosion of solid is

given in Fig. 3.1.

Synthetic

Strategies in Chemistry

3.5

Fig.

3.1. Cavitational erosion of

solid

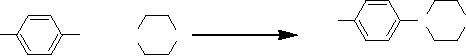

How

to carry out a chemical

reaction in an ultrasonic

bath?

A

number of common reactions

used in synthetic organic

chemistry can be carried out

more

efficiently

using ultrasound. These

reactions can be performed by

immersing a reaction

vessel

into an ultrasonic bath

(Fig. 3.2) or by immersing an

ultrasonic probe (horn) into

a

reaction

medium.

Fig.

3.2. Apparatus for carrying

out a reaction in an ultrasonic

cleaning bath

(Reproduced

from a general article

entitled, "Ultrasound: A Boon in

the Synthesis of

Organic

Compounds"

published in Resonance, 1998,

3,

56)

There

are several advantages of this

method and they are:

(i)

It

increases the yield and

the percentage of by-products

decreases.

(ii)

Reactions

occur faster, so that lower

temperatures can be used.

(iii)

Reaction

times decrease by a factor

five to fifty for identical

isolated yields.

3.6

Methods

Based on Activating the Reacting

Substance

(iv)

It

provides alternative pathways

for reactions, due to the

formation of high-energy

intermediates.

In

the following text several

specific applications of Sonochemistry

are given [3].

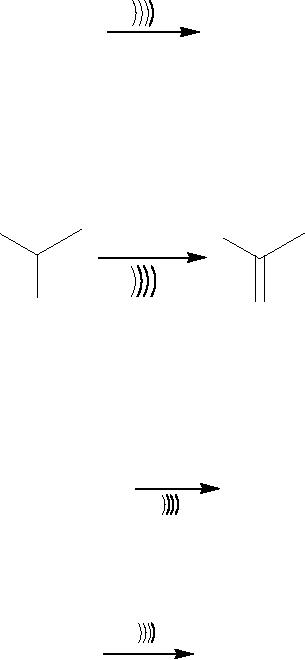

(i)

Preparation of organometallic

reagents

Sonochemistry

enables reactions involving

organometallic reagents to be carried

out safely.

The

reaction of magnesium with

ethyl, butyl and phenyl

bromides in aqueous diethyl ether

or

in

n-dibuty1

ether containing 50% benzene

or light petroleum is accelerated by

utilising

ultrasound.

R-Mg-X

R-X

+ Mg

R

= C2H5 ,

nC4H9 , C6H5

X

= Cl, Br

(ii)

Oxidation of alcohol

The

oxidation of alcohols by solid potassium

permanganate in hexane and benzene

is

significantly

enhanced by sonication in an ultrasonic

bath.

R

R

KMnO4

OH

O

(iii)

Reformatsky reaction

The

Reformatsky reaction can be

carried out in high yield

(98 %) in just 30 minutes at

2530o

C

as compared to conventional method, which

gives only 50% yield

after 12 hours at 80o C.

NaX

C4H8C=O

+ BrCH2COOEt + Zn

C4H8C(OH)CH2COOEt

(iv)

Breakdown of polymeric organometallic

compound

The

breakdown of polymeric organotin

fluoxides is carried out by

sonication method.

For

this

reaction, there is 900-fold increase in

rate as compared to conventional

reflux.

[R3SnF]n

nR3SnX

R=Me,

nBu or Ph

X=Cl,

Br, NCO

Synthetic

Strategies in Chemistry

3.7

(*Note:

In the above examples the

symbol

represents

the sonication method)

In

addition to the types of

reactions mentioned, ultrasound

has also been used in the

case of

enzyme

catalysed reactions, polmer

chemistry and coal

liquification.

Extension

of

combination

of sonochemistry with other

specific methods, such as

photochemistry and

electrochemistry

appear to be promising. Since it is an

upcoming and a recent field

of

interest,

there is a great deal more

to explore in ultrasonics as an important

tool in order to tap

its

full potential for the

discovery of new reactions

utilising highly energetic

sound waves.

The

sonochemical boom is turning

out to be a real boon for

synthetic chemistry.

2.3.

Activation by high

pressure

Pressure

represents a mild non-destructive

activation mode, generally

respecting the

molecular

structure by limiting decomposition or

further evolution of the

products. The

specific

effects of high pressure can

be of important value for

organic synthesis. The

kinetic

pressure

effect is primarily determined by

the variation of volume due

to changes in the

nuclear

positions of the reactants

during the formation of the

transition state. Related

to

volume

requirements are steric

effects since the bulkiness of

the molecules involved in

the

transition

state conditions the

magnitude of the steric

interactions.

As

a consequence,

pressure

affects volume changes and

should have an effect on

steric congestion.

As

a mild activation mode,

pressure may be considered of

value in the synthesis of

thermally

fragile molecules, permitting a

lowering of the

temperature.

In

addition, the

selectivity

is generally preserved or even

improved under such

conditions. High-pressure

chemistry

is now recognized as a powerful

method to achieve synthetic

organic reactions,

which

are not readily accessible by

usual means. The

applications of this technique

to

organic

reactions like Diels-Alder

[4] and Cyclo addition

[5] are discussed.

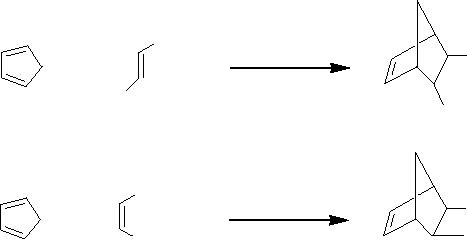

(i)

Diels-Alder reaction

The

high pressure (0.8 GPa)

Diels-Alder reaction of

N-methyl-2(1H)-pyridones with

cyclooctyne

at 90�

C

affords 1:1 cycloadducts in 60 -

80% Yield. No adduct is

recovered at

normal

pressure due to the

extrusion of methyl

isocyanate.

O

H3C

R1

N

R1

+

R2

O

CH3

R2

3.8

Methods

Based on Activating the Reacting

Substance

(ii)

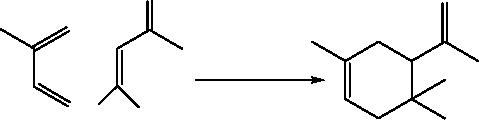

Cycloaddition reaction

Cycloaddition

of mesityl oxide to isoprene is

also carried out at high

pressure in

LiClO4/Diethy ether

medium.

O

+

20

MPa, 100 C, 24 h

Dimers

of

+

isoprene

LiClO4/Diethyether

Yield:52%

Yield:19%

When

traditional synthetic strategies appear

forbiddingly difficult or fail

utterly, the pressure

parameter,

possibly associated with

other activation methods may be

considered. Other

salient

features of this method

include:

(i)

Extreme

simplicity of the

method

(ii)

Capacity

to induce ionogenesis

(iii)

Capacity

to remove steric

inhibition

Thus

the notable advantages of this

method materialize in new or

improved synthetic

routes,

and

it adds another important

dimension to the existing

synthetic activation modes.

3.

CHEMICAL METHODS FOR THE ACTIVATION OF

REACTING

SUBSTANCE

3.1.

Non-catalytic activation

3.1.1.

Solvophobic activation

3.1.1a.

Reaction in water

In

the most recent decades, the

use of water as a reaction

solvent or co-solvent has

received

much

attention in synthetic organic

chemistry, with sometimes surprising

and unforeseen

results.

It plays an essential role in life

processes; however its use

as a solvent has been

limited

in organic synthesis. Despite the

fact that it is the

cheapest, safest and most

non-toxic

solvent

in the world, its presence

is generally avoided through

the dehydrative drying

of

substrates

and solvents. But still it

can be considered as a unique

solvent. Moreover, water

is

the

`solvent of Nature' and

therefore the use of water

as a medium for organic

reactions is

one

of the latest challenges for

modern organic chemists.

Synthetic

Strategies in Chemistry

3.9

There

are many potential reasons

to replace the classical organic

solvents by water. They

are

(i)

Cost,

safety and environmental

concern.

(ii)

Aqueous

procedures are often referred to as

green, environmentally friendly,

or

benign.

(iii)

The

unique solvation properties of

water have been shown to

have beneficial

effects

on many types of organic

reactions in terms of both the

rate and selectivity.

(iv)

Experimental

procedures may be simplified, since

isolation of organic

products

and

recycling of water-soluble catalysts and

other reagents can be achieved

by

simple

phase separation.

Selected

few organic reactions run in

an aqueous medium are

considered.

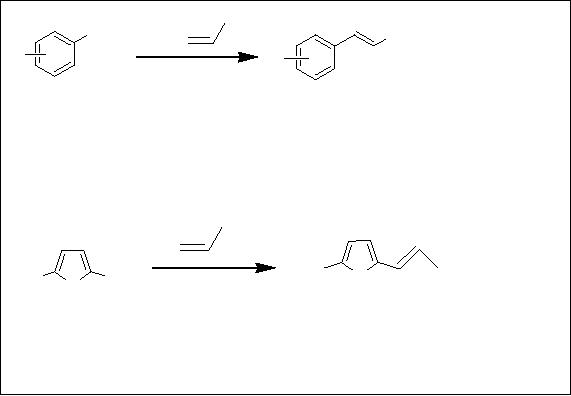

(i) Wittig

Reaction

Bergdahl

and co-workers published the

first report in the

literature describing that

Wittig

reactions

of stabilised (and poorly

water-soluble) ylides with

aldehydes are

unexpectedly

accelerated

in an aqueous medium [6].

COR2

CHO

COR2

Ph3P

R1

R1

a

66-99%

R1= H,

2-NO2, 4-NO2,

2-CN, 4-OH, 4-OMe, 4-NH2, 2-OBn, 3-OBn

R2=

Me, OMe, O-Bu, O-Troc,

Ph

COR2

Ph3P

COR2

R1

1

X

CHO

R

a

X

84-97%

X

= S, NH

R1 = H,

Br, Me, NO2

R2 = OMe,

O-Bu

a)

aldehyde (1 mmol), ylide

(1.2-1.5 mmol), H2O

(5 mL), 20-90�C, 5 min - 4 h.

Troc= 2,2,2-

trichloroethoxycarbonyl.

(ii)

Mannich-type Reactions

Kobayashi

and co-workers published an

efficient (up to 94% yield)

enantio- and

diastereoselective

protocol for Mannich-type

reactions of a hydrazono ester

with silicon

3.10

Methods

Based on Activating the Reacting

Substance

enolates

in aqueous medium. One

example of a syn

adduct

from an (E)-silicon

enolate and

two

examples of anti

adducts

from (Z)-silicon

enolates are reported

[7].

NHBz

R1

OSiMe3

BzHN

N

a

NH

O

+

EtO

EtO

R2

R3

R3

O

R2

R1

O

R1 = H, Me,

Et, R2=H, Me, R3= Et, S-tBu,

4-Me-C6H4, 4-OMe-C6H4,

4-Cl-C6H4

Ph

Ph

MeO

NH

HN

OMe

b

Where

a = acyl

hydrazono ester (0.4 mmol),

silyl enol ether (1.2

mmol), ZnF2 (100 mol%), b

(10

mol%),

CTAB

(0.02

mmol),

H2O

(1.95

mL),

0

�C,

20

h.

CTAB=

cetyltrimethylammonium

bromide.

(iii)

Deprotection of Functional

Groups

Methods

for selective deprotection of

functional groups are key

tools for organic

chemists.

The

following examples, performed in

water, open new

possibilities for the use of

this

challenging

medium. Konwar and

co-workers [8] reported a

simple protocol for

the

deprotections

of oximes and imines under

neutral conditions (yields up to

90%) using a

I2/surfactant/water

system

X

a

N

O

R1

R2

R1

R2

X=

OH, Ph

R1,

R2 = alkyl

R1,R2=

aryl

R1= H,

alkyl, R2=aryl

.

Synthetic

Strategies in Chemistry

3.11

where

a= oxime or

imine (1 mmol), I2 (20

mmol%), H2O

(15 mL), SDS (0.2

mmol), 25-

40�C,

3.5-8 h.

The

main obstacle to the use of

water as reaction solvent is

the negligible solubility of

the

majority

of organic compounds in water.

This problem can be

addressed by using aqueous

organic

solvents or phase-transfer agents.

3.1.1b.

Reaction in ionic

liquid

Ionic

liquids are low-melting-point salts

that have attracted

considerable attention recently

as

greener

alternatives to classical environmentally

damaging solvents. "The

interest is mainly

due

to their peculiar properties

such as absence of flammability,

lack of measurable vapor

pressure,

and good ability to dissolve

organic, organometallic, and

even some inorganic

compounds.

These unique chemical and

physical characteristics of ionic liquids

are

increasingly

enticing chemists to explore their

use as media for organic

synthesis.

Ionic

liquids offer numerous advantages

over conventional organic

solvents for carrying

out

organic

reactions. They are,

(i)

Easy

product recovery

(ii)

Catalysts

can be recycled

(iii)

Ionic

liquids can be reused

(iv)

Their

thermodynamic and kinetic

behavior is different

(v)

Rates

of reaction are often enhanced

and

(vi)

Selectivity

is frequently better

Examples

for Ionic

Liquids

The

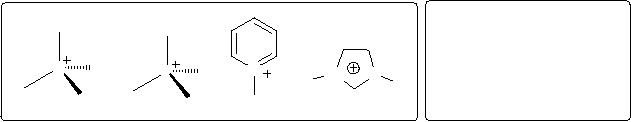

most common classes of ionic

liquids are alkylammonium

salts, alkylphosphonium

salts

alkylpyridinium

salts, and N, N�-dialkylimidazolium

salts. Few examples of

cationic and

anionic

ionic liquids are given in

Fig. 3.3.

BF4-,

PF6-, SbF6-, NO3-,

R1

R1

CF3SO3-,

(CF3SO3)2N-,

ArSO3-,

CF3CO2-,

CH3CO2-,

Al2Cl7-

N

R2

N

P

R2

R1 NH

N

R2

R3

R3

R3

R3

R

Fig.

3.3. Cationic and anionic

ionic liquids

3.12

Methods

Based on Activating the Reacting

Substance

Synthesis

and applications of halide

based ionic liquid

Halide-based

ionic liquids ILX (IL represents

cations such as 1, 3-dialkylimidazolium,

1-

alkylpyridinium

and tetraalkylammonium; X represents

halide anions) can be used

as

reagents

in nucleophilic substitution for

the conversion of alcohols to

alkyl halides. This

reaction

provides an alternative way of

preparing other types of

ionic liquids (ILA) based

on

the

conjugate bases of acids (HA)

[9].

-H2O

ILA

+ RX

ILX

+ HA + ROH

Where,

ILX:

halide-based ionic liquids;

X=Cl, Br, I; HA: acids; ROH:

alcohols

ILA:

new ionic liquids with

conjugate bases of HA

These

halide-based ionic liquids (ILX)

can also be used as reaction

media for copper-

catalyzed

nucleophilic aromatic substitution

reaction for formation of

aryl nitriles (ArCN).

Cu

catalyst

ArCN

ArY

+ NaCN

ILX,

-NaY

ArY:

Aryl halides, Y= I or Br, ILX:

halide-based ionic

liquid

X=

Cl, Br, I; Cu catalysts:

CuX, X= Cl, Br, I, CN

Trihalide-based

ionic liquids (ILX3)

that can be used as reagents

as well as reaction media

in

halogenation

reactions

-2H2O

ILX

+ 2HX + H2O2

ILX3

ILX:

halide-based ionic liquids, X=

Cl, Br, I

HX:

hydrogen halides

"The

rapid growth of interest in

ionic liquids is mainly

limited to people in academia

and

national

laboratories," "There is a lot of

skepticism among industrial chemists,

probably

because

our understanding of these

materials is limited. Before we

see industrial chemists

enthusiastically

involved in exploring the

field, a lot of work has to

be done. We need

information

on the toxicity and safety

of these materials and their

effect on the

environment,

as

well as an assessment of their

life cycles. Also, we need cost analyses

compared with

existing

technologies. In addition, it is

important to develop a good

database of all the

information

available on ionic liquids.

Unless we have all this

information, the growth will

be

limited

to a few sectors

only."

Synthetic

Strategies in Chemistry

3.13

3.1.1c.

Reaction in supercritical

media

What

is a supercritical fluid?

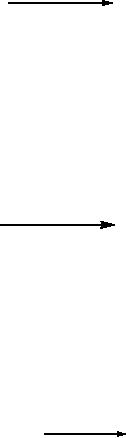

Supercritical

fluids may be defined as the

state of a compound, mixture or

element above its

critical

pressure (Pc) and critical

temperature (Tc), but below

the pressure required

to

condense

it into a solid. It possesses

the characteristics of both fluid

and gaseous

substances:

the

fluid behavior of dissolving

soluble materials, and the

gaseous behavior of

excellent

diffusibility.

They occupy a point where

pure and applied science

meets head on. This is

a

feature

that has attracted many

workers to the field. A

general phase diagram for

critical

fluid

is given in Fig. 3.4.

Fig.

3.4. General phase diagram

for super critical

fluid

(Reproduced

from the web page:

http://www.ed406.upmc.fr/cours/shaldon.pdf)

Reactions

under supercritical conditions

have been used for

large-scale industrial

production

for

most of the twentieth century,

but the application of

supercritical fluids (SCFs) in

the

synthesis

of complex organic molecules is

only just emerging. Research

in this field has

been

particularly

active in the last decade of

this century, because the

following special

properties

of

SCFs make them attractive

solvents for modern

synthetic chemistry.

3.14

Methods

Based on Activating the Reacting

Substance

Increased

reaction rates and

selectivities resulting from

the high solubility of

the

�

reactant

gases

Rapid

diffusion of solvents

�

Weakening

of the solvation around the

reacting species and the

local clustering of

�

reactants

or solvents.

These

fluids are easily recycled

and allow the separation of

dissolved compounds by a

�

gradual

release of pressure

Sequential

and selective precipitations of

the catalyst and product

would be possible.

�

Example

for Carboncarbon bond formation

reactions in supercritical

fluids

(i)

Diels-Alder

reaction

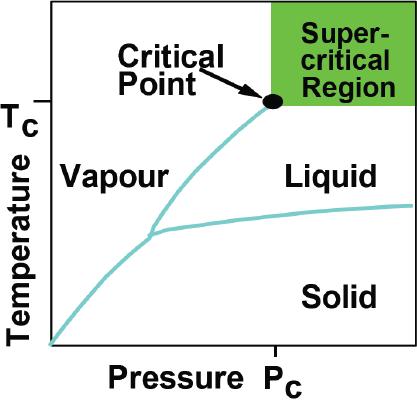

The

DielsAlder reaction is the most

widely-used synthetic method

for the synthesis of

polycyclic

ring compounds. Kolis et al

[10] have reported the

possibility of performing

DielsAlder

reactions in superheated and

scH2O

due to the unique properties

of scH2O

[11].

The

reactions tested were the

cycloadditions of cyclopentadiene (1)

with diethyl furmarate

(2)

and

diethyl maleate (4) using

scH2O

as the solvent. They

obtained yields of 10 and

86% for 3

and

5, respectively, after 1 h. Although

the yield of the endo/exo-2,

3-diethyl ester of 5-

norbornene

3 was low, equal amounts of

both isomers of 5 were formed in

good yield from

the

cis diene.

CO2Et

scH2O

CO2Et

+

375

oC,

1h

EtO2C

CO2Et

2

3

1

CO2Et

scH2O

CO2Et

+

CO2Et

375

oC, 1h

CO2Et

5

4

1

3.1.2.

Solvent Free or Solid State

Reaction

Synthetic

Strategies in Chemistry

3.15

A

solvent-free or solid-state reaction

may be carried out using

the reactants alone

or

incorporating

them in clays, zeolites,

silica, alumina or other matrices.

Thermal process or

irradiation

with UV, microwave or ultrasound

can be employed to bring

about the reaction.

Solvent-free

reactions obviously reduce pollution,

and bring down handling

costs due to

simplification

of experimental procedure, work up

technique and saving in

labour. These

would

be especially important during

industrial production.

Often,

the products of solid state

reactions turn out to be

different from those obtained

in

solution

phase reactions. This is

because of specific spatial

orientation or packing of

the

reacting

molecules in the crystalline

state. This is true not

only of the crystals of

single

compounds,

but also of co-crystallized

solids of two or even more

reactant molecules. The

host-guest

interaction complexes obtained by

simply mixing the components

intimately also

adopt

ordered structure. The

orientational requirements of the

substrate molecules in the

crystalline

state have provided

excellent opportunities to achieve

high degree of

stereoselectivity

in the products. This has

made it possible to synthesize chiral

molecules

from

prochiral ones either by

complexation with chiral

hosts or formation of

intermediates

with

chiral partners.

Experimental

method

If

two or more substrates are

involved in the reaction,

they are thoroughly ground

together in

a

glass mortar or cocrystallized,

and allowed to stay at room

temperature or transferred to a

suitable

apparatus and heated carefully in an oil

bath or exposed to appropriate

radiation until

the

reaction is complete.

More

sophisticated reaction procedures are

also adopted, if

necessary.

TLC can monitor the

progress of the reaction. In

some cases, a small quantity

of

water

or a catalyst may be added. If it is a

single-compound reaction, it is subjected

to heat or

radiation

directly. Care is to be taken to collect

the volatile products, if

they are produced. In

this

article illustrative examples

representing a number of organic

syntheses performed

under

both

thermal and photochemical

conditions are described

[12].

Examples

(i)

Solid-state reactions are

not really a new concept.

They have been reported even

in

undergraduate

text books. In fact, the

historically significant first

organic synthesis of

urea

by W�hler achieved in 1828

belongs to this class

Solid

NH4NCO

NH2-CO-NH2

3.16

Methods

Based on Activating the Reacting

Substance

(ii)

Pyrolytic distillation of barium or

calcium salts of carboxylic acids to

prepare ketones is

even

now a commonly used

procedure.

(Ph-CH2-COO)2Ba

Ph-CH2-CO-CH2-Ph +

BaCO3

(iii)

Michael Addition

The

addition of a nucleophile to a

carbon-carbon double bond

with a strong

electron-

withdrawing

group at the vinylic

position is known as Michael

addition.

NO2

Al2O3

O

O

+

CH3NO2

Ph

Ph

Ph

Ph

(iv)

Aldol Reaction

Aldol

condensation is an important reaction of

aldehydes and ketones in

forming carbon-

carbon

bonds. The addition of an

enol or enolate ion of an

aldehyde or a ketone to

the

carbonyl

group of an aldehyde or a ketone is

aldol addition, or aldol

condensation, if water is

eliminated

in a subsequent step to produce a, b-unsaturated

aldehyde or ketone.

Many

variations

of this reaction are known

and are called by different

names.

NaOH

Solid

r.t

Ar-CHOH-CH2-CO-Ar' +

Ar-CH=CH-CO-Ar'

ArCHO

+ Ar'-CO-CH3

5

min; 97%

(

In solution only 11% yield

was realized in 5

min)

(v)

Oxidations of alcohol to

ketone/aldehyde

Cr-Oxides

t-Bu

OH

t-Bu

O

Solid

Cr-Oxides

CHO

CH2OH

Solid

Synthetic

Strategies in Chemistry

3.17

3.1.3.

Activation by Physicochemical

Methods

3.1.3a.

Reaction in Micellar

media

Micelles

are dynamic colloidal aggregates

formed by amphiphilic surfactant

molecules.

These

molecules can be ionic,

zwitterionic, or non-ionic, depending on

the nature of their

head

groups, their micelles being

classified in the same way.

In dilute solutions,

amphiphile

molecules

exist as individual species in

the media and these

solutions have completely

ideal

physical

and chemical properties. As

the amphiphile concentration

increases, aggregation of

monomers

into micelles occurs and, as

a consequence, these properties

deviate gradually

from

ideality. This concentration is

called the critical

micellisation concentration.

During

the

formation of micelles, head group

repulsions are balanced by

hydrophobic attractions

and

for

ionic micelles, also by attractions

between head groups and

counterions. Hydrogen

bonds

can

be also formed between adjacent head

groups.

It

is well known that

performing the reactions in

micellar media instead of

pure bulk

solvents

can alter the rates

and pathways of all kinds of

chemical reactions.

Micelles

are

able

to

(a)

Concentrate the reactants

within their small

volumes,

(b)

Stabilise substrates, intermediates or

products and

(c)

Orientate substrates so that

ionization potentials and

oxidationreduction

properties,

dissociation

constants, physical properties, quantum

efficiencies and reactivities

are

changed.

Thus,

they can alter the

reaction rate, mechanism and

the regio- and

stereochemistry. For

many

reactions, rate increments of

5100-fold over the

reactions in homogeneous solutions

have

been reported. In some cases, rate

increments may be higher and

increments in the

order

of

106-fold have been

observed.

Example

(i)

Ring opening reaction of

epoxide

The

ring opening reaction of

styrene oxide with NaCN

was studied in the micellar

solution of

sodium

dodecyl sulfate (SDS) as an

anionic micelle at different

concentrations in the

presence

of catalytic amounts of Ce(OTf

)[13].

Ph

Micelle(SDS)

PhCH(OH)CH2CN +

PhCH(CN)CH2OH

O

Ce(OTf)4,

Cat, rt, NaCN

92%

8%

3.18

Methods

Based on Activating the Reacting

Substance

The

CMC of SDS= 8.1x10-3 M

Thus,

it is established that, in many

cases, performing the

reactions in micellar media

instead

of

organic solvents can alter

rates and the pathways of

the reactions.

3.1.3b.

Reaction in Microemulsion

Media

When

water is mixed with an

organic liquid immiscible

with water and an

amphiphile,

generally

a turbid milky emulsion is

obtained which, after some

time, separates again into

an

aqueous

and an organic phase. On the

water-rich side, the mixtures consist of

stable

dispersions

of oil droplets in water,

which coagulate with rising

temperature. A sponge like

structure

is obtained if the mixtures

contain approximately equal amounts of

water and oil.

On

the oil-rich side, dispersed

water droplets are found,

which coagulate with

decreasing

temperature.

The size of the domains is a

function of the amphiphile

concentration and the

volume

fractions of water and oil.

Since microemulsions contain

both a polar

component

(water)

and a non-polar component

(oil), they are capable of solubilising a

wide spectrum of

substrates.

The mechanism of solubilisation is

similar to that in micellar

solutions. The

micelles

are replaced by the oil

domains, which are capable

of solubilising all kinds

of

hydrophobic

substances. The solubilisation of

polar substances takes place

analogously

through

the aqueous domains of the

microemulsion.

The

solubilisation capacity of

microemulsions

is generally superior to that of

the micellar solutions and

can therefore, affect

the

rate and course of a certain

reaction.

The

use of microemulsions as media

for organic reactions is a

way to overcome the

reagent

incompatibility problems that are

frequently encountered in organic

synthesis. In this

sense,

microemulsions can be regarded as an

alternative to phase transfer

catalysis. The

microemulsion

approach and the phase

transfer approaches can also

be combined, i.e. the

reaction

can be carried out in a

microemulsion in the presence of a

small amount of phase

transfer

agent. A very high reaction

rate may then be obtained.

The reaction rate in

a

microemulsion

is often influenced by the charge at

the interface and this

charge depends on

the

type of surfactant used. For

instance, reactions involving anionic

reactants may be

accelerated

by cationic surfactants. The surfactant

counterion also plays a

major role for

the

reaction

rate. The highest reactivity

is obtained with small

counterions, such as acetate,

that

are

only weakly polarizable.

Large polarizable anions,

such as iodide, bind

strongly to the

interface

and may prevent other

anionic species to reach the

reaction zone.

Example

Synthetic

Strategies in Chemistry

3.19

(i)

Nucleophilic

substitution reactions were

performed in H2O/CO2 (w/c)

microemulsions

formed

with

an

anionic

perfluoropolyether

ammonium

carboxylate

(PFPE COO-NH4+) surfactant. These reactions

between hydrophilic

nucleophiles

and

hydrophobic

substrates

were

accomplished

in

an

environmentally

benign microemulsion without

requiring toxic organic

solvents or

phase

transfer catalysts.

(ii)

The

reaction between benzyl

chloride and potassium bromide to

form benzyl

bromide

is the first organic

reaction performed in w/c

microemulsion [14].

This

reaction

between a nonaqueous compound

soluble in CO2 and a CO2-insoluble

salt

may be expected to take

place at or near the surfactant

interface.

Cl

Br

+

K+Br-

K+Cl-

+

3.1.4c.

Electrochemical Activation

Reactive

intermediates such as carbocations,

carbanions, radicals and

radical ions can be

electrochemically

generated from various electroactive

species. Those intermediates

may

react

chemically (C) or electrochemically

(E) according to EC, ECE

mechanisms. Anodic

oxidations

produce acidic or electrophilic

species, which can react

with nucleophiles or

(and)

eliminate

protons or electrophiles. Cathodic

reductions afford basic or nucleophilic

species,

which

can react with protons or

electrophiles or (and) eliminate

nucleophiles. In this

way,

using

direct electrolytes can

selectively perform functional

group conversion,

substitution

reactions,

addition reactions, cleavage

reactions and coupling

reactions.

Activation

by

transition

metal catalysts is required when

the organic substrate is not

electroactive or leads to

non

desired reactions. The

metal-catalysed electrosynthesis proceeds

by a double activation:

i)

chemical activation of the

organic substrate by the electrogenerated

active form of a

transition

metal catalyst that

generates an organometallic species

more easily reduced

than

the

organic substrate, ii) followed by

activation by electron transfer of

the organometallic

species

formed in the previous

chemical activation step.

This double chemical

and

electrochemical

activation causes new

reactions to proceed, which involve

either, the

classical

organic reactive species,

produced in any electrochemical

steps (carbanions) or

organometallic

complexes (anionic or neutral) as

the basis of new

reactivity.

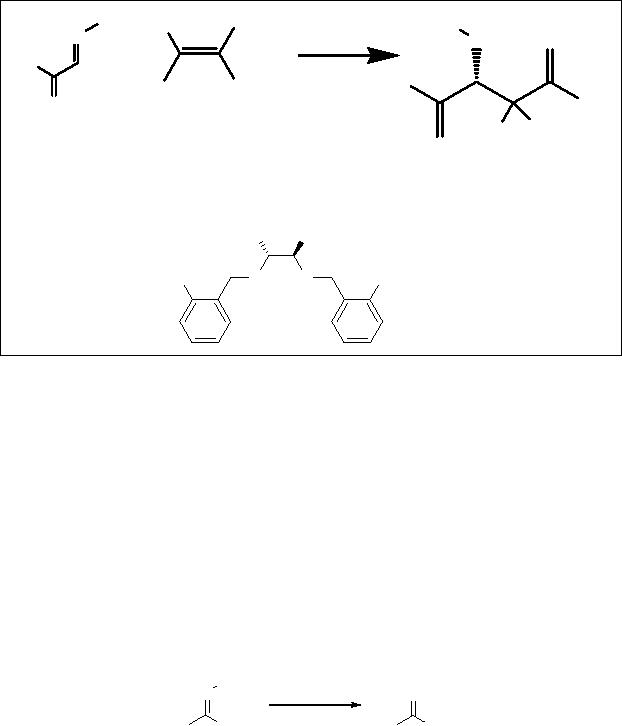

Example

3.20

Methods

Based on Activating the Reacting

Substance

Allylations

of aldehyde

Using

a recyclable electrochemical process

(up to five cycles with

excellent yield), a

tin-

mediated

protocol for the allylation

of aldehydes (95-100% yield) is

developed [15].

O

OH

Br

a

+

R

R=

Alkyl, aryl

Where

a = graphite electrode (2.0

V), aldehyde (5 mmol), allyl

bromide (8 mmol), SnCl2 (10

mmol),

H2O

(10 mL), r.t., 6-10

h.

3.2.

Catalytic Method of

Activation

The

word catalysis came from

the two Greek words,

the prefix, cata meaning

down, and the

verb

lysein meaning to split or

break. A catalyst breaks down

the normal forces that

inhibit

the

reactions of the molecules; a

widely accepted definition of catalyst

being, `a substance

that

increases the rate of

approach to equilibrium of a chemical

reaction without itself

being

substantially

consumed in the reaction process'.

Catalysis is the phenomenon of a

catalyst in

action,

wherein lowering of the

activation energy is a fundamental

principle that applies to

all

forms

of catalysis homogeneous, heterogeneous or

enzymatic.

Broadly

catalysis can be divided

into five categories:

(i)

Homogeneous

Catalysis: Both

the reactant and catalysts are present in

the same

phase

(ii)

Heterogeneous

Catalysis: Reactant

and catalysts are present in separate

phase,

the

catalyst is solid and the

reactant either liquid or

gas

(iii)

Bio

Catalysis: Also

known as enzyme-catalysis.

(iv)

Photo

Catalysis: Energy

for reactions is from light

source (hν) (e.g. TiO2

photocatalytic

purification and treatment of

H2O)

3.2.1.

Homogeneous catalysis

Homogeneous

catalysis is a chemistry term

which describes catalysis

where the catalyst is

in

the

same phase (ie. solid,

liquid and gas) as the

reactants and products.

The

hydrolysis of esters by acid

catalysis is an example of this -

all reactants and catalyst

are

dissolved

in water:

CH3CO2CH3(aq) + H2O(l) ↔ CH3CO2H(aq)

+ CH3OH(aq) - with

H+ catalyst.

Synthetic

Strategies in Chemistry

3.21

Example

Hydrogenation

of maleic acid to succinic

acid

O

H

O

O

H

H2,

Pd/C

OH

HO

OH

HO

H

EtOH

H

O

Advantage

and drawbacks

Highly

efficient in terms of slectivity (i.e.

regioselectivity. enantiomeric excesses)

and

�

reaction

rates, due to ther

monomolecular nature.

Catalyst

recovery can be very

difficult (due to the

homogeneous nature of

the

�

solution).

Product

contamination by residual catalyst or

metal species is a

problem.

�

3.2.2.

Heterogeneous Catalysis

Heterogeneous

catalysis is

a chemistry term which

describes catalysis where

the catalyst is

in

a different phase (ie.

solid, liquid and gas,

but also oil and

water) to the reactants

and

products.

Heterogeneous catalysts provide a surface

for the chemical reaction to

take place

on.

Example

(i)

Synthesis of Ammonia by Haber

process

3H2(g) + N2(g) ↔ 2NH3(g)

- catalysed

by Fe(s).

In

the Haber process to

manufacture ammonia, finely

divided iron acts as a

heterogeneous

catalyst.

Active sites on the metal

allow partial weak bonding

to the reactant gases, which

are

adsorbed

onto the metal surface. As a

result, the bond within

the molecule of a reactant is

weakened

and the reactant molecules

are held in close proximity to

each other. In this

way

the

particularly strong triple

bond in nitrogen is weakened

and the hydrogen and

nitrogen

molecules

are brought closer together

than would be the case in

the gas phase, so the

rate of

reaction

increases

(ii)

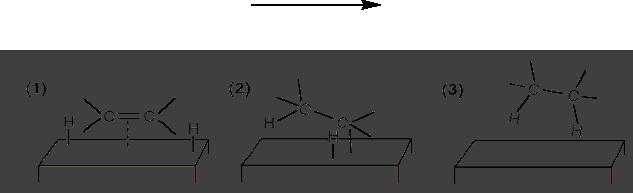

Hydrogenation of ethene on a solid

support

In

order for the reaction to

occur one or more of the

reactants must diffuse to the

catalyst

surface

and adsorb onto it. After

reaction, the products must desorb

from the surface and

diffuse

away from the solid surface.

Frequently, this transport of

reactants and products

from

one

phase to another plays a

dominant role in limiting

the reaction rate.

Understanding these

3.22

Methods

Based on Activating the Reacting

Substance

transport

phenomena and surface chemistry

such as dispersion is an important

area of

heterogeneous

catalyst research. Catalyst surface

area may also be considered. A

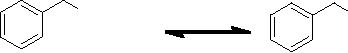

pictorial

representation

of hydrogenation of ethane on solid

support is shown in Fig.

3.5.

Ni

or Pd catalyst

CH2=CH2

CH3-CH3

Fig.

3.5. Pictorial representation of

hydrogenation of ethene on solid

surface

(Reproduced

from the web page:

http://en.wikipedia.org/wiki/Heterogeneous_catalysis)

Advantages

and drawbacks

Heterogeneously

catalyzed reactions allow

easy and efficient

separation of high

value

�

products

from the catalyst and

metal derivatives.

However,

selectivity and rates are

often limited by the

multiphasic nature of

this

�

system

and/or variations in active

site distribution from the

catalyst preparation.

3.2.3.

Enzyme or biocatalysis

Biocatalysis

can be defined as the

utilization of natural catalysts, called

enzymes, to perform

chemical

transformations on organic compounds.

Both enzymes that have been

more or less

isolated

or enzymes till residing

inside living cells are

employed for this

task.

The

most important conversion in the

context of green chemistry is

with the help of

enzymes.

Enzymes are known as biocatalyst

and the transformations are

referred to as

biocatalytic

conversions. Enzymes are now

easily available and are an

important tool in

organic

synthesis. Biocatalytic conversions have

many advantages in relevance to

green

chemistry.

Some of these are:

Most

of the reactions are

performed in aqueous medium at ambient

temperature

�

and

pressure.

Biocatalytic

conversions normally involve

only one step.

�

Protection

and deprotection of functional

groups is not

necessary

�

Synthetic

Strategies in Chemistry

3.23

Reactions

are fast reactions.

�

Conversions

are stereospecific.

�

Special

advantage of biochemical reaction is

that they are

chemoselective,

�

regioselective

and stereo selective.

A

number of diverse reactions

are possible by biocatalytic

processes, which are

catalysed by

enzymes.

The

major six classes of enzymes

and the type reactions

they catalyse are

discussed.

(i) Oxidoreductases: These

enzymes catalyst oxidation-reduction

reactions. This class

includes

oxidases (direct oxidation with

molecular oxygen) and

dehydrogenases

(which

catalyse the direct removal of

hydrogen from one substrate

and pass it on to

a

second substrate.

(ii)

Transferases:

These

enzymes catalyse the transfer of

various functional groups.

Eg.

Transaminase

(iii) Hydrolases:

This

group of enzymes catalyses

hydrolytic reactions. Eg.

Esterase

(esters)

(iv)

Lyases:

These

are of two types, one

which catalyses addition to

double bond and

the

other

which catalyses removal of

double bond. Both addition

and elimination of

small

molecules

are on sp3 hybridised carbon.

(v)

Isomerases:

These

catalyse various types of isomerisation,

e.g. racemases,

epimerases

etc.

(vi)

Ligases:

These

catalyse the formation or cleavage of

sp3 hybridised carbon.

The

enzymes are specific in

their action. This

specificity of enzymes may be

manifested in

one

of the three ways:

a.

An enzyme may catalyze a

particular type of reaction,

e.g. esterases

hydrolyses

only ester. Such enzymes are

called reaction

specific.

Alternatively,

an enzyme may be specific

for a particular class of

compounds.

These

enzymes are referred to as substrate

specific, e.g., Urease

hydrolyses

only

urea and phosphatases hydrolyse

only phosphate esters.

b.

An enzyme may exhibit

kinetic specificity. For

example, esterase

hydrolyse

all

esters but at different

rates.

c.

An enzyme may be stereospecific.

For example, maltase hydrolyses

alpha-

glycosides

but not beta-glycosides. On

the other hand emulsin

hydrolyses beta

glycosides

but not the alpha

gluycosides.

3.24

Methods

Based on Activating the Reacting

Substance

d.

It should be noted that a

given enzyme could exhibit

more than one

specificities.

The

oxidation accomplished by enzymes or

microorganisms excel in

regiospecificity,

stereospecificity

and enantioselectivity.

An

unbelievably large number of

enzymatic

oxidations

have been accomplished.

Examples:

(i)

Conversion of alcohol into acetic

acid by bacterium acetic in presence of

air (the process is

now

known as quick-vinegar

process)

Bacterium

acetic

CH3CH2OH +

O2

CH3COOH + H2O

(ii)

Conversion of sucrose into

ethyl alcohol by yeast (this

process is used for

the

manufacture

of ethyl alcohol.

Invertase

2C6H12O6

C12H22O11

+ H2O

Yeast

Invertase

C6H12O6

2C2H5OH + 2CO2

Yeast

(iii)

Oxidation of Galactose

Galactose

oxidase (GO) is a fungal

enzyme that catalyzes the

two-electron oxidation of D.

galactose

to the corresponding aldehyde

with the concomitant

reduction of molecular

oxygen

to

hydrogen peroxide.

OH

OH

HO

CH2OH

HO

CHO

GOase

O

H2O2

+

+

HO

O

HO

OH

OH

(iv)

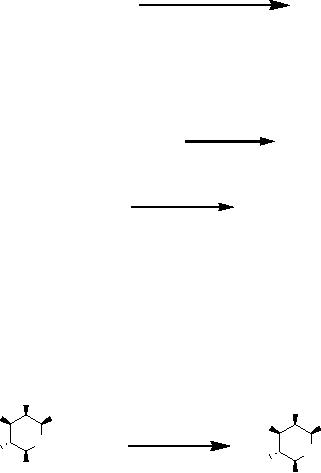

Hydroxylation of aromatic

rings

Benzene

undergoes oxidation with Pseudomonus

putida in presence of oxygen

and gives the

cis-diol.

Synthetic

Strategies in Chemistry

3.25

Pseudomonus

OH

Putida

OH

Cis-3,5-cyclohexdiene-1,2-diol

The

path to new chemical

entities often shows the

limitations of existing tools

both in

biocatalysis

and organic chemistry.

Organic synthetic procedures to prepare a

compound in a

target-oriented

synthesis can damage other functional

parts of the molecule.

Protection-

deprotection

schemes can lead to a dead

end, when a certain

protecting group cannot

be

cleaved

off.

In

biocatalysis, on the other

hand, the required

biocatalytic toolbox

and

methodology

might not be readily

available, therefore limiting a

biocatalytic approach.

New

toolboxes,

ingredients, and methodologies at

the interface of classical organic

synthesis and

biocatalytic

reactions bridge the gap

between these two areas.

Since product isolation

and

purification

involves a substantial amount of

time in the preparation of

chemicals,

methodologies

to simplify these tasks are

necessary to get the pure

product into the

bottle

with

less work-up time.

Efficient

and safe new

pharmaceuticals, intermediates and

analytical reagents need to be

prepared

under certain safety,

health, and environmental

and economical

boundary

conditions.

Biocatalytic

reactions have been shown to

overcome these

limitations

successfully

and are becoming

increasingly important in industrial

manufacturing. Building

bridges

between biocatalysis and

organic synthesis will therefore create

roads to new

synthetic

strategies and technological frontiers of

both fundamental and

practical interest.

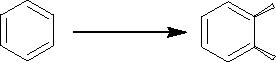

3.2.4.

Photocatalysis

Photocatalysis

is

the acceleration of a photoreaction in

the presence of a

catalyst.

In

catalysed

photolysis, light is absorbed by an adsorbed

substrate. In photogenerated

catalysis

the

photocatalytic activity (PCA) depends on

the ability of the catalyst

to create electronhole

pairs,

which generate free radicals

(hydroxyl ions; OH-) able to

undergo secondary reactions.

Its

comprehension has been made

possible ever since the

discovery of water electrolysis

by

means

of the titanium dioxide.

Commercial application of the

process is called

Advanced

Oxidation

Process(es) (AOP). There are

several methods of achieving AOP's

that can but do

not

necessarily involve

TiO2 or even the use of UV.

Generally the defining

factor is the

production

and use of the hydroxyl

ion.

Example

(i)

Chlorophyll as photocatalyst

3.26

Methods

Based on Activating the Reacting

Substance

Chlorophyll

of plants is a type of photocatalyst.

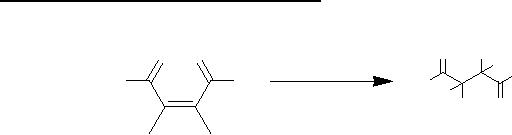

Photocatalysis compared to

photosynthesis,

(Figure

6) in which chlorophyll captures sunlight

to turn water and carbon

dioxide into

oxygen

and glucose, photocatalysis

creates strong oxidation agent to

breakdown any organic

matter

to carbon dioxide and water

in the presence of photocatalyst,

light and water.

Fig.

3.6. Comparison of photocatalysis

with photosynthesis

(Reproduced

from the website:

http://www.mchnanosolutions.com/whatis.html)

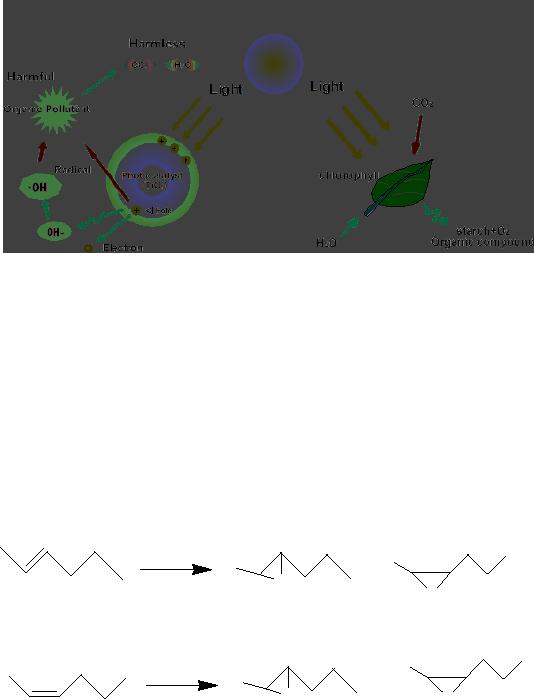

(ii)

Epoxidation of trans and cis-2-hexene by

TiO2

The

reaction was carried out on

photoirradiated TiO2 powder using

trans-2-hexene or cis -2-

hexene

as the starting material.

From trans-2-hexene, trans-2,

3-epoxyhexane was

obtained

as

the main product with

the ratio between trans and

cis-2, 3-epoxyhexane being

98.4 to 1.6.

In

the case of cis-2-hexene,

the ratio of trans to cis-2,

3-epoxyhexane was 12.0 to

88.0.

trans-2,3-epoxyhexene

trans-2-hexene

cis-

2,3-epoxyhexene

O2

O

TiO2

O

98.4

1.6

cis-

2,3-epoxyhexene

trans-2,3-epoxyhexene

cis-2-hexene

O2

O

O

TiO2

12.0

88.0

A

large number of recent reports on

the photo catalytic reaction

of organic compounds

have

satisfied

the basic requirement of organic

synthesis, e.g isolation and

identification of

product.

Hence photocatalystic reaction is

novel synthetic tool as well

as activation mode.

Synthetic

Strategies in Chemistry

3.27

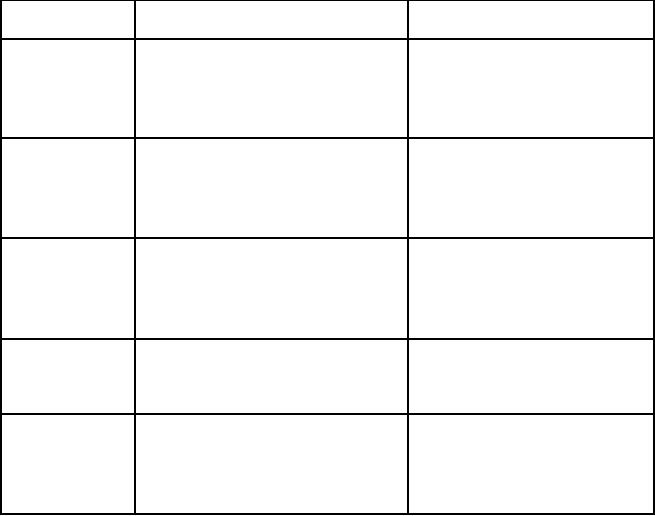

4.

CONCLUSION

The

diversity of activation methods in

organic synthesis has grown

noticeably in recent years.

These

methods have many advantages compared to

traditional techniques. They also

have

some

drawbacks. A summary of advantages and

drawbacks of a few activation

methods,

which

are discussed in this

article are summarized in Table

3.1.

Table

3.1. Summary of features of activation

processes

Activation

mode

Advantages

Drawbacks

Large

volume reactions

Hazardous

temperature control

Fast

reactions (Elimination of volatile

Safety problems (reactions

in

solution)

Microwave

products)

No

reproducibility

Simple

non-destructive method

Low

volume reaction

No

or little work-up

Cost

of equipments

Pressure

Excellent

reproduciblity

Limited

to homogeneous

reactions

(difficult of mixing)

Simple

method

No

generality

Large

volume reaction

Cost

of equipments

Ultrasound

No

or little work-up

Hazardous

temperature control

Adaptable

to heterogeneous reaction

Considerable

acceleration of rate No

generality

Solvophobic

constant,

Possibility

of hydrolysis

interactions

Cheap

environmentally safe

method

Low

temperature efficient

method

No

generality (limited to a

few

Enzymatic

Highly

selective method

specific

reactions)

catalysis

Cost

enzymes

Sensitive

to temperature

This

article shows that the

methods described are fast

and efficient. Relatively

high yields

are

achieved in a very short

time.

The

methods and the results when

compared with

conventional

processes are found to be

inexpensive, more eco-friendly

and high yielding.

Therefore

choosing the correct mode of

activation for a particular

reaction depends

entirely

on

the knowledge of chemists in this

area. In conclusion, this

article reports

important

examples

of activation modes highlighting

the implementation of new

synthetic strategies. It

may

be of great help to chemists of present

and future

generation.

3.28

Methods

Based on Activating the Reacting

Substance

5.

REFERENCES

1.

D. Bogda and M.Ukasiewicz, Synlett,

1 (2000)

143.

2.

J. S. Yadav and B. V. Subba

Reddy, Green

Chemistry,

2

(2000)

115.

3.

V. Singh, K. P. Kaur, A. Khurana

and G. L. Kad, Resonance, 3

(1998)

56.

4.

K. Matsumoto, M. Ciobanu, M. Yoshita

and T. Uschida, Heterocycls, 45

(1997)

15.

5.

G. Jenner and R. Ben Salem, Tetrahedron, 53

(1997)

4637.

6.

J. Dambacher, W. Zhao, A. El-Batta, R.

Anness, C. Jiang and M,

Bergdahl,

Tetrahedron

Lett., 46 (2005)

4473.

7.

T. Hamada, K. Manabe and S.

Kobayashi, J.

Am. Chem. Soc., 126 (2004)

7768.

8.

P.

Gogoi, P. Hazarika, and D.

Konwar, J.

Org. Chem., 70 (2005)

1934.

9.

R.

X . Ren, J.X. Wu, Org.

Lett., 3 (2001)

3727.

10.

M. B . Korzanski, and J. W. Kolis,

Tetrahedron

Lett.,

38

(1997)

5611.

11.

J. Gao, J.

Am. Chem. Soc., 115 (1993)

6893.

12.

G. Nagendrappa, Resonance,

7

(2002)

59.

13.

N. Iranpoor, H. Firouzabadi and M.

Shekarize, Org.

Biomol. Chem.,

1

(2003)

724.

14.

B. Gunilla, C. Jacobson, T. Lee and K. P.

Johnston, J.

Org. Chem., 64 (1999)

1201.

15.

Zha, A. Hui, Y. Zhou, Q.

Miao, Z. Wang and H. Zhang,

Org.

Lett., 7 (2005)

1903.

Books

1.

A.S. Bommarius, B.R. Riebel,

Biocatalysis:

Fundamentals and Application,

Wiley

VCH

Publisher, 2007.

2.

V.K. Ahluwalia, N. Kidwai, New

Trends in Green Chemistry, Kluwer

Academic

Publishers

and Anamaya Publishers,

2004.

3.

M. Kaneko and I. Okura, Photocatalysis:

Science and Technology,

Biological and

medical

physics series, Springer

Publishers, 2003.

Websites

1.

http://www.bentham.org/aos/Samples/aos1-1.htm

2.

http://books.google.co.in

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES