|

SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice |

| << SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY |

| CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES >> |

Chapter

- 14

SYNTHESIS

OF CHEMICALS FROM CARBON DIOXIDE

T.

M. Sankaranarayanan

INTRODUCTION

Carbon

dioxide is an atmospheric gas

contains one carbon and two

oxygen atoms. It is

well

known chemical compound and

its chemical formula

CO2.

Dry ice

is

nothing but

solid-state

carbon dioxide. It was one of the

first gases to be described as a

substance

distinct

from air.

In

the 17th century, the

Flemish chemist Jan Baptist

van Helmont observed that

when

he

burnt charcoal in a closed vessel, the

mass of the resulting ash

was much less than

that

of

the original charcoal. His

interpretation was that the rest of

the charcoal had been

transmuted

into an invisible substance he

termed a "gas" or "wild

spirit" (spiritus

sylvestre). The

Scottish physician Joseph

Black studied some of the

properties more

thoroughly

in the 1750's. He found that

limestone (calcium carbonate) could be

heated or

treated

with acids to yield a gas as

he termed "fixed air." He observed

that the fixed

air

was

denser than air and did

not support either flame or

animal life. He also found

that it

would,

when bubbled through an

aqueous solution of lime

(calcium hydroxide),

precipitate

calcium carbonate, and used this

phenomenon to demonstrate that

carbon

dioxide

is produced by animal respiration and

microbial fermentation. In 1772,

Joseph

Priestley

used carbon dioxide produced

from the action of sulfuric

acid on limestone to

prepare

soda water, the first

known instance of an artificially

carbonated beverage. CO2

was

first liquefied (at elevated

pressures) in 1823 by Humphrey Davy and

Michael

Faraday.

The earliest description of

solid carbon dioxide was

given by Charles

Thilorier,

who

in 1834 opened a pressurized container of

liquid carbon dioxide, only

to find that the

cooling

produced by the rapid

evaporation of the liquid

yielded a "snow" of solid

CO2.

Most

of the combustion of organic

matter, volcanic out gassing

and respiration

processes

of living aerobic organisms are the

main sources of the carbon

dioxide. Various

microorganisms

from fermentation and cellular

respiration also produce it.

During the

photosynthesis

plants take in the carbon

dioxide and using both the

carbon and oxygen to

form

carbohydrates. In addition, plants also

release oxygen to the atmosphere,

which is

subsequently

used for respiration by

heterotrophic organisms, forming a

cycle. It is

14.2

Synthesis

of Chemicals from Carbon

dioxide

present

in the earth's atmosphere at a low

concentration and acts as a greenhouse

gas. It

is

a major component of the

cycle.

Green

house effect is nothing but an

increase in the absorption of

radiation energy from

sun

caused by the existence of

gases in the earth atmosphere.

Because of this

absorption

the

earth atmospheric temperature is

raising which is called

"global warming". Some

of

the

gases like CO2,

CH4, O3, CFCs and H2O

vapors are called "green

house gases".

Mainly

these gases are responsible

for this absorption.

CO2 being an important

member

of

these gases is responsible

for many climatic changes

demonstrating the importance

of

CO2 content in atmosphere. Because of

mounting of Industrial Revolution,

the Percentage

of

carbon dioxide in the earth

atmosphere is increasing virtually at the

rate of 1% per

annum;

from 250ppm of the

pre-industrial period to a present level

of 400ppm (315ppm

in

1958, 340ppm in1984).

Because of this global

warming the snow cover in

the northern

hemisphere

and floating ice in the artic

ocean have decreased

considerably. Moreover,

globally

sea water level increased up

to 8 inches in the last

decade. There is an increase

in

worldwide

precipitation by one percent. There is

abnormal rainfall through

out the world.

Unfortunately,

greenhouse gases are likely to

increase the rate of climate

changes.

CARBON

DIOXIDE - CHEMICAL AND PHYSICAL PROPERTIES

1)

Carbon dioxide is a colorless

gas.

2)

When inhaled at high

concentrations (a dangerous activity

because of the

associated

asphyxiation risk), it produces a sour

taste in the mouth and a

stinging

sensation

in the nose and

throat.

3)

These kind of effects result

from the gas dissolving in

the mucous membranes

and

saliva, forming a weak

solution of carbonic

acid.

4)

Its density at 25 �C is 1.98 kg

m-3,

about 1.5 times that of

air.

5)

It has no electrical dipole. As it is

fully oxidized, it is not very

reactive and, in

particular,

not flammable.

6)

At temperatures below -78 �C, carbon

dioxide condenses into a

white solid called

dry

ice. Liquid carbon dioxide

forms only at pressures above

5.1 atm; at

atmospheric

pressure, it passes directly between

the gaseous and solid phases

in a

process

called sublimation.

Synthetic

Strategies in Chemistry

14.3

7)

Water will absorb its own

volume of carbon dioxide, and

more than this

under

pressure.

About 1% of the dissolved

carbon dioxide turns into

carbonic acid. The

carbonic

acid in turn dissociates partly to

form bicarbonate and carbonate

ions.

Test

for Carbon dioxide

When

a lighted splint is inserted

into a test tube containing

carbon dioxide, the flame

is

immediately

extinguished, as carbon dioxide

does not support combustion.

(Certain fire

extinguishers

contain carbon dioxide to

extinguish the flame). To

further confirm that

the

gas

is carbon dioxide, the gas

may be bubbled into calcium

hydroxide solution.

The

calcium

hydroxide turns milky

because of the formation of

calcium carbonate.

Applications

1)

Liquid and solid carbon

dioxide are important

refrigerants, especially in the

food

industry,

where they are employed

during the transportation and

storage of ice

cream

and other frozen foods.

Solid carbon dioxide is

called "dry ice" and is

used

for

small shipments where

refrigeration equipment is not

practical.

2)

Carbon dioxide is used to

produce carbonated soft drinks and

soda water.

Traditionally,

the carbonation in beer and

sparkling wine come about

through

natural

fermentation, but some

manufacturers carbonate these

beverages

artificially.

3)

The leavening agents used in

baking produce carbon

dioxide to cause dough

to

rise.

Baker's yeast produces carbon dioxide by

fermentation within the

dough,

while

chemical leaveners such as

baking powder and baking

soda release carbon

dioxide

when heated or exposed to

acids.

4)

Carbon dioxide is often used

as an inexpensive, nonflammable

pressurized gas.

Life

jackets often contain canisters of

pressured carbon dioxide for

quick

inflation.

Steel capsules are also sold as

supplies of compressed gas

for air guns,

paintball

markers, for inflating

bicycle tires, and for

making seltzer. Rapid

vaporization

of liquid CO2 is

used for blasting in coal

mines.

5)

Carbon dioxide extinguishes

flames, and some fire

extinguishers, especially those

designed

for electrical fires;

contain liquid carbon

dioxide under pressure.

Carbon

dioxide

also finds use as an atmosphere for

welding, although in the

welding arc,

it

reacts to oxidize most

metals. Use in the automotive

industry is common

despite

14.4

Synthesis

of Chemicals from Carbon

dioxide

significant

evidence that welds made in

carbon dioxide are quite

delicate than

those

made in more inert atmospheres, and

that such weld joints

depreciate over

time

because of the formation of

carbonic acid. It is used as a

welding gas

primarily

because it is less expensive

than more inert gases

such as argon or

helium.

6)

Liquid carbon dioxide is a good

solvent for many organic

compounds and it has

begun

to attract attention in the

pharmaceutical and other chemical

processing

industries

as a less toxic alternative to

more traditional solvents

such as organic

chlorides.

It's used by some dry

cleaners for this

reason.

7)

Plants require carbon

dioxide to conduct photosynthesis, and

greenhouses may

enrich

their atmospheres with

additional CO2 to

boost plant growth. It has

been

proposed

that carbon dioxide from

power generation be bubbled

into ponds to

grow

algae that could then be

converted into biodiesel

fuel. High levels of

carbon

dioxide

in the atmosphere effectively exterminate

many pests. Greenhouses will

raise

the level of CO2 to

10,000 ppm (1%) for several

hours to eliminate

pests

such

as whitefly, spider mites, and

others.

8)

In medicine, up to 5% carbon dioxide is

added to pure oxygen for

stimulation of

breathing

after apnea and to stabilize

the O2/CO2 balance

in blood.

9)

A common type of industrial

gas laser, the carbon

dioxide laser, uses

carbon

dioxide

as a medium.

10)

Carbon dioxide is commonly

injected into or adjacent to

producing oil wells.

It

will

act as both a pressurizing agent and,

when dissolved into the

underground

crude

oil, will significantly reduce its

viscosity, enabling the oil

to flow more

rapidly

through the earth to the

removal well. In mature oil

fields, extensive pipe

networks

are used to carry the

carbon dioxide to the

injection points.

Carbon

dioxide - Dry Ice

1)

Dry ice

is a generalized trademark for

solid ("frozen") carbon

dioxide. Prest Air

Devices,

a company formed in Long

Island City, New York in

1923, coined the

term

in 1925.

Synthetic

Strategies in Chemistry

14.5

2)

Dry ice

at normal pressures does not

melt into liquid carbon

dioxide but rather

sublimates

directly into carbon dioxide

gas at -78.5 �C (-109.3 �F).

Hence it is

called

"dry ice" as opposed to

normal "wet" ice (frozen

water).

3)

Compressing

carbon dioxide gas to a

liquid form, removing the

heat produced by

the

compression, and then letting

the liquid carbon dioxide

expand quickly

produce

dry ice. This expansion

causes a drop in temperature so

that some of the

CO2 freezes

into "snow", which is then

compressed into pellets or

blocks.

Supercritical

Carbon dioxide

Carbon

dioxide also could be used

more widely as a solvent and

for example

super

critical CO2 (the

state existing at 31.0C and

72.8 atm). Now a days Carbon

dioxide

could

be used more widely as a

solvent and for example

supercritical carbon

dioxide

offers

advantages in terms of stereo

chemical control, product

purification synthesizing

fine

chemicals and pharmaceuticals. People

are extracting caffeine from

coffee by using

supercritical

carbon dioxide. More over

the advantage of using CO2 is

oil gas recovery

and

ponds of genetically modified algae

that can convert power plant

CO2 into biodiesel.

As

noted above, CO2 is

generally considered to be a green or environmentally

benign

solvent

and is naturally abundant. CO2 has

been suggested as a sustainable

replacement

for

organic solvents in a number of

chemical processes and is currently

used in the dry

cleaning,

and in parts degreasing. While CO2 is

certainly not a panacea,

there are a

number

of characteristics, which suggest

that CO2 could

provide environmental and

economic

benefits. The nontoxic

nature of CO2 has

a number of advantages. For

example,

in food and pharmaceutical applications,

usage of CO2 greatly

reduces future

liability

costs and can also facilitate regulatory

approval of certain processes. An

example

is

the conversion of pharmaceuticals

into nanometer-size particles

for injectable use.

Another

instance in which supercritical

carbon dioxide could be advantageous is

in

situations

involving contact between

hydrophilic and hydrophobic solvents. In

this case,

the

mutual solubility of the two

phases is designed to be small.

However, some cross-

contamination

is inevitable, typically leading to a

costly remediation. The use

of CO2 as

the

hydrophobic phase produces contamination

that is both benign and

readily reversible.

Examples

include liquid-liquid extraction

between organic and aqueous

phases as well as

emulsion

polymerization of water-soluble monomers.

In applications where emissions

are

14.6

Synthesis

of Chemicals from Carbon

dioxide

unavoidable,

CO2 is

relatively benign to the

environment. Examples range from

use of

CO2 in enhanced

oil recovery to use as a

foaming agent or as the solvent in

dry cleaning.

Using

supercritical CO2 as

a solvent also has advantages

that arise from chemical

and/or

physical

properties. In reactions involving

gaseous reactants in liquid phases,

the use of

supercritical

CO2 with its ability to

dissolve large amounts of

most gases could

allow

kinetic

control of reactions as opposed to

limiting of reaction rates by

the transport of the

gaseous

reactant across the

gas-liquid interface. In reactions

where CO2 is

a reagent, its

use

as a solvent would also favor

the reaction. Carbon dioxide

may also offer

advantages

in

reactions such as free-radical

polymerizations and oxidations where a

chemically inert

solvent

is required.

CHEMICALS

SYNTHESIS FROM CARBON

DIOXIDE

It

is well known that CO2 is

very stable gas and highly

unreactive but plants are

utilizing

it

for example in the

photosynthesis of carbohydrate from

CO2. Can we also

find the

ways

to make chemicals from CO2 artificially?

Surely it will be an

environmentally

benign

route, and this process will lead to

green chemistry. The main

process which use

CO2 are

1)

Synthesis of urea.

2)

Synthesis of salicylic acid

3)

Synthesis of cyclic carbonate and

polycarbonate

4)

Synthesis of methanol.

Synthesis

of urea by using CO2 currently

is a well-established process. The

capacity is

approximately

90 million metric tons per

annum as per 1997 statistics. Other

reactions

are

in pilot plant scale.

Besides to these reactions

there are many reactions,

which utilize

CO2. It will be a

great feed stock for making

commodity chemicals, fuels and

materials. It

already

plays a major role for a

variety of applications. But

there are few catches.

One is

that

CO2 is

very stable, which means it

takes extra effort to

achieve the molecules so

that

it

will react. Professor Christopher. M. Rayner of

the University of Leeds, in

England,

has

been working on CO2 conversion.

He published a review article

recently on the

potential

of CO2 in

synthetic organic chemistry.

Approximately 115 million

metric tons

of

CO2 is

used annually by the global

chemical industries but

really that does

not

compare

to the approximate 24 billion

metric tons. Bulk chemicals

already produced

Synthetic

Strategies in Chemistry

14.7

routinely

from CO2 include

urea to make nitrogen fertilizers,

salicylic acid as a

pharmaceutical

ingredient, and polycarbonate based and

plastics. The simplest

reactions

of

CO2 are those in which it is

simply inserted into an X-H

bond. Examples are

the

insertion

of CO2 into

organic amines to afford carbamic

acids, which may be

converted

into

organic carbamates. More

recent examples include the

insertion of CO2 in

P-N bonds

of

P (NR2)3 compounds

to form P (NR2)(OCONR2)

compounds

and the reaction of

2

ammonium

carbamates (derived from

CO2)

with alkyl halides in the

presence of crown

ethers

to form useful urethane

intermediates. This is an example of

using CO2 to

replace

phosgene,

a highly toxic intermediate in

chemical synthesis. Reactions

are known in

which

CO2 undergoes

insertion into Sn-C bonds of

allyl tin compounds to

form

carboxylated

allyl derivatives and which

are catalyzed by Pd complexes.

Another

interesting

reaction is the insertion of

CO2 into alkanes such as

methane to form acetic

acid.

The

activation of a C-H bond and

CO2 insertion are much

fascinating .The

thermodynamics

of this reaction are

marginal; however, adjusting

the reaction

conditions

and

coupling this reaction with

energetically favorable product

processes could

improve

conversion

efficiencies. Carbonates, (RO)2CO, can also be prepared by

inserting CO2

into

O-H

bonds followed by dehydration or by

oxidative carboxylation of olefins.

This

synthetic

approach has the possibility of

providing a new route to

compounds that have

very

large potential markets.

Related reactions in which

CO2 is

incorporated into

product

molecules

without reduction have been

used in the synthesis of

polymers.

The

groups of Inoue and Kuran

performed initial work in

this area. In recent years,

a

number

of new catalysts have been

developed for co polymerization of

CO2 and

oxiranes

to

form polycarbonate. These studies have

increased the productivity of

this reaction by

100

times and have also expanded the range of

applicable monomers

(oxiranes).

Polypyrones

are another potentially

interesting new class of

polymer. It has been

prepared

from diacetylenes and CO2 in

the presence of Ni catalysts; a

related reaction is

the

telomerization of butadiene and CO2 to produce lactones.

Urethanes have also

been

prepared

by the reactions of dicarbamate ions

formed by insertion of CO2 into diamines,

followed

by Pd-catalyzed coupling to

1,4-dichloro-2-butene. Reductive

carboxylations in

which

the CO2 unit is incorporated into

the product are also

known.

14.8

Synthesis

of Chemicals from Carbon

dioxide

In

the case of alkynes and

olefins, electrochemical reductive

carboxylations result in

effective

addition of the formic acid

C-H bond to C-C double or

triple bonds. For

example,

building on the earlier

stoichiometric results of Hoberg,

Dunach and co-workers

used

Ni bipyridine complexes and sacrificial

Mg anodes to reductively couple

acetylene

and

CO2 to

form propenic acid. Similarly,

Sylvestri reported that the

reductive coupling

of

CO2 with styrene is catalyzed

by benzonitrile. Bromoarenes can also be

reductively

carboxylated

to form the corresponding

carboxylic acid using Ni diphosphine

catalysts.

More

recently, the sequential

reductive coupling of two

molecules of CO2 to

butadiene to

form

3-hexen- 1,6-dioic acid has

been reported. This approach

provides a new route to

a

Nylon

precursor. Another important

monomer, ethylene, can be prepared

by

electrochemical

reduction of CO2 in

aqueous solutions with

current efficiencies as high

as

48%.

The production of this

monomer by this remarkable

12-electrons reduction offers

a

potential

route to polyethylene from

CO2.

The preceding results

clearly indicate that

it

may

be possible to produce a large variety of

polymers in the future using

materials

derived

from CO2.

Under

oxidative conditions, CO2 may

react with olefins to give

cyclic carbonates

that

find

wide industrial applications. In

these transformations heterogeneous

catalysts are

currently

more promising and viable

than homogeneous ones. Another

potentially useful

reaction

of CO2 is

the dehydrogenation of hydrocarbons.

Examples are the

dehydrogenation

of ethyl benzene and propane over metal

oxides to form styrene

and

propene,

respectively. In these reactions, no

part of the CO2 molecule

is incorporated into

the

organic product, rather the

oxygen of CO2 serves

to remove two H atoms of

the

hydrocarbon.

CO2 is

currently used as an additive in

the synthesis of methanol

from CO

and

H2, and it is

believed that reduced forms of

CO2 are kinetically

important

intermediates

in this process. Recently,

efficient heterogeneous catalysts have

been

developed

for CO2 hydrogenation

to methanol. However, the

thermodynamics for

methanol

production from H2 and

CO2 are not as favorable as

that for production

of

methanol

from H2 and

CO. For example, at 200 �C

the equilibrium yield of

methanol

from

CO2 is

slightly less than 40%

while the yield from CO is

greater than 80%. The

reduction

of CO2 can be rendered more favorable by

the use of hybrid catalysts

that

dehydrate

methanol to form Dimethyl

ether. Other copper-zinc

based catalysts have

also

Synthetic

Strategies in Chemistry

14.9

been

used for methanol synthesis.

Fisher and Bell et

al. studied

Cu/ZrO2/SiO2 catalysts

by

in-situ

infrared

spectroscopy and suggested some

mechanism for the route

to

methanol.

Ethanol has also been

produced by the hydrogenation of

CO2.

This fuel is

attractive

because it has a somewhat

higher energy density than

methanol and it is not as

toxic.

However, the selectivity for

ethanol production is comparatively

low (<40%).

The

hydrogenation of CO2 to

methane and higher hydrocarbons is also

known. For C2

and

higher hydrocarbons, hybrid

catalysts such as

Cu-ZnO-Cr2O3 and

H-Y zeolite are

generally

used. Noyori et

al.

have carried out pioneering

work on the catalytic

synthesis

of

formic acid derivatives by CO2 hydrogenation,

together with other substrates,

in

supercritical

CO2. In

part because of the high

solubility of H2

in CO2, an

economical

synthesis

of dimethylformamide is achieved.

Homogeneous

catalysts are also known to mediate

the rapid hydrogenation of

CO2 to

formate,

because this reaction is not

thermodynamically preferential, amines

and

supercritical

CO2 have been used to

drive this reaction. Under

the appropriate conditions,

very

high turnover numbers and

rates can be achieved. For

example, Leitner et

al.

examined

complexes of the general

type [R2P-(X)-PR2]Rh-(hfacac)

(X = bridging group;

hfacac)

1,3-bis-(trifluoromethyl)-acetonylacetonate). All the

compounds are active

catalysts

for formic acid production

from H2 and

CO2, but the most

effective has X=

(CH2)4 and

R= cyclohexyl showing good results at 25

�C and 40 atm of 1:1 H2:

CO2. The

selectivity

to formic acid is nearly

100%.

Possible

pathways for the opposing

interaction of Low-Valent Catalysts

with Protons

or

CO2 of

the CO2

reduction

product observed. If the reduced form of

the catalysts reacts

with

CO2 to

form a M-CO2

complex,

protonation yields a metallo

carboxylic acid;

further

reaction

can then produce CO by C-O

bond cleavage to form hydroxide or

water. Thus,

reaction

of a reduced form of the catalyst

with CO2,

as opposed to protons, leads to

CO

formation.

If the reduced form of the

catalyst reacts with protons

to form a hydride

complex,

subsequent reaction of the hydride

with CO2 leads to formate

production. An

interesting

example of such selectivity is

CO2 electrochemical reduction

catalyzed by

polymeric

films based on

[Ru(N-N)(CO)2]n

(N-N=poly

pyridine ligand) in aqueous

media.

Deronzier and Ziessel et

al. found

that bipyridyl ligands with

electron

withdrawing

groups in the 4,4 positions

gave catalysts which are

highly selective for

14.10

Synthesis

of Chemicals from Carbon

dioxide

formate

at pH >5 while those derived from

the unsubstantiated 2, 2 -bipyridine or

the 4,

4

-dimethyl analogue primarily

give CO at pH > 7.165 Formate was

thought to arise

from

an intermediate metal hydride, whereas CO

was thought to arise from a

metallo

carboxylicacid

generated by carbonation of an

intermediate anion followed

by

protonation.

It is unusual for homogeneous catalysts

to form reduction products

that

require

more than two

electrons.

However,

Tanaka and co-workers, reported

that the formation of

glycolate

(HOCH2COO-), glyoxylate

(OCHCOO-), formic acid, formaldehyde, and

methanol as

CO2 reduction products using

[Ru(tpy)(bpy)(CO)]2+

complexes as

electro catalysts (bpy

=

2,2

-bipyridine, and tpy =2,2 :6

,2

-terpyridine).Although

turnover numbers were

not

given for these highly

reduced species, their formation

raises the exciting

possibility

that

a single-site catalyst can result in

multi electron reductions of

CO2 and

even C-C

bond

formation.

Tanaka

and Gibson et

al.

recently succeeded in isolating

key Ru C1 compounds with

polypyridine

ligands that are models

for catalytic intermediates.

Gibson et

al.

also

isolated

ReC1 complexes with

polypyridine ligands. The

importance of photochemistry in

reactions

of some have the Re and Ru

complexes has been

demonstrated. The

formation

of

formaldehyde has also been

reported in electrochemical CO2 reduction using

transition

metal

terpyridine complexes polymerized on

glassy carbon electrodes. The

relatively

mild

conditions and low over

potentials required for some

of the homogeneous

catalysts

make

them attractive for future

studies; however, a number of

barriers must be

defeated

before

useful catalysts are

available for fuel

production.

Photochemical

reduction of CO2 is one of the significant

reactions many of the

reactions

described above rely on energy

input either in the form of

reactive bonds

(alkenes,

alkynes, etc.), hydrogen, or

electricity. Photochemical systems have

been

studied

in an effort to develop systems capable

of directly reducing CO2 to fuels or

chemicals

using solar energy.

Transition-metal complexes have

been used as both

catalysts

and solar energy converters, since

they can absorb a

significant portion of

the

solar

spectrum, have long-lived

excited states are able to

promote the activation of

small

molecules,

and are forceful. Carbon

dioxide utilization by artificial

photo conversion

presents

a challenging alternative to thermal

hydrogenation reactions, which

require H2.

Synthetic

Strategies in Chemistry

14.11

The

systems studied for photochemical

CO2 reduction studies can be divided

into several

groups:

Ru(bpy)32+ both as a photo sensitizer

and as a catalyst. Ru(bpy)32+ as

a photo

sensitizer

and another metal complex as a

catalyst. ReX (CO) 3(bpy) or a similar

complex

as

a photosensitizers. Ru(bpy)32+ and Ru(bpy)32+

type

complexes as photo sensitizers

in

microheterogeneous

systems. Metalloporphyrins also act as a

photosensitizers and

catalyst.

Photochemical CO2 reduction is normally

carried out less than

1.0 atm CO2

at

room

temperature. Therefore, the

concentration of dissolved CO2 in the solution is

low

(e.g.,

0.28 M in CH3-CN,

0.03Min water). These systems produce

formate and CO as

products.

In the most efficient systems,

the total quantum yield

for all reduced

products

reaches

40%. In some cases with Ru

or Os colloid, CH4 is produced with a low

quantum

yield.

Under photochemical conditions,

the turnover number and the

turnover frequency

are

dependent on irradiation wavelength,

light intensity, irradiation

time, and catalyst

concentration,

and they have not been

optimized in most of the

photochemical

experiments

described. Typical turnover frequencies

for CO or HCOO- are between 1 and

10h-1, and

turnover numbers are

generally 100 or less. The

abovementioned molecular

sensitizers

can be replaced with semiconductor electrodes or

particles to achieve

light

harvesting.

These systems may use enzymes or

catalysts to promote electron

transfer

from

the semiconductor-solution interface to

CO2 or reduce

CO2 directly. Typically

these

reductions

require a potential bias in

addition to solar energy

input to achieve CO2

reduction

and electrode corrosions a major

concern. This corrosion can

some times be

defeated

using

high

CO2

pressures.

Fascinating

examples

of

stoichiometric

photochemical

reactions of CO2 promoted by metal

complexes have also been

reported.

Thus,

Aresta et

al. found

that CO2 can be incorporated into

cyclopropane to afford

butyrolactone.

Kubiak et

al. demonstrated

the reduction of CO2 to the radical anion

and

subsequent

coupling to cyclohexene by the

use of a Ni complex.

Ranyar

et

al. have

worked on the catalytic

processes for reducing

CO2 to

formic acid.

It

has potential of power fuel

cell for electricity

generation and automobiles and as

a

precursor

for other fuels, synthetic

chemicals and fibers, including

polymers.

Conversion

of CO2 to CO will be more challenging

process because CO can be

used

in

a host of organic synthesis and one of

the important feed stock in

the chemical industry

for

making higher hydrocarbon

through Fisher-Tropsch

Synthesis.

14.12

Synthesis

of Chemicals from Carbon

dioxide

Nicolas

Eghbali and his group

working on conversion of CO2 and

olefins into cyclic

carbonates

in water. Geoffrey W.Coates et al.

have

developed the catalyst to

incorporate

CO2 into polymers by using

β-diminate zinc acetate and salen cobalt

carboxylate

complexes.

These catalysts promote alternating co

polymerization of various epoxides

with

CO2 to make

biodegradable aliphatic polycarbonate.

The polymers which

contain

30-50%

CO2 by

weight have gas barrier and

degradation properties that make

them

attractive

for feed packaging foam-casting to make

automotive parts and electronic

processing

applications. These kinds of polymers

also can be used to replace

propylene

oxide

segments in polyurethane foams,

which would help cut

costs. The foams are

used

for

insulation and seat cushions,

among other

applications

About

150 million tons of plastics

produced globally in a year, and

most of it is non-

bio

degradable and from energy

intensive processes that use

petroleum-based feedstocks.

Coastes

et

al. working

on limeonene oxide derived

from citrus fruit waste as

a

potential

epoxide monomer for

co-polymerization with CO2.other

research in progress

involves

developing a catalytic system

that can use untreated

CO2 directly from

industrial

waste

streams to make polymer.

Artificial

bio inspired systems is far

less complicated and therefore

easier to study

than

natural photosynthesis, in which

sun light water and CO2 are converted into

O2 and

carbohydrates.

By

using inorganic material, people

are utilizing the carbon

dioxide. The reaction

of

CaCO3 and

CO2 in water to form Ca

(HCO3)

is

responsible for the fixation of

large

2

quantities

of CO2 in the oceans. However, it

is kinetically slow. Similarly,

CO2 can also

be

fixed

by

naturally occurring

minerals.

Even

though

the

reactions

are

thermodynamically

favorable, they are slow and

would need to be enhanced

kinetically

before

they could contribute

significantly to adjusting the

carbon balance. In addition,

this

would generally require

mining and processing enormous amounts of

materials to

store

relatively little CO2.Currently, large

quantities of CaCO3

are

converted into CaO

and

CO2 (which is released into

the atmosphere) in cement manufacture. If

a natural ore

could

be substituted for CaO, a

significant release of CO2 into the atmosphere

could, in

principle,

be avoided.

Synthetic

Strategies in Chemistry

14.13

Fujita

has found success by using

rhenium tri carbonyl

complexes to mediate CO2

reduction.

The researchers homed in on one

set of catalysts bearing

bipyridine (bpy)

ligands

which includes (bpy)

Re(CO)3 and its di rhenium analog.

But the reaction

rates

for

co production are slow due to

the stability of CO2

People

are working on CO2 → CO but ultimate target

is CO2 to Methanol that

could

be

used as a fuel.

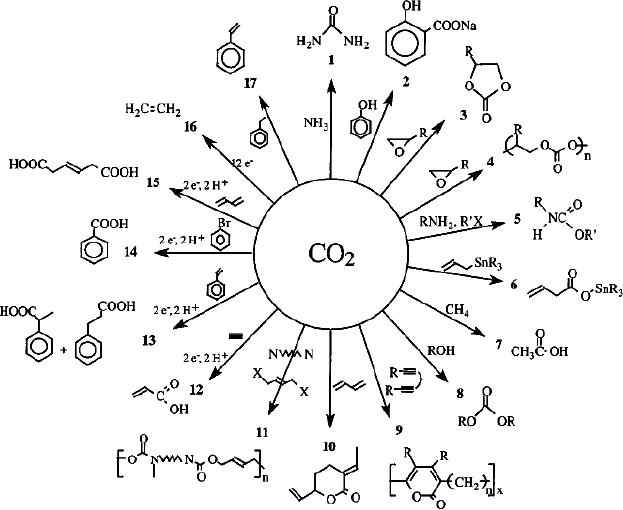

All

Possible Reactions

Fig.

14.1. Overall chemical

transformations

(reproduced

from Hironiri Arakawa, chemical

Reviews, 101 (2001)

976)

CONCLUSION

Synthesizing

chemicals from carbon

dioxide is one of the challenging

process as well as

eco-friendly

and environmentally benign route.

Using carbon dioxide as a

raw material

14.14

Synthesis

of Chemicals from Carbon

dioxide

never

going to reduce atmosphere CO2 level

or it will be very little the

effect on climate

change

but we can reduce the production of

CO2 and reduce

the usage of fossil fuel

and

shall

we make it?

REFERENCES

1.

J. M. Desimone, Science,

265 (1994)

359

2.

Hironiri Arakawa, chemical

Reviews,

101

(2001)

976

3.

Chemical & Engineering News,

April

30,

2007, 11

4.

Chemistry & Industry, July13, 2007,

13

5.

X. Xiaoding, J. A. Moulijin Energy and

Fuels, 10

(1996)

305

6.

Greenhouse

issues 1992

Feb

7.

M. A.Scibioh and B.Viswanathan

Proc.Indian

Natn Sci Acad.,

70 A (3) (2004) 407

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES