|

SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY |

| << NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC |

| SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice >> |

Chapter

- 13

SYNTHETIC

STRATEGIES - FROM LABORATORY TO

INDUSTRY

S.

Chandravathanam

INTRODUCTION

Scale-up

is an act of transferring a laboratory

process to the larger

equipment typical of a

commercial

plant, or designing a piece of

commercial equipment based on

research-scale

models.

This is often a complex

matter in which, for some

processes, trail and error

still

has

a significant foothold. Even

with careful planning and

strict methodology,

scale-up

can

be fraught with difficulty and

unexpected problems. The

reasons for this

are

numerous;

many common laboratory

methods cannot be applied at

the large scale,

equipment

may exhibit unexpected

behaviour at sizes never

used before, or critical

heat

or

mass transfer phenomena may

not be discernible at laboratory

scale.

The

design of a new plant or

commercialization of a new chemical

process represents

a

tremendous investment of time and

money. The risk is considerable and

the economic

penalty,

if the plant or process

fails to produce as expected is severe.

To minimize such

risks,

industries undertake lengthy and

expensive process research and

development

programs.

An

invention might sometimes lay

unused for ages without

paying back in terms of

industrial

realization and of profitable business

for its lack of technical

know-how. For

example,

the pigment indigo was

extracted from the sea

animals during the 13th century.

One

gram of the pigment could be

obtained from almost 10,000

numbers of the

animal.

So

that it was the very

expensive dye material, and

the colour was restricted to

the Royal

family

only, and so named as the Royal

purple. It was the situation

till Bayer in the 19th

century

studied the dye material,

and started synthesizing it from the

easily available raw

materials.

This

text deals with the

technical knowledge and on the

tools that are necessary

to

change

an invention into a true

innovation. The term

scale-up has usually been

explained

as

how to design an industrial reactor able

to replicate the results

obtained in the

laboratory.

These are done with most of

the time innovative ideas,

and sometimes with

13.2

Synthetic

Strategies From Laboratory to

Industry

many

mistakes.The scale-up usually

means that the scaling

facor of 1000 times from

the

laboratory

process to the pilot plant

scale, and further 1000 times

from the pilot to

the

industrial

scale. Typical laboratory

scale preparation lies with

in the production of 100

g/day.

A pilot plant will typically

produce 1-50 Kg/day, and the

industrial plant will be

aimed

with the production of

tons/day.

Few

of the indispensable steps which

are undertaken while going

from the laboratory

scale

to the commercial or industrial

scale are, cost estimation,

process design, pilot

plant

studies

may or may not be

accompanying with the

dimensional analysis.

COST

ESTIMATION

The

cost estimation for the

scale-up of production is a very

crucial step. For this

process,

chemical

engineers long been relying as a

rule a thumb on the use of

power law. As per

the

law the investment is

proportional to the scale of a

production facility raised to

some

constant

power, characteristic of the

particular process.

The

so called power law of

investment takes the

form,

I2/I1 =

k (Vt,2/Vt,1)1/n

Where

I is investment, Vt is

production rate and k and n are

constants.

The

power law is based on the

`minimization law', which

states that people

minimize

their

efforts per unit of dimension

whenever a change of scale or volume is

required. The

constant

n is the number of dimensions of

the production rate-limiting

activity, typically

is

either one, two or three

corresponding to the linear,

area and volumetric

dimensions.

PROCESS

DESIGN

Process

Design is the heart of the

process of scale-up. When

the research

department

discovers

a new reaction to make an existing

product or a new material,

the process

department

will have to translate these

discoveries into a new

process which could

be

commercially

and technically feasible.

The

few of the factors of

importance during this

process design stage

are,

-

Production rate

-

Temperature and pressure conditions of

the reaction

-

Every available information

about operating variables,

thermodynamics and kinetics of

the

chemical reaction

-

Stoichiometry of the main

reaction

Synthetic

Strategies in Chemistry

13.3

-

Desired yield of the

product

-

Desired product purity and the

possibility of the feed

recycling

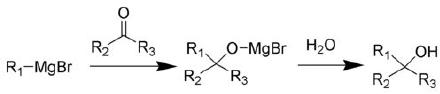

The

importance of the process design

step can be explained with one of

the case studies

with

the process design for the

manufacture of Grignard Reagent. Grignard

reagent is one

of

the important reagents in

organic synthesis for the

introduction of alkyl groups

on

carbonyl

carbon atoms. It's

requirement is vast but its

manufacturing in large scale

was

not

undertaken for a long time

for some reasons like

the high exothermicity of

the

reaction,

the high inflammability of

the solvent diethyl ether,

and the high sensitivity

of

the

reagent for water, which

needs to be used for cooling

purpose.

Grignard

reagent is prepared in situ when

alkyl halide reacts with Mg

metal scraps in

diethyl

ether.

Through

careful process design studies, these

drawbacks had been overcome;

with the

use

of alkyl chlorides or bromides instead of

iodides, the exothermicity of the

reaction

can

be reduced as a result of the reduction

in the reaction rate of chlorides and

bromides

compared

to their iodide counterpart.

Along with that, it could

also reduce the cost as the

chloride

is cheaper than the iodide.

The risky diethyl ether was

replaced with

tetrahydrofuran

(THF), which has atleast 30 �C

higher boiling point than

the former. Inert

gases

which can play both as the

cooling system and blanket replaced

water, as the

product

Grignard reagent is more sensitive to

water, if there is any

leakage.

PILOT

PLANT

A

pilot plant is generally a

collection of equipment designed to

allow operation of a

novel

process

at a scale small enough to be

safely manageable but large

enough to provide a

realistic

demonstration of operations and physical

principles as they might

apply in a

commercial

facility and to allow the

collection of meaningful engineering

data for a

further

scale-up.

Pilot

plants provide important

information on the best ways

to handle reactants,

intermediates,

products and waste streams, on energy

transfer, on the best choice

of

13.4

Synthetic

Strategies From Laboratory to

Industry

separation

technologies and an operating procedures.

Some of the many areas of

process

development

in which a pilot plant can

play an important role

are,

-

Confirming the operational

feasibility of a new

process

-

Identifying scale-up effects on

yield and selectivity

-

Collecting kinetics and design

data

-

Testing materials of

construction

-

Testing the operability of

control schemes

-

Assessing process hazards and safety

issues

-

Commercial viability of the

raw material

-

Process troubleshooting and

optimization

-

Testing process recycle

streams

Pilot

plants can be classified according to

numerous criteria. Foremost is

the fundamental

distinction

between a pilot plant for a

continuous process versus one

for a batch or

semibatch

process. In the continuous

process, pilot plants tend

to be single-purpose,

product

dedicated facilities that

are generally smaller. Batch

pilot plants, typical of

the

fine

chemical industry, tend to be

multipurpose. The requisite

flexibility to handle a

wide

variety

of products and processes can add

considerably to the complexity and cost

of a

plant.

DIMENSIONAL

ANALYSIS

Dimensional

analysis is a process by which

the dimensions of equations and

physical

phenomena

are examined to give new

insight into their

solutions. It is a powerful

technique

for spotting errors in

equations. It shows how

physical dimensions of

the

variables

that govern a problem can be

used to find physical laws.

The main requirement

for

dimensional analysis is dimensional

homogeneity it states that

all parts of an

equation

must have the same

dimension. In other words, we can

add or compare

quantities

that have similar dimensions

only.

Dimensional

analysis results in many

advantages like

-

the

reduction of number of variables in a

variable set; if there are `n'

variables or

parameters

of concern, then the total

number of dimensionless numbers is

reduced

to

n - r, where `r' is the number of

basic dimensions of all the

parameters of

concern

(Buckingham pi theorem).

Synthetic

Strategies in Chemistry

13.5

-

Gives

the guidelines for scaling

the results from model test

to the full-scale.

Otherwise

dimensional analysis sets

the rule under which full

similarity in model

test

can be achieved.

-

Nondimensional

parameters are more

convenient than dimensional

parameters

since

they are independent of the

system of units.

In

the following passage two

case studies of application of

dimensional analysis

are

given.

CASE

STUDY 1: Correlation between Meat Size

and Roasting Time

What

is the roasting time for

two times the mass of

the meat?

The

main parameters of concern

for this problem are

listed below along with

their

dimensions.

Symbol

dimension

Physical

quantity

T

roasting

time

θ

L2

A

meat

surface

thermal

diffusivity

a

L2T-1

T0

surface

temperature

Θ

temperature

distribution

T

Θ

The

higher the heat conductivity k, of

the meat, the faster is

the cooking.

The

higher the heat capacity ρCp,

the slower is the heat

transfer.

∴Thermal

diffusivity a = k/ρCp

The

total number of dimensionless

numbers are 5-3 = 2.

∏1

= T/T0

(T0-T)/T0)

or

F0

∏2

= aθ/A

When

the temperature distribution

T/T0 is

achieved throughout the meat

then it can be

said

that the meat is cooked.

T/T0 =

f

(F0)

13.6

Synthetic

Strategies From Laboratory to

Industry

F0

aθ/A

= idem

T/T0 =

idem

θ

α A

idem = identical

This

equation relates the roasting

time with the area of

the meat. But in reality

the

roasting

time needs to be calculated

with respected to the mass

of the meat.

mass

is related to area with the

following equation.

m

= ρV

α

ρL3 α

ρA3/2

the

density ρ

remains

the same irrespective of the

meat size. Therefore,

ρ

= idem

and

A

∝

m2/3

θ2/θ1 α

(m2/m1)2/3

That

is,

θ

α m2/3 =

m0.67

∴doubling

the mass of meat, the

roasting time increases by,

22/3 =

1.58 times. The

final

equation

contains only two parameters, instead of

the initial five parameters,

therefore,

the

number of supplementary experimental

runs is getting drastically

reduced.

CASE

STUDY 2: Homogeneous Irreversible 1st Order Reaction in a

Tubular

Reactor

How

much is the volume and

residence time of the

reactor to be increased for

the

increase

of volume throughput by a factor of n

(qT =

nqM)?

The

important parameters of concern

are, v - flow rate, d, L diameter

and length of the

tubular

reactor, ρ,�

-

fluid density and viscosity

respectively. T0

inlet temp.

cin,

cout inlet and

outlet conc. keff.

effective

reaction rate constant

keff. =

k0 exp(E/RT)

The

parameters of mass and heat transfer

are, D - Diffusion coefficient, Cp

heat

capacity,

k - thermal conductivity, cin ĆHR - heat of

reaction per unit time and

volume,

T0 -

inlet temp., ĆT - temp.

difference between fluid and

tube wall.

The

complete relevant list of

parameters is,

v,

d, L, ρ,

�, cout,

cin, k0,

E/R, D,

Cp, k, cinĆΗR,

T0, ĆΤ

Synthetic

Strategies in Chemistry

13.7

From

the pi theorem, the number

of nondimensional parameters should

be, 15 - 6 = 9.

The

obvious five nondimensional

numbers are,

L/d,

Cout/Cin, E/RT0

and

ĆΤ/Τ0

The

remaining four nondimensional

numbers are derived using

the following

combination

of the parameters.

=

(k0 τ)-1 (mean residence time

τ

L/v

at pipe flow)

Π1

= v/Lk0

Π2

= �/ρd2k0

=

(k0 τ

Re

L/d)-1

Π3

= D/L2k0

=

(k0 τ

Re Sc

L/d )-1

=

Da-1 (Da

= Damkohler number)

Π4

= (ρCpΤ0) / cin ĆΗR

Π5

= (kΤ0) / cin ĆΗR

d2 k0

= (k0 τ

Re Pr Da

L/d)-1

∴The

nine dimensionless numbers

are,

L/d,

Cout/Cin,

E/RT0,

ĆΤ/Τ0, κ0τ,

Re,

Sc, Pr, Da

During

scale up

�

No change of reaction temp. ∴T0 and k0

are

constant

�

No change in the physical and chemical

partners of the reaction ∴the

kinetic and

material

numbers, remain

unchanged.

�

L/d =

identical

�

To attain specified degree of conversion,

cout/cin = identical

Therefore,

the following two are

the only two parameters

need to be adjusted.

(k0 L)/v

Re

= (v d ρ) /� and

k0τ

But

it is impossible to have

both,

vd

v

L = idem and L/v = idem and L/d =

idem

For

the given condition of

qT

= nqM, , dT

= ndM,

q

∝

vd2 and vTdT2 = n

vMdM2

13.8

Synthetic

Strategies From Laboratory to

Industry

as,

Re α

v d =

idem

VT =

(VM)/n

VT =

n3 VM

and

hence τΤ = n2 τΜ (τ = V/q)

Where,

M

- model scale

T

- technological or industrial

scale

q

volume throughput

n

factor

V

volume of the

reactor

The

results state that for

the increase of volume

throughput n times the

volume of the

reactor

needs to be increased by n3 times

and the residence time needs

to be increased by

n2 times.

REFERENCES

1.

Kirk-Othmer, Concise Encyclopedia of

Chemical Technology, Fifth

Edition, Vol. 2,

John-Wiley

& Sons, 2007.

2.

John J. Mcketta (Ed.,),

Encyclopedia of Chemical Processing and

Design, Vol. 49,

1994.

3.

Marko Zlokarnik, Scale-up in

Chemical Engineering, , Wiley-VCH,

2002.

4.

Keld Johansen, `Aspects of scale-up of

catalyst production', Studies in

Surface

Science

and Catalysis, 143 (2002) 1.

5.

Gianni Donati, Renato

Paludetto, Catalysis Today, 34

(1997) 483.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES