|

ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS |

| << THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible |

| NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC >> |

Chapter

- 11

ELECTROCHEMICAL

SYNTHESIS

M

Helen

INTRODUCTION

Electrochemistry

is a

branch of science which

deals with electrical energy

and chemical

change.

Spontaneous chemical reactions liberate

electrons and they are taken

place in

Galvanic

or Voltaic Cells.

These cells are exploited in batteries

and fuel cells to

produce

electric

power. On the other hand

Electrolytic

Cells are

nonspontaneous where

electrical

energy

is required to carry out

chemical transformations. For an

example in the

process

called

water electrolysis electrical

energy is supplied to split

water in producing

hydrogen

and

oxygen. Electrolysis is exploited in

electroplating, chlorine gas

production and in

refining

metals.

Electrochemical

synthesis is

the production of chemical

products or

materials

using electricity as the

driving or controlling factor.

Electrochemical synthesis

is

achieved by passing an electric

current between two electrodes

separated by an

electrolyte.

That is, the synthesis

takes place at the electrode-electrolyte

interface. This

method

has significant potential

for improving availability of

specialty products and

for

improving

environmental compatibility in several

industrial sectors by destroying

or

converting

unwanted byproducts into

useful products. Much

progress has been made

in

the

last few decades in

advancing the basic

understanding and industrial applications

of

electrochemical

processes, but many aspects

of electrochemical synthesis are

still

inadequately

understood or explored.

FEATURES

OF ELECTROCHEMICAL SYNTHESIS

The

features that distinguish

electrosynthesis from other

synthetic methods are:

The

experiments are simple to

perform and the instruments

required are

inexpensive

and readily available.

Electrochemical

synthesis takes place at the

electrode-electrolyte interface

which

has

a very high potential

gradient of 105 V

cm-1.

Under

these conditions, the

reactions

often lead to products which

cannot be obtained in a

conventional

chemical

synthesis.

An

electrochemical synthesis is a redox

reaction. By fine-tuning the

applied cell

potential,

the oxidizing or reducing

power can be continuously varied.

This

11.2

Electrochemical

Synthesis

possibility

of continuous variation is not

available in conventional

chemical

synthesis.

The

product is normally deposited on

the electrode in the form of

a thin film or a

coating.

The

film composition can be controlled by

varying the bath

composition.

Electrochemical

synthesis is a low-temperature process

limited by the

boiling

point

of the electrolyte.

Reaction

taking place can be controlled

kinetically by controlling the

current

passed

through the cell, while it

can be thermodynamically controlled by

choosing

the

applied potential.

In

summary, electrochemical synthesis is a

`green' route to produce to

fabricate high-

purity

materials without any

additives.

ELECTROCHEMICAL

SYNTHESIS: DESIGNING

Any

electrochemical reaction depends on

the proper choice of a

number of reaction

parameters

such as:

(1)

Choice of an electrode

(2)

Choice of an electrolyte

(3)

Choice of temperature, pH,

concentration, and composition of the

electrolyte

solution

(4)

Choice of the cell design -

divided or undivided

(5)

Mode of electrolysis - potentiostatic or

galvanostatic (constant potential

or

constant

current)

In

a typical electrosynthesis, the

reactant, which is dissolved in

the electrolyte is

deposited

as a solid product.

When

a metallic salt is dissolved in

water it dissociates to

form

positively charged ions. The

solution that contains these

charged ions is referred to

as

an electrolyte or a plating solution. By

passing electric current

through this

electrolyte,

one

can reduce the metal ions to

form solid metal. This

process is referred to

electroplating

or

electrochemical

deposition.

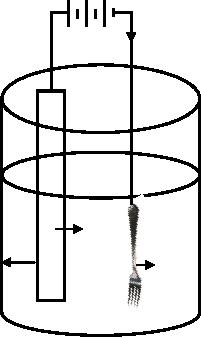

In Fig. 11.1 electroplating is

explained by

taking

silver as the anode, fork as

the cathode (fork to be plated

with silver) and

aqueous

solution

of silver nitrate as an electrolyte.

Both anode and cathode are

connected to the

external

battery. When the external

power is on silver metal at

the anode is oxidized

to

Synthetic

Strategies in Chemistry

11.3

silver

ions and moves towards cathode. At

the cathode silver ions is reduced to

silver and

deposits

on the fork. This results in

thin covering of silver on

the cathode (fork).

Battery

e-

Ag

Ag+

Anode

Fork

Cathode

aq.AgNO3

Fig.

11.1 Representation of silver

electroplating

Two

parameters determine the course of

the reaction i) the

deposition current and (ii)

the

cell

potential. Of the two, any

one of them can be controlled as a

function of time

during

the

reaction.

In

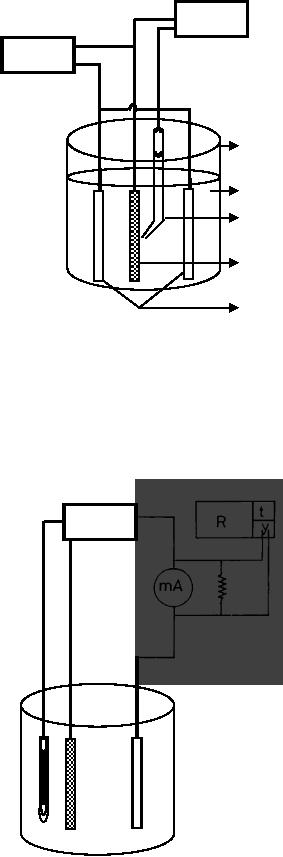

a galvanostatic synthesis (Fig.

11.2), a constant current is

applied through the

electrolytic

cell leading to deposits

with good adhesion and a controlled

morphology.

However

the cell potential drifts as

the activity (concentration) of

the reactant is

decreased.

The

drift in the cell potential

may lead to a multiplicity of

products.

A

potentiostatic synthesis is carried

out with a three-electrode

electrolytic cell

(Fig.

11.3).

The synthesis is carried out

by polarizing the electrode to a

desired potential

with

respect

to a reference electrode. The

cell current usually decays

rapidly as the

reaction

proceeds,

both due to low rates of

diffusion of the reactant

molecules from the bulk to

the

electrode

surface as well as due to decrease in

the activity of the

reactant. The

reaction

yields

a pure single-phase product selected

for by the applied

potential.

11.4

Electrochemical

Synthesis

V

G

e-

1

2

3

W.E

C.E

Fig.

11.2. Galvanostatic

Synthesis,

G,

galvanostat; V, voltmeter; WE,

working electrode; CE,

counter electrode;1,

electrochemical

cell; 2, electrolyte; 3, Lugin

capillary

P

W.E

C.E

R.E

Fig.

11.3. P, potentiostat; R, recorder;

RE, reference electrode; WE,

working electrode;

CE,

counter electrode

Synthetic

Strategies in Chemistry

11.5

VARIOUS

TECHNIQUES FOR ELECTROCHEMICAL

SYNTHESIS

Various

techniques are employed in

electrosynthesis. A list a few of

them and the nature

of

products obtained from each

are given in Table

11.1.

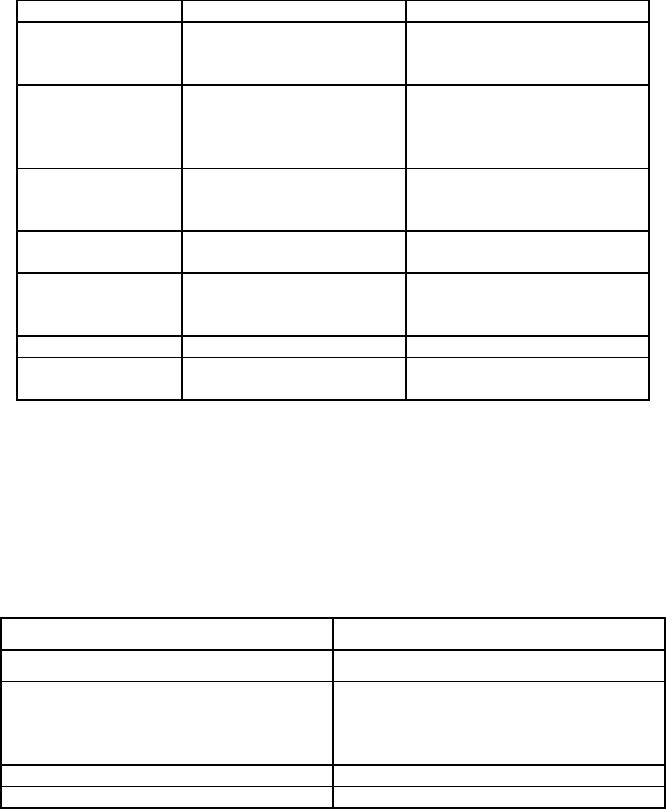

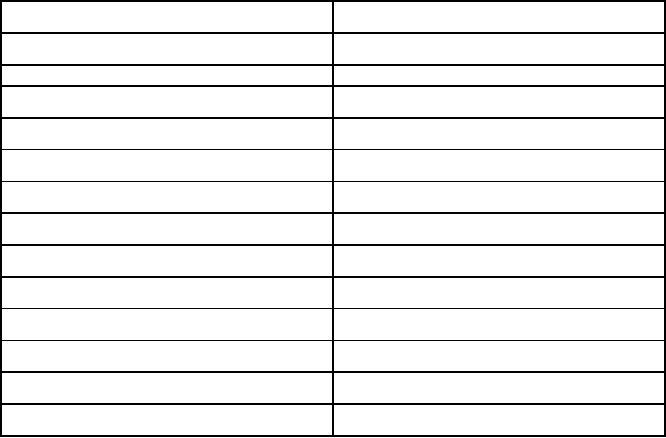

Table

11.1. Summary of the

Electrosynthetic Techniques

Technique

Product

Application

Anodic

oxidation

Coatings/films/powders/

Synthesis

of compounds with

conducting

polymers

high

oxidation state,

corrosion

control,

electrochromism

Cathodic

reduction

Coatings/films/powders

Synthesis

of

electrode

materials

for energy systems,

fabrication

of

hydroxide

films/coatings

Electrolysis

Single

crystals, pure metals

Crystal growth at moderate

of

fused salts, water

and

gases

temperature,

pure

gas

production

Electromigration

Polycrystalline

powders/

Electrode

materials

for

of

reactant species

single

crystals/carbon

batteries

and electrochromism

Layer-by-layer

Synthesis

of composites/solid

Alternate

films/coatings

solutions

voltage/current

synthesis

Electrospraying

Micro

or nanoparticles

Biomedical

applications

Electrospinning

Micro

or nanofibres

Drug

delivery, tissue

engineering,

sensors

During

anodic oxidation a metal ion

in a lower oxidation state or a

monomer like pyrrole

or

aniline is oxidized to a higher

oxidation state or polymer

anodically.

The

anodic

oxidation

technique is especially suited

for the synthesis of

compounds with metal ions

in

unusual

high oxidation states. In

Table 11.2, important anodic

syntheses are listed.

Table

11.2. Oxides and Polymers

Synthesized by Anodic

Oxidation

Compound

Application

Al2O3

Template,

molecular filters

Electrochromic

devices, lithium ion

CoO2.nH2O

batteries,

supercapacitors, and the

protection

film of cathodes in

molten

carbonate

fuel cells

FeO

and MnO2

Electrode

material

Ta2O5

Protective

coating for chemical

equipment,

11.6

Electrochemical

Synthesis

electronic

and sensor devices

Alkaline

water electrolysis

NiO(OH),

Co2O3

Battery,

Organic degradation

PbO2

Magnetic

devices, electrode material

Fe3-xLixO4

WO3 with Co, Cr,

Fe, Mo, Ni, Ru, and

Zn

Electrochromic

devices

RuO2

Supercapacitor

Photocatalyst,

humidity sensor

TiO2

V2O5 nanofibers

Battery

material, active materials

in

electrochromic

and chemochromic devices

Polypyrrole,

polyaniline, polythiophenes,

Sensors,

Electroluminescence, Protective

polyacetylenes,

polyindole

coating,

FET, Organic

semiconductors,

batterries

In

cathodic reduction electric

current is passed through a

metal salt solution and hence

the

metal

is deposited at the cathode.

This

principle is widely used to

obtain metal

coatings.

But

depending upon the

deposition potential, choice of

the anion and the pH of

the

solution

various other reactions take place at

the cathode. Switzer in 1987 introduced

this

technique

for the first time as a

synthetic route to obtain

oriented ceramic films as

well as

Polycrystalline

CeO2 powder was synthesized from

a cerous

polycrystalline

powders.

nitrate

solution. Various oxide

materials are synthesised by

using electrogeneration of

base

by cathodic reduction and their

typical applications are

listed in Table 11.3.

During

electrolysis of fused salts, a

low-melting salt containing

the transition metal

oxide,

is melted and electrolyzed at elevated

temperatures using an inert Pt electrode or

a

reactive

metal electrode such as Fe,

Co, or Ni depending on the

desired product.

During

water

electrolysis pure oxygen and

hydrogen is collected at the

anode and cathode

respectively.

Synthesis

by electromigration, is based on kinetic

control over the reaction

by

electrochemistry.

This technique involves

intercalation or deintercalation of a guest

ion

in

a host lattice by applying an

electric potential between

the electrodes.

During

pulsed electrolysis, the

working electrode is alternately

polarized anodically for

a

length

of time, t1(called

the on-time) and then

cathodically for time, t2

(called

the off-

time).

Voltage

as well as current pulses were

used to obtain oxide films

in the Pb-Tl

Synthetic

Strategies in Chemistry

11.7

system

using a stainless steel electrode and a

mixed Pb-(II)-Tl(I)

bath.

At

low current

densities,

the films were Tl-rich

while at high current densities

the films were

Pb-rich.

Cathodic

deposition of the precursor

film for the YBaCuO

system has been carried

out

from

a mixed metal nitrate bath

containing KCN as well as a

complexing agent.

The

superconductive

films obtained from a

cyanide bath show a Tc ~ 92 K

which is greater

than

all other reported values

for this class of

superconductors, obtained by

electrochemical

techniques.

High

intensity pulsed electric

fields is an interesting

alternative

to traditional techniques like

thermal pasteurization in preservation of

liquid

foods

such as fruit juices or

milk.

Conventional

preservation methods such as

heat

treatment

often fail to produce

microbiologically stable food at the

desired quality

level.

High

intensity pulsed electric

fields processing can deliver safe and

shelf-stable products

with

high nutritional

value.

Pulsed

electrodeposition is an effective method

to prepare

nano

materials of different

morphologies.

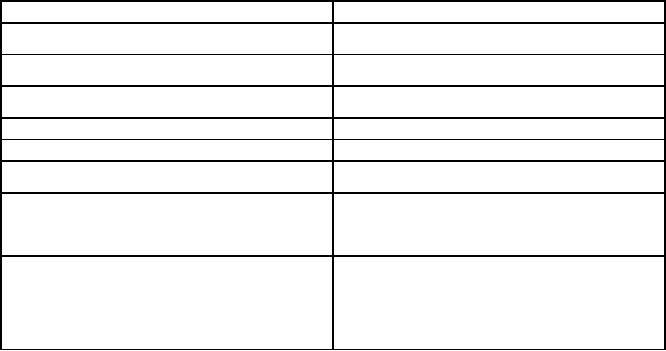

Table

3. Oxides Synthesized by

Electrogeneration of Base by Cathodic

Reduction

(reproduced

from [1])

Compound

Application

Gas

sensor, fuel cells

CeO2

La1-xMxCrO3 (M

= Ca, Sr or Ba)

Electronic

conductor

ZrO2

Ionic

conductor

Dielectric

components

BaTiO3

LaFeO3

Oxide

coating

Corrosion-protective

coating

Al2O3, Cr2O3,

Ln2Cr3O12.7H2O

Electrode

material

PbO2

Mo1-xMxO3 (M = Co, Cr, Ni, W or

Zn)

Optical

light modulators

TiO2

Photocatalyst

Nd2CuO4

Superconductor

Optical

and electronic devices

ZnO

Giant

magnetoresistance (GMR)

LaMnO3

WO3

Electrochromic

devices

11.8

Electrochemical

Synthesis

MICRO-

AND NANOPARTICLE PRODUCTION BY ELECTROSPRAYING

Electrospraying

is a

process of liquid atomisation by

electrical forces. It is a

dynamic

process

of droplet generation and simultaneously

charging by means of an electric

field.

Droplets

spraying out of a capillary

nozzle, produced by electrospraying

are highly

charged.

Charged droplets are self

dispersing in space, resulting in

the absence of

droplet

coagulation.

The deposition efficiency of a charged

spray on an object is higher

than for

an

un-charged spray. This

feature can be advantageous in thin-film

formation or in

surface

coating. Generation of the

droplet and its size can be controlled by

controlling

the

flow rate of the liquid and

the voltage at the nozzle.

Nearly monodisperse size

distribution

is achievable.

The

size of the electrospray droplets can

range from

micrometers

to nanometers.

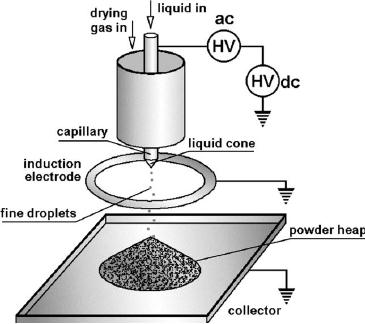

Fig.

11.4. Schematic for

production of particles of uniform size

by electrospraying

(reproduced

from [2])

Electrospraying

technique is a single-step, low-energy,

and low-cost material processing

technology,

which can deliver products of

unique properties.

Electrospraying

is

exploited

in many industrial processes

such as painting, fine

powder production, or

micro-

and nanothin film deposition. It is also

employed in microfluidic devices

and

nanotechnology.

Spraying

solutions or suspensions allows

production of particles,

Synthetic

Strategies in Chemistry

11.9

ranging

from micro to nanometer

size.

Production

of particles of uniform size can

be

accomplished

by using pulsed or ac superimposed on dc

bias voltage for liquid

jet

excitation.

By

tuning the frequency of ac

voltage, uniform size of droplets

are formed

by

disintegrating the liquid

jet. Various parameters can control

the droplet size they

are

the

bias and ac voltage magnitudes, ac

voltage frequency, and volume

flow rate of the

liquid.

Uniform

droplets can be achieved when ac and dc

voltages are adjusted

such

that

the droplets are formed and

detached at the voltage

peaks.

A

schematic diagram of

a

system for harmonic spraying

is shown in Fig.

11.4.

Electrospraying

is exploited for the

generation of micro/nanospheres for

biomedical

applications

since the process has an advantage of

not making use of any

external

dispersion/emulsion

phase which often involves

ingredients that are

undesirable for

biomedical

applications.

Chitosan

micro/nanospheres

were

synthesized

by

electrospraying

with acetic acid solution is exploited

for drug delivery

applications. This

technique

is also used to prepare polycaprolactone

(PCL) polymer particles with

a

different

microstructure by the evaporation of

solvents during the

electrospraying

process.

MICRO-

AND NANOFIBRES PRODUCTION BY

ELECTROSPINNING

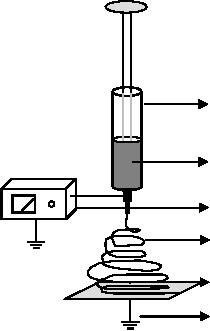

Electrospinning

is a

process in which a high

voltage electric field is

applied to a melt or

polymer

solution in order to attain charge

repulsion on the liquid

surface. This overcomes

surface

tension there by a thin

liquid jet is ejected. Narrow

jet diameter is attained due

to

the

electrostatic repulsion caused

between the charges on the

liquid surface and

the

collector

that has a different

electric field. Solid or

polymer fibres ranging from

10 m to

10

nm is attainable. As shown in Fig.

9.5, a typical electrospinning setup

consists of a

syringe

with a capillary nozzle

through which the liquid to

be electrospun is forced; a

high

voltage source with positive or

negative polarity to charge the

liquid jet and a

ground

collector.

Electrospun

textiles are exploited in

preparing filters, semi-permeable membranes,

as

scaffolding

for tissue engineering and in drug

delivery. Electrospinning has

flexibility in

selecting

materials for drug delivery

applications.

Either

biodegradable or non-

degradable

materials can be used to control

whether drug release occurs

via diffusion

alone

or diffusion and scaffold degradation.

Due to the flexibility in

material selection a

11.10

Electrochemical

Synthesis

number

of drugs can be delivered including:

antibiotics, anticancer drugs,

proteins, and

DNA.

Syringe

Sample

Voltage

generator

(

Non-woven

fiber

Collector

Ground

Fig.

11.5. Schematic of an electrospinning

system

CONCLUSION

Electrochemical

techniques such as anodic

oxidation, cathodic reduction,

alternating

current

pulsing, electrospraying and

electrospinning provide simple, cost

effective

alternative

routes for the production of

micro or nanomaterials, thin

films, coating,

composites

having unique properties and

applications. It is hoped that the

ease and

versatility

of this technique will find will

find it a permanent place in synthetic

chemistry.

REFERENCES

1.

G. H. A. Therese and P. V. Kamath, Chem.

Mater., 12

(2000) 1195.

2.

A. Jaworek, Powder

Technol., 176

(2007) 18.

3.

A. Jaworek, A.T. Sobczyk J.

Electrosta., 66

(2008) 197.

4.

N. Arya, S. Chakraborty, N. Dube,

D.S Katti, J Biomed

Mater Res B Appl

Biomater.,

2008 (In

Press)

5.

S. Tan, X. Feng, B. Zhao, Y. Zou, X.

Huang, Mater.

Lett., 62

(2008) 2419.

6.

T. J. Sill, H. A. von Recum, Biomaterials,

29

(2008) 1989.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES