|

CHAPTER

- 10

THE

ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY

And he

said unto them, it is not

for you to know the

times

or

the seasons, which

the

Father

hath put in his own

power.

The Holy

Bible (The

Acts 1:7)

My

times

are in

thy hand.

The

Holy Bible (Psalm

1:15)

To

every thing there is a

season, and a time

to

every purpose under the

heaven:

A

time to be born, and a time

to

die; a time

to

plant, and a time

to

pluck that which is

planted;

A

time

to

kill, and a time

to

heal; a time

to

breakdown, and a time

to

build up;

A

time

to weep,

and a time

to

laugh; a time

to

mourn, and a time

to

dance;

A

time

to

cast away stones, and a time

to

gather stones together; a time

to

embrace, and a

time

to

refrain from

embracing;

A

time

to

get, and a time to lost; a time

to

keep, and a time

to

cast away;

A

time

to

rend, and a time

to

sew; a time

to

keep silence, and a time

to

speak;

A

time

to

love, and a time

to

hate; a time

of

war, and a time

of

peace.

The

Holy Bible (Ecclesiastes

3:1-8)

Noah's

Ark The Technological

Marvel

13.

And God said unto

Noah, The end of all flesh

is come before me; for the

earth is

filled

with violence through them;

and, behold I will destroy

them with the

earth.

14.

Make thee an ark of gopher

wood; rooms shalt thou make

in the ark, and shalt

pitch

it

within and without with

pitch.

15.

And this is the fashion

which thou shalt make it of:

The length of the ark

shall be

three

hundred cubits, the breadth

of it fifty cubits, and the

height of it thirty

cubits.

16.

A window shalt thou make to

the ark, and in a cubit

shalt thou finish it above;

and

the

door of the ark shalt

thou set in the side

thereof; with lover, second,

and third stories

shalt

thou make it.

Genesis

6: 13-16, The

Holy Bible

10.2

Role

of Synthesis in Materials

Technology

What

is new in Materials

Technology?

The

Living Cell is the All Time

Marvel of Almighty God, The

Creator. The Living

Cell

can

apparently handle enormous

number of unimaginable, uncomprehendable

and

difficult

problems (functions) with

ease and spontaneity.

The

Living Cell performs

multiple

functions (reproduction, growth, defense,

protein synthesis, transport

of

nutrients,

information storage, site directed

information transfer, communication,

energy

conversion

and energy storage, sensing)

simultaneously. All vital functions

for the

sustenance

of life takes place in the

living cells. Thus the

Living Cells are

self-

replicating,

self-containing and

self-maintaining.

One

of the goals of Materials

Technology

is to design and synthesize the material

with artificial intelligence

that

replicate

Living Cell in all

aspects.

An

inquisitive mind now poses

the following

questions:

What

is the Living Cell? What

does a Cell mean? Where does

the term `Cell'

originate

from?

How can the Living

Cell be multifunctional and

versatile? How cells

form

complex

organisms? What is the

structure of the Cell? What

are the dimensions of

the

Living

Cell? What are the

constituents of the Cell?

Can the Living Cells be

mimicked?

Can

such mimics of the Living

Cells act as molecular

machines and

revolutionize

Materials

Technology? The

queries are recurring.

The

Cell is the basis of life.

The Cell is the smallest

unit of all living

organisms

whether

it be unicellular (eg., bacteria) or

multicellular (eg., human

beings). Human

beings

have an estimate of 100 trillion

(1014)

cells. A typical cell is of 10 �m size

and 1

nanogram

mass [1].

Robert

Hooke is the originator of

the term "Cell" and has

been derived from the

latin

word

`Cellula' meaning `a small

room'. It is worth knowing

few good things about

Robert

Hooke which are depicted in

the next few

lines.

Robert

Hooke (18th July, 1635 - 3rd

March

1703)

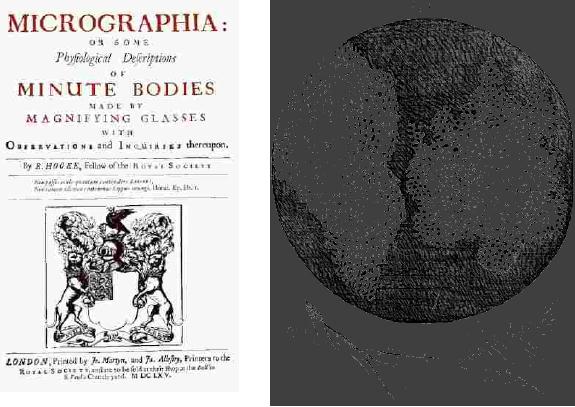

Robert

Hooke was a remarkably industrious

scientist and philosopher. He was an

active,

restless,

indefatigable genius even

almost to the last days of

his life. One of the

important

contributions

of Robert Hooke to Biology is

his book "Micrographia"

published in 1665

[Fig.

10.1 (a)]. Robert Hooke

coined the term "Cells".

This has originated from

his

microscopical

observation of thin slices of cork

(tissue of light soft bark

of Mediterranean

Synthetic

Strategies in Chemistry

10.3

tree).

He coined the word `Cell' to

the pores separated by walls

because the

observation

reminded

him of the cell of a

monastery (small rooms where

monks lived in) [Fig.

10.1

(b)].

He

has recorded his study of

the plant tissue in "Observation XVIII"

of the

Micrographia

as follows [2]:

"I

could exceedingly, plainly

perceive it to be all perforated and

porous, much like a

honey-comb,

but that the pores, or

cells, ........ were indeed the

first microscopical

pores

I

ever saw, and perhaps, that

were ever seen, for I had

not met with any

Writer or Person,

that

had made any mention of them

before this ....".

Truly,

history owes to this industrious

scientist and philosopher.

(a)

(b)

Fig.

10.1. (a) Title page of

Micrographia (1665) [3], (b)

Robert Hooke's drawings of

the

cellular

structure of cork (plant

tissue) and a spring of sensitive

plant from

Micrographia

[4].

Living

cells are divided into

two types, namely, the

Procaryotic Cells and

the

Eucaryotic

Cells. Procaryotic cells

possess simple structure

(eg. Bacteria cell) [5].

Cells

10.4

Role

of Synthesis in Materials

Technology

without

a nucleus were grouped

together as "Prokaryotes'. We human

beings, and most

of

the animals and plants,

belongs to the life form

enjoying cell nucleus and

are

collectively

called Eukaryotes [6].

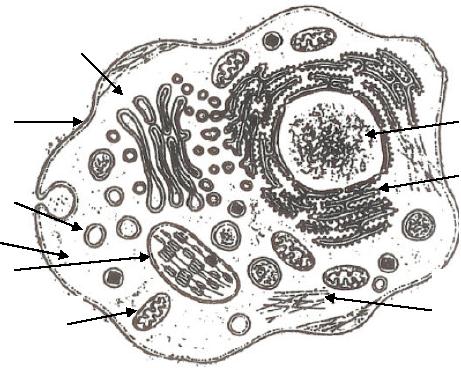

Eucaryotic cell (they carry

their DNA wrapped in a

cell

nucleus) possesses complex

structure as represented in Fig.

10.2. The cells

are

surrounded

by a double layer membrane. In

many cases the cells

are further shielded

by

a

cell wall. As a result

chemical processes taking place in a

cell would not easily

get

disturbed

by the surrounding

environment.

Golgi

Apparatus

Cell

Nucleus

Membrane

Rough

Lysosome

Endoplasmic

Reticulum

Cytoplasm

Chloroplast

Smooth

Endoplasmic

Mitochondria

Reticulum

Fig.

10.2. Schematic representation of a

eukaryotic cell and its

compartments [6]

The

cell possesses secluded areas

for specific

functions.

The

major organelles

(specialized

subunit with in a cell that

has a specific function to

perform) and cellular

structure

include the nucleus, ribosomes,

mitochondria, golgi apparatus, cytoplasm,

rough

endoplasmic

reticulum and smooth endoplasmic

reticulum. As houses are

divided into

living

room, dining room, kitchen

and bed room, living cells

too are

compartmentalized

as

shown in Fig. 10.2. Each

compartment has a specific

set of functional tasks.

For

instance,

the nucleus contains most of

the DNA which is the carrier

of genetic

information

in all the cellular life

forms. The mitochondria are

the power houses of

the

Synthetic

Strategies in Chemistry

10.5

cells.

These are the sites where

cellular respiration and a consequent

release of chemical

energy

from food takes place. Ribosomes

are the protein synthesizing

machines of the

cell.

Ribosomes are the cells

protein factory.

Can

we imagine a data storage

device of micrometer

(10-6 m) size but can

squeez

the

data equivalent of five

high-density floppy disks (5 x

1.44 MB = 7.2 MB) ?

Yes,

such a data device is

existing in Nature. The

chromosome, a very long

stretch of

DNA

wound up in a complicated way,

which determines the genetic

identity of every

living

organism on this plant is an

example of such data storing

device.

Can

we imagine a motor that is

running on and on and on but

only of size

measuring

a few hundredths of a thousandth of a

millimeter?

For

your surprise the motor is

already in existence. It is a system

mainly consisting of

the

proteins

actin and myosin. The system

serves to power our muscles.

Actin is a soluble

protein

found in muscle cells. It is

the main component of the

thin filaments. Myosin

is

the

motor protein that generates

the force and movement in

contraction of muscles.

Myosin

is the oxygen storage

protein of the muscle. When

Myosin carries an oxygen

molecule,

the oxygen molecule is

deeply burried within the

structure of the

protein.

Because

of the weak interations present

the protein is capable of

rearranging its

structure

to

be able to take up oxygen or to set it

free by way of rearranging

itself so that a tunnel

is

opened

between the oxygen binding

site and the rest of the world.

For such rapid

rearrangments

to take place weak interactions should be

present with in the

protein

structure

as well as with the substrate.

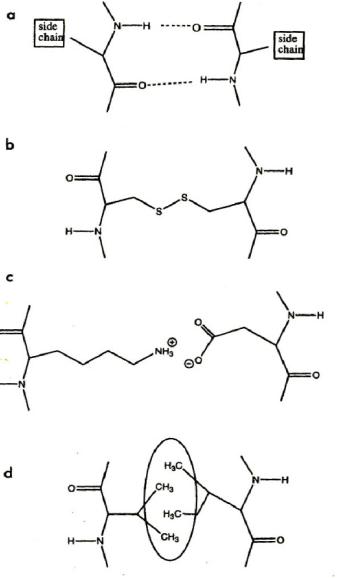

The following are some of

the weak interactions

found

in biological systems (The

Cell).

i.

Hydrogen bonding: Hydrogen

atom is normally bound to

just one atom of oxygen

or

nitrogen.

In Hydrogen bonding the

Hydrogen atom starts interacting

with a second atom.

Hydrogen

bonding is responsible for

the extremely high boiling

point in spite of its

modest

molecular weight. If hydrogen

bonding did not exist,

water would be a gas

at

ambient

temperatures.

ii.

Salt bridges: This

is because of the electrostatic

attraction between parts of

molecules

having

opposite electrical charges.

iii.

Van der Waals forces: These

forces exist between the

negatively-charged cloud of

electrons

of one atom and the positively-charged

nucleus of the other.

10.6

Role

of Synthesis in Materials

Technology

iv.

The Hydrophobic interaction: The

tendency of oily, water-avoiding

molecular

surfaces

to stick together and shut

out any water

molecules.

Thus

the first lesson one need to

learn is that the key to

generate materials that

replicate

living

cells or biological systems lies in

designing synthetic strategies

based on weak

interations

between the reacting systems as

represented pictorially in Fig.

10.3..

Fig.

10.3. Interactions that

stabilize the local

structures in proteins: (a)

Hydrogen bonds

(secondary

structure), (b) disulfide bridges

(tertiary or even Intermolecular,

(c) salt

bridges,

(d) hydrophobic interaction.

The oval shape symbolizes

the hydrophobic area

from

which water is excluded

[6].

Synthetic

Strategies in Chemistry

10.7

Can

we imagine a catalyst capable of

converting the inert

nitrogen gas from the

air

into

nitrogen fertilizer at room

temperature and atmospheric

pressure?

The

enzyme nitrogenase present in nodule

bacteria that live in symbiosis

with certain

plants

and provide them with

freshly made nitrogen

fertilizer produced from air

and

water.

There is no technical catalyst

producing ammonia from

elemental hydrogen and

nitrogen

at ambient temperature and pressure as

the nitrogenase of nodule bacteria.

Thus

it

is the dream not yet

realized by the scientists

all over the

world.

Can

we dream of the synthesis of

natural products with 100 % enantiomeric

excess

(ee)?

In

organic chemistry, particularly in

the synthesis of natural

products, one of the

major

issues

of concern even today is to

synthesize exclusively one of the

two mirror-imaged

structures

of chiral compounds. Literally,

synthetic chemists are

battling for every

single

digit

enhancement in the value of ee

beyond the statistically

50%. Interestingly

enzymes

can

distinguish the mirror

images with 100%

reliability.

Can

we synthesize catalysts

(nonnatural)

which are on a par with

natural enzymes in their

performance? This is

yet

another

challenge facing materials

technology today.

Other

important challenges ahead in

Materials Technology are

achieving computer

technology

that matches with human

brain, achieving telecommunications

technology

that

matches with nervous system of

human body. The only

means of realizing

such

breakthroughs

in materials technology is through

the evolving synthetic

strategies in

Chemistry.

Some

Benefits from Materials

Technology

Audio

tapes, audio tape players,

audio tape recorders, calculators,

cameras, compact disks

(CD's),

CD players, Barcode, Colour Printers,

Computers, Digital video

disk (DVD),

Electronic

commerce, Electronic data

interchange, E-mail, Internet,

Fax machines,

Laboratory

equipment, Laser printers, Laser

pointers, Liquid crystal

display, LCD,

Mailing

services, Measuring instruments, Modem,

Network/cable television,

Periodicals,

News

papers, Over head

projectors, Photocopy machines,

Play ground equipment,

Radio,

Refrigerators,

Slide Projectors, Scanner,

Search Engines, Switching

technology,

Telephones,

Transparencies, Type writers,

Video cameras, Vedio

conferencing are all

some

of the marvels of Materials

Technology [7].

10.8

Role

of Synthesis in Materials

Technology

Materials

Technology Vs Material's

Technology

Materials

technology is a science and a knowledge

area that describes

properties,

functions

and applications of different materials

[8]. Materials technology is

dependent

on

Material's technology, i.e.

the way materials are

architectured or build or

constructed

or

fabricated or synthesized. To gain

knowledge of Materials technology one

should

understand

the role of synthesis in

generating the materials.

New materials,

improved

production

techniques, and miniaturization are

the three essential ingredients

that have

tremendous

potential to trigger major

technological revolutions.

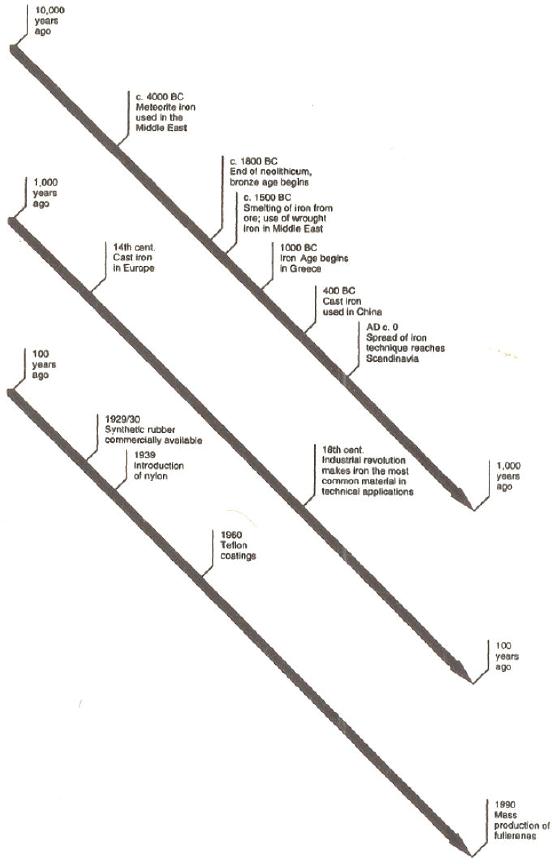

Role

of Synthesis

Materials

synthesis is so vital that

the early history of man

kind (from the stone age to

the

iron

age) is classified based on

the materials that started

new eras.

So

far the

classification

of eras is associated with or

based on materials that have

revolutionized the

respective

eras.

But

the role of synthesis has

now become so crucial in

materials

technology

that the production methods

are going to be used as

milestones of

development

rather than the material

itself. Initially materials

that are either

simply

found

or gathered from nature (wood, bones,

stones) served mankind. Progress has

been

made

from such naturally existing

materials to the use of

metals retrieved from ores

using

fire.

Metals were found to be more

versatile in their use

rather than naturally

occurring

materials.

Currently,

metals, glass and other

materials are being replaced by

polymers. This age

which

we live can be truly regarded as

polymer age because the

survival of mankind

becomes

questionable with out

polymers (substances that

are chemically assembled

from

smaller

molecules).

Again

polymers are more versatile

than metals and

naturally

occurring

materials like wood or stone.

Milestones in the use of

materials during the

last

10,

000 years have been

illustrated in Fig. 10.

4.

But

still we have not our

destination in technological advancement.

Even though

polymers

have the potential to cater to

many of our needs they can

not fulfill all

the

demands

we have for advanced materials.

The problems associated with

polymers are:

valuable

resources and energy are

used up in the production of

polymers. Also they

are

neither

biodegradable like wood nor

recyclable like iron.

Synthetic

Strategies in Chemistry

10.9

Fig.

10.4. Time line illustrating

the use of materials during

the past 10, 000 years

[6].

10.10

Role

of Synthesis in Materials

Technology

Even

though polymers have

revolutionized the way we

live, in comparison to

biological

materials

they are far inferior as

they in no way contain any

significant amount of

information,

also they cannot store energy, or

they cannot act in an intelligent

way. Thus

the

focus of the evolving

synthetic strategies has

been to produce materials

mimicking

biological

materials. Such materials

should be functional and adaptive on a

molecular

scale.

Like

our fore fathers and

ancestors we may be of the

opinion that our

present

technology

is modern, advanced, accomplished and

ultimate. Also we may tend

to

believe

that only incremental

improvements can be brought about in

the present day

technology.

Major technological breakthroughs

are believed to be hardly possible.

But

this

is not true. There is large

room for the change to

betterment as change happens to be

the

law of life. The enormous

scope and potential for such

a major advancement can be

noticed

if we compare our present day synthetic

strategies or production

methodologies

with

the synthetic strategies

adopted by molecular machinery in

living cells. So long

almost

all the available synthetic

strategies handled bulk

amounts (countless atoms or

molecules)

which yielded materials

whose properties can only be

controlled with in a

limit.

But the properties of

materials obtained by adopting

such synthetic

strategies

dealing

with bulk amounts are

not adaptive or intelligent.

Even though the tools

and

machinery

that one currently uses to

carry out simple processes

automatically they can no

way

go down below macroscopic or at

the most microscopic levels.

In sharp contrast, in

the

living cells, the structures

of inorganic building materials

are controlled at the

molecular

level guiding the

precipitation of the mineral

from solution for

instance.

Incidentally,

the most complex machines of

the cell are not

bigger than 25 50 nm.

Thus

there

is ample scope and also the

way is long to meet the

materials technology

mimicking

the

Living Cell. At the moment

The Time of reaching the

destination is not

clear.

Information

technology, Nanotechnology and

Biotechnology are regarded as

the three

eyes

of the new millennium. New

synthetic strategies can open access to

new materials.

Materials

are transformed into useful

products by working on them

with hands and tools.

Production

technology underwent a drastic change.

From millennia useful

products are

made

manually. Now most of them

are made by machines. Except

those processes

where

decision-making is involved all

others are being carried

out by machines. As a

Synthetic

Strategies in Chemistry

10.11

consequence

length scale is no longer

limited to such parts that

human workers could

grasp

with their hands. Thus

miniaturization of production has paved

the way for

the

miniaturization

of the products.

INFORMATION

TECHNOLOGY:

The

Beginning of Information Technology

The Age of the Printed

Book:

Now

this very second you

are reading this book. It

means you are getting

benefited by

the

revolution of book publishing

technology that has started in

15th century. Johannes

Gutenberg

(1397 1468) conceived

the idea of printing books

with movable type. He

developed

his idea into a working

technology. It is no easy job to

achieve uniform

dimensions

of letters. Such sufficiently

uniform dimensions of letter

type facilitates a

flat

printing

surface. Hence smooth lines

are obtained.

Through

years of persistent

hard

work

Johannes Gutenberg could

overcome this problem by

making the type from

metal.

He

could cast all of them in

the same mold, which

could be combined with

different

letter

shapes and adjusted in its

width. This development is a

result of several years of

hard

work. To achieve this

objective he has to borrow considerable

amounts of money.

He

could not have given

the world the printing

technology if he were not to

be

knowledgeable

in metallurgy. His major

success involves producing

160-170 copies of

the

42-line Bible shown in Fig.

10.5. The name 42-line Bible

refers to the number

of

lines

of print on each page. This

work of Johannes Gutenberg is of

iconic status as this

marked

the beginning of `Gutenberg

Revolution' and `the Age of

the Printed Book'.

The

printing of 42-line Bible by

Gutenberg is a remarkable development in

the history of

mankind

as this has broken the

information monopoly. The

new technology has put

an

end

to the Dark Ages. It has

brought about the

reformation, the enlightenment and

the

rise

of modern science. Interestingly, with in

a span of 50 years after the

production of

Bible

with printing technology

developed by Johannes Gutenberg,

more books were

produced

than in the 1000 years before.

The technology Johannes

Gutenberg developed

lasted

for more than 500 years.

Later on this printing

technology of Gutenberg was

replaced

by light reprography. This is

followed by the new

information revolution

brought

about with the invention of

personal computers.

10.12

Role

of Synthesis in Materials

Technology

Fig.

10. 5. (a) A copy of the

42-line Holy Bible, the

major work of Johannes

Gutenberg

[9].

Advent

of Computers and Internet

Information Explosion:

Advent

of computers and widespread growth of

availability and use in internet

has

brought

about revolution in the

field of information technology. Since

this development

has

only taken place over the

past two decades we are

fortunate enough to witness

the

progress.

But how could this

happen? What is the driving

force for such a

drastic

explosion

in information technology? Literally

with computers and internet

the whole

world

is at our finger tips. The

marvelous progress can be attributed to

the new synthetic

strategies

that facilitated miniaturization of

electronic elements and

circuits.

Miniaturization

means not alone saving

space or materials but

miniaturization of

electronic

circuits made them cost

effective, efficient and faster. 1000

fold enhancement

is

memory capabilities and calculation

speeds have been achieved

with in a short span

of

10

years i.e., from early

1980's to 1990's. The number

of transistors in typical

microchip

kept

on increasing exponentially from

1971.

For

every 18 months the number

of

transistors

on a microchip doubled.

In

1971 the microchip contained

only 2300

transistors

when Intel launched the

world's first

microchip.

Nearly

a hundred fold

increase

in the number of transistors

has been achieved by 1985

with the creation of

Intel

386

processor with 2, 75, 000

transistors. And today the

Tukwila contained 2

billions

transistors.

Very recently, i.e., on

14th April 2008, Intel,

the microchip leader,

unveiled

Synthetic

Strategies in Chemistry

10.13

two

drastically different processors.

They succeeded in creating

the worlds smallest

microchip

(computer processor) namely the

atom chip as well as the

worlds biggest chip

namely

the Tukwila. The size of the

atom chip is of a baby's

finger nail. The chip

packs

47

million transistors. But consumes

only over a half of a watt

of power. The atom

chip

can

power hand held internet

devices namely the mobile

internet devices, small hand

held

computers

that will help in emailing,

letter writing and calculations. On

the contrary the

Tukwila,

the new Intel chip

possessing the highest

number of transistors ever

put on the

slab

of silicon with 2 billion

transistors can do the work of

four computers. This

world's

biggest

microchip consumes 130-170 watts of

power. This will help

scientists to build

gaint

`number crunchers' far more

powerful than the Tata-CRL

`Eka' super computer

built

in India (the Tata-CRL

`Eka', computer is the

world's forth-fastest

computing

machine).

With the help of such super

computers fuelled by microchips

with 2 billion

transistors

complete genetic simulation of a

human cell can be achieved

with in a span of

a

decade or even lesser time

period. This facilitates

doctors to precisely simulate

an

unhealthy

cell in a human. Thus exact

medication can be possible. With

the advent of

nanotechnology

unimaginable advancements in the field of

information technology

are

anticipated.

NANOTECHNOLOGY:

The

word Nanotechnology was used

for the first time by

Taniguchi at the University

of

Tokyo,

Japan, in 1974. He was then

referring to need of electronics

industry to engineer

materials

at nanometer scale

[10].

On

29th of

December, 1959, Richard P.

Feynman took the shiny

example of the

living

cell to drive home his

point that individual atoms can be

arranged in the way we

want

them to be.

With

this ultimate degree of

miniaturization all the

information

contained

in all the books in the

world can be stored in the grain of a

sand. Living cell is

not

only capable of storing

enormous amount of information in a

very small volume

but

also

equipped with the hard ware

to read out the information

and retrieve the same

when

needed

and put the same into

action. In an analogous way

Richard P. Feynman

professed

that

it should be possible to write the

entire Encyclopaedia Britannica

onto the point of a

needle.

In those days when computers were

huge machines the wiring of

which filled the

10.14

Role

of Synthesis in Materials

Technology

whole

room completely, he is genius

enough and fore sighted to profess

that computers

of

the future should be made of

wires that would only be 10

or 100 atoms in diameter.

Role

of Synthesis in Nanotechnology:

Carbon

materials are very important

for Nanotechnology to flourish.

Carbon materials

are

vital, versatile, amazing and

unique. Carbon exists in

different allotropic

forms,

namely,

graphite, diamond, fullerene, and

nanotube. Graphite with its

two dimentional

hexagonal

array of carbon atoms and diamond

with its three dimensional

structure are

well

known. Fullerene and nanotubes

are newly discovered allotropic

forms of carbon.

Synthetic

Strategy that lead to the

formation of Fullerenes:

A

dream team of five scientists namely

Kroto, Heath, O'Brien, Curl

and Smally in Rice

Quantum

Institute, Texas were trying

to understand how long-chain

carbon molecules

(cyclopolyynes)

are formed in interstellar

space.

To

find an answer, they

started

vapourizing

graphite, the grand old

allotrope of carbon, by irradiating

with laser. This

experiment

has lead to the serendipitous

discovery of C60 molecule, named as

Buckminsterfullerene.

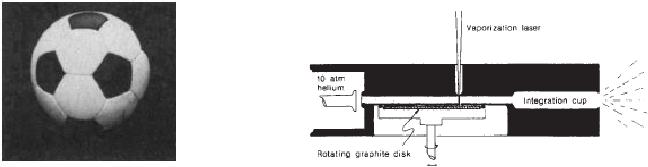

The structure of C60 molecule consisted of 32 faces, 12 of

which

are

pentagonal and the remaining 20

are hexagonal. The structure

of C60 is analogous to

common

foot ball shown in Fig.

10. 6. (a) The experimental

set up containing the

vapourization

chamber is shown in Fig. 10.

6. (b). Later on many studies

have been

carried

out on the properties and applications of

fullerens and fullerene derivatives.

Not

oniy

that, fullerene research paved

path for the discovery of

multiwalled carbon

nanotubes

by Ijima. Simply the

synthetic methodology adopted

has changed the course

and

destination of carbon science and

technology.

Carbon

species from the surface of

a solid graphite disk are

vapourized using a

pulsed

laser

source in the presence of He environment.

Nd:YAG laser producing pulse

energies

of

~ 30 mJ is used. In a typical experiment

the pulsed valve is opened.

Vapourization

laser

is fired onto the rotating

graphite disk. Carbon

species start vaporizing

into the

helium

stream, cooled and partially equilibrated

in the expansion. As a result

molecular

beam

is formed which travels into

the ionization region. The

clusters were ionized by

a

laser

pulse and the products were

analysed by mass spectrometer.

During the process

graphite

disk is rotated slowly to

produce a smooth vaporization

surface.

The

vaporization

laser beam is focused through

the nozzle to strike the

graphite. The species

Synthetic

Strategies in Chemistry

10.15

in

the vaporized graphite plasma

are cooled and clustered by

the thermalizing

collisions

of

He carrier gas. Also the

carrier gas provides

necessary wind to carry the

cluster

through

the remaining of the nozzle.

The cluster filled gas

expands freely at the

nozzle

and

form a supersonic beam which

is probed by mass spectrometer [11].

Kroto, Smalley

and

Curl were awarded nobel

prize for Chemistry in 1996

for their discovery

of

Fullerenes

in 1985.

Fig.

10.6. (a) A football (the

C60 molecule is supposed to have

the structure formed

when

each

vertex on the seams of such

a ball is replaced by carbon atm,

(b) Schematic diagram

of

the pulsed supersonic nozzle

used to generate carbon

cluster beams

Even

though Fullerens were

discovered in 1985, it is not

until 1991 when Kratschmer

and

Huffman

evolved a synthetic strategy

based on arc discharge for the

mass production of

fullerenes

that fullerene research grew

rapidly and in one way this is a

foundation stone

for

the future discovery of

nanotubes by Ijima in 1991.

Hence synthetic strategies

play a

pivotal

role in the birth as well as

destination of any new

technology.

With

the ways being available

for the mass production of

Fullerenes, derivatives of

fullerenes

could be synthesized.

Endohedral

compounds, exohedral compounds

and

heterofullerenes

are the three classes of

fullerene derivative

[12].

Fullerene

derivatives with atleast one atom or

ion located inside the 7 �

cage of

fullerene

are called endohedral

fullerenes.

Endohedral

compounds are more

polar

compared

to the parent fullerene

making the separation of fullerenes

easier. Electronic

properties

of fullerenes can be tuned by forming

endohedral derivatives.

Endohedral

compounds

find utility in the

fabrication of solar cells,

linear optical units and in

photo

conductors.

Some of the ways of

synthesizing endohedral derivatives

are by heating the

fullerene

directly with the guest gas

under pressure; evaporating fullerene in

presence of

10.16

Role

of Synthesis in Materials

Technology

metals

or metal oxide to be hosted by using

laser source or by generating an

arc.

Endohedral

compounds with noble gases,

alkali metals and lanthanides

are well known.

Recently

N@C60 has also been synthesized.

La@C82

could be

synthesized by evaporating

graphite

impregnated with La2O3 using a laser.

Rg@C60

(Rg-rare

gas), Li@C60

have

also

been

synthesized [13].

Exohedral

compounds: By

reacting C60 with CrO2(NO3)2 a

compound C60Cr2N6O21 was

obtained.

In this compound 50% Cr

species are in Cr3+ and the other 50%

were found to

be

in Cr6+ state. Such exohedral

compounds are useful for

catalytic and medicinal

applications.

Intercalation

Compounds: Alkalimetal

intercalated fullerene compounds

were found to

be

super conductors. For instance,

K3C60

has a

transition temperature of 19.8 K

and

Cs3C60

exhibited a

transition temperatures upto 40 K.

Compounds like (NH3)6Na3C60

(NH3)8Na2C60

showed

improvements in transition temperatures.

Ba6C60

and Sm3C60

have

also

been found to be

superconductors.

Carbon

Nanotubes

Synthesis

of carbon nanotubes with

desired properties in large quantities is

a challenge

ahead.

The second problem in the

successful utilization of CNT's

for a variety of

Technologies

is to remove the impurities present

such as the catalyst

nanoparticles (Fe,

Co,

Ni-Y and few others), amorphous

carbon and fullerenes. The

third hurdle is to

develop

synthetic strategies that

exclusively give either

SWNT's or MWNT's as

currently

there is no path available to

separate them. Making them

soluble is also a note

worthy

problem.

Carbon

nanotubes are a key

component of nanotechnology. Carbon

nanotubes

(multiwalled

tubes) were discovered by the

Japanese scientist Iijima in

1991. Carbon

nanotubes

were obtained as a by-product

during fullerene synthesis.

Discoovery of

carbon

tubes has supplemented the

fullerene research to a major

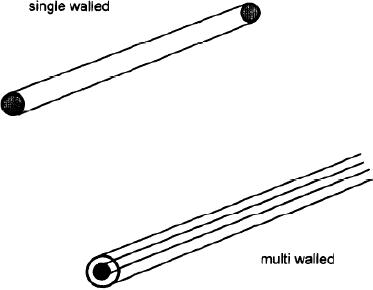

extent. Multiwalled

carbon

nanotubes should be distinguished

from single walled carbon

nanotubes. The

difference

between them is pictorically

represented in Fig. 10. 7.

Single walled carbons

nanotubes

contain one single cylinder

whose wall is made up of

hexagonal carbon

structure.

Multiwalled carbon nanotube

contains concentric cylinders

(one inside the

other)

with each cylindrical wall

being made of a graphene sheet.

Synthetic

Strategies in Chemistry

10.17

Fig.

10.7. Schematic representation of

single walled and multiwalled

carbon nanotubes

[12]

The

discovery of single walled

carbon nanotubes (SWCNT's) is

incidental. A series of

failed

attempts to synthesize MWCNT's

(multiwalled carbon nanotube's)

filled with

transition

metals resulted in the

formation of single walled

carbon nanotubes. The

credit

of

the discovery of single

walled carbon nanotubes

should be given to two

research

groups

who worked independently,

namely Iijima and Ichihashi,

NEC (Nippon Electric

Company),

Japan as well as Bethune et

al., from IBM, California

[14].

Nanotubes

of carbon are not soluble.

As a result separation and purification

are a

problem.

This has hindered the

large scale production of

carbon naotubes partially.

Fortunately

these tubes are less

susceptible to combustion. So heating in

oxygen can

brun

the impurities (other forms

of carbon namely amorphous

carbon) and can yield

pure

CNT's

[13].

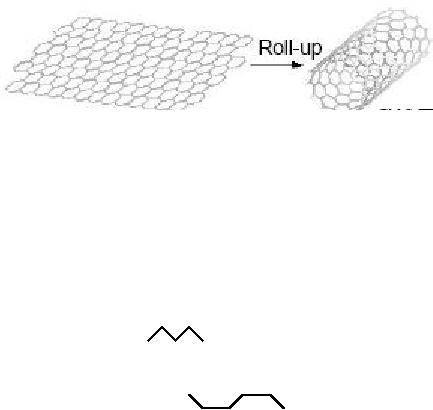

Single

walled carbon nanotubes can be envisaged

or conceptualized or understood as

seamless

(continuous and uniform through

out) cylinders rolled up

from graphene sheet

as

represented in Fig. 10. 8. A graphene

sheet is a monolayer of sp2 bonded carbon

atoms.

10.18

Role

of Synthesis in Materials

Technology

Single

walled nano tube

Graphene

Sheet

Fig.

10.8. Hexagonal net work of

carbon atoms rolled upto make a

seamless cylinder

[15].

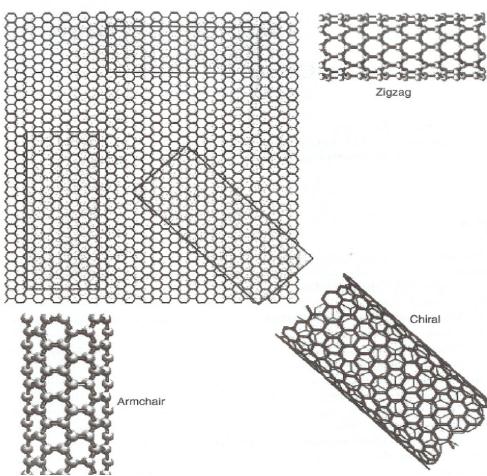

Depending

on the way in which the

graphene sheet is rolled up there can be

three types

of

carbon nanotubes, namely,

zigzag, armchair and chiral. In

zigzag tubes some of the

C-

C

bonds lie parallel to the

tube axis. The name zigzag

comes from the fact

that the edge

of

the tube possesses zigzag

structure (

).

In armchair tube some of the

C-C bonds

lie

perpendicular to the tube

axis. The name armchair

comes from the very

shape of the

edge

of the tube which looks

like arm chair (

).

Intermediate

orientations of

the

graphene sheet result in `chiral'

carbon nanotubes.

Thus

the classification of

nanotubes

into zigzag or arm chair is

based on the appearance of

the rim of the

tube

formed.

The formation of the three

types of nanotubes by changing

the way of rolling

the

graphene

sheet is represented schematically in

Fig. 10.9

Cabon

nanotubes have several

potential applications. This is

because of their

unique

properties.

Due to the high mechanical

stability carbon nanotubes

are now being used

in

carbon-carbon

composites. As carbon nanotubes are

capable of emitting electrons

from

the

tube ends they are

used for flat screen

applications. Carbon nanotues serve as

host

materials

for Li or H2 and can be exploited in energy

storage applications.

Synthetic

Strategies in Chemistry

10.19

Fig.

10. 9. Schematic representation of

the relation between

nanotube and graphene [16].

Evolution

in Synthetic Strategies

Some

of the ways of synthesizing

nanotubes include:

1.

Arch-discharge or vaporization process

(in the presence of

transition metal

catalyst)

2.

Laser-evaporation of graphite (Laser

furnace process)

3.

Chemical Vapour Deposition,

CVD (Catalytic Pyrolysis of

hydrocarbons) or Catalytic

Chemical

Vapour Deposition

(CCVD)

4.

Template Carbonization

Method

The

fine details of the

synthetic strategies are

given in the next few

pages.

1.

The Arc-Discharge

Process:

Carbon

nanotubes were first

introduced to the world by

using this synthetic

methodology.

As

stated earlier carbon

nanotubes occurred as a by-product

during the synthesis

of

fullerenes.

Kratschmer and coworkers have

used the same arc discharge

method in 1990

for

the mass production of

fullerene. The method they

have employed comprises of

10.20

Role

of Synthesis in Materials

Technology

evaporating

the graphitic anode. The two

electrodes were made to contact

with each

other

by applying an ac voltage in an inert

gas atmosphere. This results in

the generation

of

an arc that evaporates the

anodic graphite. Thus

fullerenes were generated in

bulk

amounts.

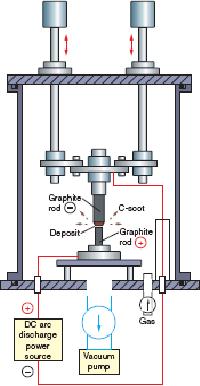

Fig.

10. 10. Schematic

representation of the apparatus

used for the synthesis of

CNT's

[17]

The

arc-discharge apparatus used for

the production of carbon

nanotubes is shown in

Fig.

10.10.

The chamber is first made

free from atmospheric air by

evacuating the

reaction

chamber

with a vacuum pump. Ambient

gas (He or Ar or CH4)

is introduced into

the

chamber.

A dc (direct current) arc voltage is

applied between the two

graphite electrodes

(rods

of carbon). The anodic

graphite evaporates. Fullerenes in the

form of sooth are

deposited

in the chamber. In addition to

fullerenes, the great treasure, CNT's

were also

found

to be deposited on to the cathode from

the evaporating anode. These

CNT's were

found

to be made of coaxial (concentric)

graphene sheets and are termed as

multiwalled

carbon

nanotubes. These results are

obtained when pure graphite

rods free from any

Synthetic

Strategies in Chemistry

10.21

metal

impurities are used as anode

and cathode. By using this arc discharge

method and

by

employing He environment large

scale synthesis of MWCNT's

could be achieved.

If

the synthetic condition is

slightly changed by using metal

catalyst (Fe or Co)

containing

graphite rod as anode instead of

pure graphite rod, single

walled carbon

nanotubes

could be obtained instead of multiwalled

carbon nanotubes. In either

cases the

cathode

is only pure cathode.

Experiments

have been carried out by

changing the

atmosphere

with in the reaction

chamber. Among He, Ar and

CH4,

CH4 gas was found to

be

the best as it resulted in

the formation of highly

crystalline nanotubes with

few

coexisting

nanoparticles which are not

wanted. The major and essential

distinguishing

feature

in the synthesis of fullerens and

CNTs is that, fullerene

cannot be produced

when

reaction

chamber contains hydrogen

containing gases (CH4 or

even H2). At

the same

time

presence of environment of H2 facilitates the formation

of CNT. During the

process

of

arc evaporation in CH4,

thermal decomposition of methane

takes place leading to

the

insitu

generation of H2 as indicated in the

following equation.

C2H2

+ 3 H2

CH4

In

presence of CH4,

the evaporation of graphitic

anode thus takes place in

pure

hydrogen

gas environment. Thus

hydrogen arc discharge is effective in

the generation of

highly

crystalline carbon nanotubes

(multiwalled). As hydrogen arc results in

high

temperature

and resultant high activity,

production of MWCNT's in

hydrogen

atmosphere

(CH4 environment) is more

effective than either He or Ar

atmosphere. Not

only

that, the unwanted carbon

nanoparticles (amorphous carbon)

which are ubiquitous

and

unavoidable can be minimized by using

hydrogen arc process

SWNT's

were synthesized in the year

1993, just two years

after the discovery

of

MWNT's

in the year 1991. SWNT's

were synthesized by the arc discharge

process using

a

graphite anode but with

metal catalyst (either Fe or Co or

metal alloys in some

cases

like

Ni-Y). In sharp contrast to the

synthesis of MWCNT's, SWNT's

were not found on

the

carbon deposit on cathode but were

obtained from the soot in

the gas phase.

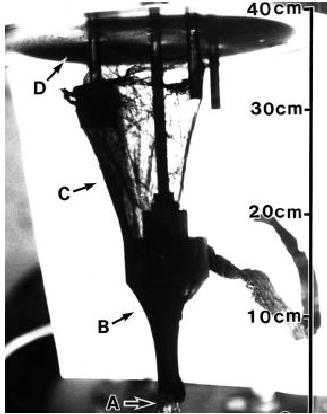

Xinluo

Zhao and coworkers has

succeeded in synthesiszing highly

crystalline

SWCNT's

with a clean surface in

large quantities by employing arc

discharge process.

The

SWNT's were obtained with 70

at.% purity.

10.22

Role

of Synthesis in Materials

Technology

Fig.

10.11. Arc discharge chamber

with a web of SWNT's [18]

(Arrow A shows the

starting

point of the SWNT web;

arrow B shows the black

thick region of

SWNT's;

arrow

C shows the half-transparent

thin region of SWNT's

growth; arrow D

points

towards

the roof of the arc discharge

chamber where the thin

film of SWNT's is

located.

This

film can be peeled of into

large slices)

The

carbon electrode employed comprises of 1

at% Fe catalyst. Inert atmosphere

is

maintained

in the reaction chamber by

H2-Ar mixture. The

catalyst Fe nanoparticles

present

in the product CNT's could

be completely eliminated by heating

the product in

air

at 693 K and also by the subsequent acid treatment

with HCl.

The

two graphite electrodes were

held vertically one over the

other with the anode

at

the

lower end and the cathode at the

upper end separated by 2 mm distance.

The

electrode

assembly was held in the

centre of the vacuum

chamber. The anode is

the

carbon

containing Fe catalyst and the cathode is

pure carbon.

Inert

atmosphere is

maintained

in the reaction chamber by

passing H2-Ar

mixture. The synthesis time

was

roughly

3 mm.

This

has resulted in the

formation of macroscopic web of SWNT's

as

Synthetic

Strategies in Chemistry

10.23

shown

in Fig. 10.11. The length of

the SWNT's is nearly 30 cm.

H2-Ar gas

mixture

played

a crucial role in the

synthesis of SWNT's.

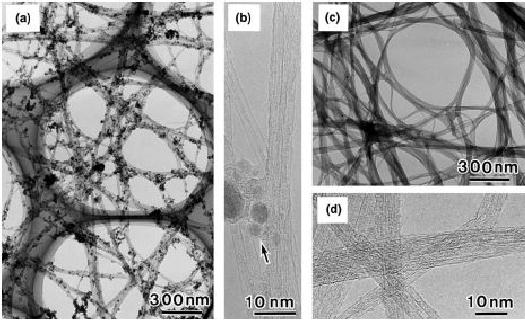

Fig.

10.12. TEM images of (a) as

grown CNT's (low

magnification, iron particles

are

seen

along with tubes), (b) as

grown CNT's (high

magnification, iron particles

are seen

along

with the graphene layers)

(c) purified CNT's (low

magnification, only CTN's

and

no

Fe particles) (d) purified

CNT's (high magnification,

only graphene folded sheets

and

no

Fe particles) [18].

TEM

images of as-grown and purified

SWNT's are shown in Fig.

10.12. Both the

low

magnification and high magnification

images are shown. It is

clear from the TEM

images

that after heat treatment and

the subsequent acid treatment with

HCl the

particulate

impurities (catalyst as well as

amorphous carbon) were

completely removed

yielding

clean and pure

SWNT's.

2.

Laser Furnace Process

The

energy density of lasers is

higher compared to any other

vaporizing device. So

lasers

are

appropriate means to vaporize materials

like carbon with high

boiling temperature

[17].

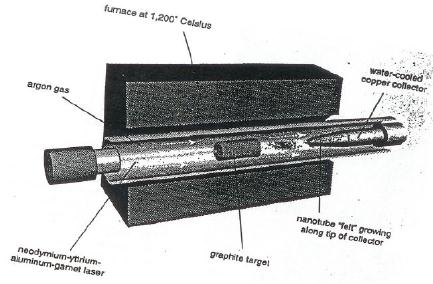

Typical

laser furnace experimental set up is

shown in Fig. 10.13. The

essential

components

are a furnace, a quartz tube

provided with a window at one end and a

trap for

10.24

Role

of Synthesis in Materials

Technology

CNT's

provided with a water

circulation at the other

end, flow system for

inert gas (Ar),

laser

source and the carbon

target.

Fig.

10.13. Laser-furnace (vaporization)

apparatus [19]

The

carbon target used is a

composite of carbon doped

with catalytic Co-Ni alloy.

The

carbon

composite (Co-Ni/graphite) is placed at

the centre of the quartz

tube having

window

at one end through which the laser

beam penetrates into the

quartz tube. The

laser

source used is Nd:YAG (Neodymium :

Yttrium-aluminium-garnet) and this

can

produce

a temperature of 1200 �C in the furnace.

CO2 can also be

used. A laser beam

from

the afore mentioned source is

introduced into the quartz

tube through the

window

and

is focused on to the carbon

composite. Ar gas is circulated

through out the

furnace.

The

carbon composite is vapourized

when the laser beam hit

the target and forms

SWNT's.

The SWNT's produced are

carried to the other end of

the quartz tube

provided

with

a trap (with water

circulation facility) where

the SWNT's are

collected.

It

is important to note that

the surface of the carbon

composite should be kept as

fresh

as

possible for the process of

vaporization to be homogeneous. Since

there is no way the

target

can be moved, the focus of

the laser onto the target

should be changed from time

to

time.

Laser furnace synthesis is an efficient

route to synthesize bundles of

single-walled

carbon

nanotubes with a narrow

diameter distribution.

Synthetic

Strategies in Chemistry

10.25

3.

Chemical Vapour

Deposition

In

this method of synthesis a

hydrocarbon (acetylene, ethylene, benzene

or methane) is

thermally

decomposed in the presence of a

transition metal catalyst

(Fe, Co or Ni) or

catalyst

support (alumina, silica or

zeolite serve as useful supports

for transition

metals)

The

process of synthesis can be carried

out even at relatively lower

temperatures (600-

1200

�C) than those which are

normally encountered in either arc

discharge process or

laser

vaporization processes.

But

we have to forgo the quality

of the nanotubes

obtained

interms of crystallinity when

the synthesis temperatures are

lower. Since this

synthetic

methodology can be employed at relatively

lower temperatures and

ambient

pressure,

CVD is simple and also forms a

viable means of producing

large amounts of

nanotubes.

Hydrocarbons

in either liquid (benzene,

alcohols) or solid

(camphor,

napthelene)

or gaseous (CH4 or C2H2) can be virtually

employed as carbon

precursors.

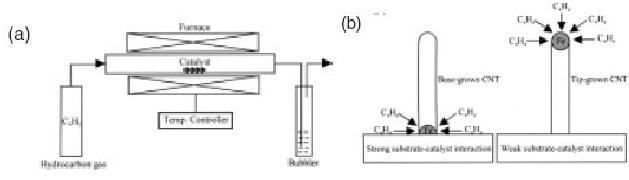

Fig.

10.14. Experimental set up

for Chemical Vapour

Deposition Synthesis, (b)

probable

models

of CNT growth [17]

The

experimental set up used for

a CVD or CCVD (catalytic

chemical vapour

deposition)

synthesis

is shown in Fig. 10.14 (a)

and the possible ways in which

the nanostructures

grow

on catalyst particles is represented

pictorially in Fig. 10.14

(b).

In

a typical process of CVD,

the catalyst is placed in the

middle of a quartz

tube.

The

quartz tube with the

catalyst is placed in a furnace capable

of generating and

sustaining

temperatures between (600-1200 �C).

The hydrocarbon vapour is

allowed to

pass

through the quartz tube

containing catalyst material present at

sufficiently high

10.26

Role

of Synthesis in Materials

Technology

temperature.

The hydrocarbon gets

decomposed. CNT's start

growing on the

catalyst

particles.

The temperature of the

furnace is then cooled to

room temperature. The

CNT's

are collected. If the carbon

precursors were to be in liquid form as

in the case of

either

benzene or alcohols then an inert

gas like Ar is bubbled

through the flask

containing

the liquid

hydrocarbon.

The

liquid hydrocarbon in the

flask is heated

simultaneously

so that vapours of the

hydrocarbon are generated. The

vapours of the

hydrocarbon

are thus carried by the

inert gas through the

catalyst particles located in

the

hot

zone of the furnace. If the

carbon precursors were to be in

solid state like those

of

naphthalene

or camphor, the hydrocarbon

vapours in such cases are

generated by placing

them

in another furnace kept at a

lower temperature prior to

the main furnace where

the

deposition

of carbon takes place over

the catalyst particles.

Analogous to the

carbon

precursors

the catalyst materials can also be in

either solid or liquid or

gaseous state. In

the

high temperature zone the

hydrocarbon vapour gets

decomposed. A variety of

carbon

species

are formed.

Such

carbon species are capable

of dissolving in the

metal

nanoparticles

of the catalyst. Once a

catalyst particle is supersaturated,

carbon species

starts

precipitating out. Initially,

fullerene dome like structure will

petrude out of the

catalyst

particle which extends into

carbon cylinders. The

position and direction of

growth

of carbon from the metal

nanoparticle depends on the

interaction between

the

metal

particle and the support .If

the interaction beween the

metal particle and the

support

is

strong, the particle is

literally immovable. The

decomposed carbon species will

be

adsorbed

into the particle initially

from all the direction

where the catalyst

particle

surface

is exposed to the carbon

species. Once a level of super

saturation of the

particle

with

carbon species is reached no

more carbon species are

adsorbed in to the

metal

particle.

Now carbon has to

precipitate out from the

metal particle. Since the

particle is

strongly

held by the support, the

only direction in which the

carbon can precipitate out

is

from

the tip. The process of

dissolution now takes place

from the sides of the

particle

near

the base and the excess

carbon is precipitated at the

mouth or tip of the

particle.

Since

the grown process starts at

the sides of the base

this is known as base

grown

carbon.

On the contrary, if there

were to exist weak

interaction between the

catalyst

particle

and the support, the

particle can now be easily

lifted vertically up above

the

support

surface the movement when

the particle gets supersaturated

with carbon that is

Synthetic

Strategies in Chemistry

10.27

being

absorbed from the tip. Since

the growth of the tube is

now originating at the tip

of

the

metal particle the mechanism

is regarded at tip grown CNT

process. Depending on

the

size of catalyst particle, we get

either SWNT's or

MWNT's.

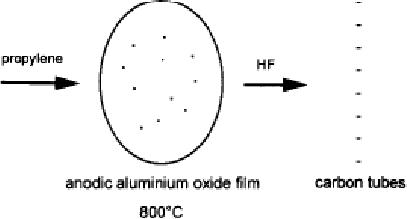

4.

Template Carbonization

Method:

The

structure directing material

(template) used for

preparing nanotubes in this

method is

the

porous aluminium plate.

Channels are created in the

aluminium plate by the

process

of

anodic oxidation in the

presence of sulphuric acid.

Carbon is deposited

pyrolytically

onto

the channels in aluminium

oxide film at 800 �C in inert

atmosphere.

Fig.

10.15. Synthesis of carbon

nanotubes by template carbonization

method [12]

After

the process of carbon

deposition and subsequent carbonization

the aluminium oxide

template

is removed by treatment with HF

(hydrofluoric acid) solution.

(Note: HF should

be

handled with utmost care.

Proper hand gloves should be

used while handling HF. It

is

so

hazardous that through skin

it can damage even the bones).

This resulted in

uniform

monodisperse

carbon nanotubes with

uniform length, diameter and

thickness. As the

temperature

of the carbonization is not

high (800 �C only), the

tubes contained structural

imperfections.

Typical synthetic steps

involved in a template assisted

synthesis are

pictorially

represented in Fig.

10.15.

10.28

Role

of Synthesis in Materials

Technology

Can

a carbon source as common as

kerosene be used for the

synthesis of nanoforms

of

carbon materials?

Kerosene

is used as a fuel for

cooking and lightening. It is a residue of

the petroleum

refinery.

Kerosene contains a mixture of various

short and long chain

aromatic and

aliphatic

hydrocarbons.

Sharon

and coworkers have used

kerosene as precursor

for

preparing

various nanoforms of carbon.

The method of synthesis comprises of

pyrolysis

of

kerosene at 1000 �C. The

experimental arrangement comprises of a

quartz tube held

horizontally

in a furnace.

Kerosene

is placed in a round bottom flask and

heated

thermostatically

at 90 �C. The vapours of

kerosene along with Ar gas

were allowed to

pass

through the quartz tube

held in a furnace. Stainless steal plates in

rectangular shape

were

placed in the center of the

quartz tube. The stainless steal

plate serves as a substrate

for

the deposition of various

forms of carbon materials.

Straight, stiff and long

fibers,

flexible,

thin hair like threads, soft

wool like clusters of

carbon, uniform

nanotubes,

bitter-gourd-like

rough fibers, earth

worm-like nanofibers and carbon

thin film deposits

were

found around and on the stainless steal

substrate.

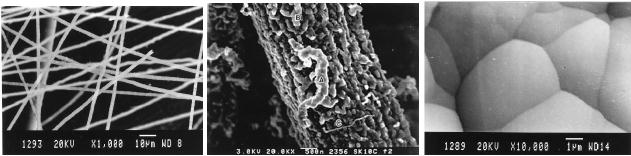

SEM

(scanning electron

microscope)

images of the various

nanoforms of carbon synthesized

are shown in Fig.

10.16.

It is to be noted that the substrate

stainless steal is a complex catalyst of

different

compositions

which govern the growth and

orientation of the nanostructures.

Important

questions

one should now consider are:

How a single carbon

precursor under given

conditions

of synthesis yields different

nanostructures simultaneously? What

factors are

responsible

for control of size and shape of

the nanostructures? Can each of

the different

carbon

nano structures be separated?

How does the synthetic

strategy adopted dictates

the

ultimate materials technology? Or in

other words, what impact

does this synthetic

strategy

have on the ultimate

materials technology? The

ultimate materials technology

is

a

function of material structure as

well as material property

which are controlled by

the

specific

synthetic strategy

employed.

For

instance, as in the present case,

the fibers

obtained

were found to be conducting and

such conducting fibers are

useful in

biosensors,

ion-activated molecular switches and

for the fabrication of

microelectrodes

for

medicinal applications. Composite

fibers can be obtained from

hair-like and wool-

like

fibers. The bitter gourd

like fibers with extremely

irregular outer surface

yields large

specific

surface area values and will be

useful for catalytic

applications. The electrodes

Synthetic

Strategies in Chemistry

10.29

fabricated

from the thin film

carbon synthesized was found to be a

substitutes to an

expensive

RuO2 coated

titanium sheet which is used

as anode against a mercuric

cathode

for

the electrolysis of brine

solution. The electrochemical

potential range of the

electrode

fabricated

from carbon thin film

material was found to be -1.24 to

1.67 V Vs SCE

(standard

calomel electrode) indicating

that water will not be

electrolysed by using

the

electrodes

(both anode and cathode)

fabricated by this carbon

material. The electrodes

fabricated

from thin film carbon

could electrolyze 30 % NaCl

solution at 300 mAcm-2 for

more

than 110 h continuously with

out any deterioration [21].

Thus the electrodes

fabricated

from the carbon obtained by

kerosene pyrolysis are

useful for

Chloro-alkali

industry

offering a solution for

toxicity problem by eliminating

the hazardous mercury

contamination

[20].

(a)

(b)

(c)

Fig.

10.16. SEM (scanning

electron microscope) images of

(a) hair like fibers,

(b) bitter

gourd - like rough fibers

and (c) carbon thin film

grown on a stainless steel substrate

Carbon

Nanotubes as STM and AFM

Tips:

Gerd

Binnig and Heinrich Rohrer at

the IBM (International Business

Machines

Corporation)

research laboratories in Zurich in

the late 1970's developed a

method of

structural

analysis namely the STM,

scanning tunneling microscopy.

Few details on the

principle

of operation of STM are

worth knowing. Electron is

not only a particle but

also

a

wave. In our daily life

walking through a brick wall

is not possible [7]. Imagine

a

nanometer

scale equivalent of a brick

wall. Let this be an energy

barrier that an

electron

following

prequantum physics would not

be able to overcome. But quantum

mechanics

tells

us that there is still a

certain probability that the

electron is found on the

other side of

the

wall since electron is not

only a particle but also a

wave. In this case the

electron

10.30

Role

of Synthesis in Materials

Technology

behaves

more like a wave and this

effect is called tunneling

which forms the basis

of

STM

analysis. The empty space

between the surface to be

studied and the probe is

regarded

as the barrier or the wall

through which an electron

normally but

occasionally

will

not passes. The tip of

the probe should be one atom

wide. The next layer

can

contain

more atoms. The probability

of tunneling decreases by a factor of

ten for each

0.1

nm of additional distance. So the second

layer has no virtual

significance. The one

atom

tip is suspended above the

object just a few atomic

radii. This distance is

readjusted

using

the measured tunneling

current. From the distance

between the STM tip and

the

surface

to be probed and the measured tunneling

current one can feel the

structure of the

surface.

The peaks and troughs of the

surface can be felt at atomic

scales with out

ever

touching

it. It has now become

possible to control the placement of

the tip with

sufficient

accuracy

establishing STM as a standard method of

analysis in materials science.

A

variation of the theme of

electron tunneling found as in

the case of STM was

presented

in 1986 by Binnig, C. F. Quate and C.

Gerber which was latter

called as

Atomic

Force Microscopy (AFM). In this

technique the probe will actually

touch the

surface.

The vertical movement of the

tip of the probe will be controlled by

the repulsive

force

measured when the surface is

touched. By 1990's individual

biomolecules such as

the

double-stranded DNA could be pictured

which made the researchers

elated. Thus

both

STM and AFM techniques are in

principle suitable for

"feeling" the fine structure

of

a

surface atom by atom.

The

performance of STM and AFM instruments

has been limited by the

quality of the

tip

which acts as a probe that

either exchanges electron with

the surface as in the case

of

STM

or touches the surface as in

the case of AFM. The

virtual characteristics a

tip

should

possess to be used as probe are: such

tips should end in a single

atom; possess a

well

defined geometry, should be

conductive and chemically inert. So

far the tool

that

worked

as a good probe tip is obtained by simply

cutting a metal wire with an

ordinary

pair

of scissors.

Is

it not surprising?

Even

though the afore mentioned

material

possessed

no such virtual attributes as

mentioned previously for an

ideal probe, the

material

derived by cutting through a

metal wire with a pair of

scissors worked very

well.

The

diameter of such a tip is of a

few hundred nanometers indicating

that the outer

most

Synthetic

Strategies in Chemistry

10.31

layer

contains thousands of atoms.

Interestingly, alternative methods

like etching the

wire

tips or some other

improvements in shaping the

metal wire only failed to

function.

Tremendous

improvements have been

brought about in the

advancement of utility of

STM

and AFM techniques for probing

the surface structure when

carbon nanotubes

(CNT's)

were used for the

first time as AFM tips by

the researchers from the

laboratory

of

Nobel Laureate Richard

Smalley. A single carbon

nanotube of 10 nm wide and 100

nm

to 1 �m long capped with

fullerene like hemisphere is glued

as molecular antenna

onto

a conventional probe. The

conventional probe was coated initially

with a suitable

glue

and then dipped into a bundle of

nanotubes. In most cases,

this effort

culminated

into

the gluing of just one tube

onto the tip.

The

new probe onto which carbon

nanotube is glued fulfilled

the ideal conditions

the

STM

or AFM tip should satisfy.

The probe with CNT tips

has a well-defined and

well-

known

molecular structure, is conductive,

chemically inert and also very

thin. Use of

carbon

nanotubes as AFM tips provided

additional advantages by being stable

to

withstand

the forces applied to the

tip and also being elastic

enough to avoid

unwanted

collisions

with the surface. More

over, now-a-days, reliable and

reproducible synthetic

strategies

are at disposal for making

such new probes (carbon

nanotubes).

Role

of Synthesis in Leather

Technology:

Transformation

of animal hides and skins into

attractive, aesthetic and useful

artifacts has

been

one of the oldest technologies of

mankind.

When

wet the animal skins

are

susceptible

to bacterial attack and

putrefy.

On

the contrary drying makes

the skin

inflexible

and useless for clothing and

other applications. Such

problems can be over

come

by the use of bactericide

during soaking . This forms

a good solution for the

short

term

preservation of skins and hides. Addition

of bactericide prevent the bacterial

attack

on

hide and skin. Addition of bactericide

convert the putrescible

biological materials

into

a

stable material resistant to microbial

activities with enhanced resistance to

wet and dry

heat.

The bactericide kill the

growth of microorganism there by

preventing the damage

to

skin and hide.

Mercury

compounds as well as a mixture of

sulfite and acetic acid were

extensively

used

as bactericides. Even though the

afore mentioned materials

are effective they

are

damageable

and harmful to the environment. So

they are no longer used

for protecting

10.32

Role

of Synthesis in Materials

Technology

the

hides and skins from bacterial

attack. Instead, bronopol

which is a highly

active

antimicrobial

chemical compound has been

the ubiquitous choice to

leather industry to

prevent

bacteria attacking the skins and

hides. Bronopol is 2-bromo-2-nitro

propane 1,

3

diol. Bronopol was invented by

The Boots Company PLC,

Nottingham, England in

the

early 1960's. It was used as a

preservative for pharmaceuticals

for the first time

[21].

Earlier

reports on the synthetic

path ways of bronopol

include reaction of

bromo-nitro-

methyl-cyclohexanol

with aliphatic aldehyde. The

main drawbacks associated

with this

method

of synthesis are the use of

cyclohexanol which is expensive and also

the use of

hazardous

sodium ethoxide. Lakshimi

Muthusubramanian and Rajat B Mitra

[22] have

succeeded

in deloping a simple but

cleaner synthetic strategy

that helped Leather

manufacturing

technology.

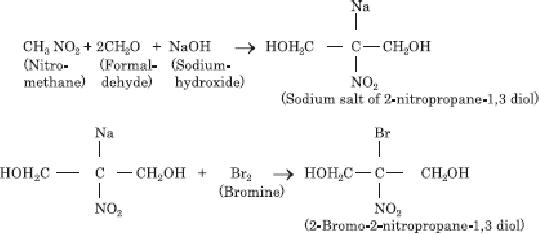

Scheme

10.1. Synthetic strategy for

Bronopol

This

method of synthesis of bronopol

includes reaction of formaldehyde